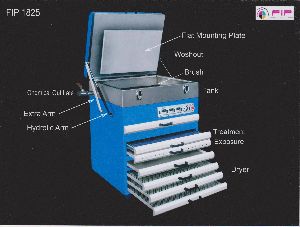

Non Woven Bags Printing Plate Making Machine .

Get Price Quote

lexography India Press is a Global Manufacturer & Exporter of flexo photo polymer plate making machine, Rubber stamp making machine, Solvent Recovery Equipment…etc. for Flexographic printing industries…FIP Group’s Head quarter in the Viramgam and Manufacturing plant in Ahmedabad, Gujarat,India. Currently, we are manufacturing Flexography photopolymer plate making Equipment, including Rubber Stamp Making Equipment, Letterpress Plate Making Equipment, pad printing photo polymer plate making equipment, Label photo polymer plate making equipment , Varnish photo polymer plate making equipment, Flexo Solvent Recycling unit, Liquid Resin Stamp making equipment, Nylon Block making equipment , Water Wash photo polymer plate making equipment , Flexo plate making equipment, Flexo photo polymer plate making machine All type of stamp making series , Embossing plate making equipment, Pharmaceutical Batch plate making equipment, Woven sack photo polymer plate making equipment, flexo photo polymer die making machine , flexo photo polymer block making machine , photo polymer batch coding machine , flexo stereo photo polymer plate making machine , and all type photo polymer plate making machine series …….for flexographic printing ..

flexo bag printing plat making machine

Get Price Quote

Features of exposure unit instant light up philips high intensity lamps unique digital timers for backmain exposure excellent lamps cooling exhausting system quick vacuum drawdown pump with indicator features of drying unit drying drawer with uniform heat distribution temperature adjustable by a precise controller unique air circulation and exhaustion design over heat sensor for safety and protection features of treatment unit chemical free operation, simple, easy save digital timer for light finishing control philips uvc high intensity lamps equipped with powerful aire hausting for big size models.

Best Deals from Bag Making Machine

Non Woven bags Printing Plate Making Machine ( 18 X 25 INCHES )

353,999 - 354,000 Per PERUNIT

all stainless steel. exposing + drying + washout + treatment. with water circulation & filtration system. simple operation, best plate result.

Bag Making Machine

Get Price Quote

We supplies custom made pouch making machine bag making machine. Bottom seal Packing; three side sealing. Order now to get best offer.

Woven Bag Gusseting & Cutting Machine

Get Price Quote

polybag making machine

1,000,000 Per Piece

We are counted amidst the renowned Polybag Making Machine Manufacturers and Polybag Making Machine Suppliers in Gujarat. As we follow the automated warehousing system, we ensure safe assembling as well as storage of the entire lot. Moreover, the system is well managed by our team of experts. By making use of premium packaging material, we can guarantee zero damage during transit. Moreover, our packaging experts stringently check the entire lot prior to final dispatch. Polybag Making Machine that we offer can produce 40 to 180m of Polybag Making material per minute.

Woven Sack Bag Cutting Machine

Get Price Quote

01 Set(s) (MOQ)

We are offering woven sack bag cutting machine. features • ideally suitable for fertilizer bag &laminated bag • high production speed of 55 mtr. Min. • user friendly operation • heavy duty vibration free structure • microprocessor based system with digital display • variation in cut length less than1% • less man power required • less space required • perfect batch counting optional • double unwinder • overhead crane for loading of heavy rolls • photo cell to cut printed laminated bag model length width speed mtr. Min connected load main motor control system dimension (lxwxh) weigth (approx.) twfcm 50-1500 800 55* 2.2kw a.c. servo 3150×16500×1550 1000kgs.

Automatic PP Woven Sack Bag Making Machine

1,000,000 - 1,300,000 Per Piece

1 Piece (MOQ)

FIBC JUMBO BAGS BALING PRESS MACHINE

Get Price Quote

Non Woven Bag Making Machine

Get Price Quote

NONWOVEN BAG:- Raw Material (non woven fabric ) 100% disposal + make roll /slitting Attach fabric roll + Assemble all inter roller + make bag + packing (1kg) + sale to market retail shop/wholesaler/distributor. Ready product (bag) it is totally disposal / recycling (within 3-6months) Use- daily consumer goods carry bag instant PP bag. And take care from earthquake accident.

Paper Bag Making Machine

Get Price Quote

We are engaged in offering patrons a wide array of paper bag making machines, which is designed to manufacture flat and satchel paper bags from kraft paper, greaseproof, white paper and poster. With the help of offered machines, one can make bags in different sizes for packing confectionery, food stuff, ready-made garments, tobacco, tea powder, groceries and dry cleaners. features: robust construction that avoid vibration properly arranged papers that make operation and adjustment very simple & quick easy to change the size it has one size plate and one size gears for one size of paper bags different size plates and size gears for flat and satchel bags are also available the width of paper reel to fed on the machine can be calculated as under :- flat bags: twice the bag width plus 2 cm for center seam satchel bags: twice the bag width plus 4 times depth of gusset plus 2 cm for centre seam bag formation: the required size of bags is obtained by fixing the exact size plate for flat or satchel to the size plate holder by changing the size gear wheel with tooth of 1 cm length, we can obtain plate holder and the length beater cuts the tubing into accurate size same as of gear size, later which is delivered via conveyor rollers to delivery cylinder the delivery cylinder is also the bottom folding and pasting cylinder bottom field after being made is pasted and later moved by the folding cylinder to the delivery cylinder for the purpose of releasing and delivery in a vertical stack printing attachment: owing to the latest technology two or four color flexo printer can easily be coupled with the paper bag making machine available in three sizes (deluxe model, medium and baby model) model hmw 101 size : 34� large 12 x 18 cms min to 42 x 60 cms max. Flat 12 x 18 cms min to 36 x 50 cms max. Satch 70 to 125 bags per minute witch depend on quality of material model hmw 102 size : medium 10 x 17 cms min to 28 x 36 cms max. Flat 10 x 17 cms min to 20 x 36 cms max. Satch floor space required 14ft. X 10ft. Without printing model hmw 103 size: baby 7 x 15 cms min to 10 x 16 cms max. Flat 7 x 15 cms min to 10 x 16 cms max. Satch 18ft. X 10ft. With printing drive : 3 hp ac & dc 1440 rpm required.

tea bag packing machines

Get Price Quote

Backed by rich industry experience, we are engaged in manufacturing and supplying a commendable range ofTea Bag packing Machine. These packing machines are available in various shapes and sizes in the market. These products are designing using superior quality of raw material. Our products are able to automatically finish the process of bag making, measuring, and seal and counting. The machine will pack the tea bags into heat sealable paper envelopes to keep the flavour to the end customer. This machine is suitable for packing the tea bags of small grain-like materials, such as tea leaf, medicinal tea and healthy tea. As a quality-oriented organization, we are focused to provide our valuable clients excellent Tea Bag packing Machine that is manufactured using high grade components. The tea bag packing machine is designed to pack tea bags with tea in them. The machine can finish bag making, measuring, filling, sealing, threading feeding, tag cutting and counting etc. It is suitable for package of broken tea, coffee, ginseng essence, diet tea, health-caring tea, medicine tea, as well as tea leaves and herb beverage. The offered machine is availed in different designs and other related specifications, in order to meet the variegated expectations of our valuable customer. Our provided range is rigorously tested by the team of our professionals. Furthermore, our clients can avail this machine from us at market leading prices. Salient Features of Tea Bag Packing Machine Servo-motor control bag pulling system. Using Ultrasonic sealing, can packing teabag with good look. Adopt PLC to control the machine, convenient to operate. PID temperature controller monitors heat sealing temperature within +I- 1ºC. Automatic edge position control assures consistent film alignment during production to produce uniform bag quality. The parts connected with products are made of SUS304 stainless steel, which can ensure the products healthful and reliable. The machine can automatically complete the products measuring, conveying and feeding, filling and bag forming, date code printing, bag sealing and cutting. Applications of Tea Bag Packing Machine Automatic packaging of granule In formed pouch for the food Pharmaceutical industry Automatic packaging of Liquids Chemical and other industries Automatic packaging of Powder

Plastic Bag Making Machine

Get Price Quote

Jumbo Bags Making Machine

Get Price Quote

Bag Making Machine

Get Price Quote

Bag Making Machine, Edge Grinding System, Slitting Rewinding Machine

PP Woven Bag Printing Machine

Get Price Quote

Compact and sturdy construction Streamlined design for maximum speed Easy to maintain and economical No bush bearings, the machine is entirely based on ball bearings Pressure release device avoides unnecessary tinting of conveyor belts Strict quality controls Efficient after sales service

Paper Bag Making Machine

Get Price Quote

Paper Bag Making Machine, Mineral water Bottle filling Capping Machine

Paper Bag Making Machine

Get Price Quote

Paper Bag Making Machine, Ceramic Parking Tiles, Cola pouch packing machine

Bag Making Machine

Get Price Quote

Bag Making Machine, Paper Napkin Making Machine

Woven Bag Cutting Stitching Machine

Get Price Quote

Woven Bag Cutting Stitching Machine, Woven Bag Making Machine