Ribbon Blender

25,000 - 500,000 Per piece

1 Piece (MOQ)

Mild Steel Ribbon Blender

200,000 Per piece

1 piece (MOQ)

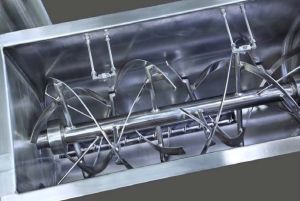

A ribbon blender mixer is a type of industrial mixing equipment used to blend powders, granules, and other bulk materials. It's known for its efficiency in achieving a uniform mix in a short period. Here's a breakdown of how it works and its key features: How It Works: Design: The blender consists of a horizontal, cylindrical shell with a ribbon-like agitator mounted inside. The ribbon agitator has two helical ribbons that rotate in opposite directions. Mixing Action: As the ribbons rotate, they move materials from the center to the outer edges and back again, creating a continuous flow that ensures thorough mixing. This action helps achieve a homogenous mixture with minimal segregation.

Best Deals from Blender

Ribbon Blender

150,000 - 380,000 Per piece

1 piece (MOQ)

The RIBBON BLENDER is ribbon mixer machine widely used for the manufacture of dry powder, talcum powder, granules, spice and low-viscosity paste and liquid in chemicals, pharmaceuticals, food and cosmetics industries. It’s especially suitable for mixing solids with solids and solids with liquids, Approximate two third of the volume of the container of Ribbon Blender/mixer is filled to ensure proper mixing. Ribbon Blender mixer is Suitable for Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, and Food industry and heat sensitive, Chemical and Cosmetic products handling large Dry and wet powder volume. It consists of a horizontal “U” Vessel with horizontally installed shaft. Hexacon Enterprises make Horizontal Ribbon Blenders is an high efficient and versatile blending machines for mixing of dry powder, granule and viscous paste homogeneously. Ribbon blender mixer to given perfect r mixing due to the innovative designs of spiral agitators inside of its U-shape Cone chamber. Ribbon blender with Screw conveyor , ribbon blender with bin , ribbon blender with sifter , ribbon blender with product transfer input and output , liquid spray systems, working plat form with variable speed drive or PLC base operation we offer as per customer product and process , Horizontal ribbon mixers range from 50-25000L or more capacity as per requested by customer . Ribbon blender and mixer with stainless steel construction or Mild steel construction main body with stainless steel U shape mixer with bottom product discharge manual and auto valve , control panel , product bin etc we offering as per customer demand for wide industreis Food, Cosmetic, Waterproof Porcelain Glazed Polished Vitrified Tile Strong Adhesive, Floor Adhesive /Ceramic, Chemical, Plastic , Dry Powder, Putty, Modified Corn Starch, Real Stone Paint, Animal feed, Pharmaceutical, Fertilizer, Plastic, Battery etc…… We offer Quality with best mixer machines, mixing machine, blender, powder mixer manufacturers and suppliers by Shree Bhagwati Group of companies. RIBBON Mixers has been developed with advanced technology to achieve high blending capabilities and is among the most efficient machines in the market. The ribbon mixing equipment can be used in either the batch or continuous flow form to achieve an even and homogeneous blend in a wide range of products. The blending technology is widely used in industries such as pharmaceutical industries, food processing, animal feed processing, chemical, fertilizers, cosmetics, pigments, and also insecticides manufacturing. The vertical blender mixer is also important in the process of distribution of liquids and pasty products in micro dosages on to carriers. Capacity FROM 50 LITERS TO 15000 LITERS The ribbon blender machine comprises of a horizontal U shaped trough and a specially developed a double helical, fabricated ribbon agitator that rotates within the trough. The machine design is based on a proven agitator technology that efficiently achieves triple mixing action and ensures fast and efficient blending. The equipment dimensions and design of the operating parts are well balanced to provide balanced material movement within the container and avoids dead spots while rapidly discharging the product. The ribbon mixer machine is made with user friendly features such as wear resistance, corrosion resistant, vacuum filling and discharge arrangements, special shaft seals, heating and cooling jackets and in a variety of sizes and models for specialized applications. The operating capacity of the ribbon blender mixer ranges from 100 liters up to 8000 liters capacity, and it is constructed with stainless steel for maximum durability.

700 Kg Double Cone Blender

250,000 Per Piece

1 Piece (MOQ)

v cone blender

225,000 - 785,000 Per Piece

1 Piece(s) (MOQ)

Ribbon Blender

Get Price Quote

The RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximate two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. Material should be charge from the top side. There are port/ports should be provided on the top cover to charge the material as well as for air vent. One discharge valve provided at the bottom side at center of the container. The discharge height could be adjust as per the requirement, so that material gets discharge in the other container directly, so that material handling time for discharge is nil and the operation is dust free In Ribbon Blender the powder moves from center to the end of container and end of container to the center of container. Hence requirement of total mixing time is very less and the RPM required are also very less. The dry material gets sufficient continuous movement due to the shape & movement of ribbon & shape of the container. Which moves material for good quality of blending? The unit is consist of one electrical motor, one worm reduction gear, belt drive between motor and gear, couple drive between gear to ( ribbon ) mixing stirrer. Container having four nos. of legs with discharge valve & top cover. Both end of mixing shaft is sealed with bush & PTFE gland housing & safety guards are provided on all moving parts.

cage blender

Get Price Quote

All type of Blenders are available for Mixing i.e. Octagonal Shape, V Shape, Double Cone, Cage, Cone & Ribbon Blender in the MOC of Contact Parts S.S.316.

Stainless Steel Ribbon Blender

Get Price Quote

From Gujarat (India), we are a prominent Manufacturer, Exporter and Supplier of Stainless Steel Ribbon Blender. Our team of experts ensures the Ribbon Blenders are fabricated using the best quality stainless steel, as per the global quality standards. These SS Ribbon Blenders are known for their high performance and low maintenance. In order to meet the urgent and bulk orders of buyers, we maintain a huge stock of Stainless Steel Ribbon Blenders in our state-of-the-art warehouse.Ribbon Blender Definition : Ribbon blenders are large, specialized blenders meant for mixing materials in bulk. They are often used in food production for both animals and humans. A ribbon blender is a large trough-shaped machine with curved metal strips shaped like ribbons.How It Works The ingredients are put in the trough and the various metal ribbons mix them until they are fully incorporated with one another.Ribbon Blenders consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer helical agitators. The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. The ribbons rotate at approx. 300 fpm moves materials both radically and laterally to insure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 100% of the rated capacity of the blender.An alternate agitator is our paddle design. The paddles are positioned to move materials in opposing lateral directions and radically. The paddle design is normally applied where friable materials are being blended and when batches as small as 15% of the total capacity are going to be mixed in one blender.

Ribbon Blender

Get Price Quote

This is a universally accepted mixer which is useful for mixing, blending and reaction of solid-solid and solid-liquid materials. They are made in different sizes according to its requirement of application. It has a U shaped trough and a shaft with ribbons is rotating inside it. The ribbons have co-axial supports that provide the strength to the curved arms. The ribbons are designed and fabricated such that the particles inside the shell move freely from one corner to another one and get in close contact with each-other and thereby are mixed very well. Also the close contact enables better reactivity among them.

Ribbon Blender

560,000 Per Piece

Ribbon Blender

380,000 Per Piece

1 Piece(s) (MOQ)

The Mahavir ribbon blender are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the Mahavir ribbon blender can in corporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon blender is available in sizes 100-8000 litters in Stainless Steel 304, Stainless Steel 316 and Mild Steel Construction.

Ribbon Blender

Get Price Quote

We are offering ribbon blender we have a state-of-the-art manufacturing facility, which helps us providing our clients with ribbon blenders. Ribbon blenders available size from 200 mm diameter to 2500 mm diameter in mild steel & stainless steel.

Reaction Blender

Get Price Quote

We offer reaction blender. The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

Double Cone Blender

Get Price Quote

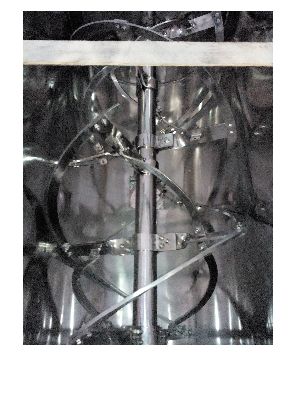

Operation: The Double Cone Blender Is An Efficient And Versatile Machine For Mixing Dry Powder And Granules Homogeneously. Two Third Of The Volume Of The Cone Blender Is Filled To Ensure Proper Mixing. Double Cone Blender Can Be Used For Pharmaceutical, Food, Chemical And Cosmetic Products Etc. Capacity: Our Double Cone Blender Is Available In 10 Kg., 25 Kgs., 50 Kgs., 100 Kgs., 200 Kgs., 300 Kgs., 500 Kgs. Capacity Salient Features: All Moving Parts Of Double Cone Blender Are Covered With SS304 Covers Safety Guards Made From SS304 Pipes Provided In Front Of The M/c. Panel Of Double Cone Blender Is Fabricated From SS304 Material With Facility Of Three Phase Indication, D.O.L. Tarter, Digital Timer & Amp Meter. As Per Customer Requirement Double Cone Blender Machine Will Be Provided With Left Side Drive Or With Right Side Drive. The Conical Shape At Both Ends Enables Uniform Mixing And Easy Discharge All Contact Parts Are Made Out Of SS304/316(as Per Customer Requirement) Quality Material Maximum Care Has Been Taken To Ensure Safe Operation Of The Unit. Food Grade Rubber Gasket Will Be Used On Both Ends Of Cone As Well As In Butterfly Valve. Inside & Outside Of The Double Cone Blender's Cone Will Be Polished To The Mirror Finished. (All Safety Guards & Covers Made Out Of SS304 In GMP Model As Required By You) In GMP Model The Conical Shape Of Both Ends Enables Uniform Mixing And Easy Discharge Suitable Size Of Butter Fly Valve At One End Of The Cone Provided For Material Discharge & Hole With Open Able Cover Provided At Other End Of The Cone For Material Charging & Cleaning. One Shaft With 03 Nos. Of Fixed/ Detachable Buffers With Mirror Polished Provided Inside The Cone.

Double Cone Blender

Get Price Quote

We offer highly efficient Double Cone Blender in the international market. The Industrial Double Cone Blender manufactured by us is used for blending with whirling blades for chopping, mixing, or liquefying materials. The output capacity of our blenders depends on the materials to be used. Besides, we are one of the prime Double Cone Blender Machine Manufacturers in India.

Ribbon Blender

Get Price Quote

Ribbon blender is used for uniform, homogeneous and quick mixing of powders and semi-wet materials of different densities by specially designed helical ribbon agitator. It can be used for Pharmaceutical, Food, Chemical, Dyestuffs & Pigment etc. For Pharmaceutical Industries, Ribbon Blender is called as Mass Mixture. Uni-Mech manufactures Continuous type and Batch type Ribbon Blenders. Uni-Mech also designs Ribbon Blenders for Chemical Reactions with Heating & Cooling applications. Ribbon Blender Design Range : Capacity range: 5 liters to 15000 liters Material of Construction: Various grades of Stainless Steel, Mild Steel, Hastelloy (cGMP model is also available). Special Features : Homogeneous Mixing Dust Free Operation Easy Handling & Operations Top Charging & Bottom Discharge through Butterfly Valve / Sliding Gate

chemical blenders

250,000 - 5,000,000 Per Piece

1 Piece (MOQ)

Double Cone Blender

Get Price Quote

The double cone blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as healthcare, food, chemical, cosmetics, detergents, fertilizers and plastics. Product Description Ideal for Mixing of powder and homogeneous lubrication of granules. Double cone blender is provide safety guard with limit switch interlocked to motor For higher capacity model. Available capacity 5 kg. to 1000 kgs. Automatic loading & unloading facilities provided. All parts made it S.S material is used for ss304 / 316 / 316L. It can be used to pharmaceutical,food,chemical and cosmetic product

octagon blender

Get Price Quote

In keeping with our theme of client satisfaction, we are offering Octagonal Blender. Octagonal Blender is considered to be high effective blending machine. It could efficiently mix dry granules and apply lubrication process with ease. This Octagonal Blender is proven for its reliable performance. Owing to its octagonal shape, it could easily process large volume of material in comparison to V and double coned blenders.

gravimetric blender

200,000 - 700,000 Per NOS

1 Nos (MOQ)