Semi Automatic Liquid Filling Machine

300,000 - 400,000 Per piece

1 piece (MOQ)

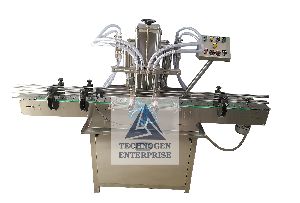

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Best Deals from Automatic Liquid Filling Machine

Automatic Linear Liquid Filling Machine

Get Price Quote

1 Piece (MOQ)

Automatic Linear Liquid Filling Machine Our Oil Filling Line is suitable for all types of food oil, refined oil and cooking oil packaging. Automatic Linear Liquid Filling Machine Edible Oil Filling Line | Oil Filling Line for Cooking Oil Packaging The Edible Oil Filling Line consists of Automatic Linear Filling Machine, Capping Machine, and Sticker Labelling Machinefor packaging 50 ml to 5 Liter bottles/jarswith up to 120 products per minute output speed Our Oil Filling Line is suitable for all types of food oil, refined oil and cooking oil packaging. Avocado Oil, Canola Oil, Vegetable Oil, Sesame Oil, Coconut Oil, Olive Oil, Peanut Oil, Sunflower Oil, Cottonseed Oil, Mustard Oil, Palm Oil, Rice Bran Oil, Safflower Oil, Almond Oil, Corn Oil/ Maize Oil, Butter Oil, Palm Kernel Oil, Rapeseed Oil, Soybean Oil, Apricot Oil, Essential Oil, Brazil Nut Oil, Cashew Oil, Cocoa Butter Oil, Macadamia nut Oil, Basil Oil, Grapeseed Oil, Hazelnut Oil, Hemp Oil, and Walnut Oil. Edible Oil Packaging Line for Packaging of Cooking Oil/ Refined Oil Welcome to the cutting-edge world of edible oil packaging with Harikrushna Machines Pvt. Ltd., where precision meets innovation to deliver top-notch solutions for your cooking oil packaging needs. HMPL's state-of-the-art edible oil filling lines redefine efficiency and reliability, setting the industry standard for oil bottling excellence. A consistent and reliable performance, maximizing your production efficiency. Oil Bottling Lines Manufacturer & Exporter in India: Explore the future of oil bottling with our advanced machinery. Our oil bottling lines handle various edible oils, providing a streamlined process from filling to packaging. Harikrushna Machines Pvt. Ltd. is an ISO 9001:2015 & CE-certified Oil Bottling Line Manufacturer and Exporter in Ahmedabad, Gujarat, India. We offer high-quality Oil Filling Systems at an affordable price. Eco-Friendly Edible Oil Packaging for Edible Oil Packaging Bottles: Our eco-friendly edible oil packaging solutions are sustainable. We offer innovative machineries that preserve the freshness of your cooking oil. And also contribute to a greener future. Embrace eco-conscious packaging without compromising on quality. The quality of your edible oil deserves the finest packaging. Our range of edible oil packaging bottles ensures the preservation of flavour and nutrients. Explore our diverse options to find the perfect fit for your cooking oil products, combining functionality with aesthetic appeal. Cooking Oil Packaging Business: Embark on a lucrative journey with HMPL's cooking oil packaging solutions. Are you starting a new venture or looking to upgrade your existing operations? Our machinery meets the demands of the cooking oil packaging business. Maximize efficiency and profits with Harikrushna Machines Pvt. Ltd. Edible Oil PET Bottles Supplier: Harikrushna Machines Pvt. Ltd. is a well-known Edible Oil PET Bottles Supplier. Experience the convenience of PET bottles for edible oil packaging. Lightweight, shatterproof, and environment-friendly. Our PET bottles are perfect for modern cooking oil packaging. Enhance the consumer experience with packaging that reflects quality and innovation. Food Oil Packaging: Our expertise extends beyond cooking oil to cover a wide range of food oils. Trust our packaging solutions to preserve the integrity of your food oils, ensuring they reach consumers in pristine condition. Elevate your food oil packaging with Harikrushna Machines Pvt. Ltd. Packaging of Cooking Oil: In the competitive market of cooking oil, packaging plays a pivotal role. Our cutting-edge technology ensures cooking oil packaging is precise and efficient, maintaining its freshness and quality. Stay ahead of the curve with our packaging solutions tailored for cooking oil. Edible Oil Packaging Companies: Join the league of successful edible oil manufacturing companies that have chosen Harikrushna Machines Pvt. Ltd. as their trusted partner. Our commitment to excellence and customer satisfaction has made us a preferred choice in the industry. Revolutionize your edible oil packaging operations with Harikrushna Machines Pvt. Ltd. – where innovation, reliability, and sustainability converge to shape the future of cooking oil packaging. Contact us for more details about Complete Edible Oil Packaging System Prices and Features.

Semi Automatic Liquid Filling Machine

95,000 Per Piece

1 Piece (MOQ)

Semi Automatic Liquid Filling Machine Purvaj Pharma Machinery is involved in offering a wide range of Semi Automatic Liquid Filling machines to our most valued clients. Our range of Semi Automatic Liquid Filling machines is widely appreciated by our clients who are located all around the nation. We are serving the industry of cosmetics, pharmaceutical, food & beverages sectors where liquids are to be packed in different kinds of containers. We keep the prices as affordable as possible. We also accepted customized orders from the side of customers. Place your order now online for the Automatic Timer Liquid Filling Machine with us.

oral liquid filling machine

Get Price Quote

1 Piece (MOQ)

Automatic Volumetric Liquid Filling Machine

255,000 Per Piece

1 Piece (MOQ)

Automatic Liquid Filling Capping Machine

Get Price Quote

Automatic Liquid Filling Inner Plugging Screw Capping Machine This automatic system comprises of a 3 stages indexing mechanism to perform a sequence of operations for Filling, Inner Plugging and Screw Capping. The unit is fabricated on rigid MS structure and cladded with SS Sheet to meet GMP requirements. All three operational stations are housed in a common acrylic cabinet to provide safe working zone. The unit is made compact & versatile with three operational stations of Filling, Inner Plugging and Screw Capping on a common center star wheel adjoined with in feed & out feed S.S. slat conveyor. Filling station consists of two / four reciprocating nozzles for peristaltic pump assisted dosing. Inner Plugging station consists of vibratory inner plug feeding device and pneumatic plug pressing unit along with pneumatic cap placement mechanism. Screw Cap sealing station consists of Vibratory screw cap feeding device along with and cap screwing unit with Rotary heads. Main drive, conveyor drive, servo capping drive & servo filling is synchronized PLC. Operation : Empty vials moving on the conveyor is fed to the center star wheel where all the operations of filling, plugging & screw capping will be performed in an indexing mechanism. Vial moves under the filling station and full dose of solution is filled in two stages under both the nozzles. Then it moves for the further operation of plugging where inner plug comes from bowl(s) through chute & being placed on the vial while it stops under the pneumatic plug-placing device, which operates in pair (in case of MPAFPC-100). Screw cap comes from the separate cap bowl through chute(s) and being placed in pair (in case of MPAFPC-100) on the plugged vial at next stop. Further moves under the capping heads where capping is done in pair (in case of MPAFPC-100) according to the pre set torque. Filled vials duly plugged & capped move on to out feed conveyor then. Salient Features : A very compact & versatile equipment for 3 in one operation. Unique for small volumes filling for Eye/Ear/Nasal drops. Smooth & efficient Filling-Inner Plugging & Screw Capping operations in one star wheel. Elegant matt finish body with acrylic enclosure on operational zone. Designed for low noise & maintenance less operation. Peristaltic pump assisted filling ensures accuracy of + 0.5 %. Pneumatic inner plug pressing & cup placement. All contact parts made of SS 316. Screw capping heads is designed to apply adequate torque. No bottle, No plug, No cap - machine stop system. Equipped with torque limiter to protect indexing mechanism. No bottle - No fill, No plug - No cap, No bottle - No plug system. PLC base operation.

Automatic Sharbat Filling Machine

250,000 Per Piece

Automatic Four Head Liquid Bottle Filling Machine

Get Price Quote

Automatic Linear Liquid Filling Machine

Get Price Quote

Heavy duty base with robust construction off S.S. matt finished body Microcontroller based system with latest technology Multiple Filling range with arrangement of different syringes and change parts No container No fill arrangement Easy and accurate adjustments of fill desired quantity with the help of change parts Various models available as per output speed requirement…

4 Hard Automatic Liquid Filling Machine

Get Price Quote

Backed by a team of diligent members, we are one of the outstanding Manufacturers and Suppliers of 4 Hard Automatic Liquid Filling Machine. Made from authenticated components and high grade steel, Hard Automatic Liquid Filling Machine is known for its flawless design, smooth functioning and long service life. We are trusted by our clients for competitive prices and capability of delivering all orders in the set time frame.

Fully Automatic Liquid Filling Machine

Get Price Quote

Automatic Liquid Filling Machine

220,000 Per Piece

1 Piece(s) (MOQ)

Automatic Liquid Filling Machine

600,000 Per Piece

Semi Automatic Liquid Filling Machine

Get Price Quote

Supported by a well-organized network and dependable resources, we have developed as a reputed supplier of Semi Automatic Liquid Filling Machine. We are one of the respected names in the market of Ahmedabad(India) and are offering amazing deals on our products. Salient features : S.S. Elegantly matt finished body. Simple Design. Easy to operate. Low Power Consumption & Maintenance Free. Highly Accurate Range - 5ml. to 1000ml. Speed -300 to 1500 containers / Hour depending on volume / viscosity of the liquid to be filled. Packing Material - Bottles, Jars & Pouches Rigid vibration free construction for trouble free performance

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Automatic Liquid Filling Machine

Get Price Quote

Manufacturer & exporter of Automatic Liquid Filling Machine & Automatic Electronic Filling Machine. Our product range also comprises of Semi Automatic Liquid Filling Machine and Volumetric Liquid Filling Machine. Gained prominence in the industry as a reliable organization, we are engaged in providing Automatic Liquid Filling Machine. Widely demanded in food processing, beverages and dairy industries, our offered filling machines are provided in various specifications. These machines are delivered timely to gain maximum client-satisfaction.

Semi automatic piston type liquid filling machine

65,000 - 75,000 Per No

1 piece1 (MOQ)

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Operation : Bottles are feed on to in-built Infeed Turn Table, from where it delivered to SS conveyor belt. Conveyor belt transport Bottles to Filling Station. Filling station has Pneumatic bottle stopper for exact bottle neck centering of bottles during filling Operation. Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose. The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum use of time. After liquid filling bottles are delivered to capping/labeling machine conveyor for further operations. Salient Features: cGMP Model Rigid vibration free construction for trouble free performance. SS Elegantly matt-finished body. Elegant and easy control panel for total control on operation. Minimum change over time from one size to another container or fill size. User friendly Machine. Low maintenance cost. All contact parts made of S.S. 316. All contact parts made of S.S. 316. No Bottle – No Filling System. Pneumatic Control Bottle Stopper. Filling Accuracy ± 1 % in single dose (Depends upon fill size & nature of liquids). Machine provided with PLC (OPTIONAL) as per customer requirement.

Automatic Liquid Soap Filling Machine

Get Price Quote

Automatic Liquid Filling Machine

Get Price Quote

We are offering Veerkrupa Engineering are manufacturers and Exporters Of Filling Machine , Automatic Liquid Filling Machine manufacturers, Automatic liquid filling machines, Automatic Liquid Filling Machine manufacturer, 2 Head Liquid Filling Machine, 6 Head Liquid Filling Machine, 4 Head Liquid Filling Machine in Ahmedabad , Gujarat , India.

Semi Automatic Volumetric Liquid Filling Machine

Get Price Quote

Semi Automatic Twin Head Volumetric Liquid Vial/Bottle Filling Machine Model LIQFILL-20 is suitable for Round or Flat shape Bottles or Vials with maximum speed of 25 Products per minute. The Machine can give speed of 20 to 25 per minute depending on nature of Liquids, Neck Diameter or Vial/Bottle and Fill Volume. Machine suitable for small volume production having multiple products. Machine construction in Stainless Steel finish with Twin Head Operation. All parts coming in contact with Liquids are made from SS 316 Materials. SPECIAL FEATURES: No Product - No Fill System All contact parts are made of SS 316 material with easy removal system for Auto-Claving/Sterilization/cleaning Machine construction in SS 304 material Very High Fill Accuracy Minimum Change Over time

Automatic Liquid Filling Machine

Get Price Quote

Automatic Liquid Filling Machine Application & Process : Automatic Volumetric Liquid Bottle Filling Machine works on volumetric principle with syringe & piston & nozzle. It is used to fill liquid in bottle in pharmacy, food, dairy, agro chemicals and Beverages industries. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Drives unit with syringe & piston, Reciprocating Nozzle with self-centering devices & No container No filling system arrangement is standard features of the machine. The main drive of the machine and conveyor drive consist of gear motor with synchronized variable drive. Containers moving on S.S.304 Slat conveyor from turn table or washing machine, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. Liquid suck by syringe & piston assembly and fill in bottle through nozzle. Filling doze can be adjustable by eccentric drive block. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling. Salient Features : Designed as per cGMP - Current Good Manufacturing Practices compliance All contact parts AISI 316 & non contact parts AISI 304. Filling dose easily set by dosing block & pin. No Container - No fill system to prevent spillage of material. Rigid vibration free construction for trouble free performance. +_1% filling accuracy on single dose. Minimum change overtime, from one size to another container or fill size. UHMW-PE guide profile for SS slat belt provides smooth noiseless & frictionless working. Bottle stopper arrangement by Pneumatic system. Synchronizes filling drive with conveying drive with VFD. Drain tray around machine platform. Drip tray under the conveyor. Optional Features : Flame proof Electricals. Automatic chain washing system for conveyor belt. In-built pre-inspection. Acrylic cabinet. Pre/post Nitrogen flushing arrangements. Float tank (Holding tank) with or without stirrer.

AUTOMATIC LIQUID VIAL FILLING Machine

Get Price Quote

CPLFRS Automatic Vial Filling with Rubber Stoppering Machine is a compact model used for filling and rubber Stoppering of Injectable liquid into vials. The incoming dry vial (sterilized) are fed through the Un-scrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below Filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided for ''No Vial, No Filling'' operation. Syringes are mounted on eccentric block and driving through bottom main gear box. Volume can be either increased or decreased by increasing or decreasing stroke length of piston as per filling size. Syringes is having non return valve for sucking and delivering situation to avoid volume variation. Liquid will reach to filling nozzles through silicon transparent pipe. Nozzle will be having Up and Down movement with help of cam mechanism and it will come down when vial will be hold by star wheel for filling operation and starts filling when it starts to move up and after completion of filling operation, star wheel delivers four/six vials together on conveyor for rubber Stoppering operation. Stoppering unit consist of Star wheel, Vibrator unit and Bowl. The sterilized/autoclaved rubber stoppers stored in the vibrator bowl moves vertically to the rubber stopper chute. The vial is hold firmly by star wheel, which will be in continuous rotary motion and vial which is coming from filling unit get in to star wheel and move in rotary direction along with star wheel, during movement it will pick up the rubber stopper from the exit end of the chute and rubber stopper will be pressed by fix pressing roller, which is spring loaded. Then vial further move on conveyor and collected on out feed star wheel for next sealing operation.

Automatic Six Head Injectable Liquid Filling with Rubber Stoppering Machine

Get Price Quote

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES + 1% Filling Accuracy on single dose. Rigid vibration free construction for trouble free performance. S.S elegantly matt finished body. Elegant and easy control panel for total control on operation. Minimum charge overtime, from one size to another container or fill size. Automatic washing of conveyor belt[ optional. No container No filling system – to avoid spillage. Pneumatic control bottle stopper. cGMP Model.

Automatic Injectable liquid Vial Filling Machine

600,000 Per UNIT

1 Piece (MOQ)

injectable liquidwhen it comes to choosing a prominent and leading liquid filling machine manufacturer in ahmedabad, the jdm pharmatech is a trustworthy name. our products have been designed and engineered using state of the technology and materials that ensure .

Automatic Six Head Injectable Liquid Filling Machine

Get Price Quote

Direction Left to Right Production Rate Up to 100 to 120 Vials/Min. (For 5ml. fill size) Fill Capacity 0.5 ML to 100 ML( Up to 50 ML single dose & for 100 MLdouble dose) Accuracy ± 1 % Electrical Supply 9.0 HP Power Requirement 415 Volts, 3 Phase (4 Wire System), 50 Hz. Height of Conveyor Adjustable from 900 to 950 MM Dimensions 3000 MM (L) x 1150 MM (W) x 1550 MM (H) Net Weight 950 Kgs. (Approx.) Gross Weight 1250 Kgs. (Approx.) Type of Rubber Stoppering Pick & Place Syringes available forDifferent Fill Volume 0.5 ML to 2 ML2 ML to 10 ML10 ML to 50 ML No. of Syringes 06 Nos. Fill Sizes 0.5 ml. to 100 ml. Vial Sizes 2 ml. to 100 ml. Rubber Stopper Sizes 13mm, 20mm, 28 mm & 32 mm

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

We are offering automatic volumetric liquid bottle filling machine. Description automatic volumetric liquid bottle filling machine work on volumetric principle with diving nozzles. The unit is made compact,versatile and enclosed in stainless steel elegantly matt finish body, of s.s slat conveyor, reciprocating nozzle with self-centering devices & ss syringe. No container no filling system arrangement is standard feature of the machine. The main drive of the machine and conveyor drive consist of ac motor with synchronized variable ac frequency drive. Operation containers moving on s.s. Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system.the twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling.

Automatic Liquid Filling Machine

Get Price Quote

Almost existing industrial machinery are obtained with semi or full automation. Modern engineering practices offer ideal and efficient automation for the precise and errorless functioning. It is also beneficial that are accessible with total elimination of human errors. When it is matter belonging medicine, one must highly precise about dose and product with complete exclusion of all kinds of contamination. Considering entire technical and mechanical criteria, to offer effective and advanced functioning machinery, we have designed and developed qualitative range of the automatic liquid filling machine includes automatic 2, 4, 6 head digital/electronic liquid filling machine. It contains stainless steel, matt finished body. It contains low friction wear surface. it is provided with self lubrication system. It requires least change over time for the different size of the containers. To operate such machinery, no special skill required. Such user friendly machinery is equipped with drain tray under conveyor. Ideal pneumatic system to prevent short circuit MCB is given PLC based control panel Rigid structure helps vibration free operations High filling accuracy