turn tables

Turn Table System for transfer or movement of various type of Vials, Bottles, Jars on any Powder Filling, Liquid Filling or Tablet Bottle Packing Lines. Turn Table can be used with any machine for collection or feeding of products and also used to change the total line direction for “L” shape or “U” shape movement of line or for Linear movement of line but it can works as a buffer system, If any of machines stop during the online operation, Turn Table can collect the outfeed product from machine or similarly can feed the products to machine without interrupting the complete line. Turn Table is available in various diameter as per detail mentioned below of 600, 750, 900 or 1200 mm as per customers requirement. TT-24 : 600mm DiameterTT-30 : 750mm DiameterTT-36 : 900mm DiameterTT-48 : 1200mm Diameter Most commonly used size of Turn Table us 900mm Diameter. Turn Table frame is made from S.S. 304 Frame Structure duly supported with With heavy duty M.S. Material “C” profile for extra Support for Top Plate and Gear Box. Machine with S.S.304 Enclosures, Aluminimum Top Plate having Stainless Steel Cladding. Turn Table with A.C. Variable Frequency Drive System for smoother Start and Stop opetation for unstable products as well as speed control. Turn Table can also be made from Fully Stainless Steel Top Plate on request.

...more

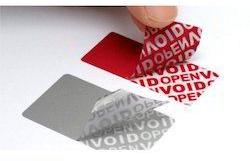

Tamper Evident Labels

Tamper Evident labels can be use on vitamins, food jars, electrical components, consumer and industrial products for warranty issues as well as for tamper evidence.Security Labels, Tamper Evident Seals, and security tapes do not make the products or containers "tamper proof" or "tamper resistant", they instead indicate "tamper evidence" or show that the product or package has been opened or tampered with.Tamper evident security label and security seal include asset labels and tags, product warranty VOID tamper evident labels, computer security label seals, bag seals, chemical drum security seals, drug transport security seals, carton sealing printed security tape, bag sealing tamper evidence tape, and container security seals and tape.

...more

Sticker Labelling Combine Machine

Once Gain, First Time in India, new concept of Labelling introduced by BROTHERS is a combination of Wet Glue and Sticker (Self-Adhesive) Labelling in one Machine. COMBI Labelling is a perfect machine where customer require to operate their production line having application of Wet Glue as well as Sticker Label on thie Glass, Plastic or PET Bottles. No Need to keep two separate Labelling Machine, just one COMBI Labelling Machine complete your need of two labelling operation in one machine. Machine with Maximum seed of 300 Labels per minute for Vials and 250 Labels per minute for Bottles depending on Product Diameter, Height and Length of Labels. COMBI Labelling is a unique Labelling machine to fulfill your requirement of Glue as well as Sticker Labelling in one machine. BUILT-IN UNIQUE FEATURES For GLUE LABELLING : No Label - No Gluing , No Product - No Label System Built in online Coding System for printing B.No. Etc. Using Rubber Stereos Fully Stainless Steel finish Machine Suitable for any type of Grooved Surface of Product* Built in Product Jamming Sensor to avoid damage/breackage of the Bottles at infeed* 30 to 50% Glue Saving on each Label due to Strip Gluing System* Easy to Change Label Application height on Bottles Synchronized speed of Label application with Gluing, Printing and Product Feeding Fully Gear Drive System - No Chain Drive Low Vacuum - Machine Stop System BUILT-IN UNIQUE FEATURES FOR STICKER LABELLING : No Label Data Input/retrievals require for any Label Size No Change Parts for Product and Label size Colour Touch Screen with PLC operation Missing Label in Roll - Machine Stop System with Alarm Label Roll Empty - Machine Stop System with Alarm Missing Label on Product - Machine Stop System* Single Pot On-line Speed Variation control Synchronized speed of Label Dispensing, Conveyor and Product Tower Light showing the machine status / operation Virtually Maintenance free machine Easy to change label application height User Friendly Label Placing Adjustments Self Protected against Voltage Fluctuations Fully Stainless Steel finish Machine Toughened Glass with S.S. Structure Safety Cabinet* Turn Table* Vision System for checking various detail on Labels*

...more

Semi Automatic Wet Glue Labelling Machine

Brothers Pharmamach , the Pioneer manufacturers of Labelling Machines in India have introduced India’s First, Versatile Semi Automatic Wet Glue Labelling Machine Model BS-40 in 1990. The Machine is developed for use of the customers requiring lower rate of production for their round bottles/containers, where Automatic Labelling Machine are not economical. No Change Parts required for Label size and Bottle Size, the change over time for Bottle as well as for Label size is couple of minutes. Machine is suitable for Labelling on Round Bottles, Jars, Tins, Cans, Containers and other round objects. It is capable of Labelling up to 40 units per minute depending on products and label size. Machine with more than 500 satisfied customers in India and Abroad. Operation of Machine is so Simple and Easy, Operator is required to Feed the Bottle and machine applies the label on it, after labelling operation operator can pick up the bottle. Cleaning of the machine requires very little time and skill which operator required to do in routine after each operation UNIQUE FEATURES : No Change Parts required for Change in Containers and Label Size. Suitable for Glass, Plastic, PET, Composite, Aluminum, HDPE, LDPE Bottles, Tins and Jars Grooved and Brut Shaped Bottles can also be labelled Optional Electronic Label Pickup System Compact Table Top model for ease in handling Glue Consumption minimize by Specially designed Strip Gluing System Suits partial as well as complete/overlapped labelling No Container - No Label System Stainless Steel 304 Enclosures Heavy Duty Machine construction with Heavy Duty Gear Box and Motor for longer life. Suitable for Pharmaceutical, Food, Beverage, Distillery, Cosmetic, Pesticide, Agro-Chemical and similar products.

...more

Semi Automatic Volumetric Liquid Filling Machine

Semi Automatic Twin Head Volumetric Liquid Vial/Bottle Filling Machine Model LIQFILL-20 is suitable for Round or Flat shape Bottles or Vials with maximum speed of 25 Products per minute. The Machine can give speed of 20 to 25 per minute depending on nature of Liquids, Neck Diameter or Vial/Bottle and Fill Volume. Machine suitable for small volume production having multiple products. Machine construction in Stainless Steel finish with Twin Head Operation. All parts coming in contact with Liquids are made from SS 316 Materials. SPECIAL FEATURES: No Product - No Fill System All contact parts are made of SS 316 material with easy removal system for Auto-Claving/Sterilization/cleaning Machine construction in SS 304 material Very High Fill Accuracy Minimum Change Over time

...more

SEMI AUTOMATIC ROTARY BOTTLE WASHING MACHINE

The Rotary Bottle Washing Machine Model BOTTLEWASH-90 , is suitable for Washing various types of Bottles ranging from 15 ml to 1000 ml size with maximum speed of 90 Bottles per minute. Machine construction is in Stainless Steel finish including frame structure. All parts coming in contact with Washing Zone and Jets are made from SS-316 Material. Intermittent handling of Bottles ensures the maximum time for washing. Machine also offers various customised options for washing sequence as per customers requirements. Washing process takes place with Four different Washing Zones for optimum washing. Machine also equipped with external washing of Bottles. We can also customised the machine to suits special type of bottle or size and also washing sequence. We have also another lower capacity Model BOTTLEWASH-60 with speed of 60 bottles per minute for lower speed requirement and also require small area compare to 100. SPECIAL FEATURES : 16 Jets for each washing zones All contact parts made of SS-316 material Machine construction is in SS-304 material Suitable for 15 ml to 1000 ml Bottle Size* Machine with Geneva-Cam Mechanism Washing sequence can be made as per customers requirements. Built-in 2 Pumps and 2 Tanks Machine main drive with Safety Clutch System

...more

Self Adhesive Polyester Labels

Self Adhesive Sticker Labelling Machine is effectively used in various sectors in Self Adhesive Labeling Applications. They may be used offline in standalone applications or can be easily integrated into your packagingfilling lines. Automatic Self Adhesive Sticker Labeling Machine is used for Labeling of round container which are previously filled and sealed. No change parts are required for change over of container size. Machine conveyor will receive container from in feed turntable, it will be separated by the feeding roller assembly to maintain the pre determined space between the two containers according to the label length and container diameter. Label is placed on the container immediately when it will be sensed by the container sensor, it ensures instant adhesive of label’s edge. Then it passes through the pressing unit resulting in precise registration and crease-free application. It does not require any change parts for change in container diameter or label sizes. In Self Adhesive Sticker Labelling Machine label height from bottom can be also adjustable for different kind of containers. Self Adhesive Sticker Labelling Machine is used to apply label on various side of container such as front, back, top, bottom, side, corner (frontsideback), wraparound (semi or full), and body.

...more

Security Labels

Pharmaceuticals, Drug Containers and Other Medical Supplies ,Packaging Cartons and Boxes,Banking, Legal And Financial Document Seals, Aircraft Security Seals for Civil Aviation, Freight and Cargo Security Labels, Government Security Seals, Mobile Phone Boxes and Batteries, PC Hardware and Software Components.

...more

Packing Conveyor

The Packign Conveyor Belt System for online manual packing of various type of Vials, Bottles, IV Fluid Bottles or any product in carton for any Powder Filling, Liquid Filling or Tablet Bottle Packing Line. Packing Conveyor Belt suitable for online operation with Double Side Seating for Higher output depending on customers requirement. Packing Conveyor Belt available in any length with 9 inch PVC Center moving belt with two side 10 to 12 inch width Stainless Steel Top for packing operation. The system can also be supplied with Variable Drive Speed System. Inspection Conveyor can be connected directly to outfeed of capping machine for collection of products for inspection in Pharmaceutical, Food or other industries. We are also specialize in supplying specially made Packing Belt System for Food Industries having requirement for Exports. Our Packing Conveyor Belt system is suitable for Grapes, Pomegranate or other fruits. We can supply packing conveyor system for Single Layer, Double Layer or Triple Layer operation and final packing conveyor to be connected with Labelling System to apply Label on Punnet or Cartons. Single Layer conveyor can be made of PVC belt of Roller type belt depending on customer requirement. Double Layer conveyor belt having top side roller belt system for movement of heavy weight product crates. Triple layer conveyor belt having top side roller belt system for movement of heavy weight product crates, middle conveyor for transporation of finished and packed products Punnet or Cartons to the labelling machine and bottle belt for collection or movement of product waste etc. Centre belt system also having individual Stainless Steel Top Working Table with facility to use Weighing Scale etc. We can also design and supply Packing Conveypr as per customers customised requirement for use on any packing line in Pjarmacetuical, Food, Chemical, Pesticide or other industries.

...more

Offline / Semi Automatic Rotary Bottle Washing Machine

The Rotary Bottle Washing Machine Model BOTTLEWASH-90 , is suitable for Washing various types of Bottles ranging from 15 ml to 1000 ml size with maximum speed of 90 Bottles per minute. Machine construction is in Stainless Steel finish including frame structure. All parts coming in contact with Washing Zone and Jets are made from SS-316 Material. Intermittent handling of Bottles ensures the maximum time for washing. Machine also offers various customised options for washing sequence as per customers requirements. Washing process takes place with Four different Washing Zones for optimum washing. Machine also equipped with external washing of Bottles. We can also customised the machine to suits special type of bottle or size and also washing sequence. We have also another lower capacity Model BOTTLEWASH-60 with speed of 60 bottles per minute for lower speed requirement and also require small area compare to 100. SPECIAL FEATURES : 16 Jets for each washing zones All contact parts made of SS-316 material Machine construction is in SS-304 material Suitable for 15 ml to 1000 ml Bottle Size* Machine with Geneva-Cam Mechanism Washing sequence can be made as per customers requirements. Built-in 2 Pumps and 2 Tanks Machine main drive with Safety Clutch System

...more

label applicators

Label applicators are machines that automatically apply printed labels to products. Labeler can apply a wide variety of label configurations to cases and cartons, increasing production flexibility and speeding changeover. The Print and Apply Model with Multi Panel Applicator features a stepper motor driven vacuum belt that stages the labels prior to application. This unique system smoothes the label application operation and helps in achieve high speeds.Ideal for high changeover environments where tremendous production flexibility is needed, the Print and Apply Model with Multi Panel Applicator can be changed over in less than one minute with no tools and no change parts required. The electronic changeover is accomplished simply by changing the settings on the touch screen control panel.

...more

Inspection Conveyor Belt System

The Automatic Inspection Belt System for Visual Inspection of various type of Vials, Bottles or IV Fluid Bottles for any Powder Filling, Liquid Filling or Tablet Bottle Packing Line. Inspection belt suitable for online operation with Single Side seating or Double Side Seating for Higher output depending on customers requirement. Inspection belt available in any length with S.S. Slat Conveyor Belt in Center having Two Separate S.S. Slat Belt in front and back of centre conveyor for use of both side of Inspection Conveyor. The system also having Black and White Board with proper illumation for visual inspection of any product. Inspection Conveyor can be connected directly to outfeed of capping machine for collection of products for inspection. Inspection Conveyor can be supplied as per customers customised requirement for use on any packing line.

...more

Injectable Volumetric Motion type Liquid Vial Filling

The Automatic Four Head Volumetric Motion type Liquid Vial Filling with Vacuumetric Rubber Stoppering Machine Model LIQFILL-100IRMOTION is suitable for Round Vials with maximum speed of 120 Vials per minute. The Machine can give Maximum speed of 120 Vials per minute depending on nature of Liquids, Vial Neck Size and Fill Volume. Machine construction in fully Stainless Steel finish including machine frame structure. Machine with unique motion filling system, Filling Nozzle moves alongwith Vials during the Liquid Filling Process without stoppage of Vials and also with time tested Vaccumetric Rubber Stoppering System for positive placement of Rubber Stopper on Vials at higher speed. Machine with built-in Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing vials for smoother operation. All parts coming in contact with Liquids and Rubber Stoppers are made from SS 316 Materials. SPECIAL FEATURES: No Vial - No Fill System, No Vial - Machine Stop System No Stopper - Machine Stop System Synchronized movement of Vial and Filling Nozzle, no stoppage of vial during filling operation Vaccumetric Rubber Stoppering System. All contact parts made of SS 316 material with easy removal system for Auto-Claving/Sterilization/Cleaning Machine construction in SS 304 material Diving Nozzle for Foam free filling Very High Fill Accuracy Automatic Infeed and Exit of Vials Minimum Change Over time Built-in A.C. Variable Freq. Drive System

...more

Injectable Volumetric Liquid Vial Filling And Rubber Stoppering Machine

The Automatic Four Head Volumetric Liquid Vial Filling with Rubber Stoppering Machine Model LIQFILL-100IR is suitable for Round Vials with maximum speed of 100 Vials per minute. The Machine can give Maximum speed of 100 Vials per minute depending on nature of Liquids, Vial Neck Size, Fill Volume and Rubber Stopper size. Machine construction in fully Stainless Steel finish including machine frame structure. Machine with built-in Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing vials for smoother operation. All parts coming in contact with Liquids and Rubber Stoppers are made from SS 316 Materials. Machine also available with Vaccumetric type Rubber Stoppering System. SPECIAL FEATURES: No Vial - No Fill System, No Vial - Machine Stop System No Stopper - Machine Stop System All contact parts made of SS 316 material with easy removal system for Auto-Claving/Sterilization/Cleaning Machine construction in SS 304 material Diving Nozzle for Foam free filling Very High Fill Accuracy Automatic Infeed and Exit of Vials Minimum Change Over time Built-in A.C. Variable Freq. Drive System

...more

Injectable Powder Filling with Rubber Stoppering Machine

The Automatic Injectable Powder Filling with Rubber Stoppering Machine Model DRYFILL-120i, is suitable for Round Vials with maximum speed of 120 Vials per minute. Specially Machine construction in fully Stainless Steel finish including machine frame structure. Machine with built-in Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing vials for smoother operation. All parts coming in contact with Powders are made from Ss316 Materials. The Machine is equipped with Single Head Single Track Eight Port Powder wheel, which works on Vacuum and Air Systems to Fill powder in Vials, with on-line Vibrator type Rubber Stoppering system, The stopper inserting system operates in a contineous mode with synchronized speed of machine. Machines also comes in various options like Single Track Double Powder Wheel, Double Track Double Powder Wheel, Single Track Single Powder Wheel and Double Track Single Powder Wheel System to match the customers customised requirements. SPECIAL/OPTIONAL* FEATURES : No Vial - No Fill System All contact parts made of SS316 material with easy removal system for AutoClaving/Sterilization Machine contstruction in SS304 material Separate Variable Speed Drive for Powder Hopper No Crossover Contamination during Charging of Powder due to new Design of Powder Hopper Hopper can be completely dismental for easy cleaning Minimum residue of Powder in Hopper at the end of batch resulting in less wastage of powder Tool Less adjustment of Doctor Blade and Wiper Blade saves valuable time and easy for setting Tool Less change over for Powder Hopper and Well Agitator Filling Accuracy of +/- 1% depending on powder at controlled humidity below 30% Rh Built in Rubber Stoppering System Multiple dosing system with the help of change parts Built in Turn Tables with Separate Drive for speed control of infeed and outfeed of vials Various safety features including Clutch system for Vial Breackage Machine Bottom with all over minimum clearance of 6” Height Moving conveyor above the top plate maintaining proper gap for meeting current application needs. Automatic Infeed and Exit of Vials Powder Hopper for charging with better position and design without crossing the line. No Stopper - Machine Stop System Low Air - Machine Stop System Low Vacuum - Machine Stop System Heavy Duty Mounting system for Powder Wheel for Trouble Free long term opreation

...more

Induction Cap Sealing Machine

Automatic Induction Cap Sealing Machine suitable for various type of Plastic or Glass Bottles used on any Liquid Filling, Powder Filling or Tablet Bottle Packing Line. Machine suitable for Sealing Bottle Neck using Weds provided inside the Cap. Machine can be connected to any capping machine by installing the Induction Sealing Head on outfeed conveyor of Capping Machine for online operation or can be supplied with Transfer conveyor system to use it offline or to connect with any machine for online operation. Induction Sealing Machine available with various speed range depending on type of Bottles, Bottle Size and most important Bottle Neck Diameter. Machine suitable for complete online operation to connect with any Packing Line. Note : WE DO NOT MANUFACTURE INDUCTION CAP SEALING MACHINE but we can arrange to supply the same using our source from Local supplier of India for any Packing Line. We have sold many lines with Induction Sealing Machine in India and Abroad for Pharmaceutical, Food, Cosmetic and other industries.A

...more

Hot Foil Coding Machine

When selecting labeling equipment keep in mind, whether online coding is needed? If yes then there are various type of coding system available or offered by labeling machine manufacturer such as Hot Foil Coding system which uses Hot Foil Ribbon and Metal Character to Print, Contact Coder uses Rubber Stereos and Liquid Ink to Print,Thermal Transfer coder using Thermal Transfer Film or Ribbon, Inkjet Coder using HP Ink Cartridge like Desktop Inkjet printer Cartridge and Laser Coder.

...more

Double Side Sticker Labeling Machine

Self Adhesive Vial-Bottle Labeling Machine is used for fullpartial wrap around labeling on different size of round container. It is capable of labeling up to 150 containers per minutes depending on products and label size. There are also other types of models available for Round, Oval, Flat, Square, containers with single and double side labeling. Fully automatic sticker labeling machines are used for thin diameter containers such as Ampoules, Vial, Inhalers etc.

...more

Double Head Injectable Powder Filling with Rubber Stoppering Machine

The Automatic Twin Head - Twin Track Injectable Powder Filling with Rubber Stoppering Machine Model DRYFILL-120i.Twin, is suitable for Round Vials with maximum speed of 120 and/or 250 Vials per minute. Specially Machine construction in fully Stainless Steel finish including machine frame structure. Machine with built-in Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing vials for smoother operation. All parts coming in contact with Powders are made from Ss316 Materials. The Machine is equipped with Single Head Single Track Eight Port Twin Powder wheel, which works on Vacuum and Air Systems to Fill powder in Vials, with on-line Vibrator type Rubber Stoppering system, The stopper inserting system operates in a continues mode with synchronized speed of machine. Machines with Double Track Vial Moving system having Single Track Twin Head Powder Wheel System, helps to achieve speed of 240 vials per minuet using twin track twin head or can be used for Single Head operation also with speed of 120 vials per minute. SPECIAL/OPTIONAL* FEATURES : No Vial - No Fill System All contact parts made of SS316 material with easy removal system for AutoClaving/Sterilization Machine contstruction in SS304 material Separate Variable Speed Drive for Powder Hopper No Crossover Contamination during Charging of Powder due to new Design of Powder Hopper Hopper can be completely dismental for easy cleaning Minimum residue of Powder in Hopper at the end of batch resulting in less wastage of powder Tool Less adjustment of Doctor Blade and Wiper Blade saves valuable time and easy for setting Tool Less change over for Powder Hopper and Well Agitator Filling Accuracy of +/- 1% depending on powder at controlled humidity below 30% Rh Built in Rubber Stoppering System Multiple dosing system with the help of change parts Built in Turn Tables with Separate Drive for speed control of infeed and outfeed of vials Various safety features including Clutch system for Vial Breackage Machine Bottom with all over minimum clearance of 6” Height Moving conveyor above the top plate maintaining proper gap for meeting current application needs. Automatic Infeed and Exit of Vials Powder Hopper for charging with better position and design without crossing the line. No Stopper - Machine Stop System Low Air - Machine Stop System Low Vacuum - Machine Stop System Heavy Duty Mounting system for Powder Wheel for Trouble Free long term opreation

...more

Dosing Cup Placement-Pressing Machine

The Automatic Rotary Pick N Place type Wick, Plug, Measuring/Dosing Cup Placement / Cap Pressing Machine Model CAPPRESS-160R-pnp. Machine is suitable for Round or other shape of Glass, Plastic, PET, LDPE, HDPE Bottles with maximum speed of 160 Bottles per minute depending on Bottle Diameter, Bottle Height, Bottle Shape and Wick/Plug/Measuring Cup / Cap Size. Machine with Pneumatically operated Gripper type capping head system for uniform Placement and Pressing on bottles.The Machine is equipped with Orientation type Cap Feeder or Vibratory type Bowl Feeder depending on Plug/Cap shape and size for continues feeding for online operation on any liquid of powder filling line. Machine suitable for various sizes of Bottles and Plug/Wick/Measuring/Dosing Cup with the help of change parts. Specially Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. SPECIAL/OPTIONAL* FEATURES : Pneumatically operated Gripper type capping head No Bottle - No Cup / Cap System No Plug / Measuring Cup / Cap - Machine Stop System Machine construction in Stainless Steel Finish Infeed and Exit Star Wheel with Overload Clutch System to avoid Bottle breackage Single Drive Synchronizing Total Operation of Bottle Feeding, Bottle Holding Belt and Top Holding / Pressing Belt System Measuring Cup / Cap Feeder with Variable Speed System for feeding control of caps. Minimum Change Over and Setting time Hopper can be completely dismantle for easy cleaning Various safety features including Clutch system to avoid Bottle Breakage Single Drive synchronizing operation of Conveyor and Star Wheel Minimum Change over time

...more

Carton Printing Machine

Automatic Carton Code Printing Machines can print on plain, Laminated and Varnish Carton as well as on Polythene Bags. Automatic High Speed Label Code Printing Machine is suitable to Print Batch No., Price, and Expiry Date etc.

...more

Automatic Wet Glue Labelling Machine

A Long awaited Perfect Automatic Wet Glue Labelling Machine Model LABELWET-125 in completely STAINLESS STEEL FINISH to meet current market requirement for the products having very Long and Wide Labels and Large Sized Bottles/Containers.. LABELWET-125 is made for Labelling on many kind of round Bottles, Jars, Tins, Cans and other Cylindrical products used by Food, Beverage, Ayurvedic and other industries. LABELWET-125 is Economical, Efficient and Reliable having more than 100 installations in India and Abroad in Food, Agro-Chemicals and Pesticide industries. The machine also has Completely Stainless Steel Finish, No Bottle No Label system and No Label No Gluing system. Optionally A.C. Variable Speed Control, Pulse Counter, Safety Guard also available. The LABELWET-125 Model comes in two different version with suitability to most of requirement in Foodl and allied industries to match individual requirement of customer with their specification and speed. BUILT-IN UNIQUE FEATURES : 30 to 50% Glue Saving on each Label due to Strip Gluing System No Label - No Gluing System eliminating wastage of Glue No Bottle - No Label System eliminating wastage of Labels Easy to Change Label Application height on Bottles Synchronized speed of Label application with Gluing and Bottlel Feeding Easy Change over system with Low cost change parts Least Change over time for Bottle and Label Change Parts Suitable for any type of Grooved Surface of Product Suitable for Partial, Full Wrap Around and Overlap Labelling Fully Stainless Steel Finish Machine Glue Pump with Bucket for uninterrupted glue supply for Larger Labels. OPTIONAL FEATURES : Digital Counter Safety Guard A. C. Variable Frequency Drive System Turn Table for Feeding and/or Collection of Bottles. Tower Light showing the machine status / operation Special Sensing system for checking missing label on product suitable for Labels with UV Ink or UV Coating Low Air - Machine Stop System

...more

Automatic Viscous Liquid Filling Machine

Automatic Eight Head Volumetric Viscous Liquid/Paste Filling Machine Model LIQFILL-150s is suitable for Round or Flat shape Bottles or Jars with maximum speed of 150 Products per minute. Machine design specially suitable for Viscous Liquid or Gel/Paste which also require to Fill HOT with Temperature of more than 40 degree celcius. The Machine can give speed of 80 to 150 Products per minute depending on nature of Liquids, Neck Diameter of product and Fill Volume. Machine suitable for Normal as well as Hot type of Liquid/Paste/Gel or Cream. Machine construction in Stainless Steel finish with Single Head Operation. All parts coming in contact with Liquids are made from SS 316 Materials. SPECIAL FEATURES : No Product - No Fill System All contact parts are made of SS 316 material with easy removal system for Auto-Claving/Sterilization/cleaning Machine construction in SS 304 material Very High Fill Accuracy Minimum Change Over time

...more

Automatic Twin Track Eight Head Liquid Bottle Filling Machine

The Automatic Twin Track Eight Head Volumetric Linear Liquid Bottle Filling Machine, Model LIQFILL-160 is suitable for Bottles with maximum speed of 160 Bottles per minute. Machine with unique twin track operation of bottles resulting in smoother movement of bottles at lower speed producing higher output. The output of Bottle Filling Machines depending on nature of Liquids, Bottle Diameter, Bottle Height, Bottle Neck Size and Fill Volume. Machine construction in fully Stainless Steel finish including machine frame structure. Machine with Optional Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing Bottles for smoother operation. All parts coming in contact with Liquids are made from SS 316 Materials. SPECIAL FEATURES : No Bottle - No Fill System, No Bottle - Machine Stop System Twin Track Bottle Movement system for smoother operation All contact parts made of Ss316 material with easy removal system for Auto-Claving/Sterilization/Cleaning Machine construction in SS 304 material Diving Nozzle for Foam free filling Very High Fill Accuracy Automatic Infeed and Exit of Bottles Minimum Change Over time Unique Free Spinning Bottle Seperator- No pneumatic operation Built-in A.C. Variable Freq. Drive System

...moreBe first to Rate

Rate This