Static Inline Hopper Concrete Batching Plant (GEPL SIH - 20)

Get Price Quote

Made out of the best high-quality premium grade raw steel, sourced from one of India’s leading raw materials suppliers, our Static Inline Hopper Concrete Batching Plant now comes with the GEPL SIH- 20 model to ensure that you get the maximum power with minimum risk. Designed to increase efficiency and effectiveness, our Static Inline Hopper Concrete Batching Plant (GEPL SIH - 20) is easy to maintain and is guaranteed to be durable, making it an ideal factory item.

Concrete Batching Machine

Get Price Quote

We are an acknowledged Manufacturer, Supplier and Exporter of Concrete Batching Machines. Our Concrete Batching Machines are widely used in the construction industry for their efficiency, cost effectiveness and easy operation. Our Concrete Batching Machines are provided with mechanical joints for smooth mobility at the construction sites. Besides, Concrete Batching Machines are equipped with a specifically designed lever system for ease of weight adjustment.

Best Deals from Batching Plants

Continuous Asphalt Mixing Plant

Get Price Quote

The appropriate response is that there is no perfect choice. For each and every site and for each and every occupation necessity there is an alternate arrangement. Thus the decision relies upon cautious examination of all the ‘periphery components’ and the kind of yield that must be created.

Asphalt Batching Plant

Get Price Quote

Asphalt is a mixture containing aggregates, binder and filler. It is usually used for building and repairing different types of roads, parking lots, play areas, and sport fields. Here, aggregates can refer to crushed rock, sand, gravel, or slags. Asphalt is utilized in building roads, railway beds, airport runways, taxiways, bicycle paths, playgrounds, running tracks, tennis courts, barn floors, greenhouse floors, ports, bridges, tunnels, landfill caps, etc. Our KEW (Stationary) series of asphalt mixing plants offers customers the industry’s finest & proven technical solution, latest generation process controls and automation together with total installation and site support, aimed to deliver precisely mixed quality asphalt – productively and profitably. KAUSHIK design team facilitates custom built asphalt plants to meet specific site demands and requirements. Available in capacities ranging from 35 to 150 TPH output in different models.

Concrete Batching Plant

Get Price Quote

Asphalt Mixing plants

Get Price Quote

1. COLD AGGREGATE FEEDER UNIT It consists of TWO independent top open type bins having total 25 tons capacity being fabricated from MS plate mounted on rigid Channel supported on channel. Each bin consists of an independent opening for feeding the aggregate with adjustable bin manual gate. Each bin deposits pre-determined aggregate via auxiliary belt on Gathering belt fitted underneath, which is driven by 03 HP A.C. Motor. A continuous type electronic load cell mounted on gathering conveyor for accurate feeding of aggregate into dryer via Slinger (cold) belt conveyor. 2. DRYING & MIXING UNIT KEW-35+ Single Drum flight Rotor Type, Drying & Mixing shell 1000 mm Dia and 4000 mm long made out of 08 mm MS plate Full shell driven by 10 HP AC motor coupled with reputed make reduction gear box. Drum rotating speed will be 12/14 RPM. Built-in Multi Cone Dust Collector having manual dust outlet, system controls the dust to contain / recycle permissible fines; it is capable of preventing the exhaust of fine dust in atmosphere for environmental control resulting into less polluted plant. Exhaust blower having balanced ID fan having 10 HP AC Motor and high Chimney, aggregate heated by Hi-Lo Pressure Jet type Electronic Burner having fuel consumption 175/200-liters/Hr maxi. The DM unit fitted on robust & sturdy chassis made out of Heavy I Beams with perfectly aligned and correct distance for dryer chain to rotate without any extra efforts. 3. ASPHALT TANK Insulated with glass wool having 10-ton capacity with direct-fired heating method thru light oil auto burner electric ignition. Variable speed 03 HP D C. drive for pump to synchronize with dry aggregate flow rate to produce mix conforming to design mix at all loads, thermostatic control to control the burner to maintain at pre-set asphalt temp. 4. LOADOUT (HOT) CONVEYOR Hot mixed material conveyed from chamber of drum will be discharged into hydraulic storage hopper fitted at discharged end of conveyor driven by 05 HP AC motor coupled with SMSR gearbox. The Hydraulic dual gate hopper opened via Cylinder powered by a compact power packed and the operation is automatic duly controlled from AC Panel. Hopper consist scrapper for cleaning the load-out belt properly and assuring falling hot-mixed material in to hopper.

Pneumatic Big Batching Machine

Get Price Quote

1 Piece (MOQ)

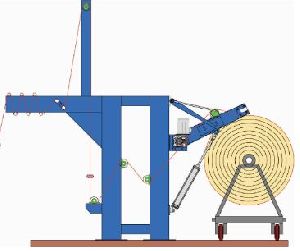

Can wind the Fabric edge to edge, creaseless at speed upto 90 Meters/ Minute. Provision of Pneumatic Cloth Guider help in edge to edge einding of the fabric without any damage upto 1500 mm Diameter. Universal machine for woven and non-woven Fabric. Less space required. Working Width ranges from 1400 mm to 3400 mm. Batch created on this machine are most useful to be installed before entry in Flat Printing Machine or Rotary Printing Machine.

Mobile Concrete Batching Plant

25,000 - 65,000 Per piece

1 Piece (MOQ)

Inkjet Batch Coding Machine

11,000 Per piece

Batch Coding Machine

250,000 - 950,000 Per Pieces

1 Pieces (MOQ)

fully automatic batch coding machine

Get Price Quote

10 Piece (MOQ)

Double Drum Asphalt Mixing Plant

3,500,000 Per Set

1 Set(s) (MOQ)

Our double drum hot mix plant is suitable for high capacity mixing requirements, in out double drum asphalt mixing plant the drying of aggregates and mixing of aggregates is done in two different drums given precise mixing quality with anti gradation of aggregates and mix recipe.

Concrete Batching Plant

1,500,000 - 5,000,000 Per piece

1 piece (MOQ)

Coninfra Machinery Pvt. Ltd. is well-known for its concrete batching plant division for designing stationary and mobile concrete batching plants in Ahmedabad. We are devoted to offering the highest quality products at affordable prices while ensuring it meets our client demands and requirements. Delivering the best is the motto that drives us to constantly strive to provide tailored solutions in the form of our world-class equipment including concrete mixer, canal paver finisher, and machines for cement silo.

Asphalt Batch Mix Plant

Get Price Quote

Concrete Batching Plant

1,500,000 Per Set

1 unit (MOQ)

Mini Mobile Batching Plant

1,951,000 Per Piece

Batch Coding Machine

48,000 - 75,000 Per PCS

𝐒𝐀𝐆𝐀𝐑 𝐏𝐀𝐂𝐊𝐀𝐆𝐈𝐍𝐆! ADD🚘 :- G.F.572/3585, Shop No.4, Gujarat Housing Board, Opp. Gayatri Mandir, Bapunagar,

Batch Coding Machine

Get Price Quote

Batch Printing Machine

Get Price Quote

Akshar Enterprise is the renowned name among the Batch Printing Machine Exporters of India. We are widely acclaimed for our Batch Code Printing Machine. The output capacity of our machines varies as per the product�s model. They are available in various shapes and sizes. We also provide Automatic Batch Printing Machine, which is equipped with latest technology. They are available with us in both motorized and manual model. Product Series : AKSHAR MY-380F Product Model : MY380F Description : solid-ink coding machine is a kind of special label printing equipment, and suitable for printing labels on the surface of paper, nonferrous plastic film and aluminum foil. It adopts cantilever type mechanism, light and precise. Its lengthways-printing position is controlled by electronic device, and can be adjusted discretionarily. Moreover, it uses advice, and solid ink roller for printing, which has six colors for choice, black, red, yellow, blue, white and green. The printed words is clear and not easy to erase and change.