Automatic Volumetric Liquid Filling Machine

210,000 - 550,000 Per Piece

1 Piece (MOQ)

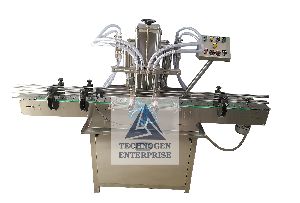

Automatic Volumetric Liquid Bottle Filling Machine works on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Reciprocating Nozzle with self-centering devices & SS Syringe. No container No filling system arrangement is standard features of the machine.

Automatic Volumetric Liquid Filling Machine

255,000 Per Piece

1 Piece (MOQ)

Best Deals from Automatic Volumetric Liquid Filling Machine

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Automatic Volumetric Liquid Filling Machine

Get Price Quote

1 Piece (MOQ)

Automatic Volumetric Liquid Filling Machine The Automatic Volumetric Liquid Filling Machine consists of a main structure, product transmission belt with an adjustable guide, safety acrylic cover (OPTIONAL), Pneumatic/mechanical bottle stopping facility, nozzle & syringes, electrical panel, motor, sensor, AC drive & mains ON/OFF. Key Features:- The Filling Machine is manufactured or developed accordance with GMP standards. The structure is made of MS cladded with SS 304. Rigid vibration-free construction for trouble-free performance. SS Elegantly matt finished body. The pharma/food grade PVC braded tubes are used for the filling purpose. Drain tray around the machine platform. Drip tray under the conveyor. Elegant and easy control panel for total control on operation. All interlock must be shown on the control panel. ± 1 % Filling accuracy on single dose. No Bottle No Filling System – Machine stops at Home position. Diving nozzle device. Minimum changeover time, from one size to another bottle or fill size. Self-lubricating UHMW-PE guide profile for SS slat chain provides a low friction wear surface, smooth and noiseless conveying. Pneumatic/Mechanical bottle stopping arrangement. Synchronized two nos. AC drives for the main motor & conveyor belt. SS measurement scale for filling volume adjustment. Safety guard for conveyor gearbox, motor, and pneumatic cylinders. MCB for overload protection, and prevent against short circuit. Inbuilt protection against overcurrent, voltage fluctuation, short circuit in AC frequency drive.

Semi Automatic Volumetric Liquid Filling Machine

75,000 Per Piece

1 Piece (MOQ)

Automatic 8 Head Volumetric Liquid Filling Machine

Get Price Quote

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Product Code : 03 Product Specification

Semi Automatic Volumetric Liquid Filling Machine

78,000 - 90,000 Per Piece

1 Piece (MOQ)

The quality-driven Semi Automatic Volumetric Liquid Filling Machine – Table Top comprises the main structure, product holding mechanism, nozzles & syringes, electrical panel, motor & mains for On and Off function. Salient Features Robust vibration free design Minimum changeover time Less maintenance Emergency On/ Off User friendly Application Filling Industry Pharmaceuticals Beverages FMCG Food processing

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

We are eminent suppliers of Automatic Volumetric Liquid Bottle Filling Machine. Available for 4 head, 6 head and 8 head liquid bottle filling, our machines are reputed for their accuracy and functionality. This machine is extensively used across various industries including Pharmaceuticals, chemicals, Pesticides, Cosmetics and beverages. This machine can be used to fill liquid in round, oval, flat and oval shaped bottles, made of PET, plastic, glass or other material. The machine is designed to offer low maintenance and all contact parts are made from superior quality S.S Material - cGMP Model. Priced reasonably, this machine is customizable as per order.

Automatic Volumetric Liquid Filling Machine

Get Price Quote

4 Head Automatic Volumetric Liquid Filling Machine

225,000 - 275,000 Per Nose

1 piece 2,75,000/-IRS. (MOQ)

4 head volumetric automatic liquid filling machine

180,000 - 350,000 Per Number

1 Piece (MOQ)

Volumetric Automatic Liquid Filling Machine

240,000 Per Piece

1 Piece (MOQ)

Features : ± 1 % Filling accuracy on single dose. No Bottle No filling system. Rigid vibration, free construction for trouble free performance. S.S. elegantly matt finished body. Begant and easy control panel for total control on operation. Minimum changeover time. tram one to another container or fill size. Self lubricating UHMW-PE guide profile for SS slat chain provides low friction wear Surface, smooth and noiseless conveying. Pneumatic bottle stopping arrangement. Synchronized two nos. A/c drive for main motor & conveyor belt.Safely guard for conveyor gear box, motor and pneumatic cylinders.

Automatic Eight Head Volumetric Liquid Filling Machine

150,000 - 350,000 Per nos

1 Nos (MOQ)

Salvin Industries is offering world Class Equipment with German technology for Bulk Drugs, Cosmetics & Food , Pharmaceuticals, Chemicals Industries machinery is an added advantage of automatic processing & packaging machineries for Dairy , Distilleries & pesticides , Cosmetics & Breweries etc. Apart from this, the company also manufacturers automatic machines for Lube & toiletries packaging, Food & Edible oil packaging machineries.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

1 Piece (MOQ)

DESCRIPTION Automatic Volumetric Liquid Bottle Filling Machine work on volumetric principle with diving nozzles. The unit is made compact,versatile and enclosed in stainless steel elegantly matt finish body, of S.S Slat Conveyor, Reciprocating Nozzle with self-centering devices & SS Syringe. No container No filling system arrangement is standard feature of the machine. The main drive of the machine and conveyor drive consist of A/C Motor with synchronized variable A/c Frequency drive. OPERATION Containers moving on S.S. Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system.The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling. The dosing block with a hexagonal bolt fitted below syringes. This means fill size can be easily set. Depends on container size, Fill size, Neck diameter of container, and container, and nature of liquid etc. We can supply as per customer requirements. With help of change parts.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

The incoming dry bottles containers are placed manually below the feed nozzle and set volume is filled through volumetric cup set fitted with adjustable disc guide. Machine is semi automatic so output will totally depend on operator efficiency. Volumetric cup filling machine is single discharge for dosing system is specially designed to best suit powder/granulate dosing mechanism. Machine is also available with automation features.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

To ensure utmost satisfaction of the buyers, we make sure that the delivery schedule should be properly maintained. Headquartered in Ahmedabad(India), we are acknowledged for providing excellent products domestically. Details : Depends on container size, Fill size, Neck diameter of container, and container, and nature of liquid etc. We can supply as per customer requirements.With help of change parts.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

We are offering automatic volumetric liquid bottle filling machine. Description automatic volumetric liquid bottle filling machine work on volumetric principle with diving nozzles. The unit is made compact,versatile and enclosed in stainless steel elegantly matt finish body, of s.s slat conveyor, reciprocating nozzle with self-centering devices & ss syringe. No container no filling system arrangement is standard feature of the machine. The main drive of the machine and conveyor drive consist of ac motor with synchronized variable ac frequency drive. Operation containers moving on s.s. Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system.the twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Description:‘GMP’s’ Automatic Volumetric Liquid Bottle Filling Machine work on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Reciprocating Nozzle with self-centering devices & SS Syringe. No container No filling system arrangement is standard features of the machine. The main drive of the machine and conveyor drive consist of A/c Motor with synchronized variable A/c Frequency Drive. Salient Features: • ± 1 % Filling accuracy on single dose.• No Bottle No Filling System.• Rigid vibration free construction for trouble free performance.• SS Elegantly matt finished body. • Elegant and easy control panel for total control on operation.• Minimum charge overtime, from one size to another container or fill size.• Self-lubricating UHMW-PE guide profile for S.S. slat chain provide low friction wear surface, smooth and noiseless conveying.• Error code display on A/c frequency drive on control panel.• Drain tray around machine platform.• Drip tray under the conveyor.• Pneumatic bottle stopping arrangement.• Synchronized two nos. A/c drives for main motor & conveyor belt.• Safety guard for conveyor gearbox, motor and pneumatic cylinders.• MCB for over load protection, and prevent against short circuit.• Inbuilt protection against over current, voltage fluctuation, short circuit in A/c frequency drive. Operation: Containers moving on SS Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling. The dosing block with a hexagonal bolt fitted below syringes. This means fill size can be easily set.

Semi Automatic Volumetric Liquid Filling Machine

Get Price Quote

Semi Automatic Twin Head Volumetric Liquid Vial/Bottle Filling Machine Model LIQFILL-20 is suitable for Round or Flat shape Bottles or Vials with maximum speed of 25 Products per minute. The Machine can give speed of 20 to 25 per minute depending on nature of Liquids, Neck Diameter or Vial/Bottle and Fill Volume. Machine suitable for small volume production having multiple products. Machine construction in Stainless Steel finish with Twin Head Operation. All parts coming in contact with Liquids are made from SS 316 Materials. SPECIAL FEATURES: No Product - No Fill System All contact parts are made of SS 316 material with easy removal system for Auto-Claving/Sterilization/cleaning Machine construction in SS 304 material Very High Fill Accuracy Minimum Change Over time

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Operation : Bottles are feed on to in-built Infeed Turn Table, from where it delivered to SS conveyor belt. Conveyor belt transport Bottles to Filling Station. Filling station has Pneumatic bottle stopper for exact bottle neck centering of bottles during filling Operation. Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose. The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum use of time. After liquid filling bottles are delivered to capping/labeling machine conveyor for further operations. Salient Features: cGMP Model Rigid vibration free construction for trouble free performance. SS Elegantly matt-finished body. Elegant and easy control panel for total control on operation. Minimum change over time from one size to another container or fill size. User friendly Machine. Low maintenance cost. All contact parts made of S.S. 316. All contact parts made of S.S. 316. No Bottle – No Filling System. Pneumatic Control Bottle Stopper. Filling Accuracy ± 1 % in single dose (Depends upon fill size & nature of liquids). Machine provided with PLC (OPTIONAL) as per customer requirement.

Automatic Volumetric Liquid Filling Machine

Get Price Quote

SALIENT FEATURES:- ± 1 % Filling Accuracy On Single Dose. No Bottle No Filling System. Rigid Vibration Free Construction For Trouble Free Performance. S.S. Elegantly Matt Finished Body. Elegant And Easy Control Panel For Total Control On Operation. Minimum Change Overtime, From One Size To Another Container Or Fill Size. Self Lubricating UHMW- PE Guide Profile For SS Slat Chain Provides Low Friction Wear Surface, Smooth And Noiseless Conveying. Error Code Display On AC Frequency Drive On Control Panel. Drain Tray Around Machine Platform. Drip Tray Under The Conveyor. Mechanical Bottle Stopping Arrangement. Synchronized Two Nos. A/C Drives For Main Motor & Conveyor Belt. OPTIONAL FEATURES:- Automatic Chain Washing System For Conveyor Belt. In-built Pre-inspection. Acrylic Cabinet. Acrylic Cover On Conveyor. Float Tank (Holding Tank) With Or Without Stirrer.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES + 1% Filling Accuracy on single dose. Rigid vibration free construction for trouble free performance. S.S elegantly matt finished body. Elegant and easy control panel for total control on operation. Minimum charge overtime, from one size to another container or fill size. Automatic washing of conveyor belt[ optional. No container No filling system – to avoid spillage. Pneumatic control bottle stopper. cGMP Model.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

we are offering automatic volumetric liquid bottle filling machine, filling accuracy on single dose. rigid vibration free construction for trouble free performance. s.s. elegantly matt finished body. elegant and easy control panel for total control on operation. minimum change over time , from one size to another container or fill size. reciprocating filling nozzle with self centring device to avoid foaming. the unit is made compact & versatile -as per gmp norms. no container no filling system-to avoid spillage. synchronised a.c. drives for conveyour & main drive. technical specification model no dalf-100 (4 head) dalf-150 (6 head) outputhour* 2500 to 6000 3500 to 9000 electric motor main machine 1 hp 440 volts 3 phase 50 (four wire) conveyor 0.5 hp 440 volts 3 phase 50 (four wire) container size ø 30 mm to ø 100 mm, maximum height 210 mm fill size 10 ml. to 500 ml. (with the help of required change part) overall dimension 2035mm (l) x 1050mm (w) x 1400mm (h) *note : depending on nature of liquid & fill size.

Automatic Volumetric Liquid Filling Machine

Get Price Quote

KEY FEATURES : ± 1 % Filling accuracy on single dose. No bottle No filling system. Rigid vibration free construction for trouble free performance. Drain tray around machine platform. Pneumatic bottle stopping arrangement. Minimum change overtime, from one size to another container or fill size. OPTIONAL FEATURES : Acrylic cabinet Automatic chain washing system for conveyor belt Nitrogen Flushing Float tank (Holding tank) with or without stirrer PLC Based control Panel

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Automatic Volumetric Liquid Filling Machine, packaging machineries

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Automatic Volumetric Liquid Filling Machine, Liquid Packaging Machinery

Semi Automatic Volumetric Liquid Filling Machine

Get Price Quote

Semi automatic volumetric liquid filling machines are two head, table top, fully GMP model used to fill variety of liquids. This machine works on the volumetric principle and is fitted with two syringes on the sides. The volume of the machine can be easily adjusted by increasing or decreasing the eccentricity. Motor and gearbox of the liquid filling machines are covered in a SS cabinet. Volumetric liquid filling machines is available in varied dimension and capacities. The machine consists of Reciprocating Filling, Driving type Nozzle, multi dose filling system, PLC control panel, Container Platform, syringe Holders, HDPE Tubes and Piles and on line starter. Features: Specially designed valve to avoid any drip age Machine can be provided with diving nozzles for foamy liquids Three different speeds depending upon capacity of bottles. Minimum change over time from one size to another container or fill size

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Automatic Volumetric Liquid Bottle Filling Machine, Bottle Labeling Machine