Mineral Water Bottling Plant

200,000 - 1,400,000 Per piece

A mineral water bottling plant is a facility where natural mineral water is collected, treated, bottled, and packaged for sale to consumers. The plant must also comply with various regulations and standards to ensure the safety and quality of the water and the packaging.

FRP RO Mineral Water Plants

500,000 - 1,500,000 Per 10000 LPH

FRP RO Plant (एफआरपी आरओ प्लांट) Manufacturers In Ahmedabad Acuapuro Water Equipment India Pvt. Ltd. is offering a high-quality & affordable price “FRP RO Plant Manufacturer” in Ahmedabad, India. We are also manufacturing a wide range of products which include pure Mineral Water Plants, FRP RO Plant for Oil Industries, Industrial RO Plant Machines, Stainless Steel RO Plants &

Best Deals from Bottling Plant

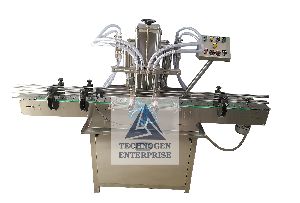

Automatic Liquid Filling Machine

Get Price Quote

As a dependable name, we source raw materials from the well-known providers who are certified. Thus, we guarantee only quality-approved products at customer's end. Owing to our expertise in the domain, we are able to supply excellent quality Automatic Liquid Filling Machine at very reasonable price. Features : Filling Accuracy on Single dose. Rigid vibration free construction for trouble free performance. S.S. elegantly matt finished body. Elegant and easy control panel for total control on an operation. Minimum change over time , from one size to another container or fill size. Reciprocating Filling nozzle with the self-centering device to avoid foaming. The unit is made compact & versatile -as per GMP norms. No container No Filling system to avoid Spillage. Synchronized A.C. drives for conveyor & main drive. Model no DALF- 100 (4 head) DALF-150 (6 head) Output/hour- 2500 to 6000 3500 to 9000 Electric motor - main machine 1 hp / 440 volts / 3 phase / 50 (four wire) conveyor 0.5 hp / 440 volts / 3 phase / 50 (four wire) Container size ø 30 mm to ø 100 mm, maximum height 210 mm Fill size 10 ml. To 500 ml. (with the help of required change part) Overall dimension 2035mm (l) x 1050mm (w) x 1400mm (h)

mineral water packing machines

Get Price Quote

We offer range of Water Pouch Filling Machines applicable in filling oil, butter milk, water liquor, milk, soft drinks and other free flowing liquids. Our Liquid Pouch Packaging Machine is highly probable in working and available in varied specifications to cater to the needs of the clients in the diverse manner.

Bottle Filling Machine

Get Price Quote

1 Piece(s) (MOQ)

we are offering filling machine stopring machine. Technical details power: 0.5 hp, 3 phase 1400 rpm motor 2 amp. 230 v 1 phase (vibrator coil) output: 5000 to 15000 container hour conveyor height: adjustable 750 to 900mm net weight: 650 kgs. Gross weight: 850 kgs. Overall dimensions: 1530 mm (l) x 790 mm (w) x 1700 mm (h)

Mineral Water Bottle Filling Machine

900,000 Per Units

Jar Automatic Rinsing Filling and Capping Machine

Get Price Quote

20 Liter's Jar Automatic Rinsing Filling & Capping Machine 240 / 360 / 480 JAR PER HOUR 1st Wash-Tap Water (Inner + Outer Wash) 2nd Wash-Hot Water(Inner Wash) 3rd Wash-Product (Mineral) Water Wash (Inner Wash) & 2nd Filing (fine Fill) 4th Pump :- 1st Filling(Course Filling) Air Require :- 7Cfm With 8Kg / Cm.square Heater :- 3kw. (1.5 Kw X 2nos.) P.L.C. With Display (H.M.I)

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Automatic Four Head Bottle Air Jet Cleaning Machine

Get Price Quote

BHAGWATI’s Automatic Vertical Air Jet Cleaning Machine work on positive air pressure & vacuum cleaning. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor & Reciprocating cleaning nozzles. No container No cleaning system arrangement is standard features of the machine. The main drive of the machine and conveyor drive consist of A/c Motor with synchronized variable A/c Frequency Drive. Automatic Vertical Air Jet Cleaning Machine can accomplish a task by a photoelectric system, all the bottle should be cleaned before being filled, when an empty bottle arrives at the specified position, a cleaner comes down automatically until at the mouth of the bottle, then pure air is pressed into the bottle, and the impurity inside of the bottle is removed by vacuum system. This product conforms to the requirements of GMP completely.

Rotary Bottle Washing Machine

Get Price Quote

Automatic Rotary Bottle Washing Machine

Get Price Quote

Packaged Drinking Water Filling Machine

Get Price Quote

Manufacturer & exporter of Automatic Liquid Filling Machine & Automatic Electronic Filling Machine. Our product range also comprises of Semi Automatic Liquid Filling Machine and Volumetric Liquid Filling Machine. Gained prominence in the industry as a reliable organization, we are engaged in providing Automatic Liquid Filling Machine. Widely demanded in food processing, beverages and dairy industries, our offered filling machines are provided in various specifications. These machines are delivered timely to gain maximum client-satisfaction.

Bottle Filling Machine

275,000 Per Piece

1 Piece(s) (MOQ)

Bottle Inspection Machine

Get Price Quote

100 Piece(s) (MOQ)

Our company is a well-known supplier of Bottle Inspection Machine in Gujarat. The Machine’s self-alignment bearing mechanism helps in its easy maintenance system. The length of this apparatus can be adjusted as per the convenience of its operator. The PVC black and white board of this product is made as per GMP norms. The essential parts of Bottle Inspection Machine include its A/C frequency variable drive, direct gear drive, UHMW self-lubrication guide. Its vibration free operating system and smooth working procedure have made the machine the most sought pharmaceutical machine in the market. As a wholesale Bottle Inspection Machine supplier in India, we offer our machines for affordable prices to our clientele.

Stainless Steel Mineral Water Plant

Get Price Quote

Mineral Water Filtration Plant

Get Price Quote

Buy the best quality Mineral Water Filtration Plant that is the perfect outcome of the best practices and the innovative techniques. As we ensure complete safety of the products at our end, we follow stringent and organized warehousing system in our state-of-the-art warehouse. Moreover, the system is supervised by experts.Features : Low maintenance Easy installation Durability Robustness

Bottle Filling Equipment

Get Price Quote

Bottles are feed on to in-built Infeed turn table, from where it delivered to SS conveyor belt. Conveyor belt transport bottles to filling station. Filling station has Pneumatic bottle stopper for exact bottle neck centering of bottles during filling operation. Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose. The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum use of time. After liquid filling bottles are delivered to cappinglabeling machine conveyor for further operations.

Liquid Bottel Filling Machine

Get Price Quote

Glass Bottle Washing Machine

Get Price Quote

What is typical bottle washing machine is comprised of ? •A rugged wall thickness provides a well-built tank base for a long-lasting life and is designed to meet the significant applications to which the equipment will be subjected. •Complete stainless steel body of 18 gauge, 316 grade water and chemical grade to prevent from contamination. •Holds with a cleaning capacity of 80 bottles per minute, depends on operator skills. •Inbuilt water heater for heating water to raise a temperature from 0* celcius to 120*celsius with sensors display to control water temperature. •Control panels with push button start for ease of operator and a protection grill. •Removal of waste water system. •Grill holder for bottles above warm water for disinfecting and for avoiding dusts into container. •0.5 hp, 900 rpm standard motor. •Three, standard nylon bristle white brush 0. 60mm with pp base or aluminum base •Brush as per bottle dimensions for effective brushing along with brush speed adjustment with the help of pulley and belt. Nissan's bottle cleaning brushes can be manufacture in different dimension as per bottle's requirments and shapes for effective brushing & cleaning thoroughly in & out. we intimate different raw materials i. E. nylon bristle and types of base i. E. Alluminium base keeping the fragility of bottles on mind, so that bottles remain unbreakable and clean while cleaning.

rotary bottle washer

Get Price Quote

Geneva Mechanism. Four inner (Included one air wash) & one outer. Sequence of washes to customer's choice. Easy operation. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading. Individual solenoid valve for each washing sequence that eliminates carbon plate and other accessories reduces leakage and maintenance to minimum. Higher capacity centrifugal pumps to wash bigger bottles (500 & 1000 ml.). (optional) The stationary nozzles avoid chipping of bottle necks.The stationary nozzles avoid chipping of bottle necks. Pumps and tanks are mounted on portable stand for easy maintenance. Bottle guide system especially for lightweight bottle. Separate panel control to avoid any short circuit due to spraying of water. S.S. glycerin filled pressure gauges.