Verticle Long Shaft Sump Pumps

Application The “Active” sump pump is suitable for handling hin, clean or slightly contaminated liquids, such as water, cooling water, Effluent, Cleaning Products, Chemicals and hydrocarbons. Sulfuric acid application, Acid transfer, Aquariums, Chemical processing, Chloralkali, General processing industry, Light slurries, Organic chemicals, Polymers, Petrochemical processing, Slurries, Solvents, Waste Processing. CD4MCU, Hast alloy B & C, etc.

Pressure : Up to 6 Kg / cm2

...more

Vertical Polypropylene Pump

Application Water treatment Plant, Electro Planting & Steel Rolling Mills, Loading / unloading like HCL, Sulphuric acid / Alkali, Caustic Liquid. Scrubbing of corrosive gasses like CI2, NH2, BR2, etc. Ideal for Circulation of chemicals in metal finishing industry.

Pressure : 5 Kg / Cm2

...more

Tyre Coupling

Tyre couplings are also known as the Self aligning couplings. These couplings are popular because of their self aligning nature and they provide smooth vibration while the operation takes place. They also avoid the metal contact and are very efficient in nature. They take shock loads and help in minimizing the misalignment in the shafts and helping to maximize the power transmission between the shafts. The tyre couplings gives low stiffness and are capable in handling high misalignment between the rotating shafts. The tyre couplings are highly suited for the vertical drives and offer the possibility of moving highly critical vibrations without having effects on the driving machine element. The tyre couplings that we offer to the users are maintenance free and are easy to handle. This has indeed made us an reputed tyre coupling manufacturers because of the kind of flexibility and reliability that our components offer to the customers of our company. No lubrication is required to tyre couplings that we offer and the easy installation that our coupling offers to the customers makes us the leading tyre coupling suppliers. Due to our inevitable reputation of delivering the customer expecting products, we have taken control of a large network in the market. This has led to the development our company and we even export the tyre couplings to many other countries. The positive feedbacks that our company has from our customers have given us the opportunity of being tyre coupling suppliers. Our tyre couplings provide easy replacement and easy maintenance. The tyre coupling provides Simplified design – the design helps the coupling to take large misalignments and automatically compensate with a flexing body. Shock loads absorption- The tyre couplings offers absorption of large shock loads and provide efficiency in the operation. Self aligning- The tyre couplings are self aligning and can take up the shapes. No lubrication- these couplings provides no lubrication and easy maintenance. Highly safe- since there is no metal to metal contact between the two shafts, there is no current flow. And this provides high safety. Easy installation- the tyre coupling as mentioned earlier are highly flexible and self aligning. Therefore they are easy installed. We have a number of dimensions of the tyre coupling available and this makes it easy to deliver the customer when the customer is in need of the coupling. It can take up large amount of torque and vibrations and still can maintain its shape because of the flexibility that the tyre coupling provides. These are highly reliable and offers smooth operation in the machine member. They do not have any projecting members and gives life to bearings. And it Takes high end level shock load and is easy to be replaced. These tyre couplings can be potentially used in explosive atmosphere and still provide safety. These couplings can avoid the unpleasant sound the machine offers and can give a good sound free operation.

...more

Teflon Bellow Seals

We at Active Seals manufacture the Teflon Bellow Seals of a high range. The products are manufactured using high-quality raw materials, which are procured from renowned vendors of this market. We do not compromise on quality at all. The products require low maintenance and are very easy to handle and use. The seals of the product are well fabricated from virgin Teflon for efficient use. The seals are so made that they are independent of the direction of rotation and is of balanced type Bellow. This makes it a reliable and flexible bellow seal. We are the Teflon Bellow Seal Manufactures providing you with seals which are perfectly suitable for the application for the corrosive chemicals, oxidizing, and reducing agents and acidic. The products of our company are recognized for its flawlessness and for standing up to the expectations of the clients. The seals are used for purpose of ensuring the fine flow of pipelines from the primary glass equipment. We at Active Seals have well fabricated the Bellow Seals for its variety of applications in various industries. We as the Teflon Bellow Seal Suppliers provide with the Bellow Seals that can be used efficiently for the prevention of the backflow and keeping the pressure well under control. The seals are extensively used in various industries like petrochemical, chemical, pharmaceutical and many more such industries. The company also manufactures PTFE Mechanical Seals. The Active Seal is the popular manufacturing company which provides with PTFE Mechanical Seals. We as the Teflon Bellow Seal suppliers deal with all types of PTFE and ceramic mechanical seals. This product is a highly corrosive component. We use the virgin PTFE Material to make this product so that it comes out as an output which is flawless. It is most demanded in the petrochemical, chemical and pharmaceutical industries and has a vast usage in the refineries. These are cost effective as a corrosive media sealing. The Teflon Bellow Seal is widely used in acids, alkalis and in extremely corrosive services. We as Active Seals ventured into this business so as to provide with the requirements of various industries in general, and the mechanical seals and the valves industry specifically. We offer with a wide range of products at highly competitive rates but not compromising on the quality standards. We offer the customized products of PTFE which are extensively used in the process industries to seal the materials. We strongly believe in customer satisfaction and thus keep coming up with innovative ideas to cater to our client’s changing demands and requirements.

...more

Single Spring Seals

A Single spring seal is used to handle the fluids like gunk and muck. Single spring seal is used in different companies for different operation related to sludge and water. With the help of this seal a pump can transfer sludge and water with no any leakage. We construct the seals with a large variety of suitable raw material. We believe in providing the highest quality products to our valuable clients, because it helps in building a good relationship between customer and dealer. The selection of the Single spring seal manufacturers for its construction is determined by the liquid seal and space limit. The benefit of this type of production is the openness of the design makes your product a non clogging element of the spring seal. We are the most experienced and talented single spring seal suppliers in Ahmadabad and we always believe in serving the best quality product on time. We use advance material along with the unparalleledlayout concept, which makes our seal long lasting. Even we are the single spring seal suppliers in thiscompetitive field of business, we manufacture the innovative product and export in other countries. Our experienced and talented team develops and design diverse of seal with innovative ideas, which helps our customer in rotating equipments like pumps, blowers and mixers. The Active engineering company is here to assist you in your reliability products so that you can achieve world class performance. 20 Years ago, generally pump shafts were sealed via rings of elastic packing, squashed by a packing gland, but this sort of shaft seal needs a fair quantity of leakage just to lubricate the packing and keep it chill. Then the progress of the “mechanical seal,” which fulfil the work of preventive product leakage in the order of the pump shaft with twoplane surfaces (one stationary and one revolving). Still this sort of mechanical seal faces also needfew amount of leakage across the faces, to create a hydrodynamic film, this leakage usually evaporates and is not visible. Mainly pump shafts today are preserved by means of the mechanical seals. However, because of the fineelements used for this new sealing technique, mechanical seal failures are the biggestreason of pump down time. We have a team of the skilled workers, which check the quality of the product during the production and after the production, so you don’t need to worry after taking our services. We provide the high quality products with cost effective prices, which is the most important factor for anybody. Even we design the products according to the unique requirements of the customers, because customer satisfaction is our only priority. So let us change your mechanical seal with our new modernized single spring seal.

...more

single seal

We have developed the wide range of the single seal with high tensile strength. It consists of sturdy construction. It is the abrasion resistant seal. It is made from high grade raw material. It is of flexible type seal.

...more

Shaft Seal

At Active seals we are designing some of the best and high quality Rotary Shaft Seals. The Shaft Seals designed and developed are extremely flexible and reliable in the quality of their make. Since they are designed by industry expert technicians they are flawless and of utmost quality. Our experience and use of modern technology in supplying and fabricating range of Shaft seals make us one of the leading Rotary Shaft Seal Manufacturers in the country. We boast in manufacturing some of specific shaft seals as required by many of our clients from across the industry. The Primary function of the shaft seal is to prevent leakage and provide shield from the media getting contaminated. In order to manufacture quality shaft seals we have the full instruments and machinery. Some of the industry experts are toiling 24x 7 to deliver some of the custom shaft seals as demanded by our specific clients. We train our technician teams to keep them updated with the latest trends and market developments. Due to the better management and coordination along with best technology we have created a niche in the industry we serve in. There are various types of shaft seals that are manufactured at Active seals. We are not only the manufacturers but we are also Rotary Shaft Seal Suppliers in the industry. Some of the shaft seals manufactured at our company are high temperature seals, agitator seals, compressor seals and high pressure seals along with many other varieties of specific manufacturing. We also have the capacity to develop and design seals specific to the requirements of clients. The seals are mostly in high demand in the fields of Paper and pulp, Petrochemical industry, refineries and sugar industry and some chemical and other allied industries. The Seals manufactured by Active seals are sturdy and strong to take any bearing on them. With a lot of features and strong characteristics the shafts seals are extremely long lasting and durable. The diameter of shaft determines the type of shaft seal required. Also it is highly dependent on the speed of shaft for its rotation. We always take into account the main factors that determine the designing of shaft, which are mainly the temperature, and pressure that they will be exposed to. Every shaft seal manufactured at Active seals will have longer service life since they are manufactured with best available raw materials. The shaft seals provided by our company are reliable and optimum in quality with excellent performance guaranteed. Application Industrial gear Compressor Rolling mills Washing machines Diesel engines Agriculture Mechanical units Food industries Chemical industries Pharmaceutical industries

...more

Self Priming Pumps

The self-priming pump is a pump which uses air-water mixture so as to reach a fully-primed pumping condition. It overcomes the problem of air binding through the process of mixing air with water in order to create a fluid with the pumping properties which are much like that of regular water. It then gets rid of the air and moves only water like any other normal pump. We at Active Seals are the Self Priming Pump Suppliers. We make the product available to everyone who needs it at a price which is reasonable enough. The product is of high quality and works efficiently. Not only are we the suppliers for this product but we are also the Self Priming Pump Manufacturers. We manufacture various types of this product for the sludge type media application to be done. The product is also manufactured and made available in all types of alloy grades. We manufacture the SG type Self Priming non clog pumps and make it available in a wide range for the customers to choose from. The pumps manufactured by us are very durable, save energy and is installed with excellent thermal features. We believe in advancement and thus we make use of the advanced manufacturing facilities to manufacture our products. The pumps made at our company have turned out to be very efficient for the rain water disposal and the also the sewage treatment plant. The pumps are well-made to handle the mud and the slushy water. The Self Priming Pump of our company is available with enhanced features. All types of negative and positive suction working is possible with these pumps and are available in various M.O.C. like C.I. Bronze, Gun Metal, Stainless Steel and various other alloys too. The maximum solid hand size is up to 25 mm with head up to 35 Mtr. The capacity of the pump is 75m3/hour with the suction head of up to 7.5 Mtr. The sealing types used are Mechanical Seal and Gland. The pump can be used for dewatering swamps, Trenches and basements, Swimming pools, Marine application, Effluent Treatment Plants, Transfer of lubricants like Petrol, Diesel, Spirits, Gas Oils, Kerosene and many more. We not only operate at the local level but also at the national and inter-national level. Active Seals is in fact a leading Self Priming Pump supplier with its customers in various countries. We provide with highly efficient and good quality products which are the best that you can get at the available price range.

...more

Rubber Bellow Seal

The Active engineering company has a top position among the leading industries and suppliers of a rubber bellow seal. We manufacture the product from the top quality raw material along with the advance technology. These kinds of products are mainly used in plastic immersion, pumps, centrifugal pumps and many other firms. We are a famous supplier of an array of rubber bellow seal. Before the final delivery, our products are thoroughly checked by our quality team for smooth running of the business. Rubber bellow seal manufacturers maintain their business on the basis of reliability, honesty and healthy relationships. Being a best Rubber bellow seal supplier in Ahmadabad, we need to create the diversity, of seal as per client’s requirement and we put innovative ideas while making the product as per time. Rubber bellow seal supplier is develop their business by providing good quality products and complete customer satisfaction to their precious customer. This kind of seal can be used in spite of way of rotation, because the torque acting is not transmitted the coils. This sort of seal used in sewage applications and also with the waste water application. Rubber bellows seal is used in diverse of industries for various applications as per the needs of the products like single, back to back and face to face arrangement. The best thing about the rubber below seal is very economical and easy to maintain. These seals are used in cold water as well as hot water, oil pumps, refrigeration compressor and fuel injection pumps. The active engineering company is engaged in serving rubber bellow seal, manufactured by their talented professionals, who have tremendous knowledge in this domain .These commodities are produced with the best quality raw material along with latest machines. The offered commodities are available in various forms, sizes as per the requirement from our dear customer. Its special features are as follows Long service life Unparalleled quality Bendable Our offered commodities are extensively used to protect joints and shafts from friction and corrosion. The presented range is well known in the field business, because of its different features like durability, outstanding quality and heat bearing capacity. The active engineering company is trusted name in offering a huge collection of bellow mechanical seals. This type seal is used to close within the pump so as to ignore the contact with the exterior world in order to protect from leakage. These Bellow Mechanical Seals give a high degree of axial elasticity to reimburse lack of concentricity of the beam or misalignment due to push movement of the shaft. Moreover, the Bellow Mechanical Seals are used for higher temperature applications like refinery, chemical industries and petrochemical. Operating Limits :To Be Use For: Water pumps Submersible pumps Sewage pumps Shaft Diameter : 10mm to 100mm Pressure : 16 bar Temperature : -20oC to +200oC Sealing faces : Carbon, Tungsten Carbide, Ceramic (99.5 %), Silicon Carbide, Chrome Steel Elastomer : Viton, NBR, Nitrile, Neoprine, Aflas, Silicon as per application Hardware : SS 316 / SS 304

...more

Rotex Spider Couplings

Here, at Active Engineering Co., a plethora of uncompromised and highly recommended Rotex Spider Couplings are manufactured on a large basis and with all the varying vibrant colours of blue, green , red and yellow. To continue to keep ourselves well rooted in the industry, we offer all our mechanical seals in perfect and leading price. The main reason why Rotex Couplings are designed and manufactured is to transmit torque between the drive and driven components through the spiders. The perfect combination of the spiders and the couplings prevents any misalignments in the machines. Rotex spider couplings are divided based on their small dimensions, low mass moments of inertia and the low weight. The working or the service life of the Rotex Spider Coupling are enhanced and improved by the accurate all over machining. TBeing experienced in the industry for more than two decades, we have the privilege of constructing a large clientele. We consider the unique need of the customers and design the required coupling. Our experience, dedication to our clients and our highly professional staff for so many years have made us the leading Rotex Spider supplier in the industry. Active Engineering Co. has all standard materials manufactured in the company. The couplings and spiders are all made of high quality polyurethane material and it has significantly higher resistance to higher temperatures. They also have a long service life than the previously used polyurethane material. Rotex Spider Couplings are made in a manner that they are torsionally flexible and emits positive torque movement. Any operational vibrations are reduced and dampened to run the run the entire system smoothly. Also, they are manufactured in a way that they allow a spider to establish in between them. The spiders have crowned teeth so edge pressure is prevented if the shaft is misaligned. Rotex Spider couplings are also capable enough to compensate with the axial, angular and the radial displacements of the shafts that needs to be connected. It is designed in a special manner to prevent all the kinds of misalignments and the shocks in the industry. Being the leading and highly reputed Rotex Spider Suppliers in the industry, our couplings are in high demand in many industrial sectors and in different instrument applications. If we want to lengthen the life span of the instrument, it is crucial that you chose the best quality Rotex Spider from the highly recommended Rotex Spider supplier like Active Engineering Co.

...more

rotex coupling

It is our esteemed clientele of many years who have helped us reach the pinnacle of success in this industry of mechanical seals. We develop a variety of Rotex Couplings that are required for different reasons. We ensure that the raw material that is used namely the polyurethane is of high quality that is of high temperature resistant. Due to our experience of more than 20 years in the industry, we now stand tall confidently in the industry. Here at active Engineering Co., we are a one stop to shop Rotex Coupling supplier in the mechanical seals industry. We feel proud to serve both the day to day competitively priced market with all the high quality products. The small dimensions, the low mass moments of inertia, and the low weight mainly characterize Rotex Coupling. The actual over all working of the instrument is based on the running quality and service life of the coupling. Couplings are mainly used to deliver positive torque transmission. The unnecessary and the operational vibrations an shocks are dampened and reduced due to these couplings. Both the coupling halves with the concave claws on the inside are peripherally offset to one another. They are designed in such a way that an involute spider can be fitted inside it. the main purpose of the teeth of the spider being crowned is to avoid edge pressure if the shafts are misplaced. All our couplings are made sturdy and are flexible. As supplier we are the most preferred ones in the industry. Our trained technician and machinery complement us in the quality at our premises. The Rotex coupling manufactured have long life span and are highly efficient. The couplings produced by our company can be used in a variety of industry but it is mainly utilized in the automotive industry. Most of the couplings are low in their maintenance and preferred choice of many clients. We have clients from across the globe that prefer to chose buying the Rotex Couplings from our company due to the overwhelming quality and advanced technology utilized in the process of manufacturing them We are proud to be the main Rotex Coupling suppliers of all types of Industrial coupling especially the Rotex Types of Coupling. With the advanced technology, we have kept ourselves updated with some of the new techniques and processes used in the manufacturing of Rotex Coupling.

...more

Rotary Gear Pump With Helical Gear

Application To deliver variety of light and viscous liquid such as Oil, Aats, Coal Tar, Paints, Molasses. Highly viscous materials and liquids. Paints, Ammonia, Glycerin, Grease etc.

Type : Mechanical Seal / Gland Type

...more

Pump Spares

We are engaged in manufacturing the centrifugal pump and self priming pumps compatible spares. We offer the pumps for domestic and industrial usage. We provide best quality pumps and all types of sturdy and durable mechanical seals. We understand the value of time limit, and provide quick service for the same. We are fully equipped with all types of necessary modern machinery and instruments for the pump servicing and spare arrangement. We also provide the services for the mechanical seals and pumps for the plants. We provide quick service for the pumps and seals

...more

pulp & paper mill pump

Application Pulp and Paper Industries Chemical & Process Industries Palm Oil Mills & Refineries Waster Water Treatment Sugar Mill. Triea and Tested In the Pulp Industry for conveying Chemical Pulp Mechanical Pulp Recycled Fibers Caustic, Lye Fibrous Sludge Food Industy Sewage Water Treatment

Pressure : 16 Bar

...more

Ptfe Mechanical Seal

The active engineering is the popular manufacturing company providing a PTFE mechanical seal. We are dealing with all types of PTFE and ceramic mechanical seals. The PTFE is the highly corrosive component. We make use of the virgin PTFE material. It is very demanding in the chemical, petrochemical and pharmaceutical industries. It has vast usage in the refineries. To Be Use For : Extremely Corrosive servies Acid & acidic atmosphere General & Light Chemicals Operating Limits : Shaft Diameter : 18mm to 100mm Pressure : Vacuum … 5 bar Temperature : -45oC to +180oC Material Of Construction : Sealing faces : Carbon, Ceramic(99.5 %), Silicon Carbide, PTFE, GFT, CFT Elastomer :PTFE, GFT, CFT Hardware : SS 316, Hastelloy C, Monel, Alloy 20

...more

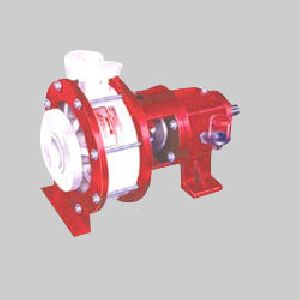

Polypropylene Pump

We are a prime supplier of Agitator Seals around the world. We manufacture standard size Agitator Seals along with custom made Agitator Seals as per customers preferred specifications. Our wide range of Agitator Seals is exported to different countries for usage in industries. We are an Agitator Seals Manufacturer with high industry demand. We are the main Agitator Seals Suppliers for the pharmaceutical, food and beverage industry around the globe. In pharmaceutical and food industry there stands a huge chance of contamination of products during the agitation process that is conducted inside the Agitator Seals. Such contamination occurred can easily affect the quality of the products, or it may turn the product unusable. We are an Agitator Seals Supplier, whose manufactured Agitator Seals do not require any lubricating agent for lubrication of the faces. The demand for our Single Seal and Double Seal Agitator Seals is growing day by day making the largest Agitator Seals supplier in the world. Agitator Seals produced us has a wide variety of usage in different industries – that include – vessels, glass line vessels, blowers and reactors. Our manufactures Agitator Seals are mainly used in the best in class Industrial Agitators. Sturdy construction Corrosion resistant Consists hardness Dimensionally accurate Temperature resistant Abrasion resistant Leakage proof. Along with the manufacture, we also are the best Polypropylene Pump Suppliers offering a huge quality range of this pump such that the pumps are made available in various models so as to meet the varied requirements of different industries accordingly. The products are well designed and properly fabricated so as to resist the corrosive chemicals like alkalies, acids and solvents too. The pump is available in semi open impeller as well as acid corrosion mechanical seal. The pump is very simple to install and as easy to operate. One does not required any special training for people to use these kinds of pumps. On the technical side, the maximum capacity of such pumps is 50m3/hour with a head of 35 Mtr. The temperature is ambient and the M.O.C in which it is available is Molded Propylene. The sealing type is Mechanical Seal Fitting and the impeller type is semi open. Owing to our customer friendly approach and the accomplishment of customer requirements within the specified time frame, we are also recognised worldwide and are the Polypropylene Pump suppliers. The sophisticated facilities available in our company enable us to meet the demands of our huge customer base spread across the globe and the demands are ever-growing. The professionals of our company work in coordination to meet the demands of our clients and increase the customer satisfaction. Not only do we provide with best quality products but we also provide the clients with excellent after sales service so as to make sure that the pumps work efficiently throughout. The Polypropylene Pump finds its application in various fields like food industries, Dyes and Chemical Industries, Textile Processing Plant, Oil and other fuels, Pharmaceuticals Industries, Effluent Treatment Plant, Petro-Chemical Industries, Dairy Industries, Fertilizer Industries and the list just goes on. At Active Seals we provide with products that leave you hassle free with high rate of performance. Application : Used in continuous processing acid pickling line in steel industries. For filteration and pressurise feeding in dyes and intermediate industries. Excellant for vacuum ejectors. Scrubbing of corrosive gases like Cl2 Br, I. So2 For descaling of tubes These pumps are high head (up to 35 mtrs.) with different capacity coupled to 2900 rpm motors.

Application : Acid, HCL, Gases-CI2, Br, I, So2 and etc…

...more

Pin Bush Coupling Type-KB

We provide a large range of the bush pin copling type-KBand KX of the best quality. The coupling transmits the torque through the steel bolts of high tensile characteristics. The couplings are very flexible and consist of the absorbing power of stock loads. We have developed the couplings of various types of technical specifications. We offer the finest quality couplings at industry leading price. Specifications : High Tensile Strength Custom design Corrosion Resistant Reduce Vibration

...more

Multi Stage Boiler Feed Pump

Application Boiler Feed, Marine, Fuel Oil, Power Plant, Industrial Clear Water, Condensate Water, Multi Storied Building Water Supply.

...more

Mono Block Pump

Application Cooling tower, Water supply for domestic use in apartments, Hostels, Swimming Pools, Automobiles service station. Power Plant, Railway LineHead

Type : Single Phase / Three Phase

...more

Metal Single Spring Seal

We offer the metal single spring seal manufactured from finest quality of raw material. It is easy to operate and simple to install seal. It is specially designed to handle the fluids like slurries and sludge. It is widely used in the sewage. The seals are popular for the tolerance. metal single spring seal is also favorable with our valuable clients for higher tensile strength.

...more

Industrial Couplings

At Active seals, we are some of the industry best to manufacture Industrial Couplings. The couplings are in general terms used to join or connect two different rotating shafts. We are the Industrial Coupling manufacturers who provide quality couplings to many industrial for various applications in their respective regions. We utilize only high grade materials for the manufacture of couplings and are preferred mainly on account of our quality and seamless delivery. Our company designs and manufactures some of the highly flexible Industrial couplings. They have the maximum flexibility against misalignment and can be used for a variety of applications. The industrial couplings manufactured at our company have various capacities and can be used in number of industries. The raw material utilized for the manufacturing is the best in its class. On account of which they are the strongest and most sturdy irrespective of the use in whichever industry. The couplings manufactured by Active seals is guaranteed with long service life and hence we are also known as Industrial Coupling suppliers for the quality and service that we offer. In common terms any coupling is a device that attaches the two components that drive. It is a device that helps to transmit the torque in midst of two rotating components known as shafts. Since the two are separate rotating object it requires scope to permit misalignment in between the two objects. Since the coupling are located in between the two shafts they have the responsibility to permit these misalignments. They also have the responsibility to allow stringent movements and prevent excessive misalignments. In order to make the articles work efficiently proper coupling needs to be chosn such that the components work in proper sync. With our technology and expert technicians we continue to deliver the best couplings for various industries that makes us the best manufacturer, supplier for the industrial couplings. The couplings manufactured by us are highly demanded and used in various industries. They are mostly used in the automobile industry. Couplings are manufactured by using C. I , Aluminum and M. O. C along with GGG40, which is of the alloy grade of raw material. There are various bore sizes and key way sizes available. The maximum distance of length that the industrial coupling can cover is also self designed at our design studio. You can customize the design as per your requirements. The industrial couplings offered by us are excellent in quality and less priced. M.O.C. – C.I., Aluminum, GGG40 ( Alloy Grade) Spider : Polyurethane with up to98 sh A Hardness. Maximum Bore and Keyway Size available. Maximum Distance length available. Excellence quality with lowest price.

...more

Industrial Agitator SeaL

Globally, we are among the most trusted manufacturer and supplier of Industrial Agitator Seals. Our Agitator Seals are produced from the best raw material available to ensure best in class quality and maximum satisfaction of our customers. Agitator Seals produced by us have a very high demand in a wide range of industry due to its unmatched quality and the best performance. When the subject comes to price, we also consider it with a high level of importance, so we try our level best to keep the price very economical but we do not compromise with our product’s quality for that. Our Agitator Seals are priced very economically with the best in class quality.

...more

Impellers component

Impeller is the rotating component of a centrifugal pump. There are various types of impellers in the market, we are the Impeller manufacturer in India at Active Seals. The impeller does the job of transferring energy in order to drive the pump. It transfers the energy from motor to the pump by accelerating the flow of fluid away from the rotation center. The velocity that is achieved by this movement by the impeller is transferred in the form of pressure. This pressure is taken by pump casing on account of the outward movement of the fluid. We manufacturer all types of impellers and are the Impeller suppliers across India. There are mainly three types of Impellers that are manufactured by our company. They are the open impeller, Semi open impeller and the Close impeller. All impellers can be manufactured with many different types of materials. The form of any impeller is like a closed cylinder, which is short in size and has an inlet for the inflow of fluid. The structure of the impeller also has vanes in order to push the fluid radically inside the impeller. We have some of the industry best technicians who ensure that we design and manufacture some of the flawless and seamless designed impellers. We are constantly training and teaching our technicians so that we are not far away from the technological advancements of the scenario. We are also known as the countries best impeller supplier and are providing world class services to many countries across the globe. Our technology and machinery drives us to manufacture some of the best impellers in the country and allows us to provide best services across the globe as well. Impellers are manufactured by the use of following materials in our company. Some of the materials that we utilize in order to deliver the impellers are C. S, S. S, P. P, 304, C. I, 316 and many others. We provide customized services and designs specific to our clients and hence we are leading in the industry of supply and export of impellers. There are many impellers, which are without the blades. Such impellers are used in the water jets. It is the use of these impellers that they are mostly chosen in the speed boat industry as propellers. We strive to deliver some of the best impeller designs in the category of Open Impeller, Close Impeller and Semi Open Impellers.

...more

Horizontal Side Suction Pump

Application Filter Press Feeding, Dyes & Intermediates, Slurry transfer Cake transfer, ETP Plant, Sugar & Food Industries

Type : Mechanical Seal / Gland Type

...moreBe first to Rate

Rate This