2 Bricks Semi Automatic Fly Ash Bricks Machine

160,000 - 180,000 Per piece

1 piece (MOQ)

Automatic Solid Cement Brick Making Machine

1,100,000 Per Set

Best Deals from Brick Making Machine

Manual Brick Making Machine

55,000 - 55,000 Per Piece

1 Piece (MOQ)

Brick Type Vacuum Packing Machine

180,000 Per Piece

1 Piece (MOQ)

Hydraulic Brick Making Machine

110,000 Per Piece

1 Piece (MOQ)

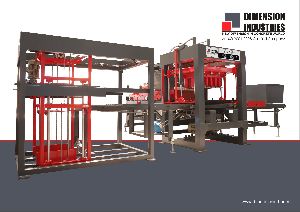

Fully Automatic Fly Ash Bricks Making Machine

Get Price Quote

Our company holds expertise in manufacturing and supplying of Fully Automatic Fly Ash Bricks Making Machine. The Fully Automatic Fly Ash Bricks Making Machine is engineered to perfection by our skilled team in compliance with the set industrial guidelines using high quality and economical material. The Fully Automatic Fly Ash Bricks Making Machine is widely used for a number of applications like controlling soil erosion, construction and landscaping. Details : Production : 25000BricksDay System : Fully PLC automatic Controlled Technology : Hydro+Vibro Technology

Fly Ash Brick Making Machine

Get Price Quote

Manual Fly Ash Brick Making Machine

35,000 - 35,000 Per Piece

1 Piece (MOQ)

Light Weight Bricks Line

Get Price Quote

Laxmi EN-Fab designs and manufactures AAC lightweight block making plant, to meet the specific requirements of the market and customers. As a new building material, AAC lightweight block production line fulfills the demand of concrete industry, which requires to save the natural resources and protect the environment. With Germany technology and our own R&D, we provide our customers state-of-the-art AAC lightweight block making plant. AAC is produced out of a mix of cement, lime, fly ash, gangue, river sand and aluminium powder etc., through batching, mixing, casting, cutting and autoclaving. AAC has the advantages of extremely light weight, high compressive strength, excellent thermal insulation, great acoustic insulation and high fire resistance. AAC can be produced in a large variety of sizes, from stand blocks to large reinforced panels, and it can be cut, sawn, drilled, nailed and milled like wood, making it an extremely workable product. AAC is environment-friendly and new building material. Annual Capacity (300 days) Power Daily Capacity Cycle Time No. Of Autoclaves 50,000 m3year 400 kW 166 m3day 10 hours 2 (¢2 × 26.5) 100,000 m3year 500 kW 333 m3day 10 hours 4 (¢2 × 26.5) 150,000 m3year 630 kW 500 m3day 10 hours 6 (¢2 × 26.5) 200,000 m3year 720 kW 666 m3day 10 hours 8 (¢2 × 26.5) 300,000 m3year 1,186 kW 1,000 m3day 10 hours 8 (¢2.85 × 32.5) *Theoretical output with suitable aggregates and materials. Advantages Large variety of sizes: AAC lightweight block production line enjoys a large variety of sizes, from standard blocks to large reinforced panels. Excellent thermal insulation: It achieves very high thermal energy efficiency due to its very low thermal conductivity. This benefits the saving on heating and cooling costs. Extremely light weight: It weighs approximately 50% less than other comparable building products. High compressive strength: Its solid structure makes it highly load bearing. The entire surface area is used in structural calculations to improve its strength. High dimensional accuracy: Thanks to its dimensional accuracy, AAC is extremely easy to install, as no thick mortar is required. Great acoustic insulation: Its porous structure provides a high acoustic insulation. High fire resistance: It has an extremely high fire rating of at least 4 hours and more. Termite resistance: It cannot be damaged by termites or insects. High workability: Thanks to its excellent sizeweight ratio, the construction with AAC is very rapid. Although AAC is a solid building material, it can be cut, sawn, drilled, nailed and milled like wood. This benefit makes it an extremely workable product.

Brick Making Machine

Get Price Quote

1 Piece (MOQ)

We, at AMPL are paramount manufacturer and exporter of fly ash bricks – blocks & pavers Making Automatic Machines. We have expertise in Machinery Production which is considered for Green Housing Projects worldwide. Our machine and products are manufactured using highest quality raw material and higher technology at our high-end manufacturing unit in observance with international quality standards. We design and develop these products as per the requirement of ईंटे बनाने की मशीन the clients, as we believe in meeting the precise requirements while maintaining the international quality standard at the same time.

brick crushing machine

Get Price Quote

Brick Crushing Machine is manufactured using super grade components and ultra modern techniques in observance to set industry standards. Machine offered in different specifications to meet exact demand of clients in specified manner. Features : Robust construction High productivity Durability Importance : Brick crusher is very useful for crushing wasted bricks into pieces which can be further used for other construction work. It is incorporated with heavy duty plates and main shaft, delivers high output in very short time. The product is capable of producing brick pieces of different sizes according to customer requirements. Offering Bricks Crusher : Bricks crusher is very useful for crushing wasted bricks, into small pieces, which can be used for other construction work. Incorporated with heavy duty plates and main shaft (crushing unit), machine delivers very high output, in short time. Moreover, it is capable of producing brick pieces of different sizes according to customer's requirement. For more information, please feel free to contact us.

Fly Ash Brick Making Machine

35,000 - 50,000 Per piece

1 piece (MOQ)

Fly Ash Brick Making Machine

50,000 Per Piece

Exporter of fly ash brick making machine manufacturer, automatic brick making machine manufacturers, cement block making machine, fly ash brick making machine in Ahmedabad, Gujarat, india.

brick crushing machine

Get Price Quote

Fully Automatic Fly Ash Brick Making Machine

Get Price Quote

Concrete brick making machine

1,500,000 - 4,800,000 Per SET

1 Set (MOQ)

we are providing india's best hydro+vibro concrete compacting technology brick | paver | block making machine.

Clay Brick Making Machine

Get Price Quote

We are engaged in manufacturing and exporting a wide range of clay brick making machine. Our machines give great output and high performance giving smooth and good quality material. It has the capacity to produce large number of bricks (tons) and at best quality. The number of bricks produced is increased in spite of having fewer employees in your company.The machines are available at best price and best quality which helps the company earning more profit. The machine produced by us has many eminent specifications in the machines improving the quality of product which are not easily available in other companies’ machine. As bricks making machine manufacturer, we provide un-matching quality of machine that last for a long time span and are highly efficient in producing best quality bricks. The bricks making machine are made utilizing the top grade materials and latest fabrication methods under the supervision of skilled experts. Each machine is made with great care and checked under various quality check parameters to ensure their working efficiency.

Nilmani Brick Making Machine

1,250,000 Per Piece

Brick Making Machine

Get Price Quote

Our range of products include hydraulic 40 ton brick making machine, automatic fly ash brick making machine, fully automatic fly ash brick making machine, high pressure fly ash brick making machine and fly ash brick making machine. Specifications: 3 Stroke in a minute 6 Pavers in a Stroke 8 bricks in a stroke Pan Ø: 1500 mm Side Wall Height: 550 mm Bottom Plate: 140 mm M.S Side Wall Plate: 6 mm M.S Motor: 7.5 HP, 1440 rpm 3 phase Hydraulic: 10 HP Taper conveyor: 2 HP Down Conveyor: 1 HP Vibrator: 2 HP Pan Mixer: 7.5 HP X 2 NOS Total Power: 30 HP Ramming: 1 no Box: 2 nos Feeder: 1 no Wooden Pallet Conveyor: 1 no Conveyor Belt Thickness: 8 mm Length 22 foot Well designed PLC control system Tank Capacity For Hydraulic Oil: 400 liters Single Layer Feeder box Electrical PLC control panel Bricks Removal: Through 10 ft conveyor Total Weight: 3500 kg Operating Pressure: 220 bar-100 ton Mixing Rough Material: From pan mixer to conveyor through conveyor to storage box, then storage box to feeder and to auto ram and box

Concrete brick making machine

Get Price Quote

This machine has an output of 4 Bricks at one time(9X4X3 SIZE ). Engineered to perfection, the Manual Concrete Brick Making Machine(MCM-333).comprises of sturdy vibrators, conveyors, pan mixers, etc. This model of Manual Concrete Brick Making Machine (MCM-333). has a production capacity of 2000 Bricks per shift.