stirrer machine

Get Price Quote

High Speed Stirrer

56,000 Per Piece

1 Piece (MOQ)

Best Deals from Agitator

Single Phase Mobile Agitator Mixture

232,000 Per Unit

1 Unit (MOQ)

High Speed Stirrer

35,000 Per Piece

1 Piece (MOQ)

Paddle Agitator

25,000 Per Piece

05 Piece (MOQ)

stainless steel agitator

15,000 - 70,000 Per Piece

1 Piece (MOQ)

A stainless steel agitator is a type of mixing device used in industrial and commercial applications to stir and mix liquids, powders, and other materials. It consists of a rotating shaft with paddles, blades, or other mixing elements attached to it, which are designed to move the material being mixed in a specific way. Stainless steel is often used for agitators because it is corrosion-resistant, durable, and can withstand high temperatures and pressures.

Agitator - Stirrer

Get Price Quote

APPLICATION & PROCESS : We design and manufacture a wide range of agitators for liquids and Paste for all process in the pharmaceutical, chemical, food, cosmetics and similar industries. Agitators are provided with different types of agitation components for process such as mixing, blending, dissolution, dispersion, homogenization, reaction, fermentation, oxidation, digestion and emulsification of liquid, paste, ointment, solution, viscous material and solid-liquid. Agitators are designed and adapted to any vessel shape and can be implemented with or without lower support. Different types of blades can be combined depending on the process requirements. The sealing system are designed and adapted depending on the requirement of the various process and start from simple retainers to double mechanical seals. Agitators are available with different type of mounting as per suitability of the process and users requirements. Different types of blades can be combined depending on the process requirements and various conditions including the stirring objective, tank shape, rotating speed, viscosity, mixing blades of different configurations should be applied for different operating objectives. Different mixing blades follow various specifications to design and select the configurations of the blades. The ratio of the blade to the inner diameter of the tank, angular speed of the blade top, viscosity change during mixing process and the range of the flow volume are the factors to be considered. There are various types of blade mixer and can be categorized into axial flow and radial flow according to the flow pattern of the fluid in the tank. The main factors affecting mixing performance are as below and the commonly used configurations are listed for reference: Shape, diameter, sweep back angle and slant angle of the mixer blade. Number of layers and the vertical position of the mixer blade where it is installed. Rotating speed of the mixer blade. Shape, inner volume, number of baffles and outline dimensions of the mixing tank. Batch operation or continuous operation. Agitators available with different type of drives and speeds with direct motor and with gear drive as per process requirements. Agitators are suitable for mixing volumes 5 liters to 10,000 liters. SALIENT FEATURES : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available for volume of 5 liters to 5,000 liters. Available various different type of mixing blade. Available different mounting of stirrer assembly. 1. Wall mounting 2. Telescopic Stand 3. Top of the vessels / Tanks. 4. Bottom of the Vessels / Tanks. Can be provided Variable Speed Drive for stirrer by VFD. Option available for Explosion proof motor and controls panel. « Colloid Mill

Industrial Stirrer

Get Price Quote

This type of machine consist of a motor of reputed make. All contact parts will comprise of S.S 304 material. It will have a protecting cage with two 20 mm bar held apart by closing flat ring clamping on to the bar. The shaft will be coupled directly to the motor shaft. An extra bearing on the coupling sleeve will be provided to reduce the load on the motor bearing. lt will consist of an impeller of special design.

Agitators

Get Price Quote

Energy efficient agitators find application in all type of Pulp Storage Chests, including Height Density Towers, Mixing Chest & Machine Chest. The sturdy design incorporate Bearings & Glands. located outside, optimally designed adjustable propeller blades. All parts coming in contact with stock made of stainless steel, the agitators are highly energy efficient and have the Provision for adjusting the vane angle to suit specific process requirement of gentle or strong agitation.

Agitators

Get Price Quote

With an experience of over two decades in handling the various process applications in Dyes, Intermediates, Pigments, Pesticides, Fine Chemicals, Rubber Chemicals, Bulk Drugs, API and Nutraceuticals. We offer well-engineered and optimum agitation solutions, mixing agitators, industrial agitators, chemical agitator, industrial agitator, chemical agitators, for all your Mixing Tasks. Offering Homogenization / Blending Liquid - Liquid Mixing Gas - Liquid Mixing Solid - Liquid Mixing / Reaction / Suspension High Viscous Mixing Applications Along with the ability for Design and Fabrication of Process Vessels, we offer complete mixing agitators, chemical agitators, mixers, blenders, reactors with shortest deliveries for trouble free lifelong operations

fluid agitator

Get Price Quote

Agitators

Get Price Quote

We are one of the prime suppliers of various types of Agitators. We design the most ergonomic stirrer which consumes less power & gives maximum output. They are also fabricated from HDPE/PP Compressed Sheet. We offer agitators with Rubberlining, HDPE lining, PP Lining for corrosion prevention. Our team of highly trained engineers designs an optimal mixing solution for your specific requirement. We can recommend a superior agitator design for your mixing by reducing power consumption and batch time and improving your product quality.Moreover they are practically maintenance free & have a long life. Types of Agitators : Anchor Type Agitator Pedestal Type Agitator Pin Bush Agitator

Agitators

Get Price Quote

Energy efficient agitators find application in all type of Pulp Storage Chests, including Height Density Towers, Mixing Chest & Machine Chest.The sturdy design incorporate Bearings & Glands. located outside, optimally designed adjustable propeller blades. All parts coming in contact with stock made of stainless steel, the agitators are highly energy efficient and have the.Provision for adjusting the vane angle to suit specific process requirement of gentle or strong agitation.

Industrial Agitator

Get Price Quote

Agitators

Get Price Quote

Energy efficient agitators find application in all type of Pulp Storage Chests, including Height Density Towers, Mixing Chest & Machine Chest.

high speed agitator

20,000 Per Piece

Our company has sculpted a remarkable place in the market as a reputed firm of High Speed Agitator. Features: : Sturdy design Excellent functioning Reliability

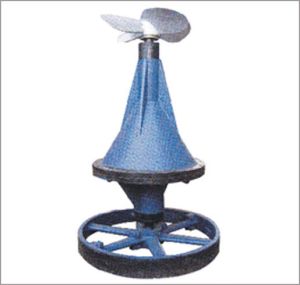

chest agitator

Get Price Quote

A wide range of chest agitators are constructed from stainless steel and consist of reliable mechanical seal and rugged gear reducer. We are the prominent company that is engaged manufacturing and supplying highly durable Chest Agitator. Furthermore, this Chest Agitator is made available in different specifications at reasonable price. Features:=>Used for agitation of pulp in storage chest.=>Chest agitator are made of sturdy and robust design.=>Material of construction of body is C.I. with stainless steel propeller.=>Highly energy efficient.

agitator assembly

Get Price Quote

Our company has been recognized as the leading manufacturer in offering Agitator Assembly to the clients. This product is designed with the supreme perfection at modern manufacturing unit from quality standard material. This Agitator Assembly is known for attributes such as sturdy construction, dimensional accuracy and of best quality. The offered range of agitator assembly is verified by quality controllers on various measures to make sure excellent performance. FEATURES Constant performance Robustly constructed Corrosion resistant

High Speed Stirrer

Get Price Quote

PVS High-Speed Stirrer (1Hp Single phase to 10 Hp 3phase) Specially design for High speed mixture of chemical.

Agitator - Stirrer

Get Price Quote

Application & Process: At PRISM, We design and manufacture a wide range of agitators for liquids and Paste for all process in the pharmaceutical, chemical, food, cosmetics and similar industries. Agitators are provided with different types of agitation components for process such as mixing, blending, dissolution, dispersion, homogenization, reaction, fermentation, oxidation, digestion and emulsification of liquid, paste, ointment, solution, viscous material and solid-liquid. Agitators are designed and adapted to any vessel shape and can be implemented with or without lower support. Different types of blades can be combined depending on the process requirements. The sealing system are designed and adapted depending on the requirement of the various process and start from simple retainers to double mechanical seals. Agitators are available with different type of mounting as per suitability of the process and users requirements. Different types of blades can be combined depending on the process requirements and various conditions including the stirring objective, tank shape, rotating speed, viscosity, mixing blades of different configurations should be applied for different operating objectives. Different mixing blades follow various specifications to design and select the configurations of the blades. The ratio of the blade to the inner diameter of the tank, angular speed of the blade top, viscosity change during mixing process and the range of the flow volume are the factors to be considered. There are various types of blade mixer and can be categorized into axial flow and radial flow according to the flow pattern of the fluid in the tank. The main factors affecting mixing performance are as below and the commonly used configurations are listed for reference: Shape, diameter, sweep back angle and slant angle of the mixer blade. Number of layers and the vertical position of the mixer blade where it is installed. Rotating speed of the mixer blade Shape, inner volume, number of baffles and outline dimensions of the mixing tank Batch operation or continuous operation. Agitators available with different type of drives and speeds with direct motor and with gear drive as per process requirements. Agitators are suitable for mixing volumes 5 liters to 10,000 liters. Salient Features: Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available for volume of 5 liters to 5,000 liters. Available various different type of mixing blade. Available different mounting of stirrer assembly.1. Wall mounting.2. Telescopic Stand.3. Top of the vessels / Tanks.4. Bottom of the Vessels / Tanks. Can be provided Variable Speed Drive for stirrer by VFD. Option available for Explosion proof motor and controls panel.