Hydrocyclone Filter

Get Price Quote

500 Piece (MOQ)

Rubber Conveyor Belt Vulcanizing Press

Get Price Quote

1 Unit (MOQ)

Best Deals from Cast Iron Filter Press

Plastic Frame Fine Dust V-Shape Compact Filters

200 - 1,500 Per piece

10 Piece (MOQ)

Metal Frame Filter

Get Price Quote

10 Piece (MOQ)

Rubber Conveyor Belt Vulcanizing Press

300,000 - 600,000 Per Piece

1 Piece (MOQ)

Sparkler Filter Press

100,000 - 500,000 Per Number

1 Piece (MOQ)

Filter Press Machine

50,000 - 650,000 Per piece

A filter press machine is a mechanical device used for solid-liquid separation processes. It is designed to separate solids from liquids by passing a slurry through a series of filter plates and frames arranged in a vertical or horizontal orientation. The slurry is pumped into the filter press machine and the solids are trapped in the filter chambers while the liquid passes through the filter cloth and exits the machine.

Pharmaceutical Filter Press

Get Price Quote

filter size for 8x6,.

Lab Filter Press with Pump

Get Price Quote

Zero Hold Up Filter Press

Get Price Quote

The Cartridge assembly consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquids spreads out equally on each plate fitted with filter media. Solids remain on filter media and clear. filtrate flows through precisely made holes on sides of plates and collects in the shell, which then comes out through the outlet. In this process, solids are evenly distributed on each plate. The cake is then cleaned from the filter material and used again for filtration process.

Horizontal Filter Press

Get Price Quote

We bring forth high precision Horizontal Filter Press in the international market. Our Horizontal Plate Sparkler Type Filter Press is used for the separation of sold or liquid from a sample. The separation process is done throng the plates in this filter press. Apart from that, we are one of the leading Horizontal-Type Filter Press Exporters from India.We bring forth high precision Horizontal Filter Press in the international market. Our Horizontal Plate Sparkler Type Filter Press is used for the separation of sold or liquid from a sample. The separation process is done throng the plates in this filter press. Apart from that, we are one of the leading Horizontal-Type Filter Press Exporters from India.

Zero Hold Up Filter Press

200,000 - 1,000,000 Per Pieces

1 Piece(s) (MOQ)

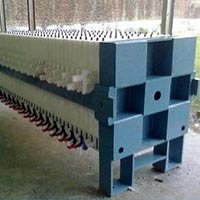

Filter Press

60,000 - 350,000 Per Piece

1 Piece(s) (MOQ)

Features: GMP model stands on SS trolley Manufactured using quality raw material such as S.S. 304/316/316L M.O.C Available in various sizes and different diameters having numerous number of plates It also provides the Back wash facility for continuous operations. Two filter plates are available – Deep and Shallow The horizontal filter plates prevent the cake dropping from the shell. Application Area : Pharmaceutical Industries Chemical Industries Food Processing Industries Cement Industries Distillation Plants Oil Industries Dairy Industries Paint Industries Beverages

Filter Press

Get Price Quote

01 Set (MOQ)

Various Types of Filter Press We provide all types of filtration solution for Solid Waste from Liquids,with high range oriented quality of filter plates and filter cloths.

Membrane Filter Plates

Get Price Quote

The initial operation of a membrane filter press is identical to that of its recessed chamber counterpart. However once the filtration cycle is complete and final filtration pressure is achieved the feed into the filter press is stopped. At this point the plates within the Filter Press can be inflated using either air or hydraulic pressure to exert a mechanical force on the filter cake retained in the chamber. The effect of the squeeze is to physically compress the filter cake and force out additional moisture held within the cake giving a drier end result.

Hydraulic Filter Press

Get Price Quote

Hydrocyclone Filter

Get Price Quote

Range 20 and 25M3hr(2"), 40M3hr(3"), and 50 M3hr (3" & 4") Standards IS 14743 Application Primary filtration for Micro Irrigation Systems

Filter Press Machine

Get Price Quote

Operation: This system consists of a closed circuit manufacturing facility from feeding of Sugar / Water Phase to loading the Volumetric Liquid Filling Machine to prepare Sugar solution. With vacuum system or mechanical system or manually the Sugar and Water, are loaded. The Sugar Syrup Vessel is supplied with high speed stirrer. Electrical heating (In small model) Steam heating facility (In bigger size model) . The sugar syrup is prepared at required temperature & is transferred to Manufacturing Vessel by vacuum or by transfer pump. The product during emulsion formation is re-circulated through In-Line Homogenizer / Liquid Transfer Pump. The Pump also discharges the product in the Storage Vessel. The Storage Vessel is then taken to the filling area ( if it is small capacity ) and is connected to again Liquid Transfer Pump. Or Storage Vessel remain fixed ( In bigger size ) & pump transfer the Liquids in the float tank which is connected with filling machine. The entire Plant can be operated by centralized operating panel by one operator The plant is equipped with an electrical control panel with digital temperature indicators / controllers and digital timers. Minimum two batches per shift of the same product can be assured in this plant. This plant conforms to cGMP standards (Paint Free Construction). The Salient Features: It is possible to operate the Plant by one operator and one helper. All material transfers are done by vacuum or by transfer pumps. All cGMP vessels (paint free construction) Silicon (food grade) gaskets are used. The entry of stirrer & high speed emulsifier can be from top or from bottom (as per customer requirement) or In-line Emulsifier. All vessels can be sterilized due to internal pressure of 1 Kg. / Sq. cm. Customer can use CIP & SIP facilities of CIP & SIP connections equipped in the entire plant The control panel indicates all values of temperature & time of the plant digitally. Ampere is indicated on Ampere meters. Tri clover joints are given with all the inlet & outlet connections which are very easy for cleaning & replacement. All contact parts are of SS 304 / SS 316 (SS316 - L / as per customers requirements.) All pipes, pipe fittings and valves are of SS304 / SS316 ( as per customer requirement ), internally electro polished, with tri-clover ended joints. A micro processor based automatic operating plant can be designed ( as per customer requirement ).

Horizontal Filter Press

Get Price Quote

1 Piece (MOQ)

filtroUNO® Horizontal Filter Press combines proven filtration with the benefit of easy maintenance due to its flow design. The horizontal arrangement of the plates assures economical operation and uniform clarity by maximizing the distribution of the filter cake. During filtration, all solids are retained on the pads in the press. Cleaning is quick and easy by simply removing the entire bundle. FEATURES ÷ Superior, clean filter tank processing ÷ Efficient for batch or continuous operation ÷ Internal filter plate cartridge assembly fully contains filter cake ÷ Fast, easy removal of filter plate ÷ Positive sealing during increased pressure differential ÷ Complete recovery of product ÷ Engineered to be used with or without filter aids ÷ Wide range of filter media available: paper/sheets and non-wovens/woven cloth ÷ System can be supplied with or without pump (FLP or Non-FLP) ÷ Wide variety of connections and plate sizes ÷ Zero fluid loss ÷ Fully integrated skid and trolley designs

Membrane Filter Press

Get Price Quote

1 Piece (MOQ)

The membrane strainer is a solid liquid separation equipment using the principle of pressure feeding. It is being used successfully in almost every industrial filtration processes. It includes a series of filter / strainer plates and frames or recessed plates which are arranged alternately. A filter / strainer medium is provided in between the plates. A feeding pump is utilized to force the liquid through the medium leaving the solid trapped inside. Because of its simplicity and flexibility, the chamber Membrane Strainer has been widely applied in clarification and dewatering applications.