Ribbon Blender

25,000 - 500,000 Per piece

1 Piece (MOQ)

Ribbon Blender

150,000 - 380,000 Per piece

1 piece (MOQ)

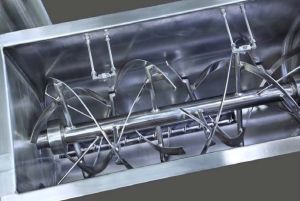

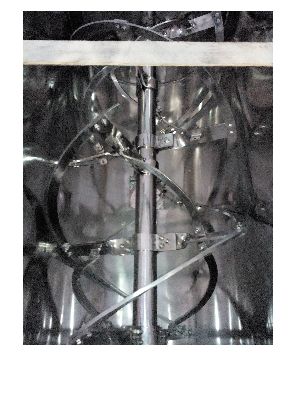

The RIBBON BLENDER is ribbon mixer machine widely used for the manufacture of dry powder, talcum powder, granules, spice and low-viscosity paste and liquid in chemicals, pharmaceuticals, food and cosmetics industries. It’s especially suitable for mixing solids with solids and solids with liquids, Approximate two third of the volume of the container of Ribbon Blender/mixer is filled to ensure proper mixing. Ribbon Blender mixer is Suitable for Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, and Food industry and heat sensitive, Chemical and Cosmetic products handling large Dry and wet powder volume. It consists of a horizontal “U” Vessel with horizontally installed shaft. Hexacon Enterprises make Horizontal Ribbon Blenders is an high efficient and versatile blending machines for mixing of dry powder, granule and viscous paste homogeneously. Ribbon blender mixer to given perfect r mixing due to the innovative designs of spiral agitators inside of its U-shape Cone chamber. Ribbon blender with Screw conveyor , ribbon blender with bin , ribbon blender with sifter , ribbon blender with product transfer input and output , liquid spray systems, working plat form with variable speed drive or PLC base operation we offer as per customer product and process , Horizontal ribbon mixers range from 50-25000L or more capacity as per requested by customer . Ribbon blender and mixer with stainless steel construction or Mild steel construction main body with stainless steel U shape mixer with bottom product discharge manual and auto valve , control panel , product bin etc we offering as per customer demand for wide industreis Food, Cosmetic, Waterproof Porcelain Glazed Polished Vitrified Tile Strong Adhesive, Floor Adhesive /Ceramic, Chemical, Plastic , Dry Powder, Putty, Modified Corn Starch, Real Stone Paint, Animal feed, Pharmaceutical, Fertilizer, Plastic, Battery etc…… We offer Quality with best mixer machines, mixing machine, blender, powder mixer manufacturers and suppliers by Shree Bhagwati Group of companies. RIBBON Mixers has been developed with advanced technology to achieve high blending capabilities and is among the most efficient machines in the market. The ribbon mixing equipment can be used in either the batch or continuous flow form to achieve an even and homogeneous blend in a wide range of products. The blending technology is widely used in industries such as pharmaceutical industries, food processing, animal feed processing, chemical, fertilizers, cosmetics, pigments, and also insecticides manufacturing. The vertical blender mixer is also important in the process of distribution of liquids and pasty products in micro dosages on to carriers. Capacity FROM 50 LITERS TO 15000 LITERS The ribbon blender machine comprises of a horizontal U shaped trough and a specially developed a double helical, fabricated ribbon agitator that rotates within the trough. The machine design is based on a proven agitator technology that efficiently achieves triple mixing action and ensures fast and efficient blending. The equipment dimensions and design of the operating parts are well balanced to provide balanced material movement within the container and avoids dead spots while rapidly discharging the product. The ribbon mixer machine is made with user friendly features such as wear resistance, corrosion resistant, vacuum filling and discharge arrangements, special shaft seals, heating and cooling jackets and in a variety of sizes and models for specialized applications. The operating capacity of the ribbon blender mixer ranges from 100 liters up to 8000 liters capacity, and it is constructed with stainless steel for maximum durability.

Best Deals from Animal Feed Making Machine

ribbon blender machine

200,000 Per Units

1 piece (MOQ)

animal feed pellet machine

Get Price Quote

Ribbon Mixer

Get Price Quote

All type of Blenders are available for Mixing i.e. Octagonal Shape, V Shape, Double Cone, Cage, Cone & Ribbon Blender in the MOC of Contact Parts S.S.316.

Feed Pellet Machine

Get Price Quote

Feed pellet machine Ideal for SMALLMODEST COMMERCIAL production, The DIA of PELLET and LENGTH of PELLET is decided by DIA of hole in DIE-RING and position of KNEFE CUTTER.Screw Feeder Conveyer and DOWN SPOUT are made from stainless steel to avoid Corrosion.

Double Ribbon Blender

550,000 Per Piece

1 Piece (MOQ)

Ribbon Blender

Get Price Quote

Ribbon blender is used for uniform, homogeneous and quick mixing of powders and semi-wet materials of different densities by specially designed helical ribbon agitator. It can be used for Pharmaceutical, Food, Chemical, Dyestuffs & Pigment etc. For Pharmaceutical Industries, Ribbon Blender is called as Mass Mixture. Uni-Mech manufactures Continuous type and Batch type Ribbon Blenders. Uni-Mech also designs Ribbon Blenders for Chemical Reactions with Heating & Cooling applications. Ribbon Blender Design Range : Capacity range: 5 liters to 15000 liters Material of Construction: Various grades of Stainless Steel, Mild Steel, Hastelloy (cGMP model is also available). Special Features : Homogeneous Mixing Dust Free Operation Easy Handling & Operations Top Charging & Bottom Discharge through Butterfly Valve / Sliding Gate

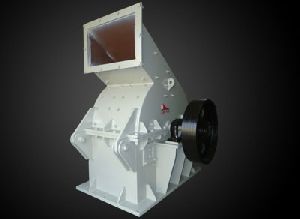

Hammer Mill

53,000 Per Piece

Ribbon Blender

380,000 Per Piece

1 Piece(s) (MOQ)

The Mahavir ribbon blender are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the Mahavir ribbon blender can in corporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon blender is available in sizes 100-8000 litters in Stainless Steel 304, Stainless Steel 316 and Mild Steel Construction.

Hammer Mill

Get Price Quote

The Hammer Mill is most suitable and convenient range to pulverize the material up to 80 - 100 mesh (150 micron). - A robustly constructed machine for crushing different mineral, chemical, Ayurvedic Herbs, Agro Products, etc... • Capacity Range: 100 - 5000 KG /HR. • Application: Different chemicals, Minerals, Pigment, Coal, and Agricultural Products like Gram, Maize, Rice, Husk, Sawdust, Ayurvedic herbs, Cattle Feed, Animal Feed, Poultry Feed, Refractory, Ceramics, Dolomite, lime stone etc. Features of Hammer Mills 1. Use Hammer Mills without cyclone and dust collector for bigger output particle size, for fine material acyclone with dust collector is used.. 2. Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material. 3. Fab-tech Engineers offered different type of material for liners and hammer as per client product for better result and best life of wear & tear part.

Ribbon Blender Mixer

Get Price Quote

We are offering ribbon blender cum mixer. specification: crushtech, ribbon mixers provides fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. Most economical way of mixing the powder if the moisture contain is not high. We can design the machine as customer's product. Crushtech, mixers can be design as per customer specification like wear resistance, corrosive resistance, vacuum filling and proper discharge arrangements, special shaft seals, heatingcooling jackets. No rcc foundation is required if fixed on a specially designed avm pad frame. Ribbon blenders are available in different sizes with s. S. & m.s. Construction. advantages: crushtech mixers are noiseless, less maintainers, heavy body construction, they are available in different sizes with s. S. & m.s. Construction. application: ribbon blender is being used in many industries like different spices, cattle feed plant, chemical industries, minerals mixing or blending, pharma industries & many other.

Ribbon Mixer

Get Price Quote

The design of the Reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass.

Ribbon Blender

Get Price Quote

We are offering ribbon blender we have a state-of-the-art manufacturing facility, which helps us providing our clients with ribbon blenders. Ribbon blenders available size from 200 mm diameter to 2500 mm diameter in mild steel & stainless steel.

SCREW FEEDER

Get Price Quote

Features: The design of a Screw feeder resembles to that of a Screw Conveyor closely but unlike a screw conveyor, a screw feeder is required to be very precise and accurate. While in a Screw conveyor the screw is filled to the extent of 30% to 40%, in a screw feeder the material completely fills the screw. This is the reason why the material is discharged with uniform and controlled rate and the rate can be varied by controlling the speed of rotation of the screw. Apart from metered feed, one of the important applications for using a Screw Feeder is where the material is dusty or toxic and hence requires an enclosed device.

Ribbon Blender

Get Price Quote

This is a universally accepted mixer which is useful for mixing, blending and reaction of solid-solid and solid-liquid materials. They are made in different sizes according to its requirement of application. It has a U shaped trough and a shaft with ribbons is rotating inside it. The ribbons have co-axial supports that provide the strength to the curved arms. The ribbons are designed and fabricated such that the particles inside the shell move freely from one corner to another one and get in close contact with each-other and thereby are mixed very well. Also the close contact enables better reactivity among them.

Ribbon Blender

150,000 - 7,500,000 Per piece

1 Piece (MOQ)

Horizontal Ribbon Blender

Get Price Quote

Horizontal Ribbon Blender gives very best result for combining of dry powdered & granules as a result of design and form of the mixing ribbon and product jar. It can provide for Pharmaceutical, Meal, Chemical and Cosmetic products etc. The HORIZONTAL RIBBON BLENDER is a proficient and resourceful blending machine and is very useful for homogeneous mixing of dry granules & powders. Roughly about two third of the volume of the container of Horizontal Ribbon Blender is filled to make certain that it is mixed properly. The Horizontal Ribbon Blender Manufacturer offers the most excellent outcome as far as mixing of dry powder and granules is concerned because of the design and shape of the container. It is very apt for Pharmaceutical, Food, Chemical and Cosmetic products processing. Material charged via the top part port/ports are put on the top cover to charge the material. It also aids in venting the air. A discharge valve is given at the bottom part at center of the container. The discharge height can be altered according to the necessity, thus the material is discharged in the extra container directly. Thus there is zero material handling time needed for discharge and the operation is totally dust free. We produce brilliant quality of Horizontal Ribbon Blenders and our product is very apt for mixing, grinding, granulation and homogenizing procedures. Features: The shape of container along with mixing stirrer allows sufficient continuous movement towards powder / granules result in good quality. All contact elements of Horizontal Ribbon Blender are created from SS 304/SS 316 top quality material Maximum care may be taken to ensure safe operation in the Horizontal Ribbon Blender Inching service for stirrer regarding discharge of materials Full cover at the top side of the container Discharge height as per client requirement Operating panel provided for safe operation of Horizontal Ribbon Blender Centrally located material Discharge valve Dust proof top cover with window provided

Ribbon Blender

150,000 - 500,000 Per Piece

1 Piece(s) (MOQ)

Ribbon Blender

560,000 Per Piece

feed mill plant

Get Price Quote

EQUIPMENT USED IN AQUA FEED PREPARATION PULVERISERS They are used for grinding the feed ingredients. Grinding of ingredients improves the feed digestibility, acceptability, mixing properties, pelletability and increases th bulk density of some ingredients. The grinders are available in various forms as described below. HAMMER MILLS Hammer Mills are mostly impact grinders with swinging or stationary bars forcing feed ingredients against a circular Screen or solid serrated section called striking plate. Material is held in the grinding chamber until it is reduced to the size of the openings in the screen. Impact grinding is most efficient with dry, low fat feed ingredients.

Feeder Screw Type

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of Feeder screw type for chemicals plants .we are manufacturer and supplier Feeder screw type and high quality material used. we are exporter india market and international market.

Ribbon Blender

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of Ribbon Blender to Mixing the Material.The design of the Reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass.

Ribbon Blender

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of Ribbon Blender to Cmixing machinery.The design of the Reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass.

Screw Feeders

144,000 Per unit

1 unit (MOQ)

Ribbon Blender

Get Price Quote

Working Principle & Features of Techno Enterprise’s Ribbon Blender: Ribbon Blenders is design to provide high mixing efficiency, blending small proportions into large stocks. Ribbon Blender is primarily designed for use with dry materials, although gas and liquid streams can also be introduced. A wide variety of configurations, for either batch or continuous mixing, are available. Application specific rotor mixing element design allows shorter batch cycle times due to increased mixing efficiency. Efficient mixing also provides good heat transfer through optional ASME Code designed jackets for heating or cooling applications. The compact and robust construction dust proof operation ensures their negligible running costs. We can offer these in various customized sizes/finishes. We provide custom made size design of the Ribbon Blender to meet your specific mixing requirements. Mixing vessels can be standard U-shape or cylindrical depending on internal pressure or vacuum requirements. Material finishes available ranging are from industrial coatings to dairy grade polishes. The classic Ribbon Blender serves multi-purpose uses in the manufacture of food, beverage, pharmaceutical, cosmetic, chemical, plastic, agricultural and other products. Given its versatility and economy, the Ribbon Blender is often the choice for most straightforward blending requirements. In a well-made Ribbon Blender, precisely designed and fabricated ribbons turn within a close-tolerance horizontal trough to produce a balanced lateral and radial movement of the batch materials. Blending cycles are relatively fast and mix quality is not hard to duplicate from batch to batch. In principle, it requires very little maintenance even when subjected to frequent product changeovers. Scaling up from a pilot Ribbon Blender operation to large volume production is also generally uncomplicated. Despite these proven advantages, as with other types of mixers and process equipment, optimal mixing performance in the Ribbon Blender still starts with proper sizing, specification and customization. This white paper outlines some strategies for achieving just that, operating to maximum efficiency and ensuring a long service life out of your Ribbon Blender. Ideal For: Seeds and Spices Adhesives Food products Animal feed Chemicals Dry and Wet Pigments Starch Products Pesticides and fertilizers Cement Industries Many Other Wet and Drying Applications as below:

Super Hammer Mill

75,000 Per unit

Pipe Screw Feeder

Get Price Quote

SCREW FEEDER

Get Price Quote

Screw feeders are useful to assist bin / hopper unloading and in producing uniform / metered feed. The pitch of the screw is kept variable in order to produce uniform draw of material across the entire hopper opening. The design of a Screw feeder resembles to that of a Screw Conveyor closely but unlike a screw conveyor, a screw feeder is required to be very precise and accurate. While in a Screw conveyor the screw is filled to the extent of 30% to 40%, in a screw feeder the material completely fills the screw. This is the reason why the material is discharged with uniform and controlled rate and the rate can be varied by controlling the speed of rotation of the screw. Apart from metered feed, one of the important applications for using a Screw Feeder is where the material is dusty or toxic and hence requires an enclosed device.

Ribbon Blenders

Get Price Quote

The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of Chopper Blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon Blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.