WATERLESS BROOM

Can be operated conveniently by towing with a tractor or jeep, Weeping width is 2.25 meter clear sweeping, Dust is collected on left hand side, Adjustable on both side as per the slope of road, Brush adjustments up to 100 mm, Two heavy duty wheels, Nylon brush bristles.

...more

TWIN-SHAFT PUGMILL MIXER

Direct gear-motor drive with transmission through synchronous, helical spur gear. Robust and rugged design to suit hardest site condition. Inner mixer wall is bolted with extremely high wear resistance austenitic Ni-Hard liners. Mixer arms and paddles, which are made from high-chrome alloy-steel and special caststeel ,are bolted to allow for easy replacement of these wear parts. Mixer discharge gate with wear resistance liners is a rotary type and pneumaticallyoperated by two cylinders. Capable to produce homogenous mix within a short mixing time, minimizing oxidation of bitumen. Non-contact infrared temperature measurement at mixer outlet. Direct discharge of asphalt hotmix to truck below.

...more

Truck Mounted Bitumen Sprayer

Endless belt feeder.Shaft-mounted gear motor for minimum maintenance.Individual-frequency control with variable feeding of material monitored and controlled remotely from control cabin.Speed vibrator motor is operated by no-flow switch to ensure continuous material flow for the sand bin.Working platform along hoppers.

...more

RECUPERATED FILLER SILO

Directly below the filter unit c/w dosing screw conveyor to the filler weigher. Caged ladder access and flat form for level indicator and screw conveyor. Level indicator to monitor the filler content. Excess filler discharge flap and piping.

...more

Pug Mill Mixer

Pug Mill mixing unit so designed to mix material with exact quantity of water content to prepare a homogeneous mixture, also designed robust quality of wear resistant paddle arms for long life. It is fitted with AC motor. Load-Out Conveyor with Hydraulic Gob Hopper & Power-Pack Stationary 10,000 liter Capacity water Tank fitted with 3 HP water pump.

...more

Pneumatic System

Single stage, air cooled, heavy duty with air receiver. Pneumatic pipeline with pressure regulator, strainers, shut-off valves. Pipes are pre-installed in the module.

...more

Plant Control And Monitoring System

Manual- or automatic-controlled monitoring system for every batch. SCADA controls are provided for a fully automatic operation Auto adjustment control of Cold Feeders based on calibrated ton-per-hour. Full graphical user friendly operator interface display using 19 LCD monitor. Windows-based operating environment allows users to use other application or shut down the PC during plants auto operation. Auto control system using independent PLC system to ensure reliable real time control. Complete manual system backup and override over the auto control using push buttons. Up to 200 Recipe & Customer input memory. Batching system comprises of 3 independent weighing scales. 2 stages weighing control for Aggregates with advance stop control based on material flow rate to ensure quicker weighing and accuracy. Customized display upon request. Plant data, function limits can be checked or changed during operation. Daily-, Monthly-, Yearly-selectable Production Database. Complete Plant System Backup on CD which includes recovery software. Report: Display, printing and print preview On-line batch printing, either to database or to printer. Production summary by Material (Graphical bar and pie chart for presentation) Production Summary By Recipe Production Summary By Customer Large database storage space User-friendly data retrieval through Search button.

...more

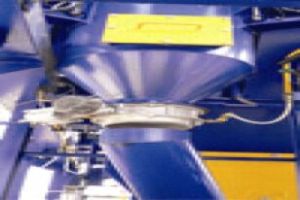

Pan Type-mixing Unit

The mixing is carried out in a Pan type-mixing unit of capacity 0.5m³.The Mixing is carried out with the help of pedal arms, which ensures homogenous mix.

Application : Industrial Use

Country of Origin : India

...more

Mechanical Broom

Endowed with sound infrastructure and qualified team, we unveil a large range of superior quality Mechanical Broom that is widely used for removing the dust of the road. Our mechanical broom sweeper is a zero maintenance machine that is highly acclaimed in the national and international market for high efficiency. As, it is manufactured from the technically advanced parts, it uses minimum man power and provides maximum output. Its high speed with excellent performance makes it perfect for metaling, wet mixed macadam surface and asphalted road surface. We are counted among the overriding mechanical waterless broom suppliers, based in India.

...more

loading conveyor

Aggregates are discharged sequentially according to the predefined sequence of loading into the mixer by the loading conveyors (500mm X 3 Ply) Chevron Belt.

...more

HOT MINERAL BINS

Each compartment is equipped with mechanical overflow chute and sampling pods. Mineral temperature sensors are located inside the sand compartment. Oversize material will flow out via overflow chute to a collection point. Each compartment is equipped with a pneumatically actuated two-stage discharge gates controlled by the computer system. Each compartment has a maximum level indicator that is wired remotely to the control room to warn operator when bins are full.

...more

FILLER WEIGHER

Designed to weigh up to 3 different sources. Sealed with neoprene, which is heat resistant in the temperature range of -40 to 150 C. Butterfly valves c/w high torque pneumatic actuator, solenoid valves & micro switches

...more

Dryer Drum

Drum is fitted with single piece, hot-formed ring without welded joint (drum tyre) on each end, mounted to the drum shell with spring plates. Each drum tyre is seated and rolled on two Trunnion rollers. Feeding end of the inclined drum is further guided by 2 guide rollers to limit the axial movement. Special shovel flights are installed to the internal surface along the drum length to transport and form efficient drying curtain to minimize fuel consumption. Special vacuum drum pressure device is fitted to control rotary actuator at the exhaust fan to regulate the air flow. Hot mineral bins and screens are dust-tight enclosed.

...more

drum

The Drum heats the aggregate and mixes it with asphalt. Unit includes an oil burner & blower. The drum shell is made of high strength steel for a long life. Years of experience results in a flight design that optimizes efficiency and minimizes fuel usage.

...more

Control Panel

Centralised air conditioned and insulated control cabin is provided with electronic control panel cabinet to operate the entire plant.

...more

Control Cabin

Size of container: 2.6 x 2.2 x 2.5 m Container with tinted glass windows at all sides. Insulated, dust proof and air-conditioned. Pre-wire electrical power and control panels along with console. Depending on plant configuration, the power requirement may change. All plant controls, PLC, switch gear and control gear are housed within the power and control panels. All motors are rated IP55, class F insulation.

...more

Cold Feed Hopper System

Endless belt feeder. Shaft-mounted gear motor for minimum maintenance. Individual-frequency control with variable feeding of material monitored and controlled remotely from control cabin. Speed vibrator motor is operated by no-flow switch to ensure continuous material flow for the sand bin. Working platform along hoppers.

...more

Cold Aggregate Feeder

Stationary cold aggregate feeder. Four-bin cold aggregate unit includes Gathering conveyor with 600 mm wide driven by 5 HP Electric Motor. Belt feeders under each bin are driven by 2 HP variable speeds drive and fitted with adjustable quadrant gates. (Capacity of each bin is approximately 10 MT)

...more

cement hopper

Cement hopper of storage capacity of 50 bags of Cement is employed along with a screw conveyor powered by a 5HP motor is used for discharging the cement in the mixer.

...more

Burner Blower

Fuel piping system, transfer pump and high pressure pump are included. Automatic controls for the burner are included to regulate the capacity based on the temperature monitor by a sensor at the drum exhaust gas outlet. Fully automatic, electrical ignition by propane gas. Flame-failure indication that is detected by photo-cell. Auto start-up of burner system for maximum safety. Fuel Pump and Accessories include :- Fuel pump (placed next to the Fuel tank and at ground level) Piping to main burner is inclusive of valve and strainer. Pressure-holding valve ensures the line pressure of fuel reach the high pressure pump of burner. From outlet of pressure holding valve, a long flexible hose is connected to the inlet filter of main burner. Flexible hose ensures fast attachment. Inlet filter is mounted

...more

BITUMEN WEIGHER

Designed to weigh up to 3 different sources. Bitumen is circulated from storage tank through 2-way valve, actuated by compressed air. Weigher tank is insulated with Rockwool slabs and heated at the base by thermal oil. Weigher is provided with overfilling protection. Mechanical dial thermometer indicates the bitumen temperature in the tank. Gravity discharge to bitumen spray pipe.

...more

Bitumen Supply Pump

Jacketed type, heated with electrical heating tape, over-pressure relief valve.

...more

Bitumen Sprayer

BAGHOUSE SYSTEM

No compressed air is required. Low-reverse air cleaning principle using pressure difference between the vacuum pressure of the exhaust gases and the reverse-air pressure. High corrosion resistant steel is insulated at the top with 50mm Rockwool slab and cladding. Filter bag cages in corrosion-resistant aluminum. Radial vane damper with electrical servo-motor actuated c/w remote operation and automatic drum suction regulator. Exhaust fan is mounted on filter outlet. Sand separator unit at the inlet to screen off the coarse filler to protect the filter bags. Damper is servo-motor actuated. Filter bags out of NOMEX or similar.

...moreBe first to Rate

Rate ThisOpening Hours