Process Control Instruments

Get Price Quote

10 Piece (MOQ)

The Orchestra of Industry: A Deep Dive into Process Control Instruments In the grand symphony of industrial production, process control instruments play a vital role as the conductor, ensuring all elements work in harmony to achieve a flawless performance. These unsung heroes silently measure, monitor, and adjust various parameters within a process, guaranteeing consistent quality, efficiency, and safety. Here, we delve into the world of process control instruments, exploring their intricate details and creative applications: The Essential Players: · Sensors and Transducers: These are the eyes and ears of the process, gathering real-time data on crucial parameters like temperature, pressure, flow rate, and liquid level. Imagine a pressure sensor acting like a meticulous percussionist, keeping beat with the pressure fluctuations within a pipe. · Controllers: The brain of the operation, controllers analyze the data received from sensors and compare it to pre-defined setpoints. Based on these comparisons, they send instructions to adjust control elements, ensuring the process stays within the desired parameters. Think of the controller as the conductor, interpreting the sensor data and directing the control elements like a skilled maestro. · Control Elements: These are the workhorses of the process, physically manipulating various aspects based on the controller's instructions. A control valve, for example, acts like a skilled trumpet player, adjusting the flow rate of a liquid by opening or closing based on the controller's commands. · Final Control Elements: These are the final actuators that directly influence the process variables. A heater, for instance, functions like a passionate violinist, increasing or decreasing heat based on the controller's instructions to maintain the desired temperature. The Symphony in Action: Imagine a petroleum refinery – a complex dance of various processes. Temperature sensors, like watchful oboists, monitor the temperature within reactors. Pressure sensors, vigilant like timpanists, keep track of pressure levels in pipelines. The collected data streams to the controller, the conductor analyzing the information. If the temperature deviates from the setpoint, the controller sends signals. A valve, acting as a responsive flutist, adjusts the flow rate of a coolant, bringing the temperature back into harmony. This continuous monitoring and adjustment by process control instruments ensures the smooth operation of the refinery, producing high-quality fuel with optimal efficiency. Beyond the Basics: Creative Applications: Process control instruments are not limited to large-scale industrial settings. Here are some creative ways they are used: · Food Production: Maintaining precise fermentation temperatures in breweries or ensuring consistent baking temperatures in ovens. · Environmental Monitoring: Tracking air quality in urban areas or monitoring water levels in reservoirs. · Pharmaceutical Manufacturing: Ensuring sterile conditions and precise dosages during drug production. · Smart Homes: Regulating temperature and humidity levels for optimal comfort and energy efficiency. The Future Symphony: Advancements and Innovations: The world of process control instruments is constantly evolving. Here's a glimpse into the future: · The Rise of Automation: Artificial intelligence and machine learning will play a greater role in process optimization and anomaly detection. · Wireless Connectivity: Instruments will communicate wirelessly, enabling remote monitoring and control. · Advanced Sensor Technologies: Sensors with greater sensitivity and wider ranges will provide even more precise data. · Focus on Sustainability: Instruments will be designed to improve energy efficiency and reduce environmental impact. The Enduring Value: Process control instruments may not be the most glamorous aspect of industry, but their role is undeniable. They ensure consistent product quality, efficient operations, and safety across various sectors. As technology advances, these instruments will become even more sophisticated, composing a future symphony of industrial excellence. The Melody of Maintenance: Keeping the Instruments in Tune Just like any musical instrument, process control instruments require proper care and maintenance to perform at their best. Here's a look at the key aspects of keeping your industrial orchestra in perfect harmony: · Calibration: Regularly calibrate sensors and other instruments using certified standards to ensure accuracy. Imagine a piano tuner meticulously adjusting the strings to ensure each note resonates perfectly. · Preventative Maintenance: Schedule routine inspections and cleaning to prevent problems before they arise. Think of this as wiping down your instruments after a performance to maintain their longevity. · Diagnostics and Troubleshooting: Utilize built-in diagnostic features or specialized tools to identify and address instrument malfunctions promptly. This is akin to a musician recognizing a faulty string and replacing it before the next piece. · Training: Ensure personnel responsible for operating and maintaining the instruments are adequately trained. · Spare Parts Inventory: Maintain a readily available stock of critical spare parts to minimize downtime in case of failures. Imagine having a spare set of strings readily available in case one breaks during a concert. The Composer's Touch: Selecting the Right Instruments Choosing the appropriate process control instruments for your specific application is crucial. Here's a composer-like approach to selecting the right tools for the job: · Process Needs: Identify the critical parameters that need to be monitored and controlled within your process. What is the conductor trying to achieve? · Accuracy Requirements: Determine the level of precision needed for the measured variables. How critical are the nuances of each note? · Environmental Conditions: Consider factors like temperature, pressure, and potential presence of corrosive materials. Can the instruments withstand the environment like a well-crafted instrument can endure a long concert? · Cost and Budgetary Constraints: Balance the desired features and functionality with your budgetary limitations. How much can the orchestra afford to invest in its instruments? · Scalability and Future Needs: Think about the potential for future expansion or changes in your process. Will the instruments be adaptable to future variations in the musical composition? By carefully considering these factors, you can select the ideal process control instruments that will become the building blocks of a successful and efficient industrial operation. The Encore: The Impact of Process Control Instruments The impact of process control instruments extends far beyond the factory floor. Here are some of the lasting benefits they bring: · Improved Product Quality: Consistent monitoring and control ensure products meet specific quality standards. This translates to a flawless performance every time, like a perfectly executed musical piece. · Enhanced Safety: By preventing process upsets and equipment failures, process control instruments contribute to a safer working environment for personnel. · Reduced Costs: Efficient operation and minimized waste lead to lower production costs. This allows the orchestra to focus on delivering a high-quality performance without unnecessary expenses. · Environmental Protection: Precise control of processes helps reduce emissions and waste, contributing to a more sustainable future. It's like composing a beautiful symphony that is also harmonious with the environment. Process control instruments are the unsung heroes of industry, silently orchestrating a symphony of efficiency, quality, and safety. By understanding their intricacies, creative applications, and the importance of maintenance, we can ensure these instruments continue to play a vital role in our industrial endeavors.

Puf Sandwich Panel

Get Price Quote

A renowned Manufacturer of PUF Sandwich Panels, Shreeji Polyfiber also supplies these PUF Sandwich Panels all over the country. Polyurethane foam of the highest quality is used in the manufacturing process of PUF Sandwich Panels which are available at the market leading prices. Warehouses [cold], Refrigerated Truck Bodies, Dairy Industry etc. are some of the applications of PUF Sandwich Panels. Features Compact & Construction friendly Water proof Termite proof Light weight Cost & Energy savings Easy installation Low maintenance Very good thermal insulation properties [-11OoC TO +110oC] Eco friendly (CFC free) Used in Govt. Institutions and departments Civil construction industries Insulation industry Cold storage Heavy duty electrical insulation industries Hospitals Chemical industries Pharmaceutical industries Hotel industries Dairy industry

Best Deals from AC Drive Control System

Radium Sign Board

450 Per Feet

50 Feet (MOQ)

Price : INR 450 - 350 -per- Feet

WPC Board

Get Price Quote

25 Piece (MOQ)

WPC Boards are the best alternate for the traditional use of wood and plywood for its durability and thermoplastic for its flexibility. WPC Boards are the overcome of the entire problem faced with the plywood. WPC Board has features such as highly resistant to extreme weather, moisture and termites and low maintenance. WPC boards outperform conventional timbers in many areas. The result is that WPC Board Product won't rot, crack, warp or splinter. WPC Boards have revolutionized the look and feel of outdoor areas. Highly versatile WPC board blends beautifully with any architectural style. Features : Minimum contraction and expansion Easy to mould, screw or grout Various finishes can be done Quicker installation Water Proof & Moisture Proof Termite Proof & Pest Proof Paintable & Washable Solid & Light Weight Weather & Ageing Resistant No Shrinking & Swelling Bacteria & Fungus Resistant Fire Retardant Timeless Warranty Maintenance Free 100% Recyclable Environment Friendly Application Wardrobes Cabinets Countertops and tables Doors Partitions False Ceilings Laboratory Tables Full Work Stations Wall Cladding Signage Fencing Switch Cabinets Electric control Panels Advertising Board and many more Suitable For Cutting Sawing Shearing Punching Drilling Nailing Milling Riveting Screwing Painting Printing Photo Mounting Embossing Engraving

Soft Starter Panel

Get Price Quote

V. D. Electricals & Engineering Co. is an acclaimed Exporter and Supplier of Soft Starter Panel from Ahmedabad, Gujarat. We bring forward the finest Soft Starter Panel that is obtained from leading production houses in India. Our Soft Starter Panel is made with high quality material that is lab tested for quality and durability. We can provide Soft Starter Panel in medium as well as bulk quantities as per orders. We are contacted by global buyers for availing this high quality product at affordable prices.

SCREEN CHANGER ELECTRIC PANEL

15,000 - 25,000 Per Piece

We offer standard Hydraulic Screen changer operating Electric panel box as well as accumulator operating Electrical panel box.

Dc Drive Panel

6,000 - 15,000 Per nos

1 piece (MOQ)

We “Patel Industries” are an ISO 9001 : 2015 certified company, with EMPIRE brand, incepted in the year 2024, at Ahmedabad (Gujarat, India). Our company is the leading manufacturer, and supplier of all types of Electric Motors like DC Motors, DC Thyristor Drive, DC Dimmer Penal, Three Phase Induction Motors, Single Phase Induction Motors, for Industries.

Electric Panels

Get Price Quote

The Electric Panels provided by us are used in varied applications and are praised for the longer service life they render. The Electric Panels that we bring forth are suitable for meeting the needs of the customers as these are made by keeping in all their specifications.

Amf Panel

Get Price Quote

We are highly noted name in the industry, engaged in manufacturing and supplying superior quality AMF Panel (Failure Panel). The offered panel is manufactured in compliance with set industry standards using high grade components and latest technology. Our panel is used for controlling all the sets of multiple DG. To fulfill the varied needs of the clients, provided panel is available with various specifications. ThisAMF Panel (Failure Panel) can be avail from us at reasonable rates.Features: Robust structure Safe operation Monitoring can be done easily Long operational life Details:This device is required to manage the failure in power supply system in commercial or industrial unit. Widely used in foundries, textile industry, sugar processing sector, chemical industry, hospitals and hotels, the AMF Panel (Failure Panel) is attached to a generator set which gets activated automatically when the panel detects a power cut off. The special attributes of our product include its self-regulating changeover mechanism from mains to stand-by generator during power failure, easy operating system, simple installation process, rust proof construction, protected against dust and vermin, ability to reduce the loss due to power supply failure and customized specifications. The other necessary details of our product include -- Voltages up to and including 1000 V AC and 1200 V AC. Insulated PVC for working voltages up to and including 1100 V. cables.

Vfd Panel

Get Price Quote

Sometimes your work space is dusty, dirty, wet, humid, corrosive, or hot. In those harsh environments, you cannot just mount your VFD exposed. You need a VFD Control panel – an enclosure that protects the VFD and other electric components. What is a VFD control panel used for? Keeping all components in one panel Keeping dust, dirt, and weather out of electrical parts A complete motor control solution (bypass, harmonic filtering, etc.)

Electric Panel Board

Get Price Quote

We are the leading manufacturers, exporters and supplier of this products.

plc based control panels

Get Price Quote

In modern world most of the conventional controls of relay-contactor based logics are being replaced by PLC based systems. Being flexibility of operation and changing of logic PLC- Programmable Logic Controllers are extensively used in all type of industries Considering the preference of client from view of past experience, availability of support we offer our client any make of PLC such as Siemens, Allen Bradley, GE Fanuc, Mitsubishi, Schneider for making of PLC based control system panels. PC CONSOLES, SCADA CONSOLES, CONTROL DESK, CONTROL POST, HMI CONSOLE, OPERATOR DESK, SWIVELLING MONITOR.

Control Panels

Get Price Quote

We are offering control panels. introduction: nissan clean india oem of electrical control panel for vehicle washing machine,derives the new equation towards the generation and technology to concour and the use of plc bases control panel with the help of lcd display can protect machine from any hazards and the fault diagnostic system. what equipments and of what features control panel for vehicle washing machine comprised of ? · electrical panel enclosure made of 14&16swg crca sheet and powder coat · separate power and control system for individual motors · auto and manual operation of the system · schneider™-electric make plc operated system · touch screen display to reduce user interface. · indication for all motors · all required field sensors installation with required safety interlocks · termination for all motors and sensors connections at a time. · user-friendly with average troubleshooting in the system · short circuit and overload protection for individual motors · panel illumination as per the requirements. · separate bus for ac and dc power supply and single or three phase ac power supply · cross ferruling system and colour coding for all wires and cables for easy maintenance and many others.

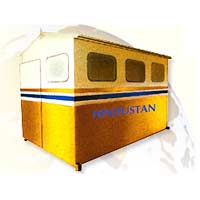

Control Panel Cabin

Get Price Quote

Avail from us highly efficient Control Panel Cabin that is used to operate the asphalt mixing plant. Made of high grade raw material these are centralized air conditioned and insulated Control Panel Cabins are provided with electronic control panel cabinet. The Control Panel Cabins offered by us are highly appreciated and are widely demanded for their optimum functioning and easy operations. Attributes Of Control Panel Cabin : ReliableHighly efficientRobust constructionEasy to operate

Control Panel

Get Price Quote

Various types of Panels offered for preferred period with quick installation by round the clock attendance to ensure reliable and trouble free Power: Manual Control Panel from 25 to 1500 KVA. Power Distribution Panels with MCCBCircuit Breakers, Auto Synchronized Control Panel to synchronize two sets with Bus Panel.

double servo printing machine

Get Price Quote

Robot Controller

72,000 Per Piece

SOLAR PANELS

Get Price Quote

We are offering qualitative range of Solar Panels that are extremely popular among the buyers for their hassle-free performance and durability. Our Solar Panels are precisely engineered using high quality components and in accordance with the set industrial norms and standards. They are easy to install, maintain and highly energy efficient. We are a renowned Solar Panels Exporter and Supplier from Gujarat, India. We can deliver our product in solid packaging and in a short span of time.

Access Control System

Get Price Quote

We are engaged in a wide range of access control systems that are widely used in diverse industries. These are manufactured using top grade materials, which increase their service life standards. These are available in various specifications thus meeting the requirements of our clients’ at most competitive prices.

Power Control Center

Get Price Quote

We have specialization in manufacturing and exporting premium quality Power Control Centers (PCC Panel). These are efficiently used to distribute the power to the different parts of the plant / building / industry / township and controls the whole power supply from one single place. These have their tremendous impact on our clients for their assured service with lesser maintenance. Made by high quality raw material, these are capable enough to control various industrial operation with guaranteed performance. Their complete set up are available for our clients in well customized form as per their requirement in very competitive price range

Electric Panel

Get Price Quote

Brij Machinery have own design for electric panel. We use standard electric switchgear for panel. Also we provide panel for automation work in high range. Our panel is make under IP 55,65 and as per customer required. We make all types of panel like PLC.

Amf Panel

Get Price Quote

Specification For Standard Automatic Failure Panel -> Floor Mounting , Cubicle Type Automatic Panel comprising of : # 1 - TP Contractor with HRC Fuses for MAINS (Upto 380 KVA) # 1 - TP Contractor with HRC Fuses & Thermal Overload Relay for Alternator (Upto 380 KVA) # 2 - Neutral Contactor for MAINS & ALTERNATOR # 1 - Volt meters with Selector Switches for MAINS & ALTERNATOR # 1 - Ammeter with Selector Switch, Frequency Meter # 3 - Current Transformers # 1 - Battery Charger , consisting of Transformer/Rectifier with surge protection network DC Voltmeter, DC Ammeter Selector Switch for Trickle, Off & Boost & Current Adjust # 1 - Mains supply Failure Monitor (voltage sensing ) # 1 - Supply Failure Timer & Restoration Timer # 1- Control Unit incorp. 3 impulse automatic engine start/stop and failure to sart' lockout # 1- Off/Manual/Auto/Test Selector Switch # 1 - ON/OFF Circuit Switch -> LAMP INDICATION & TRIP ANNOUNCIATION SCHEME Condition Indication Trip Announciation Main ON Yes - Generator ON Yes - Load on Mains Yes - Load on Generator Yes - Low Lube Oil Pressure Yes - High Water Temperature Yes - Set Fails to Start (with Alarm) Yes - Push Buttons/ Switchesfor: Engine Start/ Stop, Alternator Contactor ON/ Off & Mains Contactor Off / AMF Test WORKING OF THE PANEL : -> AUTO MODE When the supply fails, the 'Mains supply failure Monitor' operates after preset time of approx. 10 Secs. This actuates the '3 impulse Engine Start' control unit The Control Unit gives three starting impulses with an interval of 1-5 Secs, if the engine starts at the first impulse , this unit shuts off. If not , it gives further two impulses during which time, if the engine does not start, the unit shuts off, activating the audio-visual alarm for 'Set Fails to Start'. On Starting of the engine, the alternator switch gear closes automatically after the preset time of 1-10 Secs. When the Mains Supply is restored , the 'Restoration Timer' operates and after the preset time of 10 Secs., the load is automatically transferred to the Mains, and the Generator shuts down. -> TEST MODE By operating the 'AMF Test' Push Button, the conditions of Mains Failure are stimulated as explained in the Auto Mode above, without disturbing the supply through mains Switchgear. -> MANUAL MODE The DG Set operates as a standard manual operated set , and all its functions are carried out manually by means of 'Engine Start/Stop' and 'Alternator Contactor ON/OFF' Push Buttons.

Conventional Fire Alarm System

14,500 Per Set

Solar Panel

Get Price Quote

Solar Panel, LED Solar Power System, Solar Power System, led outdoor light

Electrical Panel

Get Price Quote

Electrical Panel, Change Over Switch

Lambda Control System

Get Price Quote

Lambda Control System, Mixture Steel and Rubber Pipe, Gas Kit Parts CNG Tank

Control Panel Accessories

2 Per Piece

100 Piece(s) (MOQ)

cnc machines electrical panel

Get Price Quote

cnc machines electrical panel, cnc machine retrofitting, CNC Machines

Automation Panel

Get Price Quote

We are engaged in manufacturing and supplying of automation panel

Electrical Panel

Get Price Quote

Electrical Panel, Electrical Panel Board, Pcc, mcc, Apfcr Panel, Bus Duct