Aluminium Die Casting

310 Per Kilogram

10000 Kilogram (MOQ)

Permanent Mold Aluminum Castings

650 Per Piece

100 Piece(s) (MOQ)

Highest Quality Aluminum Casting and Machined Parts manufactured as per Customer's Drawing. Facilities Available : Tool Room to make Mould Tilt Pour Machine Coruse Shoooter Machine Cutting Machine Heat Treatment Plant Shot Blasting Machine Major industries we served for casting components are Textile, Automobile and Switchgear etc.

Best Deals from Aluminum Castings

Aluminium Die Castings

Get Price Quote

We have a dedicated quality control department to ensure the products provided to you are as per international quality management systems. Our policies regarding payment are simple and quick. We have ethical business standards, and we make sure our patrons can make payment securely along with documentation.

Aluminum Steel Sand Castings

Get Price Quote

Aluminum Castings

150 - 180 Per kg

50 MT (MOQ)

Attachment - 3-4% Purity - 98+

Aluminium Rotor Die Casting

50 - 5,000 Per Piece

100 Piece(s) (MOQ)

Maruti Die Casting a company achieved a milestone in manufacturing Aluminum Die Cast Rotor with the best quality. Maruti Die Casting is the oldest Aluminum Rotor Die Casting service provider in Ahmadabad Gujarat India. Maruti Die Casting is providing assurance of 100% solidification Ratio of Aluminum in each slot.

Aluminium Gravity Die Castings

Get Price Quote

100 Piece (MOQ)

Aluminium Pressure and Gravity Die Casting

Get Price Quote

Aluminum pressure and gravity die casting was one of the most ancient processes that were followed in the metal industry. This is an automated process. The molten metal is generally poured into a permanent die or at times is Semi-permanent. The basic aim is to fill the die with the lowest amount of turbulence by making use of one single channel or more. This is to reduce the oxidation process as well as the foaming properties. Gravity dies casting involves various equipment among which moles are the most important ones. They have several advantages as well. AT Excellence Engineering is one of the coveted companies in Ahmedabad known for its reliability and high-quality products and superior services. Established in 2012 and based in Ahmedabad, we have never looked back. We are a renowned company with much versatility within us. Our first and foremost duty is to fulfil the demands of our esteemed clients who have shown trust in us. We utilize our resources and work following the demand and requirements of our clients to satisfy their needs. We are on the top because we are versatile and we never disappoint our clients. Our services include custom designing of hydraulic products. You also have the option of getting it manufactured from us at an affordable rate. Our team of professionals is industry-experienced and well trained in our domain. They look after the state of work in every sphere and report to the authority in case of any lacking or shortcomings. They one-handedly handle the exporting procedures. We also offer free customer support service on bulk purchase. This is one of the foremost reasons for our company to be the best Aluminium Pressure and Gravity Die Casting Manufacturer Supplier in Ahmedabad India. We serve to various industries by offering sustainable and cost-effective solution. Reach out to us in case of our product and service related queries.

high pressure aluminum die casting

Get Price Quote

We are offering This is Ronit Bhavsar from Rameshwar Engineering. First of all I would like to give you brief introduction of my company. Rameshwar Engineering is one of the leading manufacturers in premium Die Castings and Die Casting products since 2008. Developed by our efficient workforce, our array of Die Casting products comprises Aluminum Die Casting, Gravity Die Castings, Pressure Die Castings and Zinc Die Casting. We use high quality raw material including Zinc and Aluminum to manufacture our range, with the help of latest machines & equipment. Exhibiting features like durability and perfect finish, our products are widely used in various industries including automobile and engineering. Since our products are manufactured with the help of CAD CAM facility, we are able to generate digital images of the final product. We are also well-known for providing Customized die castings to our clients. Further, in order to ensure highest level of quality standards, we have adopted an Optical Emission Spectrometer, which analyzes each melt of the metals and alloys during production process. No product gets the verified status, until all the necessary tests and examinations are completed. With the help of our wide distribution network, we are able to reach our clients in all parts of the globe. We shall look forward to start business relationship with you. Please feel free to contact us in case of any query, we will happy to assist you.

aluminum bronze castings

Get Price Quote

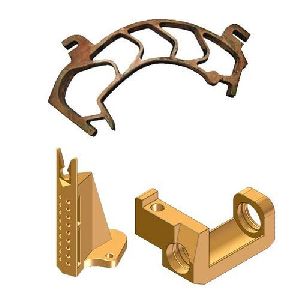

We design and manufacture superior range of Aluminum Bronze Castings to meet the requirements to diverse sectors. To meet international standards, it is certified for physical and chemical composition through comprehensive checks and testing procedure. It is manufactured by molding process that involves: Hand molding Machine molding Pneumatic M/C molding The moldings are offered in green sand, shell and CO2 moldings.

Aluminium Gravity Die Castings

Get Price Quote

We manufacture and export an extensive range of Aluminium Gravity Die Castings, which give to the requirements of railways, motor vehicle and plastic miniature industries. These are fabricated from secondary school gradient raw material using advance organisation to deliver imperfection free range. Our casting constituent are well-known for its consistency, easy assembling and robustness. Specification: Material: Aluminium Weight: 100 grams to 70 kilogram

Aluminium Casting

Get Price Quote

The enterprise is engaged in offering high quality Aluminium Die Casting, which is manufactured by fulfilling set industry standards and norms. The offered casting is manufactured using optimum quality aluminium and innovative technology by our experienced professionals at our sound production unit. The provided casting is accurate in dimension and rigorously examined on several measures of quality to ensure its quality. This casting is used to make various products. Features: Sturdiness Dimensionally accurate Corrosion resistance

aluminium alloy casting

Get Price Quote

In order to append and respond to the assorted demands of respectable clients, we are able to offer a comprehensive range of Aluminum Alloy Casting. The offered range is manufactured utilizing high-grade raw material and modern technology in conformation with the international quality norms and standards. Along with this, our personnel ensures to check the entire range to ensure that flawless products are delivered at clients' premises.

JOLLY 15 MC - OROFLAM MAKE

61,000 Per Piece

Gas burner - oroflam italy make model: jolly 15 mc cap: 43 to 117 kw, single stage, fuel: lpg ng brahma make control & gas valves, ignition transformer motor - 110 watts monobloc automatic burners, die cast aluminium version.

Aluminium Fine Valve Housing Sand Casting

62 Per Kilogram

Aluminium Gearbox Casting

100,000 Per Set

Aluminium Castings

Get Price Quote

We also deal in a wide range of Aluminium Castings for application in various industries. These castings are highly appreciated due to their quality, durability, light weight, versatile usage and sturdiness. They also have high tensile strength, corrosion resistant finish, minimum wear and tear, durability, strength and dimensional accuracy. Our array find usage in various industrial applications and gives performance for a long period of time.

Aluminium Low Pressure Die Casting

Get Price Quote

In this process, a metal mould/die is mounted on above a sealed furnace containing molten Aluminium metal. A riser tube connects the bottom of the die to the molten metal bath. The sealed furnace containing the molten metal is pressurised (typically 3-35 psi), and the metal is forced up into the mould/die slowly at a steady predetermined rate. It is important to determine the rate of filling to avoid entrapment of air and turbulence giving homogeneous defect free parts. The pressure is usually given to feed the defects like shrinkage normally associated with casting process. Once the casting has solidified (time duration 1-4 minutes typically), the pressure is released and the molten metal falls back into the bath, and the casting is ejected. Then the preparation for the next cycle begins. There is very high yields 90-95% in case of Low Pressure Die Casting leading because in effect the casting in a way acts as the gating system. Dr. Dinesh & Ramesh has set up their proprietary Low Pressure Die Casting system. Our system caters to parts from 0.5 kg to 25 kg in LPDC. The parts developed in Low Pressure offer advantages to other systems in homogeneity, yield (lowers process cost), strength as compared to other casting processes.

Aluminum Casting

Get Price Quote

All casting processes, which are used for casting metals can be applied on aluminum for its casting. A few metals have this kind of quality like aluminum. If we arrange these casting processes according to the decreasing order of amount of aluminum,

Aluminium Die Casting

Get Price Quote

We are offering a wide range of Aluminium Die Casting components that fulfills the variegated requirements of different industrial units. These aluminium die castings are manufactured using the finest grade aluminium that we procure from our reliable sources in the market and are in strict accordance with the various industry standards. Moreover, our clients can also avail these aluminium die castings in customized specifications as per their requirement and within the stipulated time frame

Aluminium Bronze Casting

1,200 Per Kilogram

Aluminum Sand Casting

Get Price Quote

Aluminium Ring Casting

190 Per Kilogram

We are the leading manufacturers, exporters and supplier of this products.

Aluminum Alloy Castings

Get Price Quote

We are offering aluminum alloy castings. aluminum can be ‘cast’ by every process used in metal casting. These processes, in descending order of quantity of aluminum casting are: die casting, permanent mold casting, sand casting, plaster casting, investment casting, and continuous casting. The casting process is selected based on factors such as cost, feasibility, quality of parts, etc. Quality refers to both, mechanical properties (ductility and strength) and soundness (surface imperfections, cracking, and freedom from porosity). Die casting alloy selection requires evaluation not only of physical and mechanical properties, and chemical composition, but also of inherent alloy characteristics and their effect on die casting production as well as possible machining and final surface finishing. Surface treatment systems are applied to aluminum die castings to provide a decorative finish, to a protective barrier against environmental exposure, and to improve resistance to wear. Decorative finishes can be applied to aluminum die-castings through painting, anodizing, chromatin, and iridite coatings. Aluminum alloy castings are dedicatedly designed by the experts, using advanced machines and tools. Specific design alloy casting can be providing as per the customer’s requirements. Aluminum alloy castings are of high quality and are available at market leading prices. permanent mold casting aluminum alloys permanent mold casting is best suited for high-volume production. Their size is larger than die castings. These castings have a very low pouring rate. They are gravity-fed. Outstanding mechanical properties are exhibited by permanent mold castings. There is a lot of scope for further improvement if they are given heat treatment. sand casting aluminum alloys this type of casting involves formation of casting mold (with sand). It is inclusive of conservative sand casting & lost-foam casting. The first one involves forming a pattern of sand, pouring the molten metal into it and breaking it once the product is formed. Lost-foam pattern involves putting a dispensable pattern of polystyrene in the mold. die casting aluminum alloys the die castings of aluminum alloys are generally produced using aluminum -silicon-copper alloys. This alloy family gives an excellent combination of corrosion resistance, good dimensional stability, lightweight, strength and cost, along with respite from ‘hot shortness’ and high fluidity which are mandatory for easy casting. If one desires a better resistance to corrosion, he should make use of alloys having a lower copper content.

Aluminium Pressure Die Casting

75,000 - 500,000 Per Unit

Aluminium Pressure Die Casting, gravity casting dies

Aluminium Pressure Die Casting

Get Price Quote

Aluminium Pressure Die Casting, aluminium pressure die casting job work

Aluminium Casting

Get Price Quote

We are offering aluminium casting. Aqeel industries ahmedabad, metal casting in ahmedabad, gujarat, ci casting in ahmedabad, gujarat, cast iron casting in ahmedabad, gujarat, s g I casting in ahmedabad, gujarat, s g iron casting in ahmedabad, gujarat, spheroidal graphite iron casting in ahmedabad, gujarat, dobby machine in ahmedabad, gujarat, s.g.i. Casting ahmedabad, gujarat, aluminium casting in ahmedabad, gujarat,, aluminium casting manufacturers in ahmedabad, gujarat, ci casting manufacturers in ahmedabad, gujarat,metal casting manufacturers in ahmedabad, gujarat,cast iron casting manufacturers in ahmedabad, gujarat, s g I casting manufacturers in ahmedabad, gujarat, s g iron casting manufacturers in ahmedabad, gujarat, spheroidal graphite iron casting manufacturers in ahmedabad, gujarat, dobby machine manufacturers in ahmedabad, gujarat, s.g.i. Casting manufacturers ahmedabad, gujarat.

Aluminum Sand Castings

Get Price Quote

Aluminum Sand Castings, Aluminum Castings, Crgo Lamination, Ferrous Metal

Aluminium Pressure Die Casting

Get Price Quote

We are manufactures of aluminium pressure die casting, aluminium & zinc pressure , gravity diecasting & dies. Welcome all the inquries

Aluminum Casting

340 - 550 Per Kg.

Aluminum Casting, Aluminum Gravity Die Casting, Sand Casting, Ci Castings