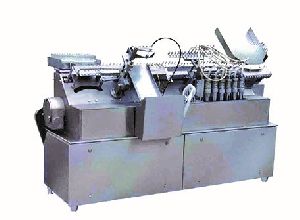

Automatic Ampoule Filling and Sealing Machine

390,000 Per piece

1 piece (MOQ)

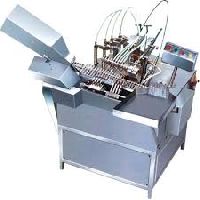

Ampoule Filling Line

5,000,000 Per Unit

1 Unit (MOQ)

Best Deals from Ampoule Filling Machine

Ampoule Filling and Sealing Machine

Get Price Quote

Heavy duty base with robust construction off S.S. matt finished body Ampoule Filling & Sealing machine is specially designed for ampoule drawing, filling and sealing combined equipment for injections In this machine, belts / reciprocating agitators are provided in the feeding station. The filled ampoules in the sealing station are spun by rotating pinions of

Ampoule Filling Machine

Get Price Quote

Ampoule filling machines are completely cover the product in the inert glass and do not have a rubber stopper or anyAmpoule Filling Machine other material in direct contact with the drug. Ampoule filling machines can be used to fill ampoules as well as vials and the speed varies according to the technology. Certain ampoule coding machines apply ring banding to the completed ampoule tips for accurate identification. Filling range of these machines is normally between 1ml to 20 ml. Most ampoule fillers are characterized with fast changeover time to accommodate a variety of ampoules in terms of shapes and size. High quality Ampoule filling machines require minimal maintenance and are very easy to clean. The installation of speed adjusting equipment and no ampoule no fill capability to ensure that unfilled ampoules are not packed. Check weight mechanism of the machine helps to maintain consistency in each batch. Sealing is done either by laser sealing system or conventional gas flame. Ampoule filling machines are completely cover the product in the inert glass and do not have a rubber stopper or any other material in direct contact with the drug. Ampoule filling machines can be used to fill ampoules as well as vials and the speed varies according to the technology. Certain ampoule coding machines apply ring banding to the completed ampoule tips for accurate identification. Filling range of these machines is normally between 1ml to 20 ml. Most ampoule fillers are characterized with fast changeover time to accommodate a variety of ampoules in terms of shapes and size. High quality Ampoule filling machines require minimal maintenance and are very easy to clean. The installation of speed adjusting equipment and no ampoule no fill capability to ensure that unfilled ampoules are not packed. Check weight mechanism of the machine helps to maintain consistency in each batch. Sealing is done either by laser sealing system or conventional gas flame.

Automatic Ampoule Filling Machine

Get Price Quote

Automatic Ampoule Filling Machine

195,000 - 265,000 Per Piece

1 Unit (MOQ)

Glass Ampoule Filling Sealing Machine

Get Price Quote

Ampoule Filling Machine

Get Price Quote

We offer our clients with ampoules Filling and Sealing Machine that is fabricated as per the industrial standards. ampoules Filling and Sealing Machine are available with in-built safety features for long term reliable operation. Further, ampoules Filling and Sealing Machine are also provided in customized specifications to meet the varied needs of the clients. Our range includes the following:- We are instrumental in offering automatic six head ampoule filling and sealing machine, model � ahfs-6. These are highly appreciated by our clients for the sealing pre mechanism and for the feature of no ampoules no filling. We offer precision engineered automatic four head ampoule filling & sealing machine, model ahfs � 4. automatic four head ampoule filling & sealing machines are manufactured using high quality components and are offered in customized solutions as per the needs of the clients. Further, automatic four head ampoule filling & sealing machine are available with a. C. Frequency drive that provides speed control for digital counter. In addition, we offer these with the pre sealing mechanism, which does not require ampoules or filling.

Ampoule Filling Machine, Sealing Device

Get Price Quote

We offer ampoule filling machine, sealing device. Ampule filling and sealing device manual:-hand operated without gas cylinder for sealing, but supplied with gas burner (filling capacity from 10ml to 50ml).

Four Syringe Ampoule Filling Machine

Get Price Quote

Ampoule Filling Machine

Get Price Quote

Technical Specifications are as below: Equipment : Ampoule Filling Sealing Machine Model : KFS-100 Optimum output 80 to 90 Ampoule/min. Overall dimensions : 1200 mm L * 1070 mm W * 965mm H Electric Power Supply : 440V. 3 Phase,1H.P Ampoule Size : Min. 9.5mm Dia to Maxi. 17mm Dia (1ml to 5ml) Construction details : The equipment consist of Hopper with loading Tray at infeed, Filling & Sealing station Loading tray : SS 304 Table top : SS 304 Change Parts : Star Wheel & Needle Ampoule Collection : Collect in Trays

Automatic Ampoule Filling AND Sealing Machines

Get Price Quote

Automatic Ampoule Filling & Sealing Machine is compact & versatile machine for the filling & sealing of glass ampoules. Ampoule Filling Sealing Machine uses in the pharmaceutical industry, apart from this Ampoule Filling Sealing Machine also having application in industries like biotech, cosmetic & chemicals. We are having different models of Ampoule Filling & Sealing Machine suitable as per need of small, medium & large volume injectable preparations. Our Automatic Six Head Ampoule Filling & Sealing Machine provides output up to 9000 ampoules/hour suitable for large batch production, Our Automatic Four Head Ampoule Filling & Sealing Machine provides output of 7200 ampoules/hour suitable for medium batch production and our Automatic Two Head Ampoule Filling & Sealing Machine provides output of 3300 ampoules/hour suitable for small & medium batch production. Salient Features Compact cGMP model. Higher output up to 6000 Ampoules per hour. All contact parts made from High Quality Stainless Steel 316L & Non-contact parts made from Stainless Steel 304. Minimum change over parts from 1ml to 10ml ampoule size. “No Ampoule – No Filling” system. Ampoule neck centering during gas flushing and filling operations. Possibility of nitrogen gas flushing before, during and after filling. Full accessibility allows easy maintenance. Machine equipped with pre-warming station. Flow Meters for regulating flames easily. Minimum change over time, little maintenance, easy cleaning. Process Operation Empty washed & sterilized ampoules receive automatically on wire mesh conveyor belt from outfeed of sterilizing tunnel. Ampoule fed automatically into in-feed hopper from the left hand side of the machine and feed to receiving rack through cassette. The moving rack which moves horizontally collect four ampoules from the receiving rack and transfer the ampoule to the machine in left to right in an inclined position through pre-gassing. Pre-gassing, Filling, Post Gassing, Pre-heating & sealing sta

Ampoule Filling Machine

Get Price Quote

We offer precision engineered Automatic Four Head Ampoule Filling And Sealing Machine. These ampoule filling machines are manufactured using high quality components and are offered in customized solutions as per the needs of the clients. Further, these are available with A. C. Frequency drive that provides speed control for digital counter. In addition, we offer these with the pre sealing mechanism, which does not require ampoules or filling. The machine built on principle of Slant travel of ampoules while filling and sealing. to take care of wide variation of ampoule neck dimensions, thicknesses and ovality of available in globe ampoules.

Single Head Closed Ampoule Filling Machine

Get Price Quote

Ampoule Filling Machine

Get Price Quote

This automatic ampoule filling and sealing machine is the new generation for ampoule drawing. ampoule filling and sealing machine Sealing and filling combine equipment for the injections ampoule filling and sealing machine This automatic ampoule filling and sealing machine is supported on 5-20ml double as well as four injection ampoule filling and sealing machine. ampoule filling and sealing machine The output of this machine is high as well as it is easy to operate. The piston measures pump as well as automatic equipment for pouring the suspension without the bottles being adopted. ampoule filling and sealing machine Natural gas, coal gas, or the gas produced through water resources may be utilized in the machine, so it’s a good machine to have. (liquid filling machine, filling machine, ampoule packing machine)

Six Head Ampoule Filling and Sealing Machine

500,000 - 1,000,000 Per Piece(s)

Offers filling and sealing machine, six head ampoule filling machine, six head ampoule sealing machine, ampoule filler sealer, single head ampoule filling machine, two head ampoule filling machine, four head ampoule filling machine, eight head ampoule filling machine, Ampoule Vial Jet Washing Machine, Ampoule Labeling Machine, Ampoule Inspection Machine by manufacturer and exporter of ampoule filling & sealing machine in Ahmedabad, India, Adinath International.

Ampoule Filling Machine

Get Price Quote

The sterilized ampoule tray can be directly loaded in to slant hopper of the unit. The synchronized star wheel Delivers ampoules, one by one on moving eccentric ampoule rack in single or two's or four's. During the stoppage of rack sequentially pre-gassing Filling, post gassing, pre heating (for single and double head only) and final Sealingannealing is achieved. At the end to the rack, optional synchronized pusher Pushes out ampoules in to tray in vertical position.

Ampoule Filling Machine, Ampoule Labelling Machine

Get Price Quote

We are offering ampoule filling machine, ampoule labelling machine. Salient features compact cgmp model. Ampoule gas centering during gas flushing and filling. Possibility of gas flushing before, during and after filling. Aisi 316l dosing syringes. “no ampoule - no filling function” fast change over due to extremely limited parts to be replaced. Possibility to memorize various parameters of different ampoule sizes. Extremely robust, high engineered. Machine equipped with pre-warming station. Minimum change over time, little maintenance, easy cleaning. Technical specification production rate : 15 to 30 ampoules per minute input specification : container dia.: 10mm to 21.5mm container height: 60mm to 140mm power specification : 1 h.p., 3 phase, 4 wire system, 50 hertz. Filling range : 1 ml to 20 ml filling accuracy : ± 1% from filling volume utility : nitrogen pressure: 1kg/cm2 oxygen pressure required: 1kg/cm2 lpg pressure required: 0.5 kg/cm2 gas for sealing : oxygen + lpg optional accessories : programmable logic control (system) with mmi aluminum profile cabinet covering full machine power specification : 1.5 h.p., 3 phase, 4 wire system, 50 hz. Overall dimension : 915mm (l) x 610mm (w) x 965mm (h) note: electrical characteristics can be adjusted as per customer’s domestic power requirements.

Ampoule Filling Machine

Get Price Quote

Laxmi Pharma Equipment offers compact Automatic High Speed Four Head Ampoule Filling & Sealing Machine, LAFS-100. The machine consist of The unit built on S. S. Square pipe frame and totally S. S. Coverings, finish, Further, the large opening available at the bottom side for ease of absolute cleaning. The pendant type electrical control panel is lifted form machine for easy of operation and safety. Self centering grippers for the transport of all ampoule diameters within the size range without the need to change.

Automatic Six head Ampoule Filling and Sealing Machine

Get Price Quote

Automatic Six Head Ampoule Filling and Sealing Machine MODEL: AHFS 6 We are instrumental in offering Six Head Ampoule Filling And Sealing Machines. These ampoule filling machines are highly appreciated by our clients for the sealing pre mechanism and for the feature of no ampoules no filling. Specifications: • Electrical rating: 1 h. P. • Power characteristic: 415 volts, 3 phase, 4 wire system, 50 cycles/sec • Finish/painted: S. S. Finish • Dimensions: 1780 mm (l) x 1350 mm (w) x 1270 mm (h) • Net weight: 900 kg approx. • Output/hour: 7200 ampoules • Ampoules size: 1ml to 10ml • Optional accessories: A. C. Frequency drive for speed control digital counter The machine built on principle of Slant travel of ampoules while filling and sealing. to take care of wide variation of ampoule neck dimensions, thicknesses and ovality of available in global ampoules. Operation: • The sterilized ampoule tray can be directly loaded in to slant hopper of the unit. The Synchronized star wheel delivers ampoules, one by one on moving eccentric ampoule rack. • During the stoppage of rack pre-gassing, filling, post gassing, pre heating and final sealing is done.

Automatic Ampoule Filling

Get Price Quote

Empty washed or sterilized ampoules fed into Hopper from the left hand side of the machine. Ampoules fed through feeding cassette to receiving rack. The moving rack which moves horizontally collect Next ampoules from the receiving rack and transfer the Ampoule to the machine in left to right in an inclined position through pre-gassing. Pre-gassing, Filling, Post Gassing, Pre-heating & sealing stations completes filling & sealing operations. Filled & sealed ampoules are collected automatically in SS tray in upright position without hand touch. Salient Features: The eccentric rack system is solid & rugged with precise grooves to ensure perfect positioning of ampoule at all operational points. All cams inside machine are steel cast to achieve better hardness and long trouble free life. Further, special jigs and fixers are created to ensure repetitive accuracy of each part. All internal cams are finally set & fixed with taper set pins to ensure that no setting required, even after a long time of usages. Further, the set pins ensure perfect positioning, while refitting. All internal plates are of MS duly safe & painted before SS cladding from outside; impart perfect fixing & total alignments. The filling Head sliding bracket, the heart of the machine is perfectly shaped & lapped to achieve play less performance. SS 316 perfectly ground syringes for accurate filling. Specially designed needles with spring loaded valves to ensure drip proof performance and easy of cleaning and mandatory sterilizations. Absolute, positive mechanical ‘ No Ampoule, No Filling’ device.

Ampoule Filling Machine

Get Price Quote

Automatic High Speed Four Head Ampoule Filling & Sealing Machine, Model No:- LAFS-100. The machine consist of The unit built on S. S. Square pipe frame and totally S. S. Coverings, finish, Further, the large opening available at the bottom side for ease of absolute cleaning. The pendant type electrical control panel is lifted form machine for easy of operation and safety.

Automatic Ampoule Filling Machine

Get Price Quote

The sterilized ampoule tray can be directly loaded in to slant hopper of the unit. The synchronized star wheel Delivers ampoules, one by one on moving eccentric ampoule rack in single or two's or four's. During the stoppage of rack sequentially pre-gassing Filling, post gassing, pre heating (for single and double head only) and final Sealing/annealing is achieved. At the end to the rack, optional synchronized pusher Pushes out ampoules in to tray in vertical position. The basic unit fitted with parts suitable for any size of Ampoule and any one fill size syringes. In the event of change over of each size of Ampoule, following change parts are required. The filling system includes filling syringes, made from stainless steel, pre & post gassing arrangements as well as mechanical "No Ampoule, No Filling" device. Filling is affected by aspirating filling product through the syringes, passing it by positive displacement through the non return valves, filling tubes and filling needles in to the ampoules. Fine setting of each filing syringe is possible. The machine is suitable for filling range from 1 ml to 20 ml. "No ampoule, No filling" system is advantageous to save the costly filling liquid. The sealing station is composed of the ampoule revolving station, sealing burners as well as draw-off jaws. The regulations of burner flames are made easier with the knob. The machine can be easily inspected and better accessed from the both the sides. The driving and controlling elements are protected from splinters, product spillage and jets of water. All the parts coming in contact with the filling liquid are made out of stainless steel 316 and can easily be cleaned and sterilized. The ampoules which are to be treated are fed from ampoule sterilization boxes to an inclined charging hopper. Alternatively, customer can make arrangement for feeding the ampoules directly from sterilized tunnel. Through the charging hopper the ampoules are passed in to ampoule feeding Wheel, which in turn transfers the ampoules positively to the ampoule carrying rack. Ampoules at a time are transported to the various processing stations. The ampoule carrying rack carries the ampoules at an angle of 52 degrees to the vertical, stroke wise. Two centering racks lift the ampoules from behind out of ampoule carrying rack for inert gas treatment and filling and sealing operation. The precision transport system ensures exact centering of ampoule necks at each working station. At the filling station, ampoules are filled accurately, at a time depending on no. of syringes. Filling is affected by aspirating filling product through the syringes, passing it by positive displacement through the non return valves, filling tubes and filling needles, in to the ampoules. Filling in the stationery position and exact centering of necks at the filling and gassing stations guarantees filling without moistening ampoules necks and uniform, safe closures. The sealing station is composed of the ampoule revolving station, burner station as well as draw off jaws. In the ampoule revolving station, the ampoules are rotated round its longitudinal axis. At sealing station, the ampoule necks are gripped by the draw off jaws and sealed when adequate plasticity of glass has been reached, the glass splinters are collected in the waste box.

Ampoule Filling Machine

Get Price Quote

pharmaceutical machinery parts, blister machine change parts

semi automatic ampule filling and sealing machine

Get Price Quote

semi automatic ampule filling and sealing machine

Ampoule Filling Sealing Machine

Get Price Quote

Ampoule Filling Sealing Machine, ampoule labeling machine

Ampoule Filling Machine

Get Price Quote

Pharmaceutical Machinery

Automatic Four Head Ampoule Filling Machine

Get Price Quote

We are offering automatic four head ampoule filling machine. Electrical rating : 1 h.p. Power characteristic : 415 volts, 3 phase, 4 wire system, 50 cyclessec. Finishpainted : s.s. Finish overall dimensions : 1200 mm (l) x 1100 mm (w) x 1000 mm (h) net weight : 400 kgs. Approx. Outputhour : 5000 to 6000 ampoules

Ampoule Filling Machine

Get Price Quote

Automatic Tube Filling machine, label code printing machine, batch

Ampoule Filling Machine

Get Price Quote

pharma machine, Pharmaceutical Machinery, Sealing Machine