Ultra Pure Nitrogen Generator

Two Tower Low Pressure Air Dryer

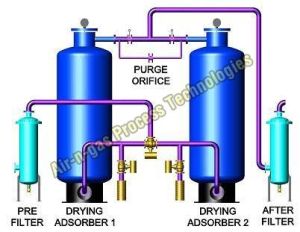

Two Tower Low Pressure Air Dryer

Three Tower Low Pressure Air Dryer

Split Flow No Purge Loss Dryer

We are a trusted Manufacturer and Supplier of Split Flow No Purge Loss Dryer from India. Our Split Flow No Purge Loss Dryer is known for its sturdy construction, durability and high performance. These Split Flow No Purge Loss Dryers are offered at market leading prices. Advantages No purge loss. No need of blower. No used of external air thus eliminating risk of contamination. Most economical in the range from 400 CFM onwards

...more

Refrigerated Bio Gas Dryer

Refrigerated Bio Gas Dryer, offered by us, is well tested and therefore, is the perfect option on which buyers can easily rely. We are enlisted among the reputed Manufacturers, Exporters and Suppliers of Refrigerated Bio Gas Dryer. We are efficient enough to process retail as well as bulk orders for retail as well as bulk orders for Refrigerated Bio Gas Dryer even at short notice period.

...more

Refrigerated Air Dryer

We are engaged in providing high quality Refrigerated Air Dryer that is manufactured in compliance with set industrial standards. The Refrigerated Air Dryer is known for its high performance and longer working life. Manufactured with precision, our Refrigerated Air Dryer is high on demand among the various industries. Features Simple non -cyclic operation Low Noise Zero Purge Loss Even lubricated air can be dried Suitable for any capacity PDP of 3 Deg C Electronic control Environment friendly refrigerant Low operating cost

...more

Psa Oxygen Plant

psa oxygen gas plants

Application : Industrial / Medical

PSA Oxygen Gas Generator

We are a well-known Manufacturer, Supplier and Exporter of PSA Oxygen Gas Generator. These generators are manufactured in compliance with set industrial standards and are widely demanded in various industries. Further, we offer PSA Oxygen Gas Generator at most competitive prices. Features Fully Automatic Operation requiring no special attention Generates Oxygen as and when required � Plug It, Switch On & Forget Easy to install and maintain � Skid Mounted & precommissioned Purity of Oxygen upto 93-95% can be achieved PSA (Twin Tower Pressure Swing Adsorption)Based upto 150 NM3/hr VPSA (Three Tower)For 150 Nm3/hr to 1500 Nm3/hr VSA (Three Tower) For capacities more than 1500 Nm3/hr

...more

Psa Nitrogen Plant

Psa Nitrogen Gas Generators

Country of Origin : Made in India

Material : IRON

Application : Industrial

Design Type : Customised

...more

Psa Nitrogen Gas Generator

Psa generator

The compressed air is passed through a twin tower psa module interconnected with automatic changeover valves. At the bottom of psa towers, activated alumina is provided which has tendency of adsorbing moisture from compressed air. After passing through this bed of activated alumina air gets dried. Supply of dry compressed air from this layer of desiccant (activated alumina) will be continuous without any interruption. Dried compressed air will now come in contact with bed of carbon molecular sieves (cms). Carbon molecular sieves are special grade of adsorbent which have the property of preferential adsorption of oxygen molecules. At a time one tower remains under nitrogen production cycle, whereas the other tower undergoes regeneration which is achieved through depressurization of the tower to atmospheric pressure. The two towers of psa modules are inter-connected with automatic changeover valves through pneumatic signal given by solenoid valve which in turn get the electrical signal from the timer provided in the control panel. The changeover time cycle will be 1 + 1 minute. The outgoing nitrogen gas is sent to a surge vessel where the minimum nitrogen pressure will be maintained with the help of back pressure regulator. The product nitrogen will now be sent to the consumer point through a pressure reducing valves at required pressure.

...more

Oxygen Generator

2,500,000 Per Units

1 Units (MOQ)

Application : Medical

oxygen gas plant

3,500,000 Per Piece

1 Piece (MOQ)

Application : Medical

Design : Customized

No Purge Loss Air Dryer

2,500,000 Per

1 Piece (MOQ)

Max Temperature : 180 Deg C

Capacity : 500-5000 CFM

Minimum Output Dew Point : -20 C

Drying Capacity : 21 - 50 cfm

Automatic Grade : Automatic

...more

Nitrogen Generator

1,000,000 Per Units

1 Units (MOQ)

Features : High utility, Supreme functionality , Greater output , Cost efficient

Capacity : 1 nm3- 500nm3

Application : Industrial

...more

nitrogen gas plant

4,551,000 Per Piece

1 Piece (MOQ)

Color : YELLOW

Country of Origin : Made in India

Brand Name : ANG

...more

MPSA Biogas Purification Plant

4,900,000 Per Piece

1 Piece (MOQ)

Power : Upto250W

Country of Origin : Made in India

Application : Industrial

Plant Design : Customized

Voltage : 240-280V

...more

landfill gas dryer

We offer landfill gas dryer. Air-n-gas process technologies has designed systems to condition methane generated through anaerobic digestion for optimal use in microturbines or combustion engines, and water vapor to protect gas compressors and to remove water vapor from low-btu gas to meet contract specifications. Designed specifically for this application is our refrigerated, landfill digester gas dryer. It is an ideal solution to remove harmful water vapor to improve the combustible quality of landfill gas and biogas, especially when the inlet gas temperature is between 40°c and 45°c. Product features include patented dew point sensor and flood level control, stainless steel heat exchanger tubes and moisture separator and modular construction for ease of servicing.

...more

Internally Heated Air Dryer

1,500,000 Per Piece

1 Piece (MOQ)

Feature : Saving in purge air loss, Compact design ,Simple operation ,Advanced version of desiccant dryer

Brand Name : AIR N GAS

Inert Gas Generators

industrial gas dryers

We offer industrial gas dryers. This is the simplest of all desiccant based air dryers. In this dryer two desiccant towers are used. While one tower is in drying, second tower undergoes regeneration simultaneously. Part of dry air coming out from tower in-line goes for regeneration of the second tower. Tower changeover takes place at every 5 minutes by a sequence controller mounted in control panel. Salient features:- simple operation. Easy to maintain. Microprocessor based controller with purge saver. No need of heater or cooler. Atmospheric dew point of (-) 40 to (-) 60 deg c can be easily achieved. Simple operation.

...more

Industrial Chiller

We are manufacturing different types of air & gas chilling plants based on refrigeration for reducing the temperature in single stage or in multiple stages..

...moreOpening Hours