3 HP Sugar Grinding Machine Without Motor

22,881 Per Piece

1 Piece (MOQ)

Confider Industries stands as a beacon of excellence in the realm of food processing machinery, offering an extensive array of products tailored for both domestic and commercial applications. With a diverse portfolio comprising over 90 meticulously crafted machines, our company epitomizes innovation, reliability, and superior quality. From humble beginnings, we have grown into a globally recognized brand, catering to the needs of customers worldwide. At the heart of our success lies a relentless commitment to delivering top-notch products that exceed expectations. Every machine manufactured by Confider Industries undergoes rigorous quality control measures, ensuring precision engineering and durability. Whether it's a small-scale operation in a home kitchen or a large-scale industrial setting, our machines are designed to meet the diverse demands of modern food processing. One of the hallmarks of Confider Industries is our unwavering dedication to customer satisfaction. We understand that purchasing a food processing machine is an investment, and thus, we go above and beyond to provide unparalleled after-sales support. Our team of experts is readily available to assist customers through calls and video calls, offering guidance, troubleshooting, and technical assistance whenever needed. We believe in building long-lasting relationships with our customers, and our commitment to after-sales service reflects this ethos. Furthermore, Confider Industries takes pride in its global reach. With an extensive network of distributors and partners, our machines are delivered to customers across continents. Whether it's a bustling city in Asia, a remote village in Africa, or a thriving metropolis in Europe, our products have found their way into kitchens and food processing facilities worldwide. This global presence underscores our reputation as a trusted provider of food processing solutions on a global scale. Innovation is at the core of everything we do at Confider Industries. We continuously invest in research and development to stay ahead of market trends and technological advancements. Our team of engineers and designers work tirelessly to develop cutting-edge solutions that streamline processes, enhance efficiency, and elevate the overall user experience. From state-of-the-art automation technologies to eco-friendly designs, we strive to push the boundaries of innovation in the food processing industry. Sustainability is also a key focus for Confider Industries. We recognize our responsibility to minimize our environmental footprint and embrace sustainable practices throughout our operations. From sourcing materials responsibly to optimizing energy efficiency in our manufacturing processes, we are committed to fostering a more sustainable future for generations to come. In conclusion, Confider Industries stands as a beacon of excellence in the food processing industry, offering a diverse range of high-quality machines for domestic and commercial use. With over 90 machines in our portfolio, a global presence, and a steadfast commitment to customer satisfaction, we continue to set the standard for innovation, reliability, and excellence in food processing.

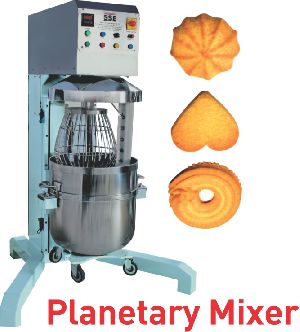

Imported Planetary Mixer

Get Price Quote

1 Piece (MOQ)

Note : Electricity Mode Power Supply 220 Volts 50Hz or 440 Valts 50 Hz as Per Order Accessories : Dough Hook Whisk Mixing Paddle Features : Copper Driver Motor Three Speed Three Fonction Whit Hook, Ball, Beat Oil Bath Gear Box Belt Transmission With Safety Guard S.S. Body Material

Best Deals from Cake Making Machine

Planetary mixer

Get Price Quote

1 Piece (MOQ)

Pharmaceutical Cream Mixer Machine

150,000 Per Piece

1 Piece (MOQ)

rice cake packing over wrapping machine

Get Price Quote

The Rice Cake is an essential diel for healthy living, we make sure the cylindrical Rice Cake packs decently and looks hyginic on the shell. Our Over Wrapping Machine - Cellophane wrapping machine boost up the packing of the product to the next level.

spiral mixer 30kg

135,000 Per Piece

1 Piece(s) (MOQ)

Planetary mixer

Get Price Quote

Our name features among the topmost manufacturers, exporters and suppliers from Ahmedabad, Gujarat. We provide supreme quality Planetary Mixer which comprises of finely polished stainless steel vessel, shafts and blades along with a tough gear box. The outstanding performance and high efficiency of Planetary Mixer along with cost effective pricing and timely delivery has made us extremely popular in the global market.

Planetary mixer

275,000 Per Set

1 Set(s) (MOQ)

planetary mixer machine

150,000 - 200,000 Per Nos

1 Nos (MOQ)

The Planetary Mixer Machine is a high-performance mixing device used for blending, kneading, and whipping various ingredients. It features a unique planetary motion where the mixing attachments rotate around both their own axis and the axis of the bowl, ensuring thorough and uniform mixing. Ideal for applications in bakeries, confectioneries, and food processing, this mixer is designed to handle a range of textures and viscosities, from light batters to dense doughs. Its durable construction and multiple speed settings offer versatility and efficiency, while its easy-to-clean components make it a practical choice for both commercial and industrial kitchens

Planetary mixer

480,000 Per Piece

1 Piece(s) (MOQ)

Planetary Mixer Water Jacketed

Get Price Quote

This mixer is designed to be used as a mixing for pastes, ointments & creams in water-jacketed kettle. It can also be used for wet powders. This mixer is provided with a mixing paddle and Teflon scrapper, which is shaped in such manner so that there is minimum clearance with the mixing kettle. The kettle is also easily removable. This Equipment can be use for heating and cooling purpose by hot & cold water circulation.

cake packing machine

270,000 Per Piece

1 Piece (MOQ)

Planetary mixer

Get Price Quote

Planetary mixer

Get Price Quote

1 Piece(s) (MOQ)

Cream Mixer Machine

35,900 - 113,500 Per piece

1 piece (MOQ)

Cup Cake Packing Machine

250,000 Per Piece

Dough Spiral Mixer

165,000 Per unit

Planetary mixer

Get Price Quote

The Planetary mixer is a machine ideal for collaborating wet and dry materials. It is a mixing assemble where the agitation pattern is of the planetary nature. The machine works on a homogeneous mixing action i.e. suspensions and semisolids. The Planetary Mixer Machine performs all the tasks like mixing, heating, cooling, vacuuming and homogenizing functions within one machine. This is a vacuum type planetary mixer which is used for mixing of ointments, wet mass, dry powders etc. The agitation assembly rotates around itself and also travels in a circular motion, thereby resulting in through mixing of the materials. Characteristic features The contact parts made up of AISI 316 and non contact parts S.S.394 Simple to mount machine is compact in structure and design It consists of a double anchor blade with planetary rotation for extremely efficient shearing force. The top lid of the machine is mounted with a motor operated lifting device. Product container is castor wheel mounted for easy load and unload to the machine. The machine has a rigid drive with planetary gear and reduction gear box Equipped with a dual speed motor for both slow and fast mixing action. The scrapper is made from teflon. Process of operation The anchor type agitator rotates in the anticlockwise direction. The paddle revolves in clockwise direction with planetary motion. The paddle generates a disturbance in the normal circular motion and dampen the vortex formation. The planetary action and mixing blade have dual speed. Moreover, the adjustable scrapers prevents the building of stagnant film between the vessel and the agitator. This ensures the efficient transfer of heat to the product during heating and cooling. The speed of the agitator and the counter paddle is adjustable. The mixing container is completely closed for efficient heating and cooling. The mixing container has been designed to operate under vacuum so that the mixing can be done in isolation from air.

spiral mixer

Get Price Quote

Spiral Mixers are available in different model options like SPN 25,SPN 50,SPN 100 and deliver efficient and consistent performance standards. These are applicable in Hospitality Sector, Bakeries and in Industrial Kitchens. Some of the standard benefits these mixers provide: Compact finish Easy handling High performance outputs Available capacities : Flour Capacity : 25 kgs, 50 kgs, 100 kgs Dough Capacity : 40 kgs, 80 kgs, 160 kgs Hourly Electrical Consumption : 3/4.5 Kw (4/6 HP),3.8/5.8 Kw (5/7.5 HP),7.3/3.75 Kw (10/5 HP) &1.125/.5625 Kw (1.5/0.75 HP) Available dimensions (L x W x H) : 625 x 1060 x 1245 mm 680 x 1120 x 1325 mm 915 x 1450 x 1360 mm Our Spiral mixer exhibit following salient features: Steady and compact Easy to handle Sturdy High performance Durable

Concrete Planetary Mixer

Get Price Quote

Backed by a team of adroit professionals, we are manufacturing and supplying an extensive quality Concrete Planetary Mixer. Ideal to mix a variety of concrete and other allied material, our offered mixer is manufactured using quality approved components that ensure its flawless performance. Furthermore, our reputable clients can avail this mixer for us in various technical specifications to cater with their specific demands. Besides, our offered mixer is available at market-leading prices for our clients. Features: High performance Rugged construction Easy to operate

detergent cake machine

Get Price Quote

Having deep knowledge of recent market requirements, we have adapted our machinery. Our engineering excellence has gained us capacity to fabricate top quality machines. Good coordination of technical brilliance and advance management has leaded us to make highly economic range of machineries. We are accepted manufacturer and supplier of various types of soap and detergent making plants. Our soap making machineries and other plants like detergent cake plant, LABSA Plant, Laundry Soap Plant, Toilet Soap Plant, Detergent Soap Plant, Acid Slurry Plant and pilot plants are highly demanded in Indore. We also provide inline machineries for batch type operation and also for the continuous operations. We provide worm conveyor, triple roll machine, simplex plodder, foot operated stamping machine and packing machine.

Planetary Mixer Vacuum+Heating Jacketed

Get Price Quote

Planetary Mixer – Vacuum+Heating Jacketed can be equipped with various mixing and kneading attachments, made of stainless steel. Depending upon type of the material to be processed, a dough arm, and a mixing paddle. Any material, which sticks to the walls of the kettle, is scraped continuously by the Teflon scrapper, which is shaped to fit exactly the kettle wall. Therefore, homogeneous mixing results in the shortest time. In this Combo Model (Vacuum+Heating) we provide digital Controller in main drive. The vacuum +Heating jacketed Planetary Mixer is suitable to attach on our Both Main Drive.

Planetary mixer

Get Price Quote

This Equipment is to speed up the process with ease and accuracy to prepare cylindrical specimens for Marshal Stability Testing Machine. The mix is uniformly heated and mixed to yield homogenous mix and better moulds for testing. The same mixer without heating jacket and some modifications can also be used for mixing of soil, cement paste, mortars, pozzolanas etc. General Descripation & Specifications Electrically operated, fitted with heating jacket for thorough mixing of Bitumen. The mixer is operated by 0.5 HP single phase electric motor connected to epicyclic type stainless steel paddle to impart both planetary and revolving motion for uniform mixing. Mixer blade has low speed of 140 + 5 rpm and medium speed of 285 + 10 rpm, while it also has a planetary movement of 62 + 5 rpm in low range and planetary movement of 125 + 10 rpm in medium range. A stainless steel bowl of approx. 5 ltr capacity with handle is also supplied. The 500 Watts heating jacket with energy regulator to control the temp. is fitted below the bowl. Complete unit is supported on a strong iron frame. Suitable to work on 220V, 50 Hz, AC single phase. Optional Accessories Asbestos Hand Gloves Transfer Tray Stainless Steel Scoop

Planetary mixer

Get Price Quote

sugar grinder machine

Get Price Quote

Planetary mixer

Get Price Quote

Planetary Mixer is ideal for mixing of wet/dry powder materials. It has a homogeneous mixing action i.e. emulsions and semisolid. It integrates mixing, vacuuming, heating, cooling and homogenizing functions into single machine, resulting in a considerably reduction in cycle time. The basis of mixing system of Planetary Mixer is a combination of planetary- rotating paddle agitator. 2 Nos. Anchor type agitator with cross baffles rotates in anti-clockwise direction with planetary motion in there axis. While paddle revolves in clockwise direction with planetary action, generating a disturbance in the normally circular flow pattern and dampen vortex formation. The mixing blade and planetary action having dual speed. In addition, adjustable scrapers are utilized to prevent the build-up of a stagnant film between the agitator and the vessel, and assure efficient heat transfer to product during heating and cooling steps. The speed of the agitator and the counter paddle can be varied separately. The Product container is castor wheel mounted for easy load and unload to the machine. The top mixing blade assembly is motorized up and down during container loading and unloading. The mixing container is jacketed for heating / cooling and completely enclosed. The product container can be designed to operate under vacuum; mixing can then be performed without entrainment of air. Top lid of the product container having charging pot for binder adding, eye glass window and light glass. SALIENT FEATURES : Designed strictly compliance with the stipulation of cGMP Product contact parts AISI 316 Quality and Non contact parts S.S.394 Quality. Machine compact in designed single base structure to for simplicity in mounting. 2 Nos. Anchor blade with planetary rotation for extremely efficient shearing force. Top lid is mounted with motorized lifting device. Product container is castor wheel mounted for easy load and unload to the machine. Rigid drive with planetary gear and reduction gear box Dual speed motor for slow and fast mixing action. Scrapper is made from Teflon. OPTIONAL FEATURES : Ac Frequency Variable Drive. Mixing bowl with heating / cooling jacket and insulated. No. of Mixing Blade : Single Blade/ Double blade/Triple Blade. Type of Blade: Paddle Blade/ Anchor type/Hart Shape Blade Centre located and top mounting high speed homogenizer. SAFETY FEATURES : Emergency stop button Limit switch at top lid Over load protection by relay.

cake cutter machine

Get Price Quote

The long cutted bars are passed through machine here they are cutted into required size cakes ready to pack with packing machine.

spiral mixer

Get Price Quote

Planetory Mixer

Get Price Quote

SPECIAL FEATURESRange of models to suit working volume 60, 100, 115, 200, 350, 600, 1000, 1500 & 2000 Liters for OINTMENT / CREAM / LOTION / PASTE / TOOTH PASTE. All contact parts are made out of S.S.304 quality material.(SS316 provided on demand on extra cost) Compact design requires comparatively smaller floor space. Lowering and lifting movement achieved through motorized drive in 140 & 200 liters model & hydraulic lifting system from 350 liters to 2000 liters size models. (In 60 & 100 liters models product container moving up & down manually. Motorised system can be provided on demand on extra cost, if required.) In all other bigger size models product container remain fixed and mixing drives comes up and down by means of mechanical or hydraulic system. Castore wheel mounted product container for the ease of mobility.(This facility available from 60 liters to 350 liters model only.) Container with fixed legs above 350 Liters model. Hence no facility of mobility of container. A high-speed emulsifier (Homoginizer) will be provided at the center axis, in 140 liters model and above capacity model only.(It can be interchangeable with disperser & necessary assembly provided with m/c) In-Line Homoginizer also provided on demand, if required. Double stirrer & SS scraper with PTFE blades for better mixing of the material.( In 140 Liters & above model only ) Single stirrer with scrapper in 60 & 100 Liters model. Planetory motion of the stirrer ( beaters ) enables faster and better mixing of the material at a considerable lesser time. As stirrer is a top driven and sealing doesnt comes in contact with product, there isnt any black particle contamination problem. Water / steam circulation jacket for mixing bowl, to heat or cool the mix during operation in OINTMENT MIXER only. (Water jacket recommended only in 60 to 350 litres model. Steam heating recommended in 600 litres to onward all models. Jacket also made out of mild steel in Standard Model & SS304 in GMP Model.) SPECIAL FEATURESAll non contact parts (general structure)made out of mild steel and claded with SS304 or crome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and non contact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model. General structure & all non contact parts are made out of Mild Steel & same will painted in Standard Model. Fixed type product container in 600 litres and above capacity models. Heater with temperature controller for heating facility. (For 60 / 100 / 200 / 350 litres OINTMENT MIXER only) 100 % utilisation of machine can be possible due to facility of change of extra product container. (In 60 to 350 litres model only) Vacuum facility provided on demand for de airation during mixing in Gel product. (For OINTMENT MIXER only) Insulation will be provided on jacket of container. (For OINTMENT MIXER only ) as a optional facility. Material discharge from bottom. Flush bottom valve provided for material discharge in 350 litres and above model only. (For OINTMENT MIXER only) M/C provided with Light glass, Sight glass ,material inlet, air suction valve for vacuum, CIP port facility. (For OINTMENT MIXER only) All connection of valve, light glass, sight glass will be triclover ended. Sampling port provided in 600 litres & above model. Flush bottom type valve in 600 litres & above model. All moving parts are enclosed with safety guards. OPTIONALSS316 product contact parts instead of SS304. Vacuum system for deairation during mixing. (For gel products) Variable speed drive for main agitators motor and emulsifier motor. Vacuum Pump Set. Flameproof model. "PLC" based operating panel for automation. Hydraulic lifting system in 60 to 200 litres model, instead of mechanical lifting system. APPLICATIONIdeal for mixing of Pharmaceutical powders, ointments, creams, lotions, pastes, tooth paste, cosmetics, food and confectioneries, rubber and rubber compound, colours and pigments, PVC & plastic material, ceramics, pesticides, insecticides, adhesives, metal powder, resins etc. etc.

Detergent Cake making Machines

Get Price Quote

We manufacture “Detergent Bar Making Machine” which are used to reduce detergent cakes with good finish. These are made of Mild SteelStainless Steel Worm Pipe, Screw and Mild Steel Fabrication stand. Fixed as well as adjustable dies are also available.