Warp Beam Trolley

Low built, robust, fabricated from heavy duty steel angles and 8 mm thick plate structure is supported by six heavy duty UHMW material wheels on four corners of trolley. Two are guide wheels turning 3600 and other two are in pair works as steered wheels. Both the pairs of wheel have been fitted in specially designed mechanism which maintains the level of trolley even on rough and uneven surface of floor. Both the pairs are self aligning by the unique design due to the facility of turning 3600 as well as vertical angle of wheel to suit floor level. Harness mounting device is fabricated in the centre of beam trolley with two solid vertical rectangle pillars perfectly in machine and fitted with two carriages which is operated by separate hydraulic cylinder. Harness mounting device has folding and expanding levers hold the frames to load and unload on loom.

...more

terry towel looms

Low built, robust, fabricated from heavy duty steel angles and 8 mm thick plate structure is supported by four heavy duty UHMW material wheels on four corners of trolley. Four guide wheels turning 3600. Two steel fork shaped lifting arms are fitted on lifting shaft and carriages on both sides which are movable and adjustable as per main barrel length and can be raised up or lowered by hydraulic lifting cylinder and chain arrangement. Special provision to accommodate short and wide working width of top beams is provided by shortening and lengthening collapsible device (telescopic type) on the trolley which is operated by manual crank turning provided at the side of the trolley.

...more

Spool Winding Machine

Packaging of the products at our end is done using quality material. Thus, our professional packing staff makes sure that there will be zero damage to the orders received by customers. Our company is ranked amidst progressive distributors of the product in Gujarat(India) as well as varied other marketplaces.

...more

Mechanical Compensating Yarn Tensioner

KFD YARN TENSIONER

Material : M.S

Country of Origin : Made in India

Feature : Easy handling,Automatic compensation of the yarn tension,Oil-damping system,Completely wear-free due to ceramic elements,Designed for high speeds, Adjustment by rows or central adjustment

...more

Hydraulic Beam Trolley

Low built, robust, fabricated from heavy duty steel angles and 8 mm thick plate structure is supported by six heavy duty UHMW material wheels on four corners of trolley. Two are guide wheels turning 3600 and other two are in pair works as steered wheels. Both the pairs of wheel have been fitted in specially designed mechanism which maintains the level of trolley even on rough and uneven surface of floor. Both the pairs are self aligning by the unique design due to the facility of turning 3600 as well as vertical angle of wheel to suit floor level. Harness mounting device is fabricated on both sides of trolley. Two solid vertical rectangle pillars perfectly in machine and fitted with two carriages which is operated by two separate hydraulic cylinders. Harness mounting device has folding and expanding levers hold the frames to load and unload on loom. Harness mounting device is strengthen by extra shaft all along the trolley and connected with sprockets and chains on both side for easy and smooth lifting of carriages.

...more

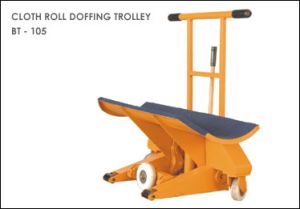

cloth roll doffing trolley

Low built, compact, narrow width trolley fabricated from heavy duty angles and steel plate structure is supported by three wheels (two guide wheels turning 3600 and one heavy duty tilting wheel fitted in centre of trolley). All the three wheels are made of UHMW material (Special synthetic material) and fitted with bearings. Tilting wheel is in centre of trolley has been attached to a specially designed mechanism which tilts the wheel vertically to give excess to a rounded pan so as to go underneath of cloth roll. Simultaneously supporting legs are also lowered and rollers of the legs rest on floor to maintain the balance of trolley and load of cloth roll.

...more

Batching Trolley

Low built, compact, trolley fabricated from heavy duty angles and steel plates, supported by four guide wheels, turning 3600 for easy movements of forward and sideways direction. Half round pan is fixed on the top side of the trolley where the heavy cloth roll is placed and remains steady while transporting. The height of the trolley is matching with the level of the batching motion from where the cloth roll is easily rolled on the top of the pan. Trolley is fitted with extra lever at the side which is used for easy rolling the cloth roll from batching motion. Operation is done manually. All the four UHMW (Special Synthetic Material) wheels are fitted with a pair of ball bearings. All the moving parts which are under load are fitted with suitable sizes of bearings. In all there are eight nos. of bearings fitted in the trolley which makes very easy and comfortable movements.

...more

Pneumatic Beam Pressing Device

Tensioning Unit

Beam Press Machine

Reverse Drum Rotation

Sizing Machine

Be first to Rate

Rate This