Hand Operate Mixer Machine

Get Price Quote

We provide our clients qualitative Hand Operate Concrete Mixer that is widely demanded in the domestic as well as international market. This Concrete Mixer is manufactured using the best quality raw materials, which provides it long functional life. Specifications : Capacity : 90 Kg. It/'s Hand Operate or Motor Operated Mixer Machine

Ribbon Blender

25,000 - 500,000 Per piece

1 Piece (MOQ)

Best Deals from Blender

Octagonal Blender

Get Price Quote

All type of Blenders are available for Mixing i.e. Octagonal Shape, V Shape, Double Cone, Cage, Cone & Ribbon Blender in the MOC of Contact Parts S.S.316.

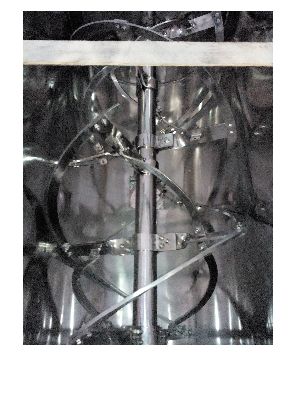

Double Cone Blender

Get Price Quote

Operation: The Double Cone Blender Is An Efficient And Versatile Machine For Mixing Dry Powder And Granules Homogeneously. Two Third Of The Volume Of The Cone Blender Is Filled To Ensure Proper Mixing. Double Cone Blender Can Be Used For Pharmaceutical, Food, Chemical And Cosmetic Products Etc. Capacity: Our Double Cone Blender Is Available In 10 Kg., 25 Kgs., 50 Kgs., 100 Kgs., 200 Kgs., 300 Kgs., 500 Kgs. Capacity Salient Features: All Moving Parts Of Double Cone Blender Are Covered With SS304 Covers Safety Guards Made From SS304 Pipes Provided In Front Of The M/c. Panel Of Double Cone Blender Is Fabricated From SS304 Material With Facility Of Three Phase Indication, D.O.L. Tarter, Digital Timer & Amp Meter. As Per Customer Requirement Double Cone Blender Machine Will Be Provided With Left Side Drive Or With Right Side Drive. The Conical Shape At Both Ends Enables Uniform Mixing And Easy Discharge All Contact Parts Are Made Out Of SS304/316(as Per Customer Requirement) Quality Material Maximum Care Has Been Taken To Ensure Safe Operation Of The Unit. Food Grade Rubber Gasket Will Be Used On Both Ends Of Cone As Well As In Butterfly Valve. Inside & Outside Of The Double Cone Blender's Cone Will Be Polished To The Mirror Finished. (All Safety Guards & Covers Made Out Of SS304 In GMP Model As Required By You) In GMP Model The Conical Shape Of Both Ends Enables Uniform Mixing And Easy Discharge Suitable Size Of Butter Fly Valve At One End Of The Cone Provided For Material Discharge & Hole With Open Able Cover Provided At Other End Of The Cone For Material Charging & Cleaning. One Shaft With 03 Nos. Of Fixed/ Detachable Buffers With Mirror Polished Provided Inside The Cone.

Ribbon Blender

150,000 - 7,500,000 Per piece

1 Piece (MOQ)

Ribbon Blender

Get Price Quote

Ribbon blender is used for uniform, homogeneous and quick mixing of powders and semi-wet materials of different densities by specially designed helical ribbon agitator. It can be used for Pharmaceutical, Food, Chemical, Dyestuffs & Pigment etc. For Pharmaceutical Industries, Ribbon Blender is called as Mass Mixture. Uni-Mech manufactures Continuous type and Batch type Ribbon Blenders. Uni-Mech also designs Ribbon Blenders for Chemical Reactions with Heating & Cooling applications. Ribbon Blender Design Range : Capacity range: 5 liters to 15000 liters Material of Construction: Various grades of Stainless Steel, Mild Steel, Hastelloy (cGMP model is also available). Special Features : Homogeneous Mixing Dust Free Operation Easy Handling & Operations Top Charging & Bottom Discharge through Butterfly Valve / Sliding Gate

Ribbon Blender

Get Price Quote

Model : 0.5 HP 100 HP 25 litter to 25,000 litter Capacity Direct Gear Drive , Counter Gear for load reduction Constraction : MS - MS / SS Coating – SS Material – Jeketared With and Without Counter Gear Ideal For : Pigment Colors - Minerals & Ores - Chemicals Technical Products Dyestuffs - Fertilizer - Insecticides - Pesticides Extra Material Handling Screw for loading & Unloading. HP required 2 HP 1440 Electric Motor 2 Nos. Capacity input and out material 75 kg per one minutes

Ribbon Blender

380,000 Per Piece

1 Piece(s) (MOQ)

The Mahavir ribbon blender are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the Mahavir ribbon blender can in corporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon blender is available in sizes 100-8000 litters in Stainless Steel 304, Stainless Steel 316 and Mild Steel Construction.

Ribbon Blender

Get Price Quote

The RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximate two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. Material should be charge from the top side. There are port/ports should be provided on the top cover to charge the material as well as for air vent. One discharge valve provided at the bottom side at center of the container. The discharge height could be adjust as per the requirement, so that material gets discharge in the other container directly, so that material handling time for discharge is nil and the operation is dust free In Ribbon Blender the powder moves from center to the end of container and end of container to the center of container. Hence requirement of total mixing time is very less and the RPM required are also very less. The dry material gets sufficient continuous movement due to the shape & movement of ribbon & shape of the container. Which moves material for good quality of blending? The unit is consist of one electrical motor, one worm reduction gear, belt drive between motor and gear, couple drive between gear to ( ribbon ) mixing stirrer. Container having four nos. of legs with discharge valve & top cover. Both end of mixing shaft is sealed with bush & PTFE gland housing & safety guards are provided on all moving parts.

Mixer Ribbon Blender

500,000 Per Piece

1 Piece (MOQ)

gravimetric blender

200,000 - 700,000 Per NOS

1 Nos (MOQ)

Reaction Blender

Get Price Quote

We offer reaction blender. The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

Double Cone Blender

Get Price Quote

1 Piece(s) (MOQ)

Double Cone Blender

120,000 Per Units

1 Units (MOQ)

v cone blender

225,000 - 785,000 Per Piece

1 Piece(s) (MOQ)

octagonal blender machine

325,000 Per Piece

1 Piece (MOQ)

Reaction Blender

Get Price Quote

The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

Double Cone Blender

Get Price Quote

The double cone blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as healthcare, food, chemical, cosmetics, detergents, fertilizers and plastics. Product Description Ideal for Mixing of powder and homogeneous lubrication of granules. Double cone blender is provide safety guard with limit switch interlocked to motor For higher capacity model. Available capacity 5 kg. to 1000 kgs. Automatic loading & unloading facilities provided. All parts made it S.S material is used for ss304 / 316 / 316L. It can be used to pharmaceutical,food,chemical and cosmetic product

Double Cone Blender

Get Price Quote

We offer highly efficient Double Cone Blender in the international market. The Industrial Double Cone Blender manufactured by us is used for blending with whirling blades for chopping, mixing, or liquefying materials. The output capacity of our blenders depends on the materials to be used. Besides, we are one of the prime Double Cone Blender Machine Manufacturers in India.

octagon blender

Get Price Quote

In keeping with our theme of client satisfaction, we are offering Octagonal Blender. Octagonal Blender is considered to be high effective blending machine. It could efficiently mix dry granules and apply lubrication process with ease. This Octagonal Blender is proven for its reliable performance. Owing to its octagonal shape, it could easily process large volume of material in comparison to V and double coned blenders.

Double Cone Blender

100,000 - 300,000 Per Piece

1 Piece(s) (MOQ)

Silent Features : The conical shape at both end enables uniform mixing and easy discharge The cone is statically balanced which protects the gear box and motor from any excessive load. Powder is loaded into the cone through a wide opening and discharged through a butterf Depending on the characteristic of the product, paddle type baffles can be provided on the shaft for better mixing, uniform blending and de-agglomeration Flame proof electricals can be provided as optional. Dust free bin charging system ensures minimum material handling.

Ribbon Blender

Get Price Quote

We are offering ribbon blender we have a state-of-the-art manufacturing facility, which helps us providing our clients with ribbon blenders. Ribbon blenders available size from 200 mm diameter to 2500 mm diameter in mild steel & stainless steel.

Ribbon Blender

560,000 Per Piece

Double Cone Blender

Get Price Quote

Capacity from 10 Liters upto 3500 Liters, Double Cone Blender is an efficient for mixing dry powder and granulates homogeneously. All the contact parts are made of stainless steel. Two-thirds of the volume of the Cone Blender is filled to ensure proper mixing. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. The conical shape at both ends ends enables uniform mixing and easy discharge The cone is statically balanced to avoid anyexcessive load on the gear box and motor. While the powder can be loaded into the conethrough a wider opening, It can be discharged through a mucon valve or a slide valve Depending upon the product, paddle types baffles can be provided on the shaft for better mixing Maximum care has been taken ensure safe operation of he unit. It can also be operated by a timer The contact parts are either made of SS 304 or 316 Flame proof motor can be supplied as optional Capacity 10 Ltrs. to 5000 Ltrs.

Doubke cone blender

Get Price Quote

Pharma machinery mfg and all taype of machine rmg.fbd ribbon blender, octa blender,Doubke cone blender,liquids line and packaging line

Ribbon Blender

Get Price Quote

We offer a ribbon blender to our clients for their various industrial needs. The ribbon blender and their sides are manufactured by us from Stainless or Mild steel materials. It comprises of a stainless steel or mild steel centre shaft fitted with specially designed agitator blades for providing the contra flow action. These blenders are equipped with a couple of ribbons. The outer ribbon moves the ingredients into the blender whereas, the inner ribbon constantly circulate the material. The drive of these consists of a gear box coupled with a heavy-duty motor. These blenders are provided with stuffing boxes on its either ends to prevent leakage. It also consists of a hopper and a discharge for loading and unloading of the processed material. Features: Provide homogeneous & quick mixing/blending. Sturdy & vibration free Provide flawless working Easy and economical maintenance High productivity and quality Applications: Chemicals Minerals Spices Sugar industries Pharmaceuticals Pulp and paper industries

Ribbon Mixer Blender

Get Price Quote

Ribbon Mixer Blender Uniform Dry Mixing Process Application & Process : Ribbon blender mixer is used for uniformly dry mixing and blending applications in the pharmaceutical, chemical, cosmetic, food, pesticides, detergents, and plastics industries. The Ribbon Blender comprises of a U-shaped horizontal trough, specially designed Double Helical Ribbon Agitator, rigid fabricated structure motor, gear box. In operation, material is filled to the top of the outer ribbon. The shaft rotates at relatively low speed and the moving ribbons push the material back and forth mixing it. The outer ribbon rotation displaces the material from the ends to the center while the inner ribbon rotations move the material from the center to the ends. This counter-current action results in homogenous blending. Mixing is achieved in 15 to 20 minutes with 90 to 95 % or better homogeneity. The bottom discharge provided for unloading of the material and easy cleaning of the mixing drum. Specially designed self adjusting sealing arrangement of unique design is provided to ensure that no black particle enters into the mixing drum. Salient Features : Available in Capacity 50 kg to 5000 kg. model. Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Uniform dry maxing process. The shape of container and mixing stirrer gives sufficient continuous movement to the powder / granules result in good quality. Minor ingredients are dispersed homogeneously without the need for pre-mixing Double or triple action with blending occurring in the small voided areas immediately behind the blending ribbons. The interlocked acrylic covers of product container, enclosed drive& Overloads relay protection. Optional Features : Orientation of discharge is in side or centre. AC Frequency Drive with Variable speed, Jacketing for heating & Cooling, Vacuumized operation. PLC controls with HMI Touch Screen. Flame Proof Electrical. Safety Features : Total drive transmission system enclosed Limit switch installed in the top lid ensure lid is closed Overload relay Protection and Emergency stop button

Conta Blender

Get Price Quote

Bin blenders or Container tumblers are used mainly for blending of dry powders for tablet production and capsule, which facilitates better flow for tablets and capsules. This is a closed contained, totally dust free single step transfer system. It can handle more than one size of container tumblers. In granulation room the dry granules enter to the IBC container for blending through a dust free connection and the same IBC container is loaded over to the blender for blending. The IBC bin locked in the resting frame in 15° then lifted by hydraulic system in 15° inclined position after that the IBC bin rotates for blending with 3 dimension action. This same container after blending loaded over the tablet press for unloading in to the tablet press hoppers.

Reaction Blender

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of reaction blender to Mixing machinery.The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

Ribbon Blenders

Get Price Quote

The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of Chopper Blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon Blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.