Band Saw Machine

500,000 Per Piece

Double Column Semi Automatic Horizontal Bandsaw

Get Price Quote

Stress Relieved Fabricated Steel Structure Hard Chrome Plated Ground Column Automatic Height Adjustment for Saw Frame Variable Pressure Control for Cutting Feed Auto Cutting Stop Push Button Type Operating Panel Board Heavy Duty Worm Gear Box Moveable Blade Support Guide Manual Blade Tensioning Arrangement Material Feeding Manually Sawing mode changes, flexible, manual & automatic Combined PLC controller complete automatic sawing procress Standard Accessories : Saw Blade Coolant Systems Machine Lamp Blade Tensioning Wrench Adjustable Bar Support Stand Tool Kit Operating & Instruction Manual

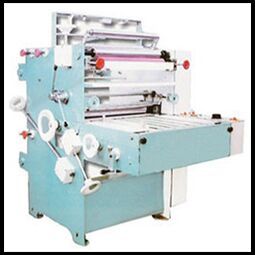

Best Deals from Card Laminators

Automatic Ball Lollipop Wrapping Machine

Get Price Quote

Toilet Soap Wrapping Machine

Get Price Quote

Automatic Single Twist Wrapping Machine

Get Price Quote

Band Saw Blade Joiner Welding Machine

30,300 - 35,300 Per Set

1 Set (MOQ)

Specially Designed for Bandsaw Blade Joining

Stretch Wrapping Machine

55,000 Per Piece

1 Piece (MOQ)

automatic horizontal flow wrapping machine

230,000 Per Piece

1 Piece (MOQ)

Lamination Rubber Roller

18,500 - 28,500 Per Piece

1 Piece(s) (MOQ)

Adhesive Coating Lamination Plant

3,251,000 Per Piece

1 Piece (MOQ)

Toilet Soap Wrapping Machine

Get Price Quote

High speed wrapping machine capable of wrapping toilet soaps with stiffener and heat sealable (hot melt coated) at a speed up to 160 ppm(depending on nature of product and wrapper). Ingress to the machine is by means of an infeed belt conveyor engineered to index at higher speed. This conveyor is set at right angle to the flow of product for subsequent wrapping operation and can have right hand or left hand orientation to suit the space requirement. Handling of product is gentle throughout the operation and any rubbing of naked soap with stationary surface is avoided, Heavy cast iron structure for vibration absorption and durability.Heavy cast iron structure for vibration absorption and durability.Automatic Print Registration Unit by means of imported sensor, PID temperature controls from Honeywell or equivalent make, The machine speed upto 160 ppm (machine speed and accuracy is dependent of quality of packing material, soap size and its quality, uniform inflow of the product) with Heavy distortion free cast structure.

Manual Edge Banding Machine

Get Price Quote

1 Piece (MOQ)

Band Sealing Machine

15,000 - 35,000 Per pcs

Automatic Shrink Wrapping Machine

Get Price Quote

Machines / Packaging Machinery /Shrink Wrapping Machine... Automatic Shrink Wrapping Machine consists of Manual in-feed finger conveyor system, Side Sealer, Shrink Tunnel, and Control Panel (PLC).

Continuous Band Sealing Machines

25,750 Per Piece

1 Piece(s) (MOQ)

Portable Edge Bander J-1000.in

Get Price Quote

Salient Features : Machine is light in weight, so it can be used for large size boards where the job is fixed onto a table & machine can be used on it.

hand wrapping machine

Get Price Quote

This Hand Wrapping Machine allows hygienic product presentation and keeps products dustfree. This wrapping machine is used for packaging food to preserve the freshness and to enhance the appearance. They are made of stainless steel construction for cleanliness and ease of maintenance and equipped with an electric heat blade that cuts the wrapping film without fumes. The heated PTFE Non Stick plate gives a tight seal. It can take a roll of wrapping film up to 18″ wide. SALIENT FEATURES Practical light-weight design Temperature control of heated plate Stainless steel construction Unit weights 6.4 kg /14 lbs (without roll) 2 Amp Fuse Voltage: 115/60hz ALSO KNOWN AS PRODUCT WRAPPING MACHINE HOT STRETCH WRAPPING MACHINE STRETCH FILMS WRAPPING MACHINE

Vertical Band Saw Machine

62,000 Per Piece

Pallet Stretch Wrapping Machine

Get Price Quote

Roll Starch Wrapping Machine

Get Price Quote

Mechanical brake for set tention Reduction gearbox with motor drive for turn table roll assembly 1000mm rubber fillet covered roll with mechanical synchronizes drive Pre settable counter for rotation of stretch film,starter for ac motor Protection against moisture and dust Prevent telescoping of rolls Save packaging cost, Labour and time Better identifications of wrapped products Give stability to the product Economical way of packaging

Printing & Lamination Roller

Get Price Quote

The Printing & Lamination Roller, which we offer, is manufactured in compliance with the set industrial standards. We are ranked among the credible Manufacturers, Suppliers and Exporters of the Printing & Lamination Roller, located in Ahmedabad. In addition, we offer these Printing & Lamination Rollers at affordable rates. Types of Printing / Lamination Offset printingRotogravure printingFlexo-graphic printingSolvent less / solvent base laminationExtrusion LaminationHeat & Press LaminationTin Printing Key Performance Indicator Dimensional accuracyGiving appropriate hardness depending on type of printing No run out on finished diameter with reference to bearing size Outstanding rubber surface finish without porosity Highlights DurableBest printing resultGood abrasion resistanceAnti-Static / anti-ozonenatConductive compound Delivery Time : 1-2 weeks (Terms & Conditions)

Box Stretch Wrapping Machine

Get Price Quote

SPSW 350 And SPSW 600 Box Stretch Wrapping Machine could be used for both single cargowrapping as well as wrapping some small cargos combined. Pneumatic top plate ensures clam and safety packing with this machine. The packing height, fixed film carriage or up-down film carriage can be chosen according to choicest customer’s requirements in this box stretch wrapping machine.

HDPE Tarpaulin Lamination Plant

4,450,000 - 45,000,000 Per Piece

currency note banding machine

38,000 Per Piece

1 Piece(s) (MOQ)

Shrink Wrapping Machine

450,000 Per Piece

Portable Edge Banding Machine

Get Price Quote

The most efficient entry-level edge-bander, the panel industry can get in this category. Do all your basic edge-banding work on it with Euro standard features like optimal and consistent glue-spreading, heat bonding and pneumatic edge-cutting. The machine guarantees perfect glueing on board as well as on tape at all times and is versatile and suitable to be used by small and large manufacturers. Efficient bonding system The glue in the glue pot, glue leveler, wiper, the extrusion screw and the heating element all make a bonding system. Pneumatic cutter on the work table The pneumatic cutting device can be set to actuate the pneumatic cuttur to cut the band. Electronic counter can be used to cut the pre-defined length for curvilinear jobs.

Lamination Plant

Get Price Quote

This is the most important extrusion machinery for extrusion coating and lamination work. The extrusion coating lamination plant is used in various industries for lamination like paper, fabric, jute, aluminum foil, polyester etc. for effective and efficient coating and lamination. Lamination Plant is used in wide spectrum of plastic processes to form a continuous profile and plastic products. We are engaged in offering a wide array of Extrusion Lamination Plants. These plants are designed & developed in line with the set industry extruders. Further, our offered plants are tested stringently on the basis of several parameters that ensure their flawlessness. Our products are fabricated under the strict supervision of our diligent quality controllers. These lamination plants are find wide application in areas like cotton cloth, hessian cloth, aluminum foils, HDPE woven Fabric for bags, Tarpaulin and paper lamination. Features: Accurate in design Resistant to corrosion Durable Cost effective

Lamination Rubber Rollers

Get Price Quote

Cooling Roller comes with a hard chrome plated surface & Rubber coated roller. Cooled water passing through its Rotary joint cools the hard chrome plated surface area of the Roll. Standard Cooling Roll cools the contact area that touches the web materials. There are different types of Cooling Rolls like single shell, double shell jacketed type, spiral type. The Surface Cooling Roller results in varying effects in different type of Cooling Rolls. Rotary Cooling Roller has a shaft with inside hole to fix rotary joint. Bigger shaft diameter is recommended to avoid breakage of end shafts as end shaft having inside hole and uneven alignment or heavy tension on shaft result brakeage so bigger shaft diameter is recommended. We are called upon as one of the major Industrial Cooling Roller Manufacturers in Gujarat(india). For hot laminating rollers (up to 220oC), we would recommend using a high-release silicone compound, as this compound is capable of withstanding such temperatures & non sticky properties. For hot lamination rollers, where temperatures will not exceed 150oC (and high load, abrasion and wear are considerations), then we would recommend using a synthetic rubber compound. These could include Hypalon, Carboxylated Nitrile and EPDM. Lamination applications, include: Paper laminators. Printed circuit board laminators. Dry film laminators. Cold lamination. Hot lamination.

rubber band cutting machine

75,000 Per Piece

1 Piece (MOQ)

Band Sealer Machine

Get Price Quote