Three Arm Bi-Axial Rotational Moulding Machine

95,000 - 130,000 Per piece

1 piece (MOQ)

Bi-Axial Machine

Get Price Quote

INDIA ROTO PLAST has come with newest making Bi-axial Rotomoulding Machine and Auxiliary Machineries for Plastic Industries. The company brings the World Class information of Bi-axial Rotomoulding Machine and Rotomoulders in India. The Process : Rotational Molding Process Is different as compared to other plastics processes In which is Prime Crucial factor. In the complete process, first the mold is loaded with raw material in resin from. The loaded mold is then shifted in to hot air oven where it is oriented and rotated at suitable low speed. As the molten resin gets properly heated & oriented, it adheres to the mold's inner surface until completely fused. Then the mold is moved to the air, water or the both to slowly reduce the temperature when the mold is still in bi-axially rotating mode. Finally, the mold is dismantled to get the finished roto-molded product and is then again reloaded for next cyclic process.

Best Deals from Bi Axial Machine

Single Station Bi Axial Machine

1,400,000 Per Piece

Single Arm BI Axial Machine

Get Price Quote

1 Piece(s) (MOQ)

Features : Low capital Investment best for startup project. Minimum overheads charges due to less space & Automatic operation Low cost machine to produce best quality 2/3/4 layer tanks with minimum weights. Excellent quality multilayer tanks possible. Any type of rotomolded products can be produced at low investment Faster ROI. Due to low investment, low running cost, less space, Unskilled operator can run machine. Less rejection rate. Low power, low fuel consumption cost Most suitable machine to produce even Bigger size tanks. Application : For large size tanks like 3000 to 40,000 Ltrs / 10,000 USG and large size simple and cylindrical rotor articles. Start Up project due to low cost.

biaxial machine

Get Price Quote

Maximum Parison Weight : 45 KG Product Removal by Automatic Take out Gripper Fast Production with Minimum Wastage Mould Clamping Force : 142 Tons Touch Screen PLC System for Automation Connected Load 430 KW & Average Running Load 230 KW Machine Required Floor Area : 9 MTR Width X 13 MTR Depth X 7 MTR Height. Note : Not in scope Accessories like Air Compressor, Shredder, Chiller, Hopper Loaders etc. are mandatory for operations, which client to arrange on its own.

biaxial rotomoulding machine

Get Price Quote

bi axial rotomoulding machine

Get Price Quote

NAROTO Bi Axial Rotomoulding Machine is mainly used in application where the process time for each arm required equal time for heating, cooling, unloading & loading. Also available for different applications like three stations, where time for heating, cooling, and unloading loading (common) area are provided.

Single Station Bi Axial Machine

1,800,000 - 2,800,000 Per piece

1 piece (MOQ)

4-Arm Bi axial rotomoulding machine

Get Price Quote

We are leading manufacturer and exporter of 3-arm and 4-arm bi-axial rotomoulding machine to our premium clients across the india and overseas.this machine is developed after extensive research and study of industry norms and as well as client requirement and the technical specifications detailed by them.

3 arm bi axial rotational Moulding Machine

1,500,000 Per Piece

1 Piece(s) (MOQ)

bi axial rotomoulding machine

Get Price Quote

We are manufacturer of Rock & Roll type machine upto 20,000 liters capacity. We also provide in this machine gas or diesel fire system. This machine use for manufacturing of big size articles.

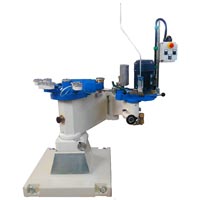

Bi-Axial Machine

Get Price Quote

✔ Complete Robust & Sturdy construction for long lasting performance. ✔ Movable Oven chamber. ✔ To minimize the heat losses with efficient Rock wool Insulation saves the heat energy. ✔ Powder coated Electrical panels with dust proof construction with PLC & HMI. ✔ Auto reversal facility for all major & minor axis are provided with timing circuit. ✔ Complete wiring as per color code and specifications recommended as per relevant. ✔ All necessary safety features and controls are provided. Superior grade paint with standard five stage process. Timing circuit for 2nd layer and 3rd layer feeding of material is also provided. ✔ Lift for powder feeding.

biaxial machine

Get Price Quote

Biaxial machine consist 34 arms and have a moving oven in which mould is warmed where hot air is used to heat the mould. The Mold is attached on a arm which rotate it in two path hence the process is called as biaxial process. The procedure is control by diff parameter of molding therefore in biaxial it is possible to produce quality product. It also provides good output as it is a continuous process and have 3 arms.

Three Arm Bi Axial Machine

2,500,000 Per Piece

Bi-Axial Rotational Moulding Machine

Get Price Quote

> advanced designed machine. > fully automatic & compact for consistent quality product. > sturdy & unique mechanical design for trouble free running. > high efficient heating chamber for the best fuel economy. > all electricalmechanical safety interlock for safe working. > high efficient lpgdiesel burner for fuel economy. > specially design blowers to work under high temperature. > unique design for easy maintenance.

Bi Axial Rotomolding Machine

1,400,000 - 2,600,000 Per Piece

Bi Axial Machine

Get Price Quote

Product Specification Moving Oven Type Rotational Moulding Machine: - Specially Designed for the Energy Saving Environmental Friendly Heating Chambers with Efficient Heat Transfer Technology. - State of the Art Technology in Designing the Insulation Panels for Better Working Environment. - Straight-arm with Four Mould Carrying Carrier Plates for Economical Working. - Machine Controls are Equipped with Necessary Interlocking, Safety Devices with Indicators and Alarm. - Microprocessor Based Machine Control Panel with Digital Display. - Plc On Specific Request. - Variable Speed A/c Motors are for Major and Minor Speed Controls. - Mould Indexing Facility. - Environment Friendly Burners Suitable for Lpg/ Cng/ Oil/ Duel Fuels.

biaxial rotomoulding machine

Get Price Quote

We are Supplier and Manufacturer by Biaxial Machine Exporter, Biaxial Rotomoulding Machine, Bi-axial Machine ,Bi-axial Moving Oven Type Rotational Moulding Machine for NK Industries Ahmedabad, India. Biaxial Rotomoulding Machine NK Industries Provides Biaxial Rotomoulding Machine, Biaxial Rotomoulding Machine, Bi Axial Moving Type Machine, Rotomoulding, Supplier in India.

biaxial rotomoulding machine

Get Price Quote

biaxial rotomoulding machine, rotomoulding moulds

biaxial rotomoulding machine

Get Price Quote

biaxial rotomoulding machine, Rotomolding Rotational Moulding Machine