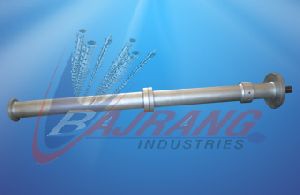

Screw Barrel

Get Price Quote

We supply Screw Barrel in any diameter for extrusion processes. We produce extruder screw and barrels in any diameter from different types of steel depending on customer requirement. Plastic extrusion is a process of melting and passing through plastic resin inside a barrel by force of screw rotating inside. At the end of barrel melt plastic formed by a die or mould acording to required parameters. Diameters are between �45 - �250mm. We produce screw and barrels for: recycling machines, injection Moulding machines,film and bag machines, PVC granules (double screw) and for all other plastic granule extruders.

Screw Barrel

25,000 Per Piece

Best Deals from Barrels

Groove Feed Screw Barrel

Get Price Quote

1000 Piece (MOQ)

The groove feed barrel facilitates efficient transportation of material and is used for achieving high shear. The coefficient of friction between the screw & barrel and the granules should be higher, as it facilitates proper melting of the material. Therefore, it is highly crucial to have groove feed in the barrel. It has a minimum diameter of 35mm and is also available in sizes based on the customers’ requirements.

Single Barrel

Get Price Quote

We are engaged in manufacturing and supplying of comprehensive range of the finest quality single barrel. Manufactured with most advanced technologies and machineries like deep holeboring machine using high grade raw materials, these products are highly appreciated for their smooth finishing, resistance to corrosion and robust construction. Stringently checked and tested on various required parameters by our experienced professionals, we are able to offer these precision engineered products at par with the industry quality standards.

Screw Barrels

Get Price Quote

Twin Screw Barrel

15,000 Per Piece

Riding on unfathomable volumes of industrial expertise, we are manufacturing and supplying an excellent range of Twin Screw Barrel. Use: Used in various drilling works. Features: Rugged construction Anti-corrosive Easy to use Note: Provided price is minimum and changes as per specifications Other Information Minimum Order Quantity: 1 set

Twin Screw Barrel

200,000 Per Pair

Screw Barrel For Plastic Machine

Get Price Quote

We hold expertise in manufacturing and exporting Screw Barrel for Plastic Machine. Our screw barrels are made from premium quality raw material known for their longer life, superior performance and ensuring best in industry quality standards. These barrels are accessible to the clients in different quantities. These screws are in high demand in the market because its chemical and the physical properties are developed in accordance of the international standards. These Screw Barrels are appreciated for their high durability and accurate dimension. Our Plastic Screw Barrels are known for it’s resistant to corrosion and have long functional lifeOur machine is known for its robust design, dimensional accuracy, corrosion resistance, less maintenance and high operational capacity. It is made available at market leading prices.

Single Screw Barrel

100,000 Per Piece

Single Barrel

Get Price Quote

We are engaged in manufacturing and supplying of comprehensive range of the finest quality Single Barrel. Manufactured with most advanced technologies and machineries like deep holeboring machine using high grade raw materials, these products are highly appreciated for their smooth finishing, resistance to corrosion and robust construction. Stringently checked and tested on various required parameters by our experienced professionals, we are able to offer these precision engineered products at par with the industry quality standards.

twin hole barrel

Get Price Quote

Backed by an adept team of experts, we are providing a wide range of Twin Hole Barrel. The provided barrel is produced at our vendor’s end using optimum grade metal alloy and innovative methods under the surveillance of trained professionals. Further, it is checked on various quality parameters before being dealt to our clients ensuring its excellence at user’s end. Clients can acquire this barrel from us at economical rate. Characteristics : Easy to install Unmatched quality Finley finished

Twin Barrel and Screw

Get Price Quote

Gas Nitriding Is A Case Hardening Process In Which Nascent Nitrogen Is Diffused Into The Surface Of A Solid Ferrous Alloy. It Gives Excellent Wear Resistance, Hardness Upto 70 Rc, I.e. 950 To 1150 VPN Is Possible. Gas Nitriding Is Performed On Finished Components.It Gives Excellent Corrosion Resistance Against Humid Air & Water.It Is A Case Hardening Process & Hence Core Can Remain Tough. Gas Nitriding Is Done On Alloy Steel Which Contains Aluminum,Chromium,Tungsten & Molybdenum. Mo Reduces The Risk Of Embitterment At Nitriding Temperature. Nickel, Copper, Silicon & Manganese Do Not Give Any Advantages Of Nitriding Nitriding Properties.Gas Nitriding Is Not Done On Carbon Steel Except For Corrosion Resistance Properties. Alloy Having Aluminum Gives Maximum Hardness & Wear Resistance.

Twin Screw Barrel

Get Price Quote

Extrusion Twin Screw Barrel

Get Price Quote

HI-TECH SCREW & BARREL is one of the most leading and reputed manufacturer of the most leading and reputed manufacturer of the extrusion screws and barrel with designs of all the reputed manufacturer extrusion machine manufacturer. Designs are available for single flight metering screws, single barrier screws, double barrier screws, variable pitch flights, multi start flights and slotted flights. lights and slotted flights. Mixing Sections the more common of which , include Maddock (spiral of straight), Hoechst, dulmage, pinned. Pineapple or combinations of these designs are available. Our varieties of screws ranges from 18mm up to 200mm depending on LD ratio.

Sleeve Fitted Barrels

Get Price Quote

High wear resistance sleeve fitted barrels for conical twin-screw extruder as well as parallel twin-screw extruder is our specialty. We have a special material developed after intensive testing for manufacturing conical & parallel twin barrels, which are normally divided into three pieces in conical barrel set & two pieces in parallel twin barrel set.Following mechanical processing each barrel section is treated using a hardening process which operate almost free of distortion. This has enabled production of twin barrel with approximately twice to thrice the service life of nitrided barrels at just 20% to 25 % addition cost. This renders the economic efficiency factor irrelevant in purchasing decisions.An additional benefit is the extended service like of twin screw extruders with wear resistant barrels can be operated at normal output for a longer period, without incurring through put losses due to wear. Thus production costs are reduced while competitiveness is improved.

Single Barrel

Get Price Quote

We are engaged in manufacturing and supplying of comprehensive range of the finest quality Single Barrel. Manufactured with most advanced technologies and machineries like deep hole/boring machine using high grade raw materials, these products are highly appreciated for their smooth finishing, resistance to corrosion and robust construction. Stringently checked and tested on various required parameters by our experienced professionals, we are able to offer these precision engineered products at par with the industry quality standards. It has deep hole driling / boring machine to manufacture barrels up to 300mm dia x 5 meters long. It has facilities for honing operation for 14mm ID to 300mm ID & 5 meter long. Features : Sturdiness Light weight Easy to install

HDPE Barrels

Get Price Quote

Right sizes for optimum export container utilization,Labeling and screen printing compliance as the surface is smooth.Excellent drop impact and stacking strength.Non-Corrosive and highly inert to chemical attackpetroleum products, Lubricants & Industrial oil.

Injection Molding Barrel

45,000 Per Set

10 Set (MOQ)

Injection Moulding barrel

Get Price Quote

We are one of the leading manufacturers and exporters of injection moulding barrel. These find application in diverse industry verticals.

Twin Screw Barrel

Get Price Quote

We supply conical Twin Screw and barrels for specific processing needs.The product is suitable for heat as well as shear sensitive material like pvc .We offer counter rotating twin screw and Barrel that are sturdy, cost effective and efficient and are ideal for usage in pipe as well as compounding.

Screw Barrel

Get Price Quote

At Tirupati industries, we manufacture all kinds of barrel tosupport all kinds of extrusion screw. We recommend to take our barrel with our screw for better performance as they are made withgreater precision and accuracy.

Screw Barrel

250,000 Per Piece

Screw Barrels

Get Price Quote

Screw Barrels, Hot Air Dryer, Hopper Loader, Granulator

Single Screw Barrel

Get Price Quote

Single Screw Barrel, Injection molding screw, Extruder Barrel

plating barrel

Get Price Quote

plating barrel, Oil Cool Rectifier, Air Cool Rectifier, Electroplating Tank

twin hole barrels

Get Price Quote

twin hole barrels, single barrels, corrosion resistant barrels

twin hole barrel

Get Price Quote

twin hole barrel, Cylinder Head, Parallel Twin Screw, Twin Screw Barrel

Twin Screw Barrel

8,000 Per Set

1 Piece (MOQ)

Twin Screw Barrel, Screw Barrels, Service Provider, Exporter

twin hole barrel

Get Price Quote

twin hole barrel

twin hole barrel

Get Price Quote

twin hole barrel, Twin Conical Screw, Single Hole Barrel, Screen Changer