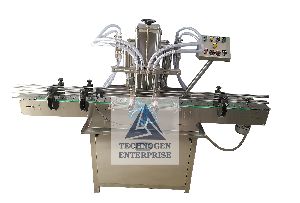

automatic oil bottle filling machine

575,000 - 1,250,000 Per pcs

1 pc (MOQ)

The Electronic PLC Based Filling Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of filling for glass, plastic or Aluminum bottles. The flow of liquid is measured and converted in to electronic signals being controlled by plc base circuitry. Minimum adjustment required to set different capacities from 500ml to 5 Ltr with varying containers. The entire range can be set on the same machine without any change parts with help of servo pulses.

Automatic Monoblock Bottle Filling

Get Price Quote

Best Deals from Bottle Filling Machine

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Bottle Filling Machine

41,000 Per piece

bottle filling capping machine

Get Price Quote

We are betrothed in manufacturing and supplying Automatic Bottle Rinsing Filling and Capping Machine that proffers quick and excellent performance in capping of bottles. This machine is accurately manufactured under the guidance of our experts in comply with industry norms. To prove high quality this machine, various tests are carried out on adverse conditions by our quality controllers. Furthermore, this is made available in varied technical specifications at affordable prices. Product details : Brand : NPM Capacity: 24 TO 60 BOTTLE PER HOUR Power Consumption 7 hp Voltage 220 V AC Electric Features : Brand: NPM High quality Bottle Capacity: 200 ml to 2 Liter.

PET Bottle Filling Machine

700,000 Per unit

1 unit (MOQ)

the application benefits are described below. features 1) bottle holding transmission & all star wheels below the neck - the bottle conveyance is stable; very convenient and swift to use different bottles for filling in the same machine by adjusting the height of conveyor and several exchanging parts. 2) instruction & indications systems are included. 3) all machine parts are made of cnc / vmc machine. 4) machine is controlled by plc and frequency convertor. 5) filling water tank low & high level inter lock. 6) machine is made of high quality ss 304 (jindal). 7) no. Bottle / no. Rinse 8) high flow nozzle with level controller 9) torque adjestable capping assembly 10) ss cap elevator hooper 11) ss infeed air conveyor with hepa air filter 12) ss outfeed conveyor with rotomotive gear box motor

Automatic Volumetric Liquid Bottle Filling Machine

180,000 - 500,000 Per Piece

1 Piece (MOQ)

The Automatic Volumetric Liquid Filling Machine comprises the main structure, product transmission belt with an adjustable guide, safety acrylic cover (OPTIONAL), Pneumatic/mechanical bottle stopping facility, nozzle & syringes, electrical panel, motor, sensor, AC drive and mains for On/Off function. . Salient Features Robust and vibration free design Minimum changeover time Compact & versatile design Easy to clean Suitable for different volumes Application Bottle/ Vail Filling Industry Pharmaceuticals Veterinary FMCG Cosmetics Biotechnology

Bottle Filling Machine

200,000 - 500,000 Per Bag

1 Piece (MOQ)

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Automatic Bottle Filling Machine for Shampoo, Lotion ,Gel ,Hair oil ,Perfume ,Beverages ,Juice ,Wine ,Liquid Soap ,Lubricant oil ,Engine oil ,Cleaning chemical Hazardous liquid ,Acid etc.work on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, of S.S Slat Conveyor, Reciprocating Nozzle with self-cantering devices & SS Syringe. No container the main drive of the machine and conveyor drive consist of A/C Motor with synchronized variable A/c Frequency drive. Containers moving on S.S. Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for cantering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling. The dosing block with a hexagonal bolt fitted below syringes. This means fill size can be easily set.

Bottle Filling Machine

275,000 Per Piece

1 Piece(s) (MOQ)

Automatic Bottle Filling Machine

Get Price Quote

With higher efficiency and reliability, our Automatic Bottle Filling Machines are taking over the countrywide market. These machines are fabricated from premium materials, in compliance with the international standards. They are further quality tested and assured. And durability and longevity are the add-on benefits that our buyers can avail themselves of. We are emerging as the promising Manufacturer and Supplier of Automatic Bottle Filling Machines in Gujarat.

Semi Automatic Bottle Filling Machine

Get Price Quote

The unit is made compact, enclosed in stainless steel elegantly mate mirror finished body. The unit consists of S.S. filling nozzle , S.S. Syringes, Cam operated Syringes will draw correct volume of liquid and deliver it through tubes to nozzle. Rigid vibration free construction for trouble free performance, S.S.Covers parts for Longer life and good house keeping. Elegant and easy reach on off switch for total control on operation. Output: 8 to 10 bottles per minute

Mineral Water Bottle Filling Machine

950,000 Per Piece

1 Piece(s) (MOQ)

Automatic Liquid Bottle Filling Machine

Get Price Quote

Mix Pickle Bottle Filling Machine

Get Price Quote

This is the Viscous Liquid Filling machine for Cream Filling machine, Lotions Filling machine, Pre-cooked curries Filling machine , Masala Pastes Filling machine, Pickles Filling machine with four filling heads (it has 2-24 piece heads to meet the manufacture’s required). It is piston type dosing pump control automatic line work. This series of machine fill liquidpaste materials of fixed quantity. It is widely used in the industries of food, medicine, cosmetics, oil and chemistry because their components contacting your materials are made of stainless steel 304 with anti-rust and corrosion resistance. You can use this machine for filling juice, beverage, grease, alcohol, pesticide, glue, and still other materials. This machine has compact and reasonable design, simple but nice appearance with easy maintenance. It is suitable to any kind of bottle and user friendly. It has

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Liquid Bottle Filling Machine

Get Price Quote

he liquid bottle filing machine is used for the filling of free flowing liquids in the in bottles, cans, jars and tubes. The Oral Liquid filling machine is suitable for filling 1ml to 5000 ml of any liquid. The Liquid Bottle Filler operates on the principle of volumetric filling. The machine is also known as the volumetric liquid bottle filling machine and is used for the filling of milk filling, shampoo filling, juice filling, liquor filling, perfume filling in the food cosmetic, beverage and Pharmaceutical industries. The Syrup Bottle Filling Machine works on a volumetric standard and has plunging filling nozzles for the filling of liquid into containers. The pharmaceutical liquid bottle filling machine has a vibration free structure. It has a diving nozzle systems for foam free filling and piston pump filling. The machine is equipped with a No Bottle No Filling" machine stop mechanism which stops the machine automatically when there is no bottle in the line. Process of operation The bottles are carried by a stainless steel conveyor belt under the filling nozzles with the help of stopper system. The reciprocating filling nozzles and mechanical stopper systems brings the bottles below the filling nozzles in the accurate position to avoid the wastage ans spillage of liquids outside the bottles. The filling nozzles fills the liquid perfectly according to the amount to be filled. A hexagonal stud stops the filling when the required amount is filled. Salient features In feed & Out feed turn table Piston pump filling mechanism Foam free filling with Diving nozzle systems for "No Bottle No Filling” system Protection clutch mounted to avoid overcrowding Linear left to right direction Suitable for filling all type of glass, plastic bottles and other round bottles On line mechanism

Liquid Bottle Filling Machine

Get Price Quote

Liquid Bottle Filling And Capping Machine (Monoblock) Harsiddh Monoblock liquid bottle filling and capping machine incorporates two packaging operations in a single stage and is therefore more economical, versatile and suitable for busy production centers. They have high production output that ranges between 30 -100 bottles per minute depends on the type of model selection and can fill containers ranging from 30-1000ml. The operation of the machines starts with unscrambling of the bottles in a round turn table before they are feed to a conveyor for filling. The filling stage has nozzles with self centering devices that are plunged to container and achieve very accurate fill. Foam free filling is achieved using nozzles that rise up during the operation. Our equipments follow the international standards and have CE certification. The equipment is assembled from high quality materials such as SS 316 for all contact parts and SS 304 for other parts. The machine uses modern control technologies that implement “no bottle–no filling” and “no caps–no capping system”. In addition, the motor has variable speed control and all parts are driven by a single motor. After filling, the bottle passes to the capping section where they are sealed. Special flow meters are used to record the fluid flow while other sensors record the number of bottles. Silent Features The machine contact parts are composed of SS316 material. Machine is robustly made of SS 304 material. Liquid filling nozzles consist of self-centralizing device. Conveyor belts are made of stainless steel. The controlled nozzles assure foam less liquid filling. Equipped with in feed and out feed for bottles. Variable AC drives to allow speed adjustments. Consumes less power and cost. Negligible chance of external dust or particles since bottles do not travel between filling and sealing. cGMP model Left to right direction No Bottle No Filling Machine stop system Single platform structure both for filling and capping that reduce the space Unbending trembling free structure for trouble free performance Stainless Steel gracefully matt finish body Direction type vibrating bowl for caps Minimum change over time Smooth and Noise free conveying Bottle stopping arrangement through pneumatic as well as mechanical systems Separately VFD drive for un-scrambler, machine main and conveyor motor

Bottle Filling Machine

170,000 Per Piece

1 Piece(s) (MOQ)

Available with2*/4/6/8/12 heads attachment Works on Syringe Base Piston Able to fill Water/Oil/Phenyl/Agrochemicals/Shampoo/Pharmachemicals into any size and shape of container Available in SS304. SS316, GMP Models Quick changeover facility from one container to other Easy and accurate adjustments of fill desired quantity Made up of hygienic materials for hygienic filling Maximum tilling accuracy: +/- 2-4% by weight output of20-50-100 bottles/min. Compatible with other filling equipments Variable speed drive for output control can be provided if required. Maximum output in minimum possible time Adjustable and space saving Low power consumption Flawless performance Compatible with the online machines zone such as capper, induction sealer, cartonator, washer, labeler etc filling size - 10-30 ml , 30-100ml , 50-150 ml -100-250ml and 500-1000 ml Automatic Grade Automatic Model No. SEALFM-40 Capacity (bottles/min) 40 Driven Type Electric, Mechanical Dimension(L*W*H) 2000*1000*800 Power Consumption (Kw) 2KW Voltage (V) 230 Brand Shiv Engineering 1) Volumetric pneumatic - Piston Filling Technology. 2) Fills Pharma Liquid,Pesticides,Oil,Water,Lubricants,Shampoo,Hand wash etc. 3) Special heat resistant cylinders and jacketed hopper for hot filling. 4) Fills from 100ml to 1000ml and upto 10liters with maximum accuracy. 5) Special stirrer in the hopper. 6) No change parts and very less maintenance. 7) PLC control system. 8) Diving Nozzle Mechanism avoids foaming and spillage. 9) Anti-drip system helps in keeping the filling area clean. Features : Eazy to operate. Accurate dimension. Maintenance.

Rotary Bottle Rinsing Filling Cappine Machine

Get Price Quote

This is high standard advance Touch Screen PLC base Rotary Rinsing Filling Capping Machine. This machine mainly used for washing, filling and capping of Non-Aerated Drink such as Mineral water, Pure Water, Non-Gas Wine Drink, Synthetic Flavoured Juice and so on. The Machine design is shorten the time for the packaging of Pet Bottle, Outside contamination and increased the sanitation condition through out the machine and economical too. It adopts neck holding type conveying-bottle structure to make changing bottle model more convenient, faster and more est. The main machine adopts advanced PLC control technology.