Automatic Horizontal Flow Wrapping Machine

230,000 Per Piece

1 Piece (MOQ)

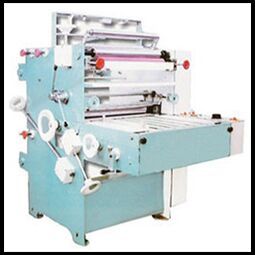

CO Extrusion Lamination Machine

1,577,000 Per Piece

1 Piece (MOQ)

Best Deals from Card Laminators

Stretch Wrapping Machine

165,000 - 170,000 Per Piece

Rubber Band Cutting Machine

75,000 Per Piece

1 Piece (MOQ)

Lamination Plant

Get Price Quote

This is the most important extrusion machinery for extrusion coating and lamination work. The extrusion coating lamination plant is used in various industries for lamination like paper, fabric, jute, aluminum foil, polyester etc. for effective and efficient coating and lamination. Lamination Plant is used in wide spectrum of plastic processes to form a continuous profile and plastic products. We are engaged in offering a wide array of Extrusion Lamination Plants. These plants are designed & developed in line with the set industry extruders. Further, our offered plants are tested stringently on the basis of several parameters that ensure their flawlessness. Our products are fabricated under the strict supervision of our diligent quality controllers. These lamination plants are find wide application in areas like cotton cloth, hessian cloth, aluminum foils, HDPE woven Fabric for bags, Tarpaulin and paper lamination. Features: Accurate in design Resistant to corrosion Durable Cost effective

Carton Box Wrapping Machine

38,000 Per Piece

1 Piece (MOQ)

Vertical Band Saw Machine

195,000 - 295,000 Per Unit

1 Unit (MOQ)

Continuous Band Sealing Machine

12,000 Per Piece

1 Piece (MOQ)

Bubble Wrapping Machine

400,000 Per Piece

1 Piece (MOQ)

Band Sealing Machine

13,000 - 15,500 Per piece

FR900 Band Sealing Machine

Get Price Quote

10 Piece (MOQ)

Vertical Band Saw Machine

Get Price Quote

Since the humble beginning the company has profoundly grown in a short span of time. Our manufacturing divisions are well equipped with the modern state - of - the - art technology machineries and equipments and the latest innovations are incorporated immediately before they become apparent in the market.

Shrink Wrapping Machine

2,500,000 Per Set

Overwrapping Machine

Get Price Quote

Over Wrapping Machine is widely applied in the products, such as Medical box, Gum, Health products, Tea-leaf, Cubic-sugar, Disk, condom, Cigarette, tape, Poker, Soap, Square-shape battery, and etc.Overwrapping machine is also known as cellophane wrapping machine is majorly used for perfume carton wrapping ,perfume box wrapping. Overwrapping machine is majorely used for clear film wrapping for condom box, condom cartons.

Wide Width Extrusion Lamination Plant

Get Price Quote

01 Set(s) (MOQ)

We are offering wide width extrusion lamination plant. Fuma multi-function extrusion coating laminating machine is developed continuously by ourselves, based on our production experience of more than fifteen years. It is characterized by advanced technique, reliable quality, easy to operate, and high automation, which is used widely in the industries of chemical, petrochemical, cement, sugar , salt, grain and wheat, animal feed, commodity items, metallurgy and mining and general purpose packaging, storage and transportation of many kinds of materials. The line uses pp or pe as raw material, through the flow-casting coating and lamination technology, achieving single-sided double-sided coating or paper-plastic lamination with substrates (plastic woven fabric), to produce coated or laminated products. The line is equipped with advanced electrical and mechanical devices throughout the whole production flow from substrate unwinding, lamination to winding, to achieve single control and group control. The dual-station unwinder uses automatic web guiding control for substrates, and brakes for surface tension control of substrates, achieving pneumatic splicing and non-stop roll changing. The laminator is equipped with preheating roll (optional) for preheating and drying of substrates. Laminating roll, silicon rubber roll and press roll are of dual-interlayer forced water cooling structure, with excellent cooling effect. The dual-station winder adopts constant-tension surface friction winding, pneumatic transverse cutting, roll changing without shutdown, and equipped with adjustable edge-trimming device, edge-strip blowing device, and length counting device.

Automatic Lamination Machine

1,800,000 Per Piece

Vertical Band Saw Machine

Get Price Quote

There is a new found our vertical band saw machine. First time in India this product made by us ECO-TOP. It is very useful in our vertical band saw machine. This eco-top are made from imported S.S. material. It is very smooth and ready to fast passing the wood. long life, improve in rubness and vetness.

Mineral Water Bottle Shrink Wrapping Machine

450,000 Per Piece

1 Piece (MOQ)

PP Strapping Band Making Machine

Get Price Quote

01 Set(s) (MOQ)

Heaven extrusion-india has developed high-tech box strapping plant to produce straps from polypropylene granules. The strap is suitable for manual clamping application, heat-sealing application and fully automatic machine heat-sealing application. We offers various models for single line, two lines, three lines and four lines straps with width of 6mm, 9mm, 12mm, 16mm and 19mm and co-extrusion plants for two layer or lining on straps with high production range from 35kg to 150 kghrs capacity. Box strapping extrusion generates plastic sections of continuous length through plastic extruder. Plastic granules are melting by required elements through plastic extruder to form a furnished product. This process is carried out through various components like extruder, quenching tank, first godet, hot water tank, stretching godet, online single color printing machine, embossing unit, stabilizing unit, third godet unit and wind on core winder

Band Saw Machine

Get Price Quote

Global outlook and features for the professionals who value precision workmanship Specially designed heavy duty body for better strength. Dynamically balanced CI broad wheels for smooth operations. 45° table tilting for angular cutting. Model No. J-530, J-540 Standard Accessories :- Saw blade, upper & lower saw blade guide set, mitre gauge, motor pulley, motor fixing plate, toolkit & m/c manual.

Shrink Wrapping Machine

Get Price Quote

Automatic Group Packing Machine is used in bulk packing of water bottle, cosmetics, juice bottles, soda bottles and other small packaging materials.we are providing this machine with one-year replacement guaranty. Allpack Engineers has set benchmark in offering Shrink Wrapping Machine to our clients. Shrink Wrapping Machine is able to fully eliminate different types of shrink wrapping problems which can result in the poor quality of packaging. It has got simple as well as excellent mechanical adjustments and operates at excellent speed. It operates in trouble free manner and is customizable as per requirements. Besides, we are offering this at market leading price.Water bottle Shrink wrapping machines suitable for gift's confectionery, bottle, cosmetics etc. It's a high speed of sealing machine and high equipment sealing. The complete process is visible & is furnish with L- sealer shaped. The automatic process of shrinkable pouch complete with web- sealer. We are provide very high quality of heat-sealing machine and branded Water Bottle Shrink Wrapping Machine. It's very easily used. Specifications : Power supply: 220 V 50 Hz Power: 12 kW Max. Packing speed: 40 bags/min Air pressure: 0.5 Mpa

Metal Cutting Bandsaw

58,000 - 1,000,000 Per Piece

Lollipop Wrapping Machine

340,000 Per Piece

1 Piece (MOQ)

Manual Edge Banding Machine

Get Price Quote

1 Piece (MOQ)

Automatic Shrink Wrapping Machine

Get Price Quote

Machines / Packaging Machinery /Shrink Wrapping Machine... Automatic Shrink Wrapping Machine consists of Manual in-feed finger conveyor system, Side Sealer, Shrink Tunnel, and Control Panel (PLC).

Lamination Machine

Get Price Quote

With wet laminations, the adhesive is applied to one substrate, usually by roller coating or air knife. The coated substrate is then nipped with another substrate, and the resulting laminate may then be left to air dry or passed through a heated oven to remove solvent and build bond strength. The types of adhesive used for wet lamination are waterborne natural products, such as starch and dextrin or waterborne synthetic latex products, such as polyvinyl acetate, acrylic, etc. 100% reactive liquids, such as polyurethanes or polyesters.Wet lamination via waterborne or solvent based adhesives is confined to applications where at least one substrate is porous (e.g., paper, cardboard, textiles) to facilitate drying. Once cured, bond strength is generally high enough to cause failure or tearing of the porous substrate. Most often, waterborne synthetic latex adhesives are utilized for wet bonding because of their high initial strength and fast drying characteristics when applied to porous substrates. Dry Lamination Dry laminations are those in which the liquid adhesive is first dried before lamination. The adhesive can be either applied to one substrate and dried or it can be applied as a hot melt type of film (essentially another film layer). The adhesive is then in the dry solid or slightly tacky stage when joined with the other substrate. The bonding is generally achieved during a high temperature, high pressure nip. The temperature and pressure are sufficient to cause the adhesive to flow and create an instantaneous bond when it cools and gels. Dry lamination can be applied to a broader range of products such as film-to-film and film-to-foil. Dry laminating adhesives are generally solvent based although considerable development has taken place to reduce or replace the solvent to meet environmental regulations. This has produced several strong competitors to conventional solvent-based adhesives such as: hot melts (e.g., ethylene vinyl acetate copolymers), 100% reactive solids (e.g., two-part polyurethanes, one part moisture curing polyurethanes and UV/EB curable acrylates), high solids solvent based (e.g., silicone), and waterborne adhesives (e.g., acrylic emulsions). A significant advantage of reactive 100% solids adhesive in addition to the reduction in possible VOCs is the possible elimination of drying ovens and resulting energy cost. Salient Features Heavy duty C.I. Cast iron & Heavy fabricated structure Gravure type coating system Liner type impression pressure assembly actuated with pneumatic piston for rubber roll Doctor blade and Nip Roller Fully insulated imported special glass wool sheet fitted in the panel (Top side & Bottom) For controlling heat loss One & One Slit type counter air flow arrangement, Divided equally are placed against roller for proper web support Exhaust are distributed through-out the length of drying chamber & individual exhaust duct for each zone Digital temperature controller with indicator & PT 100 sensor for each Zone Inside heating for Nip Steel roller Heavy duty Shaft types fix Rewinder with motor Rewind Station A. C. synchronize Drive with Load cell Center winding system / Surface Hot Air Generator Diesel / Fired Air Heater Thermic fluid Heater with Blower Coating Unit Independent A.C. Drive Pre – Heating / Exhaust Unwind Station Tension control Brake Unit with load cell feedback (Pneumatic/Motorized) Moveable unwind with web guide Note : The actual production speed will however depend on all lamination condition, such as type weight and quality of material adhesives and solvents atmospheric condition operator skillfulness etc. Ideal roller : Aluminum 85 mm O.D width inside bearing with 25 mm MS shaft. Tunnel Roll : 75mm with 20mm shaft HEATING ARRENGMENT : Heating arrangement through hot air generator 50 um to 1 lakh or 1hp blower with 12hp heater(for each chamber) Heat Controller : tharmoset or temp controller Material to be laminated : Paper Polyester, BOPP Allum, Foil LDPE & other allied material Frame Structure : CI plate up to 20/40 mm and Channel 4-2 Dryer : glass wool panel from MS sheet. Coating system : gravure type coating with CI plate up to 20 mm and With coating cylinder mounting shaft, doctor blade, and manual rubber roll lifting, Laminating lead : CI plate up to 20 mm and 1 No. HCP roll with Special type of heater arrangement for laminating subtract for perfect bonding. 1 No. full width rubber roll pressure arrangement with manual lifting common drive from coating manual SYNCRONISE for acting as a laminating drive REWIND STATION : One Rewind 50 mm EN-8 shaft complete with core holder check nuts. Common drive through mechanical clutch 1 No. Lay-on roller for Rewind

PP Strapping Band Making Machine

2,500,000 - 5,000,000 Per Piece

1 Piece (MOQ)

Surface Protection Laminator Machine

Get Price Quote

for aluminum, stainless steel and color coat sheet / strip for surface protection and avoid scratches, dents handling mark during intermediate process. model: laminator lm32, lm50 & lm 62 working sheet thickness: 0.5mm to 5 mm working width: 800mm, 1250mm & 1550mm working length: 2500mm & 3000mm, coil also can in length with support table dimension approximate size length 13.5`x width 68''x center height57" weight technical specification and mechanism: 1. 62" width 125 mm dia nitrile rubber laminating roller with ball bearings in ms blocks attached to 150 dia 50mm stroke pneumatic cylinder controlled by solenoid valve with frl & pressure indicator.2. 125 mm dia ebonite roller. driven by ac motor 2 hp 3phase and worm reduction gear box attached to roller by chain drive detachable 6' long front gravity feed conveyor with 40mm dia glass filled nylon bushes on 20mm dia ms rod with hdp spacers. 6' long back side conveyor.3. loading and unloading table, air compressor not included and need extra as a accessory laminators provide the ultimate touch applying temporary surface protection films to large surface areas can be accomplished using a variety of manual techniques. yet, to obtain professional-looking, bubble & wrinkle free laydown, a laminator is typically required. in high volume production operations a laminator is a guaranteed money saver.valgro offers a full range of standard and custom built laminators to meet the needs of your application, whether that be light to medium duty or high volume heavy duty devices for 24 x 7 utilization.if you don't see what you need on our website, we will have it built to your specifications. advantages of a laminating machine metal surface protection from weather effect contamination, finger mark and handling scratch during fabrication good alignment of the laminate to the surface – no air bubble wrinkles free coating consistent overall pressure which creates optimum adhesion of the psa film to the surface much higher production speeds than manual application can achieve a clean & professional looking finish that complements the appearance of the underlying product. high quality nitrile rubber laminating roller with ball bearings in ms blocks attached to pneumatic cylinder controlled by solenoid valve with frl & pressure indicator. conveyor pressure roller driven by ac motor 2 hp 440 v 3phase and worm reduction gear box attached to roller by chain drive detachable 6' long front gravity feed conveyor with 40mm dia glass filled nylon bushes on 20mm dia ms rod with hdp spacers. 6' long back side conveyor. power control vfd external speed & forward/reverse control .roller operation by foot switch. thickness of panel adjustable. cost of air compressor is not included approximate size length 13.5`xwidth 68''x center height57" weight 600kgs with stainless steel, finish is everything. whether you are looking for a brushed, bright annealed or mirror appearance, a single scratch can ruin the value of your product and cut through the protective surface layer which gives "stainless" its name.the problem is that your stainless steel faces many potential hazards throughout the fabrication, shipping and installation processes. the surface can be marred at any step along the way, and the cost of fixing or replacing the product can put a big dent in your profit margin.you can protect your stainless steel from damage, and protect your bottom line, with stainless steel protection film. keeping stainless spotless low-cost stainless steel protection film provides a great return on investment, as it eliminates scrapes or scratches to the steel surface itself. any damage or soiling impacts only the protective film, which is then easily peeled off and disposed of. your product remains completely clean and untouched.

Band Saw Machine

500,000 Per Piece

Band Sealing Machine

15,000 - 35,000 Per Piece

1 Piece (MOQ)