Open Width Washing Range

Get Price Quote

1 Piece (MOQ)

Open Width Wshing Machine is the only one equipped with exclusive Super Wash washing system with Triple Drun in a compartent. The system consistes of specially shaped impeller in the drum in which water jets uniformly and hits the full fabric width. Very high washing performance on the upper and back side of fabric for its whole width. Efficient removal of unfixed Dyestuff, gum and other chemicals and from the fabric. Washing machine with tanks can carry out pre-washing, rinsing and chemical treatment. Effective squeezer between the washing unit to give maximum liquor separation from bath to bath. The washing range has been designed specially for tensionless washing of fabrics. Each washing compartment with its own force-spray system, recirculation pump, filtering device, overflow, drain and heating arrangement. * Perfect synchronizing of linear speed hence tensionless and creaseless transport of fabric all along the process. * Cylinder Dryer or Float Dryer can be attached with the washer for continuous drying of the fabric. * More than 100 "THAKORE EXPORTS" Machines are in operation currently all over the world. Machines are available from 1500 mm to 3400 mm working width. Salient Features: * Excellent Washing efficiency. * Extremely sturdy construction. * Silent running. * Low energy consumption. * Easy to operate. * Operational knife spray between each strand of fabric with supply from a separate pump. * Circulation and counter flow arrangement to save water. * Low maintenance. * Quick and simple installation. * Tight closing glass windows on the sides to provide easy access. * Direct steam heating by perforated S.S. Pipes. * S.S. Bottom Rollers running in self alligning bush bearings.

Fabric Universal Tensile Testing Machine

175,000 Per Unit

1 Unit (MOQ)

Best Deals from Auxiliary Machine

Ultrasonic 8-Inch Lace Making Machine

Get Price Quote

1 Piece (MOQ)

Ultrasonic Lace Machine, also could be called ultrasonic lace sewing machine, ultrasonic sewing machine, is an efficient sewing embossing device, use to sewing, welding, cutting and embossing synthetic fiber material, processed product can be water tightness section, high efficiency, without needle and thread, without rough selvedge and smooth, hand touch feel good, etc. Widely use to process clothing, toys, food and non-woven materials. Ultrasonic lace machine main models include: ultrasonic lace machine (A type), Ultrasonic Gantry Frame Lace Sewing Machine, non-standard ultrasonic lace sewing machine, and other equipment, satisfy various industries’ requirement. ” Your professional auto non-woven sewing cutting machinery designer.” is our declaration.Features and Function The floral whorl of ultrasonic lace sewing machine made of special alloy steel is pretty durable by special heat treatment, and long using life. This lace sewing machine could be operated without pre-heating and has the advantage of continuous production, fast speed, high productivity and can do corner sewing. No smog and spark while processing, no damage to mercery edge. A general worker could operate the machine owes to the convenient and easy-understanding operation of this machine. Ultrasonic lace machine directly sewing all kinds of drapery, meanwhile trimming, hole, stamped, once forming the products, without rough selvedge and raw edge. This machine use ultrasonic for cover sewing, pressing and embossing in different materials, the output power can be adjusted according to different thickness material. This machine can print and gold blocking by retrofitting coloured paper. Ultrasonic lace machine details show The floral whorl of ultrasonic lace sewing machine made of special alloy steel is pretty durable by special heat treatment, and long using life, floral whorl diameter 100mm, can press out of larger acreage, more beautiful patterns. Intuition electronic box, more humanization, convenience to read current and amplitude display, you can adjust output power and mould rotate speed by set electronic box, suit for different materials, respectively adjust the speed of upper and lower dies. Application of ultrasonic lace machine (1)Sewing (2) Pattern edging (3) Cutting (4) Slitting (5) Holing (6) Pattern pressing (7) Forming (8) Coloring (9) Gilding (10) Edge fold and Printing grain, (11) Package welding wire fixed. Lacing: clothes, mattress cover, pillow cover, car cover, tent, packaging bag, packsack, luggage, hand bag, curtain, rain coat, wind coat, snow suit, toys, glove, tablecloth, chair cover, bedding bag, hair accessory, accessories, umbrella, lampshade and so on. Embossing: ornament, hair accessory, artwork ornaments, Christmas ornaments, wedding ornaments etc. Sewing: Non-woven bag, disposable operating coat, surgical cap, eyeshade, raincoat, PVE handbag, umbrella, packaging bag, tent, shoe and cap products, dust bag and so on. Thread forming:reflectorized material Slitting:Velcro, satin, cloth (contains 30% chemical fabric), trademark and so on. Ultrasonic lace machine, ultrasonic sewing machine, ultrasonic embossing machine, ultrasonic embroidery machine, ultrasonic trimming machine, ultrasonic compound machine, ultrasonic stitching machine, ultrasonic heat sealing machine.

Automatic Co2 Fabric Laser Engraving & Cutting Machine

275,000 - 895,000 Per Piece

1 Piece (MOQ)

FABRIC ROLL WRAPPING MACHINE

210,000 Per Piece

1 Piece (MOQ)

Electronic Jacquard Machine

Get Price Quote

500 Piece(s) (MOQ)

The Jacquard Hook that we manufacture, export and supply is manufactured by using steel and stainless steel and is highly appreciated for utmost durability, corrosion resistance and high strength. The Jacquard Hook is widely used in textile industries, carpet industries, etc. The high quality Jacquard Hook that we offer features high efficiency, easy adaptation, etc. The Jacquard Hook is suitable for most jacquard-weaving applications like furnishing label industry, carpet industry and terry towel industry. Highlights : High strength Durable Sturdy construction Additional Information : Packaging material- Wooden cases

Vacuum Ironing Table

Get Price Quote

Our team makes it possible to carry out online transactions, keeping the details confidential. Our payment procedures and the transactions we make are completely transparent and thus, clients can trust on us. Designed and developed using the premium raw material and modern work methods; we guarantee high quality standards and longevity of our products. Also, we make sure that the raw material is sourced from the trusted places. Featured with adjustable height knob, our table dimensions 18 x 48 inch.

zipper pouch making machine

Get Price Quote

Stand Up & Zipper Pouch Making Machine Our side sealing and cutting machine is a major example of the modern cutting edge machinery. The machine operates easily and has a maximum speed of 250 cycles per minute. With high dimensional accuracy, our side sealing and cutting machines have been up to the mark of the client demands. The machine is currently high in industrial demands, and has efficiently produced the desired results.

drying range machine

Get Price Quote

BOW MANGLE DRYING RANGE We have Spares of Bowl Mangle & Drying Range always readily available from Stock

Fabric Rolling Machine

Get Price Quote

Fabric Infeed can be in Roll or Loose or Plait or Batch form, Fabric outfeed can be in Tube Roll or Plait or Batch form, Specially designed Fabric Tension Unit, Top & Bottom Lights, Length Counter Meter for fabric length measurement, Hydro Pneumatic or Digital Edge Guide for perfect Edge of rolls, Reverse and forward Option at operator hand, S.S. Scroll RollerBow roller for Wrinkle removing of fabric, Guide Rollers with Smooth finish, AC Gear Motor and Variable AC drive of Standard Make, Variable speed from 0 - 50 metermin. Imported rubber emery on winding roll for extra life

Circular Cord Knitting Machines

135,000 - 200,000 Per pcs

Circular Cord Knitting Machines

steam table

18,000 Per Piece

1 Piece(s) (MOQ)

Efficient Airflow. Padding Remains Dry At All Times. Form High Porosity Padding. Connected To Table Top. Mounted On A High Torque Electric Motor For Quick Start. Activated By Spring Loaded, Full Length Foot Pedal. Low Noise & Vibration Less Performance. Efficient Moisture Suction. Quick Drying Of Table Top & Padding.

Double Head High Speed Braiding Machine

Get Price Quote

Horngears with bearing for smooth operation. Spring loaded carriers in two pieces. Machines are sutable for braiding small dia.electric cables, cords, decorative tapes, laces, sutures & indulation fibre glass sleeves & cords. Stop Motion electrical or mechanical. Frames constructed from pipes & angles. Individual motorized.

Fabric Inspection Machine

375,000 Per Piece

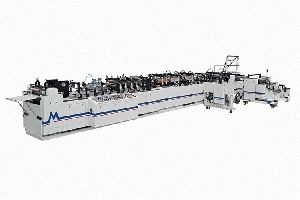

Stand Up Zipper Pouch Making Machine

4,251,000 Per Pack

1 Piece (MOQ)

FEATURES: One Master roll with shaft-less unwinder and Driven Tension control system Multiple sealing and cooling stations All stations are actuated by individual servo system to control seal and cool time Multiple Nip roller system to maintain even tension on the film Touch Screen PLC for setting of all parameters like size , sped , dwell time , temperature etc Servo actuated cutter system Auto conveyor system for easy collection of pouch

Woven Jumbo Fabric Cutting Machine

Get Price Quote

Fabric Rewinding Machine

Get Price Quote

Geogrid Fabric Slitting Rewinding Machine is able to process all types of Non-Woven Fabric of any thickness. Geogrids are commonly made polymer materials, such as polyester, polyethylene or polyproylene. They may be wovern or knitted from yarns, heat-welded from strips of material or produced by punching a regular pattern of holes in sheets of material, then stretched into a grid. The second category of geogrids are more flexible, textile-like geogrids using bundles of polyethylene-coated polyester fibers as the reinforcing component. In this process hundreds of continuous fibers are gathered together to form yarns which are woven into longitudinal and transverse ribs with large open spaces between. The crossovers are joined by knitting or a subsequent coating protects intertwining before the entire unit. Bitumen, latex, or PVC is the usual coating materials. For making different types of small rolls, Geogrid Cloth is slitted into different size of small Rolls in our Geogrid Fabric Slitter Rewinder Machine. Then these Rolls go into further process for making different types of application uses. We have been successfully Manufacturing, Exporting & Supplying all types of Geogrid Fabric Slitting Rewinding Machine.

Hydraulic Fabric Baling Machine

Get Price Quote

Curtain Tape Making Needle Loom Machine

Get Price Quote

Knit Braiding Machine

125,000 Per Piece

01 Piece (MOQ)

Fabric Cutting Machine

Get Price Quote

Neat cutting, small-curvature radius curvillinear cutting.Low noise, stable running, easy to operate and high efficiency.Incorporated with an auto knife-grinding device, easier to operate,Suitable for mass trimming cotton, woollen, linen leather and chemical fibre goods, all type of cloth, etc.

Iron Casting Grinding Machine

Get Price Quote

In order to produce quality products, we make use of superior grade raw materials. Our quality auditors strictly check the raw materials against varied quality parameters before procurement. We are a leading name, instrumental in offering wide assortment of Iron Casting Grinding Machine. Approx. Price: Rs 10.45 Lakh / UnitProduct Details: Minimum Order Quantity - 1 Unit Admit between center - 1500 mm Grinding wheel size - 400, 40, 127 mm Height - 200 mm Manually feed resolution - 0.005 mm on radius Total hp - 5.16 hp Work head and Tail stock Morse Taper - MT - 4 Features: Both Slides are hydraulically operated by reputed Hydraulic cylinders Heavy Duty Work Head having the ph. Bronze Taper bush bearing, thrust load provision having 1 hp A.C motor with three speeds through step pulley. Wheel head having spherical clearance adjustable white metal bush bearings. Hardened and ground feed screw for perfect repeat accuracy. Wheel head having 3 hp and hydraulic having 1 hp A.C Motor. An inbuilt electrical control panel board having all reputed components. Simple coolant tank with Pump and piping. More rigid and precise Tailstock having 25 mm traverses. Turcite –B slide way coated on both moveable slides to prevent stick-slip motion. 50mm Rapid approach for wheel head forward retraction.

Narrow Fabric Machine

Get Price Quote

Prashant texmach is leading manufacturer of complete range of narrow width machinery. Various machinery include Needle loom Needle loom with jacquard Drum warping machine Winding and finishing machine Selvedge warping machine Measuring and winding machine Rubber covering machine Continuous dyeing and finishing for tapes and ribbons

Fabrics Tensile Strength Testing Machine

Get Price Quote

Fabric Slitting Rewinding Machine

425,000 - 625,000 Per piece

1 Piece (MOQ)

Fabric Inspection Machine

Get Price Quote

Iron Worker Machine

Get Price Quote

Woven Sacks Fabric Cutting Machine

Get Price Quote

Woven Sacks Fabric Cutting Machine Safe and easy to operate Paddle operated cutting arrangement Limit switch based operation to reduce electricity consumption

Woven Fabric Inspection Machine

300,000 Per unit

Double Head Rope Braiding Machine

115,000 Per Piece