Waterjet Profile Cutter

1 Piece(s) (MOQ)

Cnc x-y cutting table structure : bridge structure cutting table size (x x y) : 3170 x 8130mm travel of x axis : 3000mm travel of y axis : 6000mm travel of z axis : 210 mm nc system : huaxin 320w drive : a .c. Servo drive traverse speed : 0-15 m/min power supply: 415vac, 50hz, 3 phase (standard) (or) as per your purchase order new cam software (1 set) auto- transforming dxf files into cnc program. Communication between pc and cnc through serial interface open database can save the cutting parameters of different materials. Without inputting the parameters again, you can use them in your cnc programs only by a mouse click. Motorized z axis welded grid net, easy to replace

Brand Name : Zet Cut Laser Cut Beam Cut

Country of Origin : Ahmedabad

...more

Waterjet Multi Cutting Head

Features : Decrease the Production Cost, Saving of Time, Increases the Production Capacity

Waterjet Machine - (dwj2060 - Fb)

1 Piece(s) (MOQ)

Cnc x-y cutting table structure : flying arm cutting table size (x x y) : 2100 x 6100mm travel of x axis : 2000mm travel of y axis : 6000mm travel of z axis : 210 mm nc system : huaxin 320w drive : a .c. Servo drive traverse speed : 0-15 m/min power supply: 415vac, 50hz, 3 phase (standard) (or) as per your purchase order new cam software (1 set) auto- transforming dxf files into cnc program. Communication between pc and cnc through serial interface open database can save the cutting parameters of different materials. Without inputting the parameters again, you can use them in your cnc programs only by a mouse click. Motorized z axis welded grid net, easy to replace

Brand Name : Zet Cut Laser Cut Beam Cut

Country of Origin : Ahmedabad

...more

Waterjet Cutting Table - (dwj3020 - Bb)

1 Piece(s) (MOQ)

Cnc x-y cutting table structure : bridge structure cutting table size (x x y) : 3170 x 2130mm travel of x axis : 3000mm travel of y axis : 1800mm travel of z axis : 210 mm nc system : huaxin 320w drive : a .c. Servo drive traverse speed : 0-15 m/min power supply: 415vac, 50hz, 3 phase (standard) (or) as per your purchase order new cam software (1 set) auto- transforming dxf files into cnc program. Communication between pc and cnc through serial interface open database can save the cutting parameters of different materials. Without inputting the parameters again, you can use them in your cnc programs only by a mouse click. Motorized z axis welded grid net, easy to replace

Type : CNC

Country of Origin : Ahmedabad

...more

Waterjet Cutting Machine

We offer Waterjet Cutting Machine. our company is the pioneer indian company specializing and engaged in international business which deals in multifaceted activities to accomplish its goals of establishing an outstanding position in the global market place. product name: waterjet cutting machine basic introduction: water jet machine uses cold supersonic abrasive erosion to cut almost any materials both metals and nonmetals. the highly pressurized water stream is forced through a tiny area which carries abrasive garnet to erode away the material. application of waterjet cutting machine are as follow : -metal cutting -ceramic cutting -stone cutting -glass cutting -metal profile art work -exotic & non traditional materials -automative, aerospace application -job & machine shop applications -insulation, laminates, leather, marble, plastics, quartz, rubber, silicone etc.

Brand Name : Zet Cut Laser Cut Beam Cut

Country of Origin : Ahmedabad

...more

Waterjet Bevel Cutting Head

Bevel Cutting Head NC Controlled Bevel angle can be programmed in the controller Motorized Bevel angle can be adjusted with the push of a button and the value will be displayed on the screen Manual Bevel angle can be adjusted by rotating calibrated handwheel

Type : Polyester Staple Fiber

Material : Polyester, Pure Polyester

Application : Filling Soft Toys, Pillows, Wadding

Grade : Agrade, Virgin

Color : Creamy, Off White, Semi-Dull White, White

Feature : Abrasion-Resistant, Anti-Distortion, Anti-Microbial, Anti-Pilling, Anti-Static, Flame Retardant, Heat-Resistant

Pattern : Dyed, Non-Siliconized, Siliconized

Technics : Machine Made, Stapled

Country of Origin : India

...more

Waterjet and Plasma 2 in 1 Combination Machine

Waterjet + Plasma 2 in 1 Combination Waterjet for accuracy and finishing Plasma for the edges on which higher accuracies are not required Get Higher Output Save space, as factory space is very expensive Good if you have jobshop as it gives flexibility in taking jobs You can reduce overall cost of profile cutting Huge savings on machine investments, 2 machines can be replaced by 1 Single software is used for both technology, easy to manage Only one operator required Features You can use single CAM Software with the graphical interface which will let you select the path to be cut by different technologies. Display is in different colors to indicate which paths will be cut by both technology.

...more

Water Pressure - (uhp Kmt Sl-v-50 Classic)

Kmt streamlinetm sl-v e-50 classic max. Output pressure : 55000 psi (380 mpa)max. Flow rate : 3.8 lpminlet water pressure : 0. 4 mpa (for intensifier)main motor power : 37kw / 50hpvoltage : 415 vac, 50hz, 3 phase (standard)inlet water pressure for heat exchanger : 0.8 mpaworking hour counterspecial tool kit for maintenance / repairarbitrarily hands adjusting working pressureautomatically shut down (trip off) in case of super pressure of oil or low pressure of water for protectiondimensions : (approximately) length – 1727 mm width - 914 mm height – 1203 mm

Brand Name : Zet Cut Laser Cut Beam Cut

Voltage : 415 vac, 50hz, 3 phase (standard)

Country of Origin : Ahmedabad

...more

Water Jet Cutting Machine - (dwj2080 - Fb)

1 Piece(s) (MOQ)

Cnc x-y cutting table structure : flying arm cutting table size (x x y) : 2100 x 8100mm travel of x axis : 2000mm travel of y axis : 8000mm travel of z axis : 210 mm nc system : huaxin 320w drive : a .c. Servo drive traverse speed : 0-15 m/min power supply: 415vac, 50hz, 3 phase (standard) (or) as per your purchase order new cam software (1 set) auto- transforming dxf files into cnc program. Communication between pc and cnc through serial interface open database can save the cutting parameters of different materials. Without inputting the parameters again, you can use them in your cnc programs only by a mouse click. Motorized z axis welded grid net, easy to replace

Brand Name : Zet Cut Laser Cut Beam Cut

Country of Origin : Ahmedabad

...more

Water Jet Cutting Machine - (dips9-3040)

1 piece (MOQ)

Max. Output pressure : 55000 psi (380 mpa) pressure intensification ratio : 20:1 max. Flow rate : 3.7 lpm inlet water pressure : 0.4 mpa (for intensifier) main motor power : 30kw / 40hp voltage : 415 vac, 50hz, 3 phase (standard) inlet water pressure for heat exchanger : 0.8 mpa oil recycling : 69 liters/min. Main parts of intensifier imported from abroad (high-pressure (hp) cylinder, plunger, hp seals, hp tube) integral inlet water filters (5micron, 1micron, 0.45micron in series) working hour counter special tool kit for maintenance / repair arbitrarily hands adjusting working pressure automatically shut down (trip off) in case of super pressure of oil or low pressure of water for protection dimensions : (approximately) length – 1700mm width - 1000mm height – 1200mm

Brand Name : Zet Cut Laser Cut Beam Cut

Voltage : 415 vac, 50hz, 3 phase (standard)

Country of Origin : Ahmedabad

...more

Ultra High Pressure Pump - (sl-v-75 Plus)

1 Piece (MOQ)

We are offering cutting machine - (sl-v-75 plus) etc. max. Output pressure : 60000 psi (400 mpa)max. Flow rate : 5.4 lpminlet water pressure : 0.4 mpa (for intensifier)main motor power : 56 kw / 75 hpvoltage : 415 vac, 50hz, 3 phase (standard)inlet water pressure for heat exchanger : 0.8 mpaworking hour counterspecial tool kit for maintenance / repairarbitrarily hands adjusting working pressureautomatically shut down (trip off) in case of super pressure of oil or low pressure of water for protectiondimensions : (approximately) length – 1975 mm width - 914 mm height – 1453 mm

Brand Name : Zet Cut Laser Cut Beam Cut

Voltage : 415 vac, 50hz, 3 phase (standard)

Country of Origin : Ahmedabad

...more

Streamline Plus Pump Waterjet Cutting Machine

ULTRA HIGH PRESSURE PUMP can be selected as per the material, thickness, finish and required cutting speed

Voltage : 380V

Shelf Life : 12 months

Type : Kashmiri Rajma

Shape : Kidney Shape

Style : Dried, Fresh

Application : Cooking

Cultivation Type : Common, Natural

Shelf Life : 12 Months, 6 Months

Color : Brownish, Reddish

Feature : Good For Health, No Color Added, No Preservative

Packaging Type : Plastic Packets

Storage : Cool & Dry Place

Country of Origin : India

...more

Smartfeed Auto Abrasive Delivery System

Product Details : For efficient production processes, the level of abrasive in the abrasive hopper of the machine must be constantly monitored to ensure that it does not drop below a minimum level. SMARTFEED ensures that there is always sufficient abrasive available for the cutting process. This prevents problems like accidental cutting without abrasive thus improves quality and saves time & money. SMARTFEED guarantees process safety and excellent stability in all waterjet cutting processes It has the capability of storing abrasive and delivers the abrasive to the abrasive hopper on machine, automatically. The design shows our continuous effort to improve efficiency and reduce labor requirement. High sensitive sensor which monitors the available abrasive; gives visual indication to the operator when the storage tank is to be refilled With 200 liters abrasive storage capacity, the abrasive can be directly feed-in to the abrasive hopper for continuous operation of 300 to 900 minutes (10 to 15 hours). [Higher capacity are available please request for a quote]

Application : Industrial

Color : Grey

Finishing : Coated

Driven Type : Electric

Automation Grade : Automatic

Features : Durable, Low Maintenance

...more

Waterjet Robotic Cutting Machine

1 Piece(s) (MOQ)

We offer robotic waterjet cutting machine. Our company is the pioneer indian company specializing and engaged in international business which deals in all cutting machines likewise, cnc waterjet cutting machine, cnc laser cutting machine, cnc plasma cutting machine, and robotic waterjet cutting through which we are achieving to establish an outstanding position in the global market place. Product introduction: an extremely high-pressure jet of water is an efficient method of cutting soft materials, and combining the waterjet cutting process with industrial robots is an economic alternative to the traditional punch tool method of producing complex-shaped components for car interiors, such as floor carpets, headliners and door trims. A further development of the waterjet cutting process is the addition of abrasives enabling it to cut hard materials in desired profiles. Among the forms of robotic waterjet cutting systems; plasma, laser, trim die and electric discharge media, waterjet cutting is considered a fast and flexible method for cutting most plastics, foams and some metals. The primary advantages of robotic waterjet systems are speed and flexibility. We offers following options for robotic cutting station: 1) 1 robot + 2 station 2) 2 robot + 2 station 3) 2 robot + 3 station 4) 2 robot + 4 station application of robotic waterjet cutting is as follow: cutting process of the interior pieces after press forming (including cutting shapes & holes) is an important step of automobile interior producing, as the interior pieces are always composed of three dimension curved surfaces. In the traditional manual cutting method, there are many problems such as low efficiency, uneven quantity, bad consistency & interchange ability. the interior pieces cut by water-jet have smooth surfaces & good consistency, waterjet is also the fastest & best method of interior cutting. Our robot waterjet cutting machine is developed for automobile interiors process. Advantage of robotic cutting machine: 1) high productivity 2) reduce manpower 3) flexible 4) easy to operate 5) high standard of safety 6) large cutting area

...more

robotic system

Features: Higher Productivity Reduce Manpower Flexible Easy to Operate Highest Standard of Safety Large Cutting Area

Type : Robotic System

Weight : Vary as per models

Color : White

Finishing : Polished

...more

Pro - 3 Pump Waterjet Cutting Machine

ULTRA HIGH PRESSURE PUMP can be selected as per the material, thickness, finish and required cutting speed

Material : Metal

...more

Plasma Cutting Machine

1 Piece(s) (MOQ)

We offer cnc plasma cutting machine. Our company is the pioneer indian company specializing and engaged in international business which deals in all cutting machines likewise, cnc waterjet cutting machine, cnc laser cutting machine, cnc plasma cutting machine, and robotic waterjet cutting through which we are achieving to establish an outstanding position in the global market place. Product introduction: plasma cutting is a process that is used to cut stainless steel, mild steel, and aluminum of different thicknesses using a plasma torch. In this process, an inert gas is blown at high speed out of a nozzle, at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, the plasma moves sufficiently fast to blow molten metal away from the cut. Plasma cutting being primarily a melting process can cut variety of metals. Application of plasma cutting machine is as follow: 1) auto sector – (chassis, cabins, etc…) 2) auto motive fabrication 3) ship building – (interior design contractors, ship contractors, etc…) 4) railway – (vendor of railway) 5) mining 6) pharma & medical machinery 7) food processing machinery 8) structure fabricators 9) steel service center 10) defense 11) educational institutions 12) earth moving (dumpers, buckets, etc…) advantage of waterjet technology: 1) high cutting accuracy and contouring precision 2) excellent dynamic properties 3) high positioning speeds 4) low vibration due to low profile design of machine and energy supply chain 5) use of various processes and assemblies 6) energy supply mounted on the floor 7) working widths up to 6000 mm 8) working lengths as per requirement in addition we are also dealing in products like cnc plasma cutting machine, plasma cutting machine, plasma metal cutting machine, plasma cnc cutting machine, air plasma cutting machine, plasma arc cutting machine,

Brand Name : Zet Cut Laser Cut Beam Cut

Material : Stainless Steel

Color : White

Condition : New

Finishing : Polished

Automatic Grade : Automatic

...more

Plasma Cutting Equipment

1 piece (MOQ)

Plasma cutting is a process that is used to cut stainless steel, mild steel, and aluminum of different thicknesses using a plasma torch. In this process, an inert gas is blown at high speed out of a nozzle, at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, the plasma moves sufficiently fast to blow molten metal away from the cut. Plasma cutting being primarily a melting process can cut variety of metals. application of plasma cutting machine is as follow: 1) auto sector – (chassis, cabins, etc…) 2) medium & large scale fabrication 3) ship building industries 4) railway wagon manufacturing 5) mining 6) pharma & medical machinery 7) food processing machinery 8) pre fabricator structure 9) profile cutting job shops 10) defense 11) educational institutions 12) boiler manufacturers advantage of plasma technology: 1) high cutting accuracy and contouring precision 2) excellent dynamic properties 3) high positioning speeds 4) low vibration due to low profile design of machine and energy supply chain 5) use of various processes and assemblies 6) energy supply mounted on the floor 7) working widths up to 6000 mm & length upto 20,000 mm 8) working lengths as per requirement in addition we are also dealing in products like cnc plasma cutting machine, plasma cutting machine, plasma metal cutting machine, plasma cnc cutting machine, air plasma cutting machine, plasma arc cutting machine, cnc plasma cutting machines, cnc plasma cutting machinery, cnc plasma cutting machine equipments, cutting machine, cnc cutting machine, cnc metal cutting machine, cnc steel plasma cutting machinery, cnc cutting equipments, auto cnc cutting machine, plasma cutting equipments, steel cutting machine, metal working machine, portable cutting machine.

Type : CNC

Brand Name : Zet Cut Laser Cut Beam Cut

Application : Auto sector, medium & large scale fabrication,ship building industries,mining etc.,To cut stainless steel, mild steel, and aluminum of different thicknesses

Type : Palsma Cutting Equipment

Country of Origin : Ahmedabad

...more

Neoline Pump Waterjet Cutting Machine

ULTRA HIGH PRESSURE PUMP can be selected as per the material, thickness, finish and required cutting speed

Material : Mild Steel

...more

Water Jet Machines with Multi Cutting Heads

1 piece (MOQ)

We offer water jet machines with multi cutting heads, waterjet increases the cutting efficiency which results in saving of time and thereby increases the production and decrease the production cost.

Brand Name : Zet Cut Laser Cut Beam Cut

Country of Origin : Ahmedabad

...more

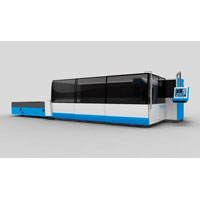

Laser Cutting System

10,000,000 Per Piece

1 Piece(s) (MOQ)

We are offering laser cutting system laser cutting system works on the principle by heating the material at the focal point of the focused laser beam above its melting point. The resulting molten material is ejected either by a coaxial gas jet or the induced vapor pressure, thus forming the cut kerf. Laser cutting system is applied for different kinds of materials like stainless steel, mild steel, and aluminum etc. Where it require precise, fast and force-free processing. Lasers create narrow kerfs and thus achieve high-precision cuts. Compared to alternative techniques like die cutting, laser cutting system is cost-efficient already for small-batch production. Application of laser cutting system is as follow: 1) job & machine shop application 2) automotive industries 3) aerospace industries 4) metal profile art work 5) machine manufacturer 6) sheet metal application 7) fabrication work 8) defense advantage of laser cutting system: 1) co2 sealed slab laser technology. 2) laser pre-mix gas bottles not required. Saves cost and space. 3) no pre heating required prior to start. 4) 48 months pro rata warranty. 5) after refilling your warranty extends to another 48 months (same as new machine) 6) low operating cost (160 rs. Per hour approx.) 7) no moving parts, less maintenance. 8) low standby power consumption. 9) we provide meniscus focusing lenses.

Brand Name : Zet Cut Laser Cut Beam Cut

Type : Laser cutting machine

Country of Origin : Ahmedabad

...more

Laser Cutting Machines

Fret not! We are here to help you out with the payment procedures. Be it online or offline payment method, we are here to assist you all the way through the payment process. Catering to the varied demands of customers, we make accessible the product basket from Ahmedabad(India).

...more

Laser Cutting Machinery

1 Piece(s) (MOQ)

We are offering laser cutting machinery. Laser cutting machinery works on the principle by heating the material at the focal point of the focused laser beam above its melting point. The resulting molten material is ejected either by a coaxial gas jet or the induced vapor pressure, thus forming the cut kerf. Laser cutting machinery is applied for different kinds of materials like stainless steel, mild steel, and aluminum etc. Where it require precise, fast and force-free processing. Lasers create narrow kerfs and thus achieve high-precision cuts. Compared to alternative techniques like die cutting, laser cutting machinery is cost-efficient already for small-batch production. Application of laser cutting machinery is as follow: 1) job & machine shop application 2) automotive industries 3) aerospace industries 4) metal profile art work 5) machine manufacturer 6) sheet metal application 7) fabrication work 8) defense advantage of laser cutting machinery: 1) co2 sealed slab laser technology. 2) laser pre-mix gas bottles not required. Saves cost and space. 3) no pre heating required prior to start. 4) 48 months pro rata warranty. 5) after refilling your warranty extends to another 48 months (same as new machine) 6) low operating cost (160 rs. Per hour approx.) 7) no moving parts, less maintenance. 8) low standby power consumption. 9) we provide meniscus focusing lenses.

Brand Name : Zet Cut Laser Cut Beam Cut

Country of Origin : Ahmedabad

Usage : Job & machine shop application, automotive industries, aerospace industries etc.

...more

Laser Engraving Machine

1 Piece(s) (MOQ)

We offer laser cutting machine laser cutting is applied for different kinds of materials like stainless steel, mild steel, and aluminum etc. Where it require precise, fast and force-free processing. Lasers create narrow kerfs and thus achieve high-precision cuts. almost all kinds of metals can be laser cut: mild steel, stainless steel and aluminum are the most common applications. Compared to alternative techniques like die cutting, laser cutting is cost-efficient already for small-batch production. Basically, metal laser cutting is effected by locally heating the material at the focal point of the focused laser beam above its melting point. The resulting molten material is ejected either by a coaxial gas jet or the induced vapor pressure, thus forming the cut kerf. The various technology used in cutting process is as follow: 1. Laser fusion cutting in the case of higher alloyed steels and aluminum, an inert gas (nitrogen, argon) is typically used as a cutting gas. This process is solely depending on the energy of the laser beam. The required laser power is therefore higher than that for laser flame cutting. Laser fusion cutting affords oxygen-free cut edges, which is particularly important when welding is the next process step after cutting. Today, laser fusion cutting is used industrially for material thicknesses of up to 15 mm. In principle, both high power co2 and solid-state lasers are suited for this kind of applications. Providing higher average power, co2 lasers are an excellent option for the separation of thicker cross sections. 2. Laser flame cutting for low-alloyed steels in particular, oxygen is typically used as a cutting gas. This process, known as laser flame cutting, receives additional energy from the exothermic reaction of the material, which is heated above the ignition temperature. The required laser power is therefore lower than for laser fusion cutting. Today, laser flame cutting is used in industry for material thicknesses of up to 25 mm. Here, too, both high power co2 and solid-state lasers are applied. Providing higher average power, co2 lasers are an excellent option for the separation of thicker cross sections. Advantages: 1) co2 sealed slab laser technology. 2) laser pre-mix gas bottles not required. Saves cost and space. 3) no pre heating required prior to start. 4) 48 months pro rata warranty. 5) after refilling your warranty extends to another 48 months (same as new machine) 6) low operating cost(160 rs. Per hour approx.) 7) no moving parts, less maintenance. 8) low standby power consumption. 9) we provide meniscus focusing lenses.

Color : Customized

Type : Laser Engraving Machine

Brand : Zet Cut Laser Cut Beam Cut

Country of Origin : Ahmedabad

...more

cnc cutting machine

Opening Hours