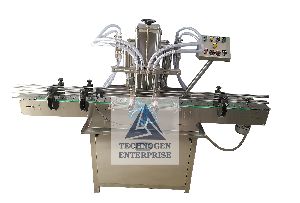

Edible Oil Bottle Filling Machine

280,000 - 450,000 Per pcs

1 pcs (MOQ)

mineral water plant

Get Price Quote

The mineral water plant uses for packaged drinking water system. It is growing business and giving the best return of investment. It is very demanding business. We provide you the best technical and commercial system to the customer for their new developments.

Best Deals from Bottling Plant

Linear Bottle Washing Machine

Get Price Quote

Description Automatic Linear Bottle Washing Machine is suitable to wash glass bottles. Machine equipped with six washing stations can be interchangeable as per specific customer’s requirements. This Linear Bottle Washer provides 3 water wash & 3 air wash for positive & pressurizing washes of bottles. All contact parts made from stainless steel 316 and non-contact parts made from stainless steel 304 materials. Bottle invert into neck down position and nozzles enters into bottle during washing cycle to meet GMP requirements. Automatic Linear Bottle Washing Machine is ideal and economic choice for online Sterile Vial Filling Line. Machine is having uses in Pharmaceutical, Cosmetic, Food, Chemical & allied industries. Salient Features A complete cGMP model All contact parts are made from high quality Stainless Steel 316L and argon arc welded All exposed parts are made from Stainless Steel 304/hard chrome plated/brass for corrosion free long life. The unit built on S.S. Square pipe frame and totally encompassed with S.S. Coverings Washing section is totally covered with acrylic cabinet. “No Container - No Washing” system. “No washing - No water supply” system. Quick change over with minimum use of tools. Variable AC frequency drive for speed adjustment. Low water consumption. Digital counter for counting production output. Fixed top nozzles at each washing station ensures external washing of vials/bottles at the same time of internal washing. Flow of washing Medias stop during the indexing of chain saves utilities. Easily cleanable & Inter changing facility. Process Operation Containers feed from the de-cartooning station are received on an In feed turn table. An in feed worm inverts container to neck down position and feeds them through a specially designed indexing device. The device carries the container forward and stops. Nozzles carrier enters into the container and activities the jet of water/air. The air/water flow is deactivated after the washing cycle is over. Device indexes the vials/bottles for next wash. A separate pumping station gives the right quantum of water at the desired pressure. Washed containers are again inverted to neck upward position to collect in out-feed tray/directly feed to tunnel.

AUTOMATIC LINEAR BOTTLE RINSING MACHINE

Get Price Quote

The Automatic Bottle Rinser Is An Ideal Companion To Automatic Bottle Filling Lines. The Bottle Rinser Can Utilize Compressed Gas To Blow Particulates Off Of The Container Or Be Used With A Sanitizing Solution Or Water To Rinse Bottles Prior To Filling. The Recovery Sink Allows The Recalculating Water Jet Pump To Recycle Sanitizing Solution To Lower Operational Costs. The Bottle Rinser Can Achieve Speeds Of Up To 40 Bottles Per Minute With A Range Of Ounces To One Gallon Without Customization. Automatic Bottle Rinser Comes Complete With An Automatic Bottle Indexing System, Soft Clasp Bottle Gripper Assembly, 4/6/8/10 Individual Rinsing Jets, Recovery Sink, Recalculating Power Pump All Based On A Heavy Duty, Stainless Steel Frame. Automatic Bottle Rinser Is A PLC Operated (Optional) Machine Controlled By An Easy To Use Operator's Alpha-numeric Display. The Bottle Rinser Can Be Used With Any Existing Conveyor And Set Up Can Be Completed In Minutes. The Versatile Components And Easy Change Over Parts Allow Bottle Changeover To Be Completed In Minutes. The "No Bottle - No Rinse" Feature Ensures That No Chemicals Or Water Is Wasted If The Bottle Rinser Work Area Is Not Full. SALIENT FEATURES:- A.C. Frequency Drive To Variable The Speed Of Conveyor And Machine No Bottle No Rinsing System Easy Container Changeover For Use With Multiple Container Types Sanitary Stainless Steel Construction Easily Integrated Into Existing Lines Pneumatic Bottle Stoppering System Inbuilt Air Filter & Lubricant System Inbuilt AISI 316 Quality 0.5 H.P. Transfer Pump Adjustable Conveyor Height To Calibrate With Other Machine Stainless Steel Control Panel For Operating The Machine

Jar Washing Machine

Get Price Quote

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Beer Filling Machine

42,000 Per Piece

1 Piece (MOQ)

SEMI AUTOMATIC WEB SEALER WITH SHRINK TUNNEL

175,000 Per Piece

1 Piece (MOQ)

Semi Automatic Tray Sealing Machine

300,000 Per Piece

1 Piece (MOQ)

Sealing: Once the vacuum and gas flushing steps are completed, the machine applies heat to seal the tray or container. This ensures that the package remains airtight and prevents any leakage or contamination. Cutting: Some machines also have cutting capabilities, allowing them to trim excess packaging material or create easy-open features on the sealed tray or container. This feature enhances the convenience and usability of the final product.

Stainless Steel Bottle Washing Machine

250,000 Per Piece

1 Piece (MOQ)

Rinsing Filling Capping Machine

Get Price Quote

Neelkanth Packaging Machinery is known in the market for liquid filling and packaging machines for industries like Food & Beverages, Oil, Agrochemicals. We manufacture Automatic Rinsing Filling Capping Machine, Semi- Automatic filling machine, Air Conveyor, Discharge Conveyor, Auto Sleeve Labeling Machine , Automatic BOPP Labeling, Automatic Web Sealer, etc. RFC Machine Serires is based on fully automatic process like Bottle Rinsing, Filling, Capping Machine etc. This machine equipped with man-machine technology with all automation. Mainly used for washing, filling and capping, etc. Sailent Features : Rotary neck holding. Air Blow Conveyor on the in feed. Slat Belt Conveyor on the out feed with Inspection Table. No Bottle - No Rinse - No Fill - No Cap. Unique Pick & Place type Capping with adjustable torque mechanism. Speed Control by AC Drive. Cap Elevator for feeding cap to the chute with automatic operation. Cap elevator for feeding cap to the chute with automatic operation. Stainless Steel enclosure provided for complete hygienic bottling. Easy open nozzles for easy cleaning. Can be linked directly to Automatic Blow Molding Machine for online Blow- Rinse-Fill-Seal. Compatible with Online Shrink Tunnel, Labeling Machine or Ink Jet Printer.

Automatic Volumetric Liquid Bottle Filling Machine

180,000 - 500,000 Per Piece

1 Piece (MOQ)

The Automatic Volumetric Liquid Filling Machine comprises the main structure, product transmission belt with an adjustable guide, safety acrylic cover (OPTIONAL), Pneumatic/mechanical bottle stopping facility, nozzle & syringes, electrical panel, motor, sensor, AC drive and mains for On/Off function. . Salient Features Robust and vibration free design Minimum changeover time Compact & versatile design Easy to clean Suitable for different volumes Application Bottle/ Vail Filling Industry Pharmaceuticals Veterinary FMCG Cosmetics Biotechnology

Linear Bottle Washing Machine

Get Price Quote

The Automatic Linear Bottle Washing Machine is ideal for washing glass bottles. This machine has 6 working stations to increase the efficiency of the number of bottles that are cleaned at one single point of time. These stations can be interchanged as per the requirements of a particular customer. The machine has been designed in such a manner that it provides 6 air and 6 water washes to a single glass bottle. The washing is positive and pressurized water is used for the purpose. Each and every part that comes in contact is made of stainless steel material of 316. The parts that do not come in direct contact are made of 304 quality stainless steel.

Automatic Bottle Filling Machine

Get Price Quote

With higher efficiency and reliability, our Automatic Bottle Filling Machines are taking over the countrywide market. These machines are fabricated from premium materials, in compliance with the international standards. They are further quality tested and assured. And durability and longevity are the add-on benefits that our buyers can avail themselves of. We are emerging as the promising Manufacturer and Supplier of Automatic Bottle Filling Machines in Gujarat.

Bottle Filling Machine

275,000 Per Piece

1 Piece(s) (MOQ)

automatic bottling machine

Get Price Quote

We have gained a remarkable position in the industry by offering a qualitative assortment of mineral water bottling plant. The offered plant is manufactured employing high-end technology and best quality raw material in adherence to industry defined parameters. Apart from this, the entire range of plant is scrupulously tested under the strict inspection of our quality examiners. This plant can be availed from us in different specifications at market leading prices. Features: shock proof maintenance free energy efficient.

Automatic Water Rinsing Machine

135,000 - 350,000 Per Piece

Rotary Bottle Washing Machine

230,000 Per Piece

Frp Mineral Water Ro Plant

Get Price Quote

We are offering frp mineral water ro plant. 1000 lph frp ro plant price: 2,00,000- pump: lubi membrane: ge power: 4 hp ( 230v 440v ac)

Bottle Filling Machine

200,000 - 500,000 Per Bag

1 Piece (MOQ)