Bottle Filling Machine

41,000 Per piece

PET Bottle Filling Machine

260,000 - 440,000 Per piece

1 piece (MOQ)

Best Deals from Bottle Filling Machine

Bottle Filling & Capping Machine

225,000 Per Piece

1 Piece (MOQ)

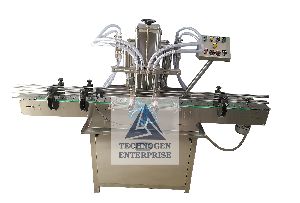

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Bottle Filling Machine

375,000 - 3,200,000 Per Piece

1 Piece (MOQ)

Hair Oil Bottle Filling Machine

360,000 Per Piece

1 Piece (MOQ)

Edible Oil Bottle Filling Machine

280,000 - 450,000 Per pcs

1 pcs (MOQ)

Glass Bottle Filling Machine

225,000 - 235,000 Per Piece

1 Piece (MOQ)

Automatic SB-ACCUFILL Liquid Bottle Filling Machine

Get Price Quote

Automatic SB-ACCUFILL liquid bottle filling machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine. Machine works on volume=time technology and speed=flow rate. The unit is made compact, versatile and SS Body. No container no filling system arrangement is standard features of the machine. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body. OPERATION : Containers moving on SS Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling. No container No filling system arrangement is standard features of the machine. The main drive of the machine and conveyor drive consist of AC Motor with synchronized variable AC Frequency Drive. The two knobs provided to set fill volume; this means fill size can be easily set. SALIENT FEATURES Accuracy ± 0.5 % in single doze. No change parts require. Different speeds can be set, depending on fill volume and foaming nature of material Body covered with SS sheet. All contact parts silicon tubing. A unit to fill variety of liquid and can be used for various type of containers. No dripping or last drop problem. No contamination. No maintenance required. No bottle no filling system. Facility provided for the fine tuning of the volume. Inbuilt protection against over current, voltage fluctuation, short circuit in ac frequency drive. Ideal for aseptic, sheer sensitive, viscous, and corrosive liquids also.

PET Bottle Filling Machine

500,000 Per

1 Piece (MOQ)

Bottle Filling Machine

600,000 - 700,000 Per piece

1 piece (MOQ)

Bottle Filling Machine

275,000 Per Piece

1 Piece(s) (MOQ)

Bottle Filling Machine

200,000 - 500,000 Per Bag

1 Piece (MOQ)

Liquid Bottle Filling Machine

Get Price Quote

With our emphasis on quality and innovation, we manufacture superior quality a Automatic Liquid Bottle Filling Machines. These machines are technologically advanced and acknowledged amidst our clients for their operational efficiency. Complying with set industrial benchmarks, these bottle filling machines are available in both standard and customized specifications alike. Product details : Grade Automatic Machine Capacity 30 to 120 bottles/min Driven Type Electric Power Consumption 1-2 HPc Material Stainless Steel Phase Single Phase Bottle size 10 ml to 1000 ml Voltage 240 V Salient features : No Bottle No Filling System Vibration free Construction for Trouble-free performance S.S Matt Finished Digital Counter For Counting Of Bottles AC Frequency Drive Direction of machine is left to right

Multipack Sauce Bottle Filling Machine

Get Price Quote

Automatic Eight Head Liquid Bottle Filling Machine

Get Price Quote

PET Bottle Filling Machine

700,000 Per unit

1 unit (MOQ)

the application benefits are described below. features 1) bottle holding transmission & all star wheels below the neck - the bottle conveyance is stable; very convenient and swift to use different bottles for filling in the same machine by adjusting the height of conveyor and several exchanging parts. 2) instruction & indications systems are included. 3) all machine parts are made of cnc / vmc machine. 4) machine is controlled by plc and frequency convertor. 5) filling water tank low & high level inter lock. 6) machine is made of high quality ss 304 (jindal). 7) no. Bottle / no. Rinse 8) high flow nozzle with level controller 9) torque adjestable capping assembly 10) ss cap elevator hooper 11) ss infeed air conveyor with hepa air filter 12) ss outfeed conveyor with rotomotive gear box motor

Automatic Volumetric Liquid Bottle Filling Machine

180,000 - 500,000 Per Piece

1 Piece (MOQ)

The Automatic Volumetric Liquid Filling Machine comprises the main structure, product transmission belt with an adjustable guide, safety acrylic cover (OPTIONAL), Pneumatic/mechanical bottle stopping facility, nozzle & syringes, electrical panel, motor, sensor, AC drive and mains for On/Off function. . Salient Features Robust and vibration free design Minimum changeover time Compact & versatile design Easy to clean Suitable for different volumes Application Bottle/ Vail Filling Industry Pharmaceuticals Veterinary FMCG Cosmetics Biotechnology

Automatic Bottle Filling Machine

Get Price Quote

With higher efficiency and reliability, our Automatic Bottle Filling Machines are taking over the countrywide market. These machines are fabricated from premium materials, in compliance with the international standards. They are further quality tested and assured. And durability and longevity are the add-on benefits that our buyers can avail themselves of. We are emerging as the promising Manufacturer and Supplier of Automatic Bottle Filling Machines in Gujarat.

Volumetric Bottle Filling Machine

150,000 - 650,000 Per Piece

1 Piece (MOQ)

volumetric liquid filling machine is compact, versatile and enclosed in elegantly matt finish body. this machine provides maximum output up to 200 bottles per min. this machine model is used in pharmaceutical, food, dairy, chemical, cosmetic and beverages industry.the speed of bottle filling machines depends on nature of liquids, container diameter, container height, container neck size and filling volume. machine construction in fully stainless-steel finish including machine frame structure as per cgmp guidelines. machine with optional turn tables at in-feed and out-feed with individual drives to match the speed of incoming and outgoing bottles for smoother operation. all contact parts of machine model are stainless steel 316 only. special features: flow meter for high fill accuracy and repeatability built in plc with color touch screen operation tri-clover joint for easy maintenance no bottle - no fill system, no bottle - machine stop system all contact parts made of ss 316 material with easy removal system machine construction in ss 304 material diving nozzle for foam free filling very high fill accuracy of ± 1 to 1.5 ml for any fill volume up to 250 ml and ± 2 ml above 250 ml pack size. machine also available with option of high fill accuracy of ± 0.5 to 1 ml. suitable for syrup and suspension having higher viscosity. automatic infeed and exit of bottles minimum change over time unique free spinning bottle separator- no pneumatic operation built-in a.c. variable freq. drive system.

Bottle Filling Machine

Get Price Quote

We manufacture and supply highly efficient bottle filling machine. The offered machine is widely used to fill bottles with varying capacities in various industries. Further, this machine is manufactured using quality stainless steel that gives it longer service life. This user friendly machine is highly demanded among clients for its durable finish standards, reliable performance and operational efficiency. technical specifications: • filling capacity variations: 50 to 300 ml • syringe options: single/double • stainless steel body • semi automatic • electric operated.

Liquid Bottle Filling Machine

Get Price Quote

Fully Automatic Volumetric 4 Head, 6 Head and 8 Head Liquid Bottle Filling Machine with cap placement system is Suitable for filling products like Pharmaceuticals, chemicals, Pesticides, Cosmetics, Beverages etc. in Flat / Oval / Square / Round shaped products having PET, Plastic, HDPE, LDPE, Glass or any other surface. Special Features: Very High Fill Accuracy of ± 1% in Single Dose All Contact parts and Syringes made from S. S. Material - cGMP Model. S. S. Elegantly Matt Finished Body No Container No Fill system to avoid spillage Rigid vibration free construction for trouble free performance. Automatic washing of conveyor belt [optional.] Pneumatically operated bottle stopper. Outside and easy control panel for total control on operations. Diving type Filling Nozzles with self-centering device Minimum charge overtime, from one size to another container or fill size S. S. Slat conveyor

Hand Sanitizer bottle filling machine

500,000 - 1,000,000 Per Set

1 Set(s) (MOQ)

VOLUMETRIC VIAL BOTTLES FILLING MACHINE

Get Price Quote

Automatic volumatric vial bottles filling machine is working on the volumetric principle. The machine consists of diving nozzles. The machine is made up of stainless steel matt finish body. It is compact and versatile. HOW IT IS SIMPLE AND QUICK : There is a twin pneumatically operated stopper system with feed below and filling nozzles. The conveyor belt moves the container to the filling nozzles. The reciprocating nozzles and stopper system can match for centering of the container below nozzles, to avoid the wastage of the liquid. The nozzle goes upwards from the bottom level to minimize the foaming. The fill size can easily set with a hexagonal bolt, below the syringe. THE FEATURES : Very much accurate, ±1% filling accuracy. Vibration free construction Error code display The platform is provided with drain tray round it, and drip tray under the conveyor The perfect pneumatic arrangement for bottle stopping The conveyor gear box, motor and pneumatic cylinders are provided with the safety guard. To prevent from the short circuit and over load, the MCB is given. For the voltage fluctuation and short circuit in A/C frequency drive there is inbuilt protection, with machine No bottle no filing system Trouble free performance with low maintenance Easy control panel Low friction wear surface, smooth and noiseless conveying. It takes minimum time to change the apparatus The bottle height gauge is adjustable for the quick and easy setting The height of the conveyor belt is adjustable to align with other machine of the line No container no cap arrangement The single A/C drive is synchronizing the platform turret and capping bowl, conveyor and star wheel. The conveyor, star wheel and platform turret is synchronized by the single motor. The S.S. matt finished body S.S. cladding or hard chrome plating of all exposed parts. The UHMW-PE guide profile for low friction wears surface. It is self lubricating leads smooth and noiseless conveying. Depending on the gauges and size of caps, the sealing pressure can varied Noise level and power consumption are very low SPECIAL FEATURES : The washing system of automatic chain for the conveyor belt There is afloat tank( holding tank) with or without stirrer In-built pre-inspection Nitrogen flushing Acrylic cabinet The cover of the conveyor is of acrylic UTILITY REQUIREMENT : Electrical Supply : Three Phase + Neutral + EarthingElectrical Load : 2 KWAir Pressure : 6 bar pressure 0.5 CFM

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

1 Piece (MOQ)

DESCRIPTION Automatic Volumetric Liquid Bottle Filling Machine work on volumetric principle with diving nozzles. The unit is made compact,versatile and enclosed in stainless steel elegantly matt finish body, of S.S Slat Conveyor, Reciprocating Nozzle with self-centering devices & SS Syringe. No container No filling system arrangement is standard feature of the machine. The main drive of the machine and conveyor drive consist of A/C Motor with synchronized variable A/c Frequency drive. OPERATION Containers moving on S.S. Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system.The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling. The dosing block with a hexagonal bolt fitted below syringes. This means fill size can be easily set. Depends on container size, Fill size, Neck diameter of container, and container, and nature of liquid etc. We can supply as per customer requirements. With help of change parts.

Monoblock Rotary Bottle Filling Machine

Get Price Quote

Semi Digital Weigh Metric Machine

Get Price Quote

We offer semi digital weigh metric machine. Sailent features * the machine can fill namkeen, grains & pulses, tea, sugar, kurkure, frymes, chees ball etc, * s.s. Top hopper with capacity: 100 ltr. With glass window & s.s. Claded stand * delivery system: pneumatically operated solenoid cylinders connected with programmable micro controller interface.(p.l.c.) * coarse & fine filling setting given. * individual setting for course & fine filling. * after getting adjusted weight p.l.c. Gives dump signal & by that material is deliver in to pouch through funnel. * filling accuracy: + 1-2%

Automatic Bottle Filling Machine

1,500,000 Per Piece

1 Piece(s) (MOQ)

Automatic Bottle Filling Machine for Water and Juice

Get Price Quote

Bottle Filling Machine

Get Price Quote

Neck Holding No Bottle No Rinsing No Filling and No Capping Two Time Rinsing Three Stage Filling Non Contact Sensors Separate Cap Hopper Having Capacity 1000 Caps Material of Contractions contact parts SS316L rest SS304 Bottle Filling Machines 20bpm - semi auto bottle filling machine 24bpm - semi auto bottle filling machine 40bpm - Fully auto bottle filling machine 60 bpm - Fully auto bottle filling machine 90 bpm - Fully auto bottle filling machine 120 bpm - Fully auto bottle filling machine 150 bpm - Fully auto bottle filling machine