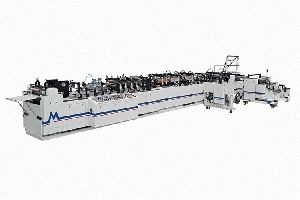

Stand Up Zipper Pouch Making Machine

4,251,000 Per Pack

1 Piece (MOQ)

FEATURES: One Master roll with shaft-less unwinder and Driven Tension control system Multiple sealing and cooling stations All stations are actuated by individual servo system to control seal and cool time Multiple Nip roller system to maintain even tension on the film Touch Screen PLC for setting of all parameters like size , sped , dwell time , temperature etc Servo actuated cutter system Auto conveyor system for easy collection of pouch

Fabric Folding Machine

Get Price Quote

We are offering fabric folding machine. 1very compact design, highly productive – handy to operate 2versatile – able to handle all kind of fabric 3normal height of heap 15 4accurate in measurement. 1 meter plaits 5fabric speed 50 meters per minute. 6available in 41” to 144” table size.

Best Deals from Auxiliary Machine

Non Woven Fabric Slitting Machine

Get Price Quote

Vacuum Ironing Table

Get Price Quote

Our team makes it possible to carry out online transactions, keeping the details confidential. Our payment procedures and the transactions we make are completely transparent and thus, clients can trust on us. Designed and developed using the premium raw material and modern work methods; we guarantee high quality standards and longevity of our products. Also, we make sure that the raw material is sourced from the trusted places. Featured with adjustable height knob, our table dimensions 18 x 48 inch.

Chainless Fabric Mercerizing Machine

Get Price Quote

1 Piece (MOQ)

Mercerisation is one of the most important processes of finishing cotton materials. The process consists of the treatment of cellulosic materials with concentrated solutions of caustic soda. Concentrated solution of caustic soda cause cinsiderable swelling of cotton fiber and allows soda to impregnate in the cross section of the warp & weft yarns. The impregnated yarn with caustic soda reflects light, hence it becomes brighter. Also, it increases its hygroscopicity, strength and improves dye affinity. The caustic soda concentration varies from 20% to 30%. Based on Buoyancy Principle. Perfect impregnation & stabilization followed by recuperator & wash tanks. Advantages of Mercerising Process; * Increase Dye Affinity. * Increased Luster. * Increased Tensile Strength. * Increased Dimensional stability of warp & weft yarn. * Elimination of immature or dead cotton. * Improved Handling effect. * Tailor made as per customer requirement. Acid Dosing arrangement, Big-Batching and Cylinder Dryer can be supplied additionally. The Machines are successfully running in India as well as Foreign Countries. The machines are available from 1500 mm to 3400 mm working width. More than 100 such "Thakore Exports" made machines are running all around the world.

Iron Worker Machine

Get Price Quote

Fabric Sample Cutting Machine

Get Price Quote

Iron Casting Grinding Machine

Get Price Quote

In order to produce quality products, we make use of superior grade raw materials. Our quality auditors strictly check the raw materials against varied quality parameters before procurement. We are a leading name, instrumental in offering wide assortment of Iron Casting Grinding Machine. Approx. Price: Rs 10.45 Lakh / UnitProduct Details: Minimum Order Quantity - 1 Unit Admit between center - 1500 mm Grinding wheel size - 400, 40, 127 mm Height - 200 mm Manually feed resolution - 0.005 mm on radius Total hp - 5.16 hp Work head and Tail stock Morse Taper - MT - 4 Features: Both Slides are hydraulically operated by reputed Hydraulic cylinders Heavy Duty Work Head having the ph. Bronze Taper bush bearing, thrust load provision having 1 hp A.C motor with three speeds through step pulley. Wheel head having spherical clearance adjustable white metal bush bearings. Hardened and ground feed screw for perfect repeat accuracy. Wheel head having 3 hp and hydraulic having 1 hp A.C Motor. An inbuilt electrical control panel board having all reputed components. Simple coolant tank with Pump and piping. More rigid and precise Tailstock having 25 mm traverses. Turcite –B slide way coated on both moveable slides to prevent stick-slip motion. 50mm Rapid approach for wheel head forward retraction.

Spindle for braiding machine

Get Price Quote

We are manufacturing all kind of spindle which is used in braiding machines. Also making bobbin for braiding machine. We are manufacturing scine last 16 years.

Yarn Fabric Baling Machine

Get Price Quote

Knit Braiding Machine

125,000 Per Piece

01 Piece (MOQ)

Woven Fabric Inspection Machine

300,000 Per unit

Fabrics Tensile Strength Testing Machine

Get Price Quote

Fabric Inspection Machine

Get Price Quote

Narrow Fabric Warping Machine

95,000 - 165,000 Per 1 unit

We provide Narrow fabric warping machine for Beam Size:200mm to 600mm. Working Width:200mm to 400mm Which is suitable for Needle loom,knitting Machine and Chorchet Machine.

Zipper Making Machine

Get Price Quote

This machine is electro-mechanical integrative, once-through fully automatic forming, touch screen operation is applied, photo-electric trace, computerized deviation rectifying function, hence accuracy and smooth. Such automatic devices as slotting device , punching device and metering device are equipped. Finished products are produced at fast speed, in high efficiency, and in firm appearance after welding. This machinery is an optical choice for the non woven bag making enterprise and businessmen devoted to the production of non woven environment-friendly bags.

Auxiliary Roll Forming Machine

Get Price Quote

The AX02G was designed specifically for use, flexibility and the convinience of the end user. Key features include: hinged table top and square drive shafts which allows easy access to change out a complete roll set in less than five minutes, quick change tooling which requires no keys or tools, quick jam clearing.

Fabric Sample Cutting Machine

Get Price Quote

A hand lever operated device with stopper is provided to get To and Fro motion of sliding table with calibration which guarantees the equal, accurate & high production of samples if is Ideal for cutting maximum fabric heap of 50mm & maximum 20 strokes per minute.

Auxiliary Roll Forming Machine

Get Price Quote

The ax02g was designed specifically for use, flexibility and the convinience of the end user. Key features include: hinged table top and square drive shafts which allows easy access to change out a complete roll set in less than five minutes, quick change tooling which requires no keys or tools, quick jam clearing.

Wire Braiding Machine

650,000 Per unit