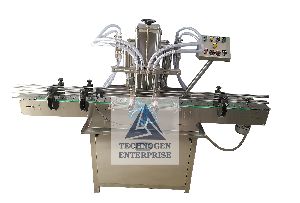

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Food Oil Bottle Filling Machine

Get Price Quote

Best Deals from Bottle Filling Machine

Edible Oil Bottle Filling Machine

280,000 - 450,000 Per pcs

1 pcs (MOQ)

Bottle Filling Machine

41,000 Per piece

Semi-Automatic Liquid Bottle Filling Machine

Get Price Quote

We are leading manufacturer and supplier of Semi Automatic Liquid Filling Machine. We are offering them durable Semi Automatic Liquid Filling machine. The offered range of Semi Automatic Liquid Filling machine is developed by competent persons, consuming optimum grade components including updated technology. Apart from this, this range of product offered by us is examined on diverse parameters and provided with unique designs which match the requirements of customers. We are committed to delivering our assignments within given time frame using customised packaging. Product details : Grade Semi-Automatic Condition New Machine Capacity 700-1000 bottles/Hour Driven Type Electric Power Consumption 1-2 HP

Bottle Filling Machine

275,000 Per Piece

1 Piece(s) (MOQ)

pickle bottle filling machine

Get Price Quote

Fill all type of Hard shell pickle. High capable of cutting any hard shell during filling. PLC control system. Available from 100gm to 1kg with single stoke. 5Kgs. Filled by multi stoke. Volumatric pneumatic Piston filling machine. Pickle transfer pump to load pickle from grould level to machine Hopper. Romming device to remove entrapped air by ramming the pickle in five different vertical axes. Special Rotating stirrer in Hopper. Available accessories like Airjet Vaccum cleaningBottle cleaning system UV chamberNitrogen flusing can be attached in the machine. Available Heat resistant cylinder, chemical resistant and Jacked Hopper for Hot filling.

Bottle Shape Pouch Filling Sealing Machine

115,000 Per Piece

1 Piece (MOQ)

Bottle Filling Machine

200,000 - 500,000 Per Bag

1 Piece (MOQ)

Automatic Bottle Filling Machine

Get Price Quote

With higher efficiency and reliability, our Automatic Bottle Filling Machines are taking over the countrywide market. These machines are fabricated from premium materials, in compliance with the international standards. They are further quality tested and assured. And durability and longevity are the add-on benefits that our buyers can avail themselves of. We are emerging as the promising Manufacturer and Supplier of Automatic Bottle Filling Machines in Gujarat.

PET Bottle Filling Machine

700,000 Per unit

1 unit (MOQ)

the application benefits are described below. features 1) bottle holding transmission & all star wheels below the neck - the bottle conveyance is stable; very convenient and swift to use different bottles for filling in the same machine by adjusting the height of conveyor and several exchanging parts. 2) instruction & indications systems are included. 3) all machine parts are made of cnc / vmc machine. 4) machine is controlled by plc and frequency convertor. 5) filling water tank low & high level inter lock. 6) machine is made of high quality ss 304 (jindal). 7) no. Bottle / no. Rinse 8) high flow nozzle with level controller 9) torque adjestable capping assembly 10) ss cap elevator hooper 11) ss infeed air conveyor with hepa air filter 12) ss outfeed conveyor with rotomotive gear box motor

Bottle Filling Machine

170,000 Per Piece

1 Piece(s) (MOQ)

Available with2*/4/6/8/12 heads attachment Works on Syringe Base Piston Able to fill Water/Oil/Phenyl/Agrochemicals/Shampoo/Pharmachemicals into any size and shape of container Available in SS304. SS316, GMP Models Quick changeover facility from one container to other Easy and accurate adjustments of fill desired quantity Made up of hygienic materials for hygienic filling Maximum tilling accuracy: +/- 2-4% by weight output of20-50-100 bottles/min. Compatible with other filling equipments Variable speed drive for output control can be provided if required. Maximum output in minimum possible time Adjustable and space saving Low power consumption Flawless performance Compatible with the online machines zone such as capper, induction sealer, cartonator, washer, labeler etc filling size - 10-30 ml , 30-100ml , 50-150 ml -100-250ml and 500-1000 ml Automatic Grade Automatic Model No. SEALFM-40 Capacity (bottles/min) 40 Driven Type Electric, Mechanical Dimension(L*W*H) 2000*1000*800 Power Consumption (Kw) 2KW Voltage (V) 230 Brand Shiv Engineering 1) Volumetric pneumatic - Piston Filling Technology. 2) Fills Pharma Liquid,Pesticides,Oil,Water,Lubricants,Shampoo,Hand wash etc. 3) Special heat resistant cylinders and jacketed hopper for hot filling. 4) Fills from 100ml to 1000ml and upto 10liters with maximum accuracy. 5) Special stirrer in the hopper. 6) No change parts and very less maintenance. 7) PLC control system. 8) Diving Nozzle Mechanism avoids foaming and spillage. 9) Anti-drip system helps in keeping the filling area clean. Features : Eazy to operate. Accurate dimension. Maintenance.

Automatic Monoblock Bottle Filling & Capping Machine

Get Price Quote

ompact GMP model. “No Bottle - No Filling” system. Single Operator for two operations. All contact parts made of AISI SS 316 material with easy removal system for easy cleaning. Machine construction in AISI SS 304 material. Infeed turn table for automatic feeding of bottles. Diving Nozzle for Foam free filling. Very High Fill Accuracy. Automatic In-feed and Exit of Bottles. Minimum Change Over time. Variable AC frequency drive for speed adjustment. Digital bottle counter for counting production output.

Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES No Bottle - No Fill System, No Bottle - Machine Stop System. All contact parts made of SS316 material with easy removal system for Autoclaving/Sterilization/Cleaning.. Machine construction in SS 304 material. Diving Nozzle for Foam free filling. Very High Fill Accuracy. Automatic In-feed and Exit of Bottles. Minimum Change Over time. Unique Free Spinning Bottle Separator- No pneumatic operation. Built-in A.C. Variable Frequency Drive System. TECHNICAL SPECIFICATION Product Rate : 120 to 200 Containers/Min (Two Head)60 to 100 Containers/Min (Four Head)90 to 150 Containers/Min. (Six Head)30 to 60 Containers/Min (Eight Head) Power Specification : 2 H.P., 3 Phase, 4 Wire System, 50 Hz. Filling Range : 30 ml to 1000 ml with the help of suitable change parts. Optional Accessories : Programmable Logic Control (System) with MMIAluminum Profile Cabinet covering full machine Overall Dimension : 1830mm (L) X 900mm (W) X 1680mm (H)Net Weight: 650 Kgs Gross Weight: 875 Kgs

5 Gallong Bottle Rinsing Filling Capping Machine

Get Price Quote

Functions of 5 Gallon Filling Machine: 1. High safety operation: automatic break protection for power leakage and short circuit;2. Under-pressure protection: when the pressure of incoming air is ≦0.5MPa, the filling equipment will automatically stop;3. Water-shortage protection: when the level of the water tank is lower than that of the liquid switch, the 5 gallon filling machine will stop working automatically. Remarks: More functions for our 5 gallon filling machines like hot tank heating washing, bottle external washing, bottle cap washing and human-computer interface control etc. could be provided upon request.

Liquid Bottle Filling Machine

Get Price Quote

he liquid bottle filing machine is used for the filling of free flowing liquids in the in bottles, cans, jars and tubes. The Oral Liquid filling machine is suitable for filling 1ml to 5000 ml of any liquid. The Liquid Bottle Filler operates on the principle of volumetric filling. The machine is also known as the volumetric liquid bottle filling machine and is used for the filling of milk filling, shampoo filling, juice filling, liquor filling, perfume filling in the food cosmetic, beverage and Pharmaceutical industries. The Syrup Bottle Filling Machine works on a volumetric standard and has plunging filling nozzles for the filling of liquid into containers. The pharmaceutical liquid bottle filling machine has a vibration free structure. It has a diving nozzle systems for foam free filling and piston pump filling. The machine is equipped with a No Bottle No Filling" machine stop mechanism which stops the machine automatically when there is no bottle in the line. Process of operation The bottles are carried by a stainless steel conveyor belt under the filling nozzles with the help of stopper system. The reciprocating filling nozzles and mechanical stopper systems brings the bottles below the filling nozzles in the accurate position to avoid the wastage ans spillage of liquids outside the bottles. The filling nozzles fills the liquid perfectly according to the amount to be filled. A hexagonal stud stops the filling when the required amount is filled. Salient features In feed & Out feed turn table Piston pump filling mechanism Foam free filling with Diving nozzle systems for "No Bottle No Filling” system Protection clutch mounted to avoid overcrowding Linear left to right direction Suitable for filling all type of glass, plastic bottles and other round bottles On line mechanism

Rotary Bottle Filling And Capping Machine

Get Price Quote

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

we are offering automatic volumetric liquid bottle filling machine, filling accuracy on single dose. rigid vibration free construction for trouble free performance. s.s. elegantly matt finished body. elegant and easy control panel for total control on operation. minimum change over time , from one size to another container or fill size. reciprocating filling nozzle with self centring device to avoid foaming. the unit is made compact & versatile -as per gmp norms. no container no filling system-to avoid spillage. synchronised a.c. drives for conveyour & main drive. technical specification model no dalf-100 (4 head) dalf-150 (6 head) outputhour* 2500 to 6000 3500 to 9000 electric motor main machine 1 hp 440 volts 3 phase 50 (four wire) conveyor 0.5 hp 440 volts 3 phase 50 (four wire) container size ø 30 mm to ø 100 mm, maximum height 210 mm fill size 10 ml. to 500 ml. (with the help of required change part) overall dimension 2035mm (l) x 1050mm (w) x 1400mm (h) *note : depending on nature of liquid & fill size.

Liquid Bottel Filling Machine

Get Price Quote

water bottle filling machine

Get Price Quote

Automatic rinser: