Automatic External Ampoule Washing machine

550,000 - 850,000 Per Piece

1 Piece (MOQ)

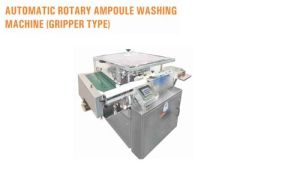

High Speed Automatic Rotary Ampoule AND Vial Washing Machine

Get Price Quote

Description High Speed Automatic Rotary Ampoule & Vial Washing Machine is specially designed to wash Ampoule & Vial with minimum contact of machine parts with container. Machine with specially designed Gripper system holds the container from Neck and invert till the washing operation completed and again after washing release the container on outfeed feedworm system in vertical position ensures positive wash of containers. Machine is suitable to wash various sizes of containers with the help of change parts. Automatic Rotary Ampoule & Vial Washing Machine is widely uses in Pharmaceutical, Veterinary & Biotech industry for performance & cGMP demanding customers. Salient Features All contact parts with the internal surface of Ampoules/Vials and the wash media are made of AISI SS 316L Stainless Steel Other parts are made from engineering plastic, FDA approved or AISI SS 304 Stainless Steel All finishes, welding joints are processed, treated & equipment selected in accordance with cGMP standards 18 Jets for 6 Internal washing zones 15 Cassette of Grippers each having 2 Grippers Suitable for 1ml to 25ml ampoule & 2ml to 100ml vials Washing sequence can be made as per customer’s requirements 3 Pumps and 3 Tanks of 25 liters each Each washing zone with independent circuit to avoid contamination Automatic Infeed and Exit of Ampoules/Vials Output capacity of up to 240 Ampoules/Vials per Minute Ampoules/Vials feed from the Infeed tray are received on an Infeed Feedworm then moves on Infeed starwheel. The Grippers picks up the Ampoule/Vial from Infeed Star Wheel and invert it in neck down position over washing needles and move along with the needle bar for Washing. On completion of a cycle, washed ampoules/vials are again inverted to neck upward position and feed to output star wheel. Washed ampoules/vials received from output starwheel can be collected on Output Tray or can be pushed to tunnel

Best Deals from Ampoule Washing Machine

Automatic External Ampoule Washing

Get Price Quote

Ampolue Washing Machine Salient Features : LC system with touch screen HMI. Output speed of 400 ampoules/Min. 3 in 1 ie. Washing, Drying, Labelling of ampoule. Water & air knife for washing & drying. Servo motor for labelling. Imported sensor for container & label. Accurate label placement.

Automatic High Speed Rotary Ampoule Washing Machine

300,000 - 650,000 Per Piece

1 Piece (MOQ)

The quality-driven Ampoule and Vial Washing Machine is designed to wash and clean Ampoule/Vial withminimum contact of machine parts with Ampoule/vial. The machine is tailor-made to wash various sizes of Ampoules/Vials with the help of change Parts. The specially designed gripper system holds the Ampoule/Vial from the neck and inverts until the Washing Operation gets over. Salient features Vibration free construction Low maintenance Efficient Durable Application Cleaning and washing of Ampoule & Vial Industry Pharmaceutical Veterinary Biotech Industries

Ampoule External Washing Machine

Get Price Quote

Ampoule Washing Machine

Get Price Quote

We offer our clients with a range of ampoules and vials Washing Machines that is manufactured using premium quality components. These are equipped with electrical controls that provide protection to the device against single phasing and motor overload. Further, these are appreciated by our clients for the features like long lasting and rust free finish. Our range of ampoules and vials Washing Machines includes multijet ampoules and vials washing machines. Also Automatic Ampoule Loaders are available with automatic loading of ampoules in combi trays of multijet washing machines that save time. Further, these are precision engineered machines that are compatible with multijet washing machines and are offered at reasonable priceshiv.

Multi-Jet Ampoule and Vial Washing Machine

Get Price Quote

MULTIJET AMPOULE & VIAL WASHING MACHINE MODEL: AHWM-432, 340, 240, 189, 110 & 50 Operation: The loaded combi tray/s are placed directly into the machine and the top cover is lowered and switch is operated for automatic sequential washing both from inside and outside for each individual ampoule. • The machine will automatically stop, after completion of cycle the small hooter will on. For removal of combi trays, reverse procedure is to be observed. • Depending On Dump Loading Or Individual Loading And Operator’s Skill, One Can Achieve As High As 30 Loading Of Combi Trays Per Hour. Salient features: • Simple and robust construction for long life and continuous service. • Positive and pressurized jets through washing needles for high performance cleaning and minimum usage of washing media. • Both internal and external washes ensure absolutely clean ampoules after sequential washing. • Wth helps of plc, the cycle time of each wash can adjusted as per your reuqirements. • Acrylic top cover for clear view of washing events taking place in the machine. • In the event of acrylic cover lifted during cycle operation, the machine will automatically stop and re-start from the same point when cover is pulled down and restarted. • One cycle consists of 2minutes ( including loading and unloading of combi trays. ) in which • 1ST WASH: D.M. WATER • 2ND WASH: AIR • 3RD WASH: D.M. WATER • 4TH WASH: AIR • 5TH WASH: WFI • 6TH WASH: AIR Input specifications: • Ampoules size: 1 ml to 25 ml ampoules • Vials size : 2 ml to 100 ml vials size Technical specifications: • Power characteristic: 220 volts, 1 phase, 50 cycles/sec • Finish/painted: s. S. Finish • Dimensions: 1120 x 980 x 1010 mm (l x w x h) • Net weight: 180kg • Output/hour: 10000 to 12000 objects • (depend on type of needle plates ) • Air : 20 cfm at 5 bar

Ampoule Washing Machine

Get Price Quote

Ampoule Filling Machine, Pharmaceutical Machinery

Ampoule Vial Jet Washing Machine Ampoule Washing Machine, Vial Washing Machine

500,000 - 1,000,000 Per Piece(s)

Offers ampoule vial jet washing machine, ampoule washing machine, vial washing machine, ampoule filler sealer, single head ampoule filling machine, two head ampoule filling machine, four head ampoule filling machine, six head ampoule filling machine, eight head ampoule filling machine, Ampoule Labeling Machine, Ampoule Inspection Machine by manufacturer and exporter of ampoule vial jet washing machine in Ahmedabad, India, Adinath International.

Semi Automatic Multijet Ampoule Washing Machine

Get Price Quote

As one of the pioneering manufacturers of Semi automatic multijet ampoule and vial washing machine, Harsiddh Engineering Co. offers products of highest quality standards. The S.S construction provides lucid operation while washing ampoules of 1ml to 25ml. additionally; the washing equipment also meets the washing demands of 2ml to 100ml vials. Microprocessor incorporation enhances the functioning of the entire unit. The washing apparatus possesses incredible technical specifications. The needle quantity of the machine is classified in 30 cycles in every hour. With a power consumption capacity of 0.25HP, this particular equipment consumes very less power. The entire machinery works on the pressure cleaning mechanism and makes very less use of the washing media. Operators can also view the entire washing process with the acrylic cover placed on the top of this ampoule washing device. By using distilled water, this device ensures perfect cleaning for all kinds of vials and ampoules. Apart from that, the machine also offers lucid operation by loading 30 trays within an hour. Our machines have CE certifications. Automatic re-start and stop process during the cyclic operation further enhances your convenience while washing. Additionally, all the contact parts of the equipment exhibit S.S 316 or HDPE polycarbonate materials, thus imparting robust strength. Silent Features Machine is suitable for washing of 2ml to 100ml vials. High pressure spray nozzles enter into the vials & ensure perfect wash. Totally fabricated from high quality SS materials including the basic frame. No change of parts required for washing of vials (5ml to 30ml), hence saving time of change over. All parts coming in contact with washing zones / jets are made from SS 316 material. Water re-cycling arrangement is possible as per customer’s requirement. Machine is totally robust and withstand continuos operation for long working hours without any trouble. Multijet ampoule and vial washing machine is equipped with PLC system & printing facility with passwords.

Ampoule Washing Machine

600,000 Per Unit

Ampoule Washing Machine

Get Price Quote

At Shree Bhagwati Machtech (India) Pvt. Ltd, we are serving the needs of the pharmaceutical industries for quite some time now. Our range of Bottle and Vial Washing Machines has extensive applications across industry verticals. These washing tools have the best specifications and features, required for the perfect washing of vials and ampoules. As one of the leading washing machinery suppliers, we stock a complete inventory of washing instruments for bottles, vials and ampoules. Our product range includes Offline or Semi-Automatic Rotary Bottle Washing tools, Automatic Linear Tunnel type Bottle Washing Machine, Automatic External Vial Washing Machine, Automatic High-Speed Inverted type Airjet Cleaning instrument and Automatic High-Speed Inverted type Airjet Cleaning tools. Apart from that, Automatic External Ampoule Washing & Labelling equipment, Automatic Four Head Bottle Air Jet Cleaning tools and Automatic Six Head Bottle Air Jet Cleaning equipment.

Rotary Ampoule Washing Machine

Get Price Quote

Competencies » Total CGMP model » Frame Made from SS-structure. » Sleek sturdy and compact design » All controls from panel » PLC-HMI touch screen Features » The infeed turret and feedworm mechanism delivers the ampules to the grippers » Grippers hold the ampoules firmly » Post that grippers are inverted. » Nozzles are inserted inside ampoules for liquid/air washes » Low water consumption » Quick change over of change parts » Washed ampoules can be collected in the tray/ pushed to tunnel » Electrnically controlled spray duration and spray cycle » Water tank and ampoule collector is needed as accessory Utilities » 415V, 3ph, 50Hz electric supply » Electric load 5 HP » Compressed air:- 5 CFM at 4 to6 kg/cm² » Water or cleaning liquid as per tank size APPLICATION » To wash vials/Ampule with water or any other liquid » Ampoule diameter upto 20mm *The output depends on ampoule geometry and characteristics of cleaning media. * Specification subject to change without prior notice.

Ampoule Washing Machine

Get Price Quote

Stainless Steel Reactor, Vial Washing Machine, Sterilizer, Drain Trap

Ampoule Washing Machine

Get Price Quote

Vial Washing Machine, automatic vial washing machine

Ampoule Washing Machine

Get Price Quote

Ampoule Filling Sealing Machine, ampoule labeling machine

Multi Jet Ampoule Vial Washing Machine

Get Price Quote

Multi Jet Ampoule Vial Washing Machine

Ampoule Vial Washing Machine

Get Price Quote

Ampoule Vial Washing Machine, Ampoule Vail Filling Machine