Wood Pellet Mill

Basically the purpose of pelleting is to take a finely devised, some time dusty, unpalatable and difficult to handle feed material and by application of heat, moisture and pressure form it into larger particles. These larger particles or pellets are easier to handle, more palatable and usually result in improved feeding result when compared to mesh freed.

...more

universal mill

PREMIUM manufacture UNIVERSAL MILLS to gring wide range of materials in desired particle size. END PRODUCTS. The BLAST ROTORS have STRAIGHTBAR OR INCLINED BAR OR PLATEBBAR mechanism and are DYNAMICALLY BALANCED. The CLASSIFIER STATORS Drums are FULL SCREEN HALF SCREEN and HALF SERRATED GRINDING TRACK OR THREE QUARTER SCREEN and ONE QUARTER SERRATED GRINDING LINER. The GRINDING TOOLS are HARDENED ELEMENTSARE are FIXED on PERIPHERY OF BLAST ROTOR. Similariy CLASIFIER STATORS SCREENS ARE FIXED in MILL BODY to get desired degree of FINE POWDER. LARGE SIZE are with AUTO FEEDING and AUTO COLLECTION arrangement mills

...more

spices processing machinery

Premium Entered in spices machineries plants. About in mid - 1970. The primary function of spices in food is to improve its flavour. After rich Experiences has Determined what combination of spices should be used for a particular dish or what dictates the composition of a blend of spices know as curry powders.

...more

Spice Processing Plant

Premium Entered in spices machineries plants. About in mid - 1970. The primary function of spices in food is to improve its flavour. After rich Experiences has Determined what combination of spices should be used for a particular dish or what dictates the composition of a blend of spices know as curry powders.

...more

Spice making machine

Premium Entered in spices machineries plants. About in mid - 1970. The primary function of spices in food is to improve its flavour. After rich Experiences has Determined what combination of spices should be used for a particular dish or what dictates the composition of a blend of spices know as curry powders.

...more

Spice Grinding Plant

Premium Entered in spices machineries plants. About in mid - 1970. The primary function of spices in food is to improve its flavour. After rich Experiences has Determined what combination of spices should be used for a particular dish or what dictates the composition of a blend of spices know as curry powders. We are offering three main unit plants for spices as follow: - 1. Chilly processing: - We are offering Two stage grinding 1st stage coarse grinding & 2nd stage fine grinding. Fine grinding screening (Grading) Provided. 2. Turmeric Processing: - It also needs two stage grinding like chilly. 1st operation coarse grinding & for II nd operation fine grinding. We also suggest screening equipment for grinding the turmeric as desired mesh.

...more

salt refining plant

Since the early days, man has been using common salt as food additive in the food to improve its taste and to meet the physiological requirements of the human body. During the coarse of development of the society as man needed a wide range of materials to meet its needs it became necessary to develop range chemicals that would meet these requirements. Salt became an important ingredient and raw material for manufacture of a large number of these chemicals. Salt is reported to have over 14,000 uses. Some of the major users are

...more

rubber grinding machine

The grinding characteristic of various materials like resins, gums, waxes hard rubbers, etc. are depend greatly upon their softening temperature. Premium offer the complete system for fiber - Rubber separation system for rubber based industries. We all are well aware that plastics & Rubber these two materials are not completely destroy to the Earth & it only changes the new formation as per industries & societies requirement as new products. In various Rubber Industries waste product is predominantly rubber coated nylon fibres for this we have to literally tear the fibre & shred the same into pieces. There is a certain amount of adhesion of rubber on fibre which has to be weakened.

...more

Rubber Grinder Mill

The grinding characteristic of various materials like resins, gums, waxes hard rubbers, etc. are depend greatly upon their softening temperature. Premium offer the complete system for fiber - Rubber separation system for rubber based industries. We all are well aware that plastics & Rubber these two materials are not completely destroy to the Earth & it only changes the new formation as per industries & societies requirement as new products. In various Rubber Industries waste product is predominantly rubber coated nylon fibres for this we have to literally tear the fibre & shred the same into pieces. There is a certain amount of adhesion of rubber on fibre which has to be weakened. The premium, which leads the sets new standards, has no choice and methods of operation.

...more

Plastic Pulverizer

PREMIUM Micro Pulverizer is a high efficiency, economical unit designed for dry or wet grinding to any specified fineness upto 250 - MIRON mesh as well as for smooth blending operations. It is a close clearance, highspeed, compact Mill ideal for grinding a wide range of abrasive, nonabrasive and fibrous materials.

...more

Plastic Grinding Mills

The material in granular form is fed from a feeding hopper to the Pulveriser. The material is Pulverised between two serrated discs & then air conveyed to a Screening equipment. The coarse material is recycled to the Pulveriser for further size reduction. The fine (desired) Powder can be filled in bags or containers. Grinding by shear. Cool grinding Chamber Because of large Airflow due to design of mill & Blower.Grinding gap between the two grinding discs can be adjusted from the outside of the machine. This Disc Mill does not have any Screen so no problem of chocking & excess heat generation. The Body of the mill is water jacketed & fabricated out of heavy mild steel. We used graded material EN-41-B for disc mill & main shaft made of EN - 8. dynamically balanced for smooth operation. This system provides noise less operation and trouble free working and mode from EN-8 material. Several options are available to simplify the cleaning process. The front door with the grinding disc can be opened easily, thus making the grinding chamber accessible for easy & fast clearing. Suitable Structural platform is supplied for Ease of operation. Necessary spare parts also ready available at our factory.

...more

Pin Mill

L & T Type Pins. Pneumatic Conveying can be offered. MOC In MS SS wear parts SS Complete Round Pins in stator and or Rotor with FINE PITC. Whizzer Type PIN MILL (Screen less) can be provided. More out put than conventional Mill NARBOW BAND of fineness Final product cool and smooth Less Power consumption OCCUIES LESS SPACE RAPID & ADEQUATE ejection of pulverized material from all over the screen. Allows FEED MATERIAL with higher percentage of FAT and MOISTUERE. STURDY & VIBRATION FREE CONSTRUCTION. Easy to CLEAN & Easy to Operate.

...more

pellet making machine

Basically the purpose of pelleting is to take a finely devised, some time dusty, unpalatable and difficult to handle feed material and by application of heat, moisture and pressure form it into larger particles. These larger particles or pellets are easier to handle, more palatable and usually result in improved feeding result when compared to mesh freed.

...more

masala mills

Premium Entered in spices machineries plants. About in mid - 1970. The primary function of spices in food is to improve its flavour. After rich Experiences has Determined what combination of spices should be used for a particular dish or what dictates the composition of a blend of spices know as curry powders.

...more

impact pulverizer machine

For pulverising material upto 60 mesh # Ideal for Pre-Crushing # 15 Standard Models # Capacity 50kg. to 25000kghr.

...more

horizontal mixers

Baby Blenders Paddle Type Mixers Single Ribbon Type Mixers Double Ribbon Type Mixers Central Spiral Ribbon Mixers Liquid Molasses Mixers Jacketed Mixers Continuous Type Mixers Molasses Blenders Twin Blade Mixers Rotor Removable Homogeneous & Fast Mixing Ideal for Dry & Wet Mixing Economically priced Easy to load

...more

Grain Hammer Mill

15 Models (Upto 200 HP) * Ideal For Precrushing & Coarse Grinding * 50 To 25,000 KgsHr.Cap. * Cool Grinding * Low Power Consumption * 3 in 1 Unit (pulverizing, Sieving & Conveying) * Available with Negative Pressure System also. * Wet milling also available. * Grinding element in different shape to application. * Bottom Discharge Also * Side Screen Opening Also * With Star Type Hammer * M.O.C. In MSSS

...more

feed mill plant

EQUIPMENT USED IN AQUA FEED PREPARATION PULVERISERS They are used for grinding the feed ingredients. Grinding of ingredients improves the feed digestibility, acceptability, mixing properties, pelletability and increases th bulk density of some ingredients. The grinders are available in various forms as described below. HAMMER MILLS Hammer Mills are mostly impact grinders with swinging or stationary bars forcing feed ingredients against a circular Screen or solid serrated section called striking plate. Material is held in the grinding chamber until it is reduced to the size of the openings in the screen. Impact grinding is most efficient with dry, low fat feed ingredients.

...more

Evator bucket

Centrifugal type Bucket Elevators Continuous Type Bucket Elevators Double Legged (Heavy Duty) Bucket Elevators Galvanised (Light Duty) Bucket Elevators Cement Plant Bucket Elevators Super Capacity Bucket Elevators Standard Parts & Accessories Bucket Elevators Systems

...more

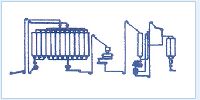

disc mill

Premium Disc Mills are rugged Construction. The main body is made of C.I Welded Steel. The FRONT DOOR, which is having SERRETED GRINDING DISC, can be easily opened and hence making conveniently for Cleaning. The door is hinged for ease of operation. The material is fed with either vibratory Feeder Screen feeder through Feeding hopper. The material is pulverised between TWO SERRETED hardened Discs. The gape between TWO plates can be adjusted by outside from outside. The ground material can be conveyed by blower through cyclone collector, which is installed with Rotary Air Lock Valve on Gyro Screen, which Screens the material and coarse material in REFED into DISCMILL for further grinding. The FINE and acceptable material is collected in DRUMSBags. Complete System is installed on Steel Frame.

...more

bone mill machinery

Bone grinding & sizing in different micron size as per industries requirement. The main users of Bone grinding powder are gelatine manufacture who supply their products to pharma Application & its related industries. This Entire System Consists Of:- 1. Belt conveyor: - This conveyor feed the different size of Bone to the Pulverise (Hammer - Mill). 2. Bone Milling: - (Hammer Mill - A size Reduction Unit) which grind the require size. This mill having specially designed hammers & dynamically balanced Rotor. 3. Roto sifter: - After size reduction the grind material passes through roto sifter for sieving purpose. This Roto Sifter having multiple stage system Grading - a unique system for necessary sinews separation arrangement.

...more

air swept mill

The complete fabricated body is constructer in close tolerance to prevent air leakage. Main shaft supported by heavy duty bearings for trouble free balanced & cool working. Hammers are swinging in main shaft with fly back system to prevent breaking of hammer or damaging of liner in case of any foreign material, hard to grind is fed. The whizzer blade may be adjusted in the taper cone according to the mesh size requirement of material. Cyclone mounted our MS structure separates air form the ground material and collects material in to bags. Fabric bag type dust collector is provided to collect fine particle from the air flow Bigger models are provided with auto feeder.

...more

air classifier mills

Lab model available Screen-Less Pulveriser with inbuilt Classifier For Fine Grinding Application Cool Grinding (Ideal for Heat Sensitive Materials) With Water Cooling Jacket Also with M.C.C. with Mimic Diagram With Reverse Pulse Air Jet Type Dust Collector Bottom Discharge Can be offered MOC: MSSS contact parts SS Complete Screenless grinding Easy adjustable classifier plate Cool grinding High degree of fineness Grinding, classification & Conveying in one operation Sharp & narrow particle distribution Wide range of applications

...moreBe first to Rate

Rate This