Water Bottling Machine

Get Price Quote

Located in the capital of engineering machinery, Ahmedabad (Gujarat, India) we “Shiv Shakti Enterprise” are actively committed towards manufacturing, exporting and supplying highly efficient Mineral Water Bottling Machine and Carbonated Drink Bottling Machine. Our offered machines are extensively demanded in pharmaceutical, chemical, food processing, mineral water and many more industries for filling, capping and packaging purposes. Bottling machines provided by us are fabricated in accordance with global quality standards from well tested components and sophisticated technology under the supervision of our veteran engineers. Being a quality driven company, we assure our clients that these bottling machines are rigorously checked against numerous parameters by our quality controllers. Our offered machines are well known among our clients due to their rugged design, smooth functioning, excellent performance, high efficiency, low maintenance cost and long working life. After considering clients' different needs, we provide these machines in customized options at most affordable prices within promised time frame. We mostly export our machines to Kenya, South Africa and Nepal.

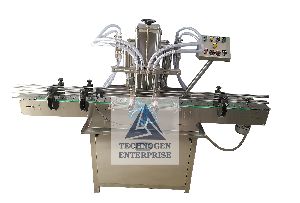

6 heads liquid bottle filling machine

Get Price Quote

Guru Techno Industries offer 2, 4, 6 headed oil filling machines for all types of oils. It fully works on volumetric principle with easy to use control panel. Oil filling machine setting and accuracy can be easily adjusted on the machine itself. It is featured with adjustable nozzles which are easily manageable and speed can be set in terms of bottle per minute. Adjustment can be made without interrupting filling sequence. Guru Techno Industries oil filling machines is used by various type oil companies for filling cooking oil, edible oil and engine oil bottles or containers. One of the features is ‘drip free nozzles’ the oil filler Machine has well designed nozzles ensuring repeat recycling of sequences. Guru Techno Industries manufactures these machines as per international standard using best quality. It is efficiently equipped with adjustable filling speed depending on the size of bottle. It has elegant and easy control panel for total control on filling operation. We can even customize machineries as per our clients depending on their specifications and requirements. We believe in customer’s satisfaction and in long term relationships. Features The unit is made compact & versatile. SS. Elegantly matt finished body. S.S. Slat conveyor. Reciprocating filling nozzle with self centering variable A/c frequency drive device. No container No filling system.

Best Deals from Bottle Packaging Machine

Water Bottle Packing Machine

350,000 Per Set

Bottle Filling & Capping Machine

225,000 Per Piece

1 Piece (MOQ)

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Semi Automatic Tray Sealing Machine

50,000 - 1,500,000 Per piece

1 piece (MOQ)

Automatic IV Fluid Bottle Packing Line

2,800,000 Per Piece

1 Piece (MOQ)

Bottle Filling Machine

275,000 Per Piece

1 Piece(s) (MOQ)

LIQUID BOTTLES FILLING MACHINE

100,000 - 800,000 Per each

Automatic High Speed Servo Liquid Bottle Filling Machine

Get Price Quote

water bottle filling machine

Get Price Quote

Carbonated drink filling machine is suitable to fill all types of soda, carbonated drinks, beverages, soft drinks in glass as well as pet bottles.Our water plant water filling bottling machine uesd for PET bottle filling all sorts of juicewinemineral waterpure water and non-carbonated beverage, realizing rinsing filling capping in one machine.

Automatic Liquid Filling Machine

220,000 Per Piece

1 Piece(s) (MOQ)

Multipack Sauce Bottle Filling Machine

Get Price Quote

Water Bottle Packing Machine

Get Price Quote

We as a manufacturer, supplier and exporter of the Grouping machine provide comprehensive solution correlated with the packaging machinery, packaging tools and packaging materials bring forth highly efficient and continuous operation packing equipment configured by considering the thermal shrinkage property of the packaging film. Our water bottle packing machine is a good example of the implementation of advanced technology, which complies with all international standards. The machine is fully automatic in which array, aggregate and alignment of the bottles is achieved by automatic operation. In the water bottle packing machine bottles are counted by lines and rows as a preset, packed with the film and at last pass through heating tunnel where thermal shirking take place by heating, cooling and forming. The long term experience in the packaging domain enables us to produce the advanced technology based water bottle packing machine equipped with third generation sealing cutter which ensures even and longer life sealing. Furthermore adopting air circulation technology, we ensure heat insulation, high accuracy for controlling temperature and absolute packaging. The whole process of the bottle packaging machine is automatic, but to meet the requirement and budget, we offer a customization option and deliver the machine as per the customer’s specification at the leading industry rate. Core Features of Water Bottle Packing Machine: High speed perfect finishing low maintenance sturdy construction Note: We as a packaging machine manufacturer, supplier and exporter from India accept specifications from you, if any, and manufacture Water Bottle Packing Machine with your preferences at the best possible price as well as assist to determine the best machine for your application and budget.

Volumetric Bottle Filling Machine

150,000 - 650,000 Per Piece

1 Piece (MOQ)

volumetric liquid filling machine is compact, versatile and enclosed in elegantly matt finish body. this machine provides maximum output up to 200 bottles per min. this machine model is used in pharmaceutical, food, dairy, chemical, cosmetic and beverages industry.the speed of bottle filling machines depends on nature of liquids, container diameter, container height, container neck size and filling volume. machine construction in fully stainless-steel finish including machine frame structure as per cgmp guidelines. machine with optional turn tables at in-feed and out-feed with individual drives to match the speed of incoming and outgoing bottles for smoother operation. all contact parts of machine model are stainless steel 316 only. special features: flow meter for high fill accuracy and repeatability built in plc with color touch screen operation tri-clover joint for easy maintenance no bottle - no fill system, no bottle - machine stop system all contact parts made of ss 316 material with easy removal system machine construction in ss 304 material diving nozzle for foam free filling very high fill accuracy of ± 1 to 1.5 ml for any fill volume up to 250 ml and ± 2 ml above 250 ml pack size. machine also available with option of high fill accuracy of ± 0.5 to 1 ml. suitable for syrup and suspension having higher viscosity. automatic infeed and exit of bottles minimum change over time unique free spinning bottle separator- no pneumatic operation built-in a.c. variable freq. drive system.

Automatic Liquid Filling Machine

600,000 Per Piece

Automatic Liquid Filling Machine

Get Price Quote

As a dependable name, we source raw materials from the well-known providers who are certified. Thus, we guarantee only quality-approved products at customer's end. Owing to our expertise in the domain, we are able to supply excellent quality Automatic Liquid Filling Machine at very reasonable price. Features : Filling Accuracy on Single dose. Rigid vibration free construction for trouble free performance. S.S. elegantly matt finished body. Elegant and easy control panel for total control on an operation. Minimum change over time , from one size to another container or fill size. Reciprocating Filling nozzle with the self-centering device to avoid foaming. The unit is made compact & versatile -as per GMP norms. No container No Filling system to avoid Spillage. Synchronized A.C. drives for conveyor & main drive. Model no DALF- 100 (4 head) DALF-150 (6 head) Output/hour- 2500 to 6000 3500 to 9000 Electric motor - main machine 1 hp / 440 volts / 3 phase / 50 (four wire) conveyor 0.5 hp / 440 volts / 3 phase / 50 (four wire) Container size ø 30 mm to ø 100 mm, maximum height 210 mm Fill size 10 ml. To 500 ml. (with the help of required change part) Overall dimension 2035mm (l) x 1050mm (w) x 1400mm (h)

Bottle Filling Machine

Get Price Quote

1 Piece(s) (MOQ)

we are offering filling machine stopring machine. Technical details power: 0.5 hp, 3 phase 1400 rpm motor 2 amp. 230 v 1 phase (vibrator coil) output: 5000 to 15000 container hour conveyor height: adjustable 750 to 900mm net weight: 650 kgs. Gross weight: 850 kgs. Overall dimensions: 1530 mm (l) x 790 mm (w) x 1700 mm (h)

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Automatic Electronic Liquid Bottle Filling Machine

Get Price Quote

Containers moving on SS Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards from bottom level of bottle towards neck during filling. The Digital filling system arrangement is standard features of the machine. The motor for filling is servo drive and conveyor drive is AC Motor with synchronized variable AC Frequency Drive. PLC Controller provided to set fill volume, speed of conveyor and set fill timing this means fill size can be easily set. Salient Features: Accuracy ± 0.8 % or 0.5Gram in single doze (Whichever is higher). No change parts require. Individual volume control for all syringes. Different speeds can be set, depending on fill volume and foaming nature of material. Body covered with SS sheet. All contact parts silicon tubing and S.S.316. A unit to fill variety of liquid and can be used for various type of containers. No dropping or last drop problem No bottle no filling system. 25 Liter Holding Tank fitted with Machine. Facility provided for the fine tuning of the volume. Inbuilt protection against over current, voltage fluctuation, short circuit in AC frequency Drive. Ideal for aseptic, sheer sensitive, viscous, and corrosive liquids also.

Bottle Filling Machine

Get Price Quote

According to recent industrial trends bottle filling machine is one of the most popular machineries catering wide range of industrial applications. It is used in varied industries for filling so many kinds of products and materials. It is used I the industries like pharmaceuticals, food processing, beverages and other. It is also one of the machineries that works with + or – 1% accuracy. It is also important while working with the liquids not to spillage or waste the liquid. To offer machinery operates with noise free and vibration free manner, we have fabricated the machine as per GMP model and also by following international norms for production and testing. It contains self lubricating system. It has low friction wear surface and high wear and tear resistance. It is provided with no bottle-no fill system. For the different size of the bottle, it takes least change over time. Necessary alarm system makes the model safe. It is provided with finger touch control with PLC based control system. Matt finished body Drain tray No spillage, no wastage User friendly S.S. cladding or hard chrome plating for the exposed parts

Semi Automatic Bottle Filling Machine

Get Price Quote

Bhagwati Semi-Automatic Liquid Filling Machine is very simple, Piston base volumetric filler. It gives very accurate volumes with remarkable speed. It is widely use in Pharmaceutical, Chemical, Paint, Cosmetic, Oil, Softdrink, Liquir Industries.

bottle packaging machine

400,000 Per Set

Bottle Filling Equipment

Get Price Quote

Bottles are feed on to in-built Infeed turn table, from where it delivered to SS conveyor belt. Conveyor belt transport bottles to filling station. Filling station has Pneumatic bottle stopper for exact bottle neck centering of bottles during filling operation. Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose. The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum use of time. After liquid filling bottles are delivered to cappinglabeling machine conveyor for further operations.

Iinjectable Liquid Filling Machine

Get Price Quote

utomatic Volumetric High Speed Six Head Bottle Liquid Filling Machine, Mode No: ALFT – 151. The machine consist of S.S. slat conveyor belt, reciprocating filling nozzle with self centering devices, S.S. – 316 Syringes, Silicon rubber tubings, easy –reach compact panel and with no container no filling system etc. It is compact, versatile. The un-scrambler has been designed in the machine to eliminate dead ends and difficult to clean spot. All its exposed parts are made of S.S. – 304. It is provided with co-eccentric nozzles, which allow quick and precise setting. Its height can be adjusted to match other machines for efficient synchronization.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES + 1% Filling Accuracy on single dose. Rigid vibration free construction for trouble free performance. S.S elegantly matt finished body. Elegant and easy control panel for total control on operation. Minimum charge overtime, from one size to another container or fill size. Automatic washing of conveyor belt[ optional. No container No filling system – to avoid spillage. Pneumatic control bottle stopper. cGMP Model.

Liquid Bottle Filling Machine

240,000 Per Piece

Mineral Water Bottling Machine

780,000 Per unit

Bottle Liquid Filling Machine

Get Price Quote

We are engaged automatic Liquid Filling Machine manufacturer and exporter in Ahmedabad, Gujarat, India. Liquid Filling Machine is used for filling of liquid products in a wide range of consumer packs with highly accurate volumetric displacement pump based system, ensuring high speed and easy changeover. Being a quality oriented organization, we are engaged in manufacturing, exporting and supplyingLiquid Filling Machine that is used for filling liquid in containers, bottles, etc. Offered machine is manufactured at our advanced manufacturing unit under the guidance of our deft professionals using the finest quality components and contemporary technology. It is suitable for filling of shampoos, lotions, syrups, sauces and oils. We offer the provided Liquid Filling Machine in differed specifications to meet the variegated requirements of our clients at rock-bottom prices.

Automatic Twin Track Eight Head Liquid Bottle Filling Machine

Get Price Quote