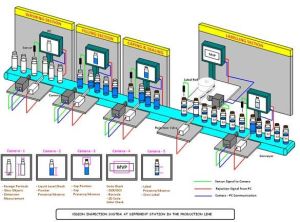

Vision Inspection System

Depend on Requirement Piece (MOQ)

We offer vision inspection system. Bestowed by a modernized infrastructure facility, our organization is manufacturing, supplying and export a wide gamut of optimum quality vision inspection system which are manufactured and designed using fine quality material and as per international quality standards. Offered range of vision inspection system can be availed from us reasonable price. mv system is used in a wide range of manufacturing industries such as: medical devices pharmaceuticals automotive parts disposable consumer goods electronic components packaging plastics scratch card printing and much more machine vision system helps you in various ways like as: to improve inspection accuracy high speed provides excellent production efficiency high consistency measures dimensions within thousandths-of-an-inch accuracy high reliability and resolution increased control over quality management flexible installation easy user interface for reduced operator burden eliminate customer complaint return of investment

...more

Vial Inspection System

We are offering vial inspection system. Our vial inspection systems are widely used in many industries for accurate quality checks and our clients have always given a positive feedback regarding them. Vial inspection systems can be availed at market leading prices by us. applications the different applications of system includesto identify any foreign particles, dust, glass particle, small creatures etc. In bottlevial after washing process. to check filling level of liquid or powder in bottlevial.to check presenceabsence of capseal on vial and also to check position of cap.to verify presenceabsence of the label on bottlevial.to verify label pattern matching and color matching.to check and verify ocr, barcode, pharmacode, 2d code on label. These ocr contains the detail of the product like batch no., m.r.p., manufacturing. Date expiry date etc. technical specification it is totally customized solution according to different application and products.this system includes following hardware :high resolution ethernet cameramega-pixel vision opticshigh intensity illuminationindustrial pc with high configurationsensorsairpiston based rejection systemthe system is having software for making decision according to pre defined criteria.we have vision pharma plus software. The software is designed especially for pharma industries.camera, optics and illumination are used mainly for grabbing image of moving object on conveyor belt at high speed. Then camera transfers image to the industrial pc(i-pc).sensor is used to synchronize vision system with machine. there is software in the i-pc, which processes and inspects particular image of the productobject and checks that inspection criteria are fulfilled or not. if product fails to fulfill pre-defined inspection criteria, software generates rejection signal and transfers that signal to rejection system so that product is rejected and stores values or images in report file which can be rejected. rejection system may be air based or piston based, depending upon weight and dimension of product. On receiving rejection signal, rejection system rejectssorts particular defective product from production line. brief about the product the vision system is used in production line for the 100% quality assurance. It inspects for visible defect in the product at high speed.vision inspection is completely replacing manual inspection using higher accuracy and higher speed compare to manual inspection. industries where this product is used pharmaceutical product manufacturerpharma machinery manufacturerbeverage machine manufacturerbeverage manufacturerpharma raw material manufacturer benefits machine vision system is pc based industrial automation that is used for 100% quality assurance at very high speed.machine vision system is throughout consistent during the work.no energy decay.24 hours availability without failure.closed loop control with maximum accuracy.plenty of data saving and fetching.high frequency measurement.very law maintenance cost and handling charge..

...more

Vial Inspection System

We are engaged as one of the well reckoned Manufacturers, Exporters & Suppliers of Vial Inspection System. Our Vial Inspection Systems are widely used in many industries for accurate quality checks and our clients have always given a positive feedback regarding them. Vial Inspection Systems can be availed at market leading prices by us. Applications The different applications of system includesTo identify any foreign particles, dust, glass particle, small creatures etc. in bottle/vial after washing process. To check filling level of Liquid or Powder in bottle/vial.To check presence/absence of cap/seal on vial and also to check position of cap.To verify presence/Absence of the Label on Bottle/Vial.To verify Label pattern matching and color matching.To check and verify OCR, Barcode, Pharmacode, 2D code on Label. These OCR contains the detail of the product like Batch no., M.R.P., Manufacturing. date expiry date etc. Technical Specification It is totally customized solution according to different application and products.This system includes following hardware :High Resolution Ethernet CameraMega-Pixel Vision OpticsHigh Intensity IlluminationIndustrial PC with high ConfigurationSensorsAir/Piston based Rejection SystemThe system is having Software for making decision according to pre Defined Criteria.We have VISION PHARMA PLUS software. The software is designed especially for Pharma industries.Camera, Optics and Illumination are used mainly for grabbing image of moving object on conveyor belt at high speed. Then camera transfers image to the Industrial PC(I-PC).Sensor is used to synchronize vision system with machine. There is software in the I-PC, which processes and inspects particular image of the product/object and checks that inspection criteria are fulfilled or not. If product fails to fulfill pre-defined inspection criteria, Software generates Rejection signal and transfers that signal to Rejection system so that product is rejected and stores values or images in report file which can be rejected. Rejection System may be Air based or Piston based, depending upon weight and dimension of product. On receiving rejection signal, rejection system rejects/sorts particular defective product from production line. Brief about the product The Vision System is used in Production line for the 100% quality assurance. It inspects for visible defect in the product at high speed.Vision Inspection is completely replacing Manual inspection using higher accuracy and higher speed compare to Manual Inspection. Industries Where This Product Is Used Pharmaceutical product manufacturerPharma Machinery ManufacturerBeverage Machine ManufacturerBeverage ManufacturerPharma Raw Material Manufacturer Benefits Machine Vision System is PC based Industrial Automation that is used for 100% Quality Assurance at very high speed.Machine Vision System is throughout consistent during the work.No energy decay.24 Hours availability without failure.Closed loop control with maximum accuracy.Plenty of data saving and fetching.High frequency Measurement.Very law maintenance cost and handling charge.

...more

Usb Microscope

Depend on Requirement Piece (MOQ)

We are offering usb microscope, digital usb microscopefeatures high speed usb 2 0 interface. wide ranges of adjustable magnification from 10x to 200x. • viewing and capture the magnified image of your specimens right on your computer screen with vga (640x480) or sxga (1280x1024) resolution active pixel technology for sharp image and accurate color reproduction. the build-in 6 white-light led and adjustable illumination ensure the magnified images are clear and bright. auto exposure, auto gain control and auto white balance for optimum image. software controllable parameters (resolution, color, brightness, saturation). high quality lens for true to life undistorted color image. bus dowered with low cower consumption - ideal for portable equipment. applicationshome: examine head scalp: teeth, or see the skin condition. education: educational & scientific purpose as an electronic microscope. Students and teachers can observe objects, materials and insects on monitor immediately with 10-200 magnification in practice class.

...more

Digital Usb Microscope

8,000 Per Piece

USB Digital Microscope is a creative device that it is an amazing and easy to use handheld digital microscope with USB interface. It broke the conception of traditional microscope, it realized these functions: measurement, save, copy, transfer image and video which are difficult for a traditional microscope. It is a small, easy to operate and portable fun. Features Handheld Digital Microscope High Speed access High Resolution up to 2.0 & 5.0MP Pixel: Excellent Images Independently developed display software Video Recording, Snap shot, Measurement facility Full screen option available Applications Industrial Inspection Electronics/Mechanical Assembly and Quality Control Medical Analysis Scientific Teaching Tool School Research Tool Printing Inspection Textile inspection Dermatology (Skin/Scalp) exam Insect dissection/observing Plant dissection/observing Collections/curio/Jewelry Inspection Reading aide etc.

...more

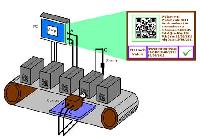

track system

We are offering track systeme, trace system. We are well trusted track and trace system manufacturers, exporters and suppliers. the vision system is used in production line for the 100% quality assurance. It inspects for visible defect in the product at high speed. Vision inspection is completely replacing manual inspection using higher accuracy and higher speed compare to manual inspection. applications this system is mainly used for quality assurance in pharmaceutical as well as in beverage and packaging industry. The different applications of system includes:- to verify the products at the time of dispatch the material.to check and verify ocr (optical character recognition), barcode, pharmacode, 2d code on label. These ocr contains the detail of the product like batch no., m.r.p., manufacturing date, expiry date etc.for “track n trace” system, used for pharma product, cosmetic product etc.“track n trace” system is most useful to get the data of the product from bulk, i.e. If there are 1000 products in single carton, one can get all detail of each and every product from the 2d code, printed on main carton. technical specifications it is totally customized solution according to different application and products.this system includes following hardware : high resolution ethernet cameramega-pixel vision opticshigh intensity illuminationindustrial pc with high configurationsensorsairpiston based rejection systemthe system is having software for making decision according pre defined criteria.we have vision reader plus software. The software is designed especially for pharma industries.camera, optics and illumination are used mainly for grabbing image of moving object on conveyor belt at high speed. Then camera transfers image to the industrial pc(i-pc). sensor is used to synchronize vision system with machine.there is software in the i-pc, processes and inspects particular image of the productobject and check that inspection criteria are fulfilled or not.if product is failed to fulfill pre-defined inspection criteria, software generates rejection signal and transfers that signal to rejection system so that product is rejected and stores values or images in report file which can be rejected.rejection system may be air based or piston based, depending upon weight and dimension of product. On receiving rejection signal, rejection system rejectssorts particular defective product from production line. industries where this product is used pharmaceutical product manufacturerpharma machinery manufacturerbeverage machine manufacturerbeverage manufacturercosmetic product manufacturerpharma row material manufacturercosmetic product machine manufacturer features machine vision system is pc based industrial automation that is used for 100% quality assurance at very high speed.machine vision system is throughout consistent during the work.no energy decay.24 hours availability without failure.closed loop control with maximum accuracy.plenty of data saving and fetching.high frequency measurement.very law maintenance cost and handling charge.

...more

Track and Trace System

We are well trusted Track and Trace System Manufacturers, Exporters and Suppliers. The Vision System is used in Production line for the 100% quality assurance. It inspects for visible defect in the product at high speed. Vision Inspection is completely replacing Manual inspection using higher accuracy and higher speed compare to Manual Inspection. Applications This system is mainly used for quality assurance in Pharmaceutical as well as in Beverage and Packaging Industry. The different applications of system includes:- To verify the products at the time of dispatch the material.To check and verify OCR (Optical Character Recognition), Barcode, Pharmacode, 2D code on Label. These OCR contains the detail of the product like Batch no., M.R.P., Manufacturing date, expiry date etc.For �Track N Trace� System, used for Pharma product, Cosmetic product etc.�Track N Trace� System is most useful to get the data of the product from bulk, i.e. if there are 1000 products in single carton, one can get all detail of each and every product from the 2D code, printed on main carton. Technical Specifications It is totally customized solution according to different application and products.This system includes following hardware : High Resolution Ethernet CameraMega-Pixel Vision OpticsHigh Intensity IlluminationIndustrial PC with high ConfigurationSensorsAir/Piston based Rejection SystemThe system is having Software for making decision according pre Defined Criteria.We have VISION READER PLUS software. The software is designed especially for Pharma industries.Camera, Optics and Illumination are used mainly for grabbing image of moving object on conveyor belt at high speed. Then camera transfers image to the Industrial PC(I-PC). Sensor is used to synchronize vision system with machine.There is software in the I-PC, processes and inspects particular image of the product/object and check that inspection criteria are fulfilled or not.If product is failed to fulfill pre-defined inspection criteria, Software generates Rejection signal and transfers that signal to Rejection system so that product is rejected and stores values or images in report file which can be rejected.Rejection System may be Air based or Piston based, depending upon weight and dimension of product. On receiving rejection signal, rejection system rejects/sorts particular defective product from production line. Industries Where This Product Is Used Pharmaceutical product manufacturerPharma Machinery ManufacturerBeverage Machine ManufacturerBeverage ManufacturerCosmetic Product ManufacturerPharma Row Material ManufacturerCosmetic Product Machine Manufacturer Features Machine Vision System is PC based Industrial Automation that is used for 100% Quality assurance at very high speed.Machine Vision System is throughout consistent during the work.No energy decay.24 Hours availability without failure.Closed loop control with maximum accuracy.Plenty of data saving and fetching.High frequency Measurement.Very law maintenance cost and handling charge.

...more

Rubber Stopper Inspection Machine

Depend on Requirement piece (MOQ)

We offer rubber stopper inspection machine . To inspect rubber online for manufacturing defects Like Burr, Black spots, White dots, Cuts on surface, etc

...more

Non Contact Measurement System

We are offering non contact measurement system. non-contact measurement system manufactured, exported and supplied by us is widely used for different purposes. The vision system is used in production line for the 100% quality assurance. It inspects for visible defect in the product at high speed. Vision inspection is completely replacing manual inspection using higher accuracy and higher speed compare to manual inspection. applications this system is mainly used for quality assurance in automobile industry, electronics industry and automotive industry. The different applications of system includes:- gear inspection in automobilepiston assembly inspection in automobilevalve assembly inspection in plasticauto partsdisk brake inspectioninjection die inspectionpin presenceabsence in electronics chipball bearing inspectionneedle bearing inspectionroller bearing inspectioncasting inspectionall kind of measurement like linear dimension, angular dimension etc.to verify any pattern of the automotive partpresenceabsence of parts in electronicsauto products technical specifications it is totally customized solution according to different application and products.this system includes following hardware : high resolution ethernet cameramega-pixel vision opticshigh intensity illuminationindustrial pc with high configurationsensorsairpiston based rejection systemthe system is having software for making decision according pre defined criteria.we have vision match-it software. The software is designed especially for automotiveplasticautomobileelectronics industry.camera, optics and illumination are used mainly for grabbing image of moving object on conveyor belt at high speed. Then camera transfers image to the industrial pc(i-pc). sensor is used to synchronize vision system with machine.there is software in the i-pc, processes and inspects particular image of the productobject and check that inspection criteria are fulfilled or not. if product is failed to fulfill pre-defined inspection criteria, software generates rejection signal and transfers that signal to rejection system so that product is rejected and stores values or images in report file which can be rejected.rejection system may be air based or piston based, depending upon weight and dimension of product. On receiving rejection signal, rejection system rejectssorts particular defective product from production line. industries where this product is used electronics product manufacturerplastic industryauto parts manufacturermachine manufacturer for automobile, electronics, automotive industryautomobile parts and assembly manufacturer features machine vision system is pc based industrial automation that is used for 100% quality assurance at very high speed.machine vision system is throughout consistent during the work. no energy decay.24 hours availability without failureclosed loop control with maximum accuracyplenty of data saving and fetchinghigh frequency measurementvery law maintenance cost and handling charge

...more

Non-Contact Measurement System

Non-Contact Measurement System manufactured, exported and supplied by us is widely used for different purposes. The Vision System is used in Production line for the 100% quality assurance. It inspects for visible defect in the product at high speed. Vision Inspection is completely replacing Manual inspection using higher accuracy and higher speed compare to Manual Inspection. Applications This system is mainly used for quality assurance in Automobile Industry, Electronics Industry and Automotive Industry. The different applications of system includes:- Gear Inspection in AutomobilePiston Assembly Inspection in AutomobileValve Assembly Inspection in Plastic/Auto PartsDisk Brake InspectionInjection Die InspectionPin presence/Absence in Electronics ChipBall Bearing InspectionNeedle Bearing InspectionRoller Bearing InspectionCasting InspectionAll kind of measurement like Linear Dimension, Angular Dimension etc.To verify any pattern of the automotive partPresence/Absence of parts in Electronics/Auto Products Technical Specifications It is totally customized solution according to different application and products.This system includes following hardware : High Resolution Ethernet CameraMega-Pixel Vision OpticsHigh Intensity IlluminationIndustrial PC with high ConfigurationSensorsAir/Piston based Rejection SystemThe system is having Software for making decision according pre Defined Criteria.We have VISION MATCH-IT software. The software is designed especially for Automotive/Plastic/Automobile/Electronics Industry.Camera, Optics and Illumination are used mainly for grabbing image of moving object on conveyor belt at high speed. Then camera transfers image to the Industrial PC(I-PC). Sensor is used to synchronize vision system with machine.There is software in the I-PC, processes and inspects particular image of the product/object and check that inspection criteria are fulfilled or not. If product is failed to fulfill pre-defined inspection criteria, Software generates Rejection signal and transfers that signal to Rejection system so that product is rejected and stores values or images in report file which can be rejected.Rejection System may be Air based or Piston based, depending upon weight and dimension of product. On receiving rejection signal, rejection system rejects/sorts particular defective product from production line. Industries Where This Product Is Used Electronics Product ManufacturerPlastic IndustryAuto Parts ManufacturerMachine Manufacturer for Automobile, Electronics, Automotive industryAutomobile parts and Assembly Manufacturer Features Machine Vision System is PC based Industrial Automation that is used for 100% Quality Assurance at very high speed.Machine Vision System is throughout consistent during the work. No energy decay.24 Hours availability without failureClosed loop control with maximum accuracyPlenty of data saving and fetchingHigh frequency MeasurementVery law maintenance cost and handling charge

...more

Video Microscope

We are offering mvp patented video microscope. Our clients have always appreciated our range of mvp patented video microscope for its high durability, excellent output and reliability. Our mvp patented video microscope is available at market leading prices by us. special features machine vision video microscope is specially patented microscope, which is available in different models.pictures of the objects to be seen on the lcd display so it is convenient for multi people watching at a time.better working condition, less tiring, ergonomic, relive fatigue resulted out of long time working with traditional microscope.all in one design, easy to operate, space saving.step less zoom inout.can be easily moved to another work space where it can be fixed.usb 2.0 facility for the image grabbingindividual rgb and exposure adjustment facilitylong life illuminationaluminum coated stand so no chance of corrosion applications electronics (micro-electronics)mechanism processingmaterial analyzingjewelry inspectionmetallurgical industrymedicine & biologyeducation & scientific research, etc. technical specification zoom range : switch between 9x to 90x on 19” lcdworking distance : 170mmh. Field of view : 55-5mmdepth of field : 55-5mm1.3 mp high definition camera10x high quality optics(lens) brief about the product it contains the whole unit with table clamp, horizontal stand, angular attachment, vertical pole, force part, 10x high quality lens, 1.3 mp high resolution camera, camera adaptor, white ring light led, light adaptor, power cable and l-key. industries where this product is used research institutemedical institute and research centerscience college, laboratory & hospitalsautomotive industryelectronic industry for what purpose it is used? especially for the hair transplantation in medical institute and hospitals.for electronic equipment testing in electronics industriesmaterial quality checking in research center.machine vision video microscope is used for 100% quality assurance for inspection in real time..

...more

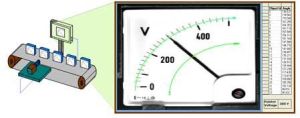

Meter Inspection System

We are offering meter inspection system.we are renowned meter inspection system manufacturers, exporters and suppliers. The vision system is used in production line for the 100% quality assurance. It inspects for visible defect in the product at high speed. Vision inspection is completely replacing manual inspection using higher accuracy and higher speed compare to manual inspection. applications this system is mainly used for quality assurance in automobile industry, electronics industry, plastic industry, automotive industry etc. The different applications of system includes : to measure the linear dimension with high speed and accuracyfor the check the performance of different flow meter with very high accuracy.to measure angular dimension with speed and accuracyall types of measurement like linear, angular and circular.pattern matching of the tiny electronicsauto parts with respect to dimension.sorting of tiny parts with respect to dimension. technical specifications it is totally customized solution according to different application and products. This system is mainly used for measurement of dimension of any object.this system includes following hardware : high resolution ethernet cameramega-pixel vision opticshigh intensity illuminationindustrial pc with high configurationsensorsairpiston based rejection systemthe system is having software for making decision according pre defined criteria.we have vision measure plus software. The software is designed especially for measurement application.camera, optics and illumination are used mainly for grabbing image of moving object on conveyor belt at high speed. Then camera transfers image to the industrial pc(i-pc). sensor is used to synchronize vision system with machine.there is software in the i-pc, processes and inspects particular image of the productobject and check that inspection criteria are fulfilled or not. if product is failed to fulfill pre-defined inspection criteria, software generates rejection signal and transfers that signal to rejection system so that product is rejected and stores values or images in report file which can be rejected.rejection system may be air based or piston based, depending upon weight and dimension of product. On receiving rejection signal, rejection system rejectssorts particular defective product from production line. industries where this product is used electronics parts manufacturerauto parts manufacturerflow meter(volt meter, a-meter, speedo meter, air flow meter, liquid flow-meter etc.) manufacturermachine manufacturer for automobile, electronics, automotive industry features machine vision system is pc based industrial automation that is used for 100% quality assurance at very high speed.machine vision system is throughout consistent during the work. no energy decay. 24 hours availability without failureclosed loop control with maximum accuracy.plenty of data saving and fetchinghigh frequency measurementvery law maintenance cost and handling charge.

...more

Meter Inspection System

We are renowned Meter Inspection System Manufacturers, Exporters and Suppliers. The Vision System is used in Production line for the 100% quality assurance. It inspects for visible defect in the product at high speed. Vision Inspection is completely replacing Manual inspection using higher accuracy and higher speed compare to Manual Inspection. Applications This system is mainly used for quality assurance in Automobile Industry, Electronics Industry, Plastic Industry, Automotive Industry etc. The different applications of system includes : To measure the linear dimension with high speed and AccuracyFor the check the performance of different flow meter with very high Accuracy.To measure Angular Dimension with speed and AccuracyAll types of measurement like Linear, Angular and Circular.Pattern Matching of the tiny electronics/auto parts with respect to dimension.Sorting of tiny parts with respect to Dimension. Technical Specifications It is totally customized solution according to different application and products. This system is mainly used for measurement of dimension of any object.This system includes following hardware : High Resolution Ethernet CameraMega-Pixel Vision OpticsHigh Intensity IlluminationIndustrial PC with high ConfigurationSensorsAir/Piston based Rejection SystemThe system is having Software for making decision according pre Defined Criteria.We have VISION MEASURE PLUS software. The software is designed especially for measurement application.Camera, Optics and Illumination are used mainly for grabbing image of moving object on conveyor belt at high speed. Then camera transfers image to the Industrial PC(I-PC). Sensor is used to synchronize vision system with machine.There is software in the I-PC, processes and inspects particular image of the product/object and check that inspection criteria are fulfilled or not. If product is failed to fulfill pre-defined inspection criteria, Software generates Rejection signal and transfers that signal to Rejection system so that product is rejected and stores values or images in report file which can be rejected.Rejection System may be Air based or Piston based, depending upon weight and dimension of product. On receiving rejection signal, rejection system rejects/sorts particular defective product from production line. Industries Where This Product Is Used Electronics Parts ManufacturerAuto Parts ManufacturerFlow Meter(Volt meter, A-meter, Speedo meter, Air Flow Meter, Liquid Flow-Meter etc.) ManufacturerMachine Manufacturer for Automobile, Electronics, Automotive industry Features Machine Vision System is PC based Industrial Automation that is used for 100% Quality Assurance at very high speed.Machine Vision System is throughout consistent during the work. No energy decay. 24 Hours availability without failureClosed loop control with maximum accuracy.Plenty of data saving and fetchingHigh frequency MeasurementVery law maintenance cost and handling charge.

...more

Machine Vision Optics

Depend on Requirement Piece (MOQ)

We are offering machine vision optics. Our organization is highly acknowledged among the clients for offering a wide array of excellent quality machine vision lens. These lenses are manufactured by our professionals using high quality raw material in compliance with the industry laid standards & norms. features: consistent performance during application high accuracy measurement important for clear image capture very low maintenance cost and handling charge" focal length: 6mm,8mm, 12mm, 16mm, 25mm, 35mm, 50mm and more.

...more

Machine Vision Lights

We are offering machine vision lights. machine vision lights. The vision system is used in production line for the 100% quality assurance. It inspects for visible defect in the product at high speed. Vision inspection is completely replacing manual inspection using higher accuracy and higher speed compare to manual inspection. applications the lights are also compulsory part in vision inspection system.in industries where continuous high speed production, such lightings are used.for high speed inspection it is obvious to use high intensity lights. technical specifications there are wide range of different types of illumination (lights) is available. Here we are describing 128 led bar light specification. operating voltage : 2412 volt dc @ 20 mapower rating : 2.5 watt per ledtemperature : 0oc to 40ocdimension length : 145mm; width: 85mm; height: 36mm lifecycle : 60,000 hrsweight : 480 gmsnumber of led : 128 industries where this product is used machine vision industrymicroscopes manufacturerindustrial automationpc based automation features high intensity light is used for 100% quality assurance at very high speed.machine vision illumination is throughout consistent during the work.for the application of sharp and high accuracy measurement very high intensity lights (red led) are used.for uncertain surface inspection there are many different techniques are used while lighting.indirect lighting is also used for special applications.high frequency measurement.very law maintenance cost and handling charge.

...more

Machine Vision Lights

Avail from us high quality Machine Vision Lights. The Vision System is used in Production line for the 100% quality assurance. It inspects for visible defect in the product at high speed. Vision Inspection is completely replacing Manual inspection using higher accuracy and higher speed compare to Manual Inspection. Applications The lights are also compulsory part in vision inspection system.In industries where continuous high speed production, such lightings are used.For high speed inspection it is obvious to use high intensity lights. Technical Specifications There are wide range of different types of illumination (Lights) is available. Here we are describing 128 LED Bar light specification. Operating Voltage : 24/12 Volt DC @ 20 mAPower Rating : 2.5 Watt per LEDTemperature : 0oC to 40oCDimension Length : 145mm; Width: 85mm; Height: 36mm Lifecycle : 60,000 hrsWeight : 480 GmsNumber of LED : 128 Industries Where This Product Is Used Machine Vision IndustryMicroscopes ManufacturerIndustrial AutomationPC based Automation Features High intensity light is used for 100% Quality Assurance at very high speed.Machine Vision Illumination is throughout consistent during the work.For the application of sharp and high accuracy measurement very high intensity lights (Red LED) are used.For uncertain surface inspection there are many different techniques are used while lighting.Indirect lighting is also used for special applications.High frequency Measurement.Very law maintenance cost and handling charge.

...more

Machine Vision Lenses

We are offering machine vision lenses. 13" 8mm f1.2 monofocal, manual iris (cs mount) monofocal manual iris machine vision lenses are an economical choice providing fixed focal lengths and a very simple and compact design. Other lenses are also there to be used with industrial cameras like 16mm, 5mm and 10 x zoom lens. Lenses are main part in vision system, without which properly focused image cannot be grabbed. For micro-measurement or high accuracy measurement application generally zoom lenses are used. applications lenses are secondary major part in vision inspection system.main purpose of lens to be used in vision inspection system is to grab clearly focused image. technical specifications there are wide ranges of different types of lenses. Here we are describing widely used 8mm lens. model no. : t0812fics-3focal length : 8mmmax. Aperture ratio : 1:1.2max. Image format : 4.8mm x 3.6mm (6mm)mount : cs-mountiris : manualfocus : manualoperating temperature : 20oc - 50ocdimensions : 34.5mm x 33mmweight : 37g industries where this product is used machine vision industrymicroscopes manufacturerindustrial automationpc based automation features lenses are throughout consistent during the workhigh accuracy measurementit is main part for clear image capturevery law maintenance cost and handling charge

...more

Machine Vision Lenses

1/3" 8mm f1.2 Monofocal, Manual Iris (CS Mount) Monofocal manual iris Machine Vision Lenses are an economical choice providing fixed focal lengths and a very simple and compact design. Other lenses are also there to be used with industrial cameras like 16mm, 5mm and 10 x zoom lens. Lenses are main part in vision system, without which properly focused image cannot be grabbed. For micro-measurement or high accuracy measurement application generally zoom lenses are used. Applications Lenses are secondary major part in Vision inspection system.Main purpose of lens to be used in vision inspection system is to grab clearly focused image. Technical Specifications There are wide ranges of different types of lenses. Here we are describing widely used 8mm lens. Model No. : T0812FICS-3Focal Length : 8mmMax. Aperture Ratio : 1:1.2Max. Image Format : 4.8mm x 3.6mm (6mm)Mount : CS-MountIris : ManualFocus : ManualOperating Temperature : 20oC - 50oCDimensions : 34.5mm x 33mmWeight : 37g Industries Where This Product Is Used Machine Vision IndustryMicroscopes ManufacturerIndustrial AutomationPC based Automation Features Lenses are throughout consistent during the workHigh accuracy measurementIt is main part for clear image captureVery law maintenance cost and handling charge

...more

Machine Vision Industrial

We are well trusted machine vision industrial pc manufacturers, exporters and suppliers. Full aluminum touch pc is a small and powerful pc system that is suitable for use in harsh work environments. It is distinguished from standard pc systems through silent operation and an increased stability, especially through the robust aluminum housing and by the lack of moving parts. applications industrial pc is mainly used as a panel pc. Machine vision system is a pc based camera vision system. I-pc is specially designed for the vision system.it can also be used as a panel pc in machine as it is light weight and compact pc that covers all features of normal pc. technical specifications operating system : linux ubuntu 9.04 pre-installed,drivers for windowslinux operating systems includedcpu : intel dual corechipset : north bridge: intel 945gse;south bridge : intel ich7mmemory : 1x1gbyte ddr ii sodimmhard drive : 8gbyte sata ssd hard drivegraphic : gma950 graphics cardaudio : realtek alc662,5.1 channel high definition audio codec2x 2w loudspeakernetwork : 1000mbit rj45 portsusb : 1 usb 2.0 ports,external connectors : vga d-sub 15-pin, 1xusb 2.0, 1x 25-pin parallel port, 1xrj-45, power onoff, 2x 12v dc-in (1x screw-able)internal io connectors : 1x mini pci-e(w-lan card with intel 4965 chip integrated)1x front panel audio header(used for loudspeaker)4x usb 2.0 header, 3x comrs232 headercom1, com2 used as external connectorscom2 switchable between rs232rs485 via jumper jp3, 1x front panel headerinput voltage : 12v dc-inoperating temperature : 0o to +60odriver : windows, linux; linux ubuntu 9.04 preinstalled industries where this product is used this product can be used in each and every kind of industry where compact size of pc required.all kind of machine manufacturerspecially designed for machine vision system features mvp-121 I pc is throughout consistent during the work.full touch screen operation so no need to use other input devices (i.e. Mouse & key board)industrial pcs are dedicated for particular application so safe to operate and work on consistently.very law maintenance cost and handling charge.

...more

Machine Vision Industrial PC 02

Machine Vision Industrial

We are well trusted machine vision industrial pc manufacturers, exporters and suppliers. Full aluminum touch pc is a small and powerful pc system that is suitable for use in harsh work environments. It is distinguished from standard pc systems through silent operation and an increased stability, especially through the robust aluminum housing and by the lack of moving parts. applications industrial pc is mainly used as a panel pc. Machine vision system is a pc based camera vision system. I-pc is specially designed for the vision system.it can also be used as a panel pc in machine as it is light weight and compact pc that covers all features of normal pc. technical specifications operating system : linux ubuntu 9.04 pre-installed,drivers for windowslinux operating systems includedcpu : intel dual corechipset : north bridge: intel 945gse;south bridge : intel ich7mmemory : 1x1gbyte ddr ii sodimmhard drive : 8gbyte sata ssd hard drivegraphic : gma950 graphics cardaudio : realtek alc662,5.1 channel high definition audio codec2x 2w loudspeakernetwork : 1000mbit rj45 portsusb : 1 usb 2.0 ports,external connectors : vga d-sub 15-pin, 1xusb 2.0, 1x 25-pin parallel port, 1xrj-45, power onoff, 2x 12v dc-in (1x screw-able)internal io connectors : 1x mini pci-e(w-lan card with intel 4965 chip integrated)1x front panel audio header(used for loudspeaker)4x usb 2.0 header, 3x comrs232 headercom1, com2 used as external connectorscom2 switchable between rs232rs485 via jumper jp3, 1x front panel headerinput voltage : 12v dc-inoperating temperature : 0o to +60odriver : windows, linux; linux ubuntu 9.04 preinstalled industries where this product is used this product can be used in each and every kind of industry where compact size of pc required.all kind of machine manufacturerspecially designed for machine vision system features mvp-121 I pc is throughout consistent during the work.full touch screen operation so no need to use other input devices (i.e. Mouse & key board)industrial pcs are dedicated for particular application so safe to operate and work on consistently.very law maintenance cost and handling charge.

...more

Machine Vision Industrial PC 01

Machine Vision Computer

We are well trusted machine vision computer manufacturers, exporters and suppliers. Full aluminum touch pc is a small and powerful pc system that is suitable for use in harsh work environments. It is distinguished from standard pc systems through silent operation and an increased stability, especially through the robust aluminum housing and by the lack of moving parts. applications industrial pc is mainly used as a panel pc. Machine vision system is a pc based camera vision system. I-pc is specially designed for the vision system.it can also be used as a panel pc in machine as it is light weight and compact pc that covers all features of normal pc. technical specifications operating system : linux ubuntu 9.04 pre-installed,drivers for windowslinux operating systems includedcpu : intel dual corechipset : north bridge: intel 945gse;south bridge : intel ich7mmemory : 1x1gbyte ddr ii sodimmhard drive : 8gbyte sata ssd hard drivegraphic : gma950 graphics cardaudio : realtek alc662,5.1 channel high definition audio codec2x 2w loudspeakernetwork : 1000mbit rj45 portsusb : 1 usb 2.0 ports,external connectors : vga d-sub 15-pin, 1xusb 2.0, 1x 25-pin parallel port, 1xrj-45, power onoff, 2x 12v dc-in (1x screw-able)internal io connectors : 1x mini pci-e(w-lan card with intel 4965 chip integrated)1x front panel audio header(used for loudspeaker)4x usb 2.0 header, 3x comrs232 headercom1, com2 used as external connectorscom2 switchable between rs232rs485 via jumper jp3, 1x front panel headerinput voltage : 12v dc-inoperating temperature : 0o to +60odriver : windows, linux; linux ubuntu 9.04 preinstalled industries where this product is used this product can be used in each and every kind of industry where compact size of pc required.all kind of machine manufacturerspecially designed for machine vision system features mvp-121 I pc is throughout consistent during the work.full touch screen operation so no need to use other input devices (i.e. Mouse & key board)industrial pcs are dedicated for particular application so safe to operate and work on consistently.very law maintenance cost and handling charge.

...more

Machine Vision Camera

We are offering machine vision camera. The dmk 21bg04.h industrial camera is having ethernet connectivity. The machine vision camera is also having 12 pin heroes connector which includes power supply, external trigger signal, strobe out signal and other general purpose input and output signal. Other industrial cameras also there which are also used in vision inspection system. Other models of machine vision camera are having fire-wire and usb connectivity. Color and monochrome cameras are also there with high resolution ccd and cmos. Generally for high speed application this type of camera is used. applications the cameras generally used for online and offline vision inspection.these cameras are used in machine vision system as well as in microscope. technical specifications there are wide range of different cameras available, we can choose particular model according to application. Here we have mentioned the specification of the ethernet camera. video format @ frame rate : 640x480 y800 @ 60, 30, 15, 7.5, 3.75format : ¼”pixel size : h: 5.6 µm, v: 5.6 µmlens mount : ccssupply voltage : 12 to 24 vdccurrent consumption : approx 500 ma at 12 vdcdimensions : h: 50.6 mm, w: 50.6 mm, l: 50 mmmass : 265 gshutter : 110000 to 30 sgain : 0 to 36 dboffset : 0 to 511max. Temperature (operation) : -5oc to 45ocoutputs : strobe out (open drain), general purpose op (open drain)inputs : external trigger (ttl), general purpose ip (ttl) industries where this product is used machine vision industrymicroscopy purposeindustrial automationpc based automation features it is used for 100% quality assurance at very high speed.the gige camera is throughout consistent during the work.high speed vision inspection systemhigh frequency measurementvery law maintenance cost and handling charge.

...moreOpening Hours