Cement Feeding System

Get Price Quote

Exporter, Manufacturer and Supplier of Cement Feeding System, Pneumatic Cement Feeding System, Cement Silo Feeding System, Feeding System, Cement Conveying System, Silo Feeding System, Aggregate Feeding System, Cement Handling System, Powder Feeding System, Cement Feeding Machine..Batching Plant, Batching Plant Silo Accessories, Silo Fabrication, Fly Ash Storage Silo, Grain Storage Silo, Powder Storage Silo, Storage Hopper, Feeding System, Cement Silo, Fly Ash Silo, Cement Storage Silo, Storage Silo, Silo, Mild Steel Silo, Steel Silo, Stainless Steel Silo, Rmc Plant Silo, Batching Plant Silo, Grain Silo, Cement Feeding System..

Mild Steel Tile Adhesive Mixing Plant

150,000 Per Unit

1 Unit (MOQ)

Best Deals from Cement Plant Parts

Cement Bricks And Block Making Machine

1,280,000 Per Set

Semi-Automatic Cement Road Paver Machine

375,000 Per Piece

1 Piece (MOQ)

Cement Feeding System

580,000 Per Piece

1 Piece(s) (MOQ)

cement grinding plant

1,000,000 Per Unit

1 Unit (MOQ)

Clinker Breaker Roater

Get Price Quote

Highly praised for presenting high-grade quality Clinker Breaker Roater, we are a celebrated Supplier in the market. We have superior storage capacity to safely store the extensive product range that we offer. Our massive and well-maintained storage space is well-connected with the shipping unit. Features: Precision made High strength Industrial application

Dry Mix Mortar Plant

Get Price Quote

Dry mix mortar plant is generally used to produce various ordinary and specific mortars, which includes plastering mortar, masonry mortar, waterproof mortar, tile adhesive mortar, wear-resisting floor mortar, thermal insulation mortars and etc. Dry mortar mix plant basically consists of wet sand feeding system, drying system, hoist lifting system, raw material storage system, weighting system, mixing system, finished product storage bin, packing system, dust collector and control system. Generally, the raw materials are put into the drying system of dry mortar mixing plant at first. After drying, the raw materials are conveyed to material storage system by hoister. Then, all of raw materials and additives will undergo accurate weighting and even blending in the mixing system of dry mortar equipment. Advantages lie in that customers can either pack the mortars in bags or just keep them in the finished product bin according their actual demand.

Cement Plant

9,000,000 Per Unit

Ready Mix Plaster Plant

3,000,000 Per Piece

Cement Block Making Machine

Get Price Quote

This Machine Can Produce Cement Brick,Concrete Block Like Solid Block, Hollow Block & Paver Block as per your requirement.

Cement Feeding System

310,000 Per Units

1 Units (MOQ)

Cement Silo

500,000 Per Unit

Cement Feeding System

Get Price Quote

Cement Feeding Systems are constructed of mild and structural steel, and mounted on a base. FS pumps are equipped with pedestal blocks that support a pump screw which helps to provide a smooth, balanced operation. The screw is dynamically balanced and areas of this screw, along with other parts of the pump in direct contact with the material to be conveyed, are made of hardened, wear-resistant material and special hard surfacing where required. The screw is directly coupled to the driving motor but can be v-belt driven.Standard equipment on FS pumps includes a pressurized seal and bearing assembly that extends the service life of the discharge seals by preventing the material being handled from entering the bearing area. Each pump system includes the pump, drive motor and compressed air source.It is the most versatile and speedy method of transferring bulk material from one point to another within a defined area.

Rotary Kilns

Get Price Quote

A Rotary kiln is a processing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include: Cement Lime Refractories Metakaolin Titanium dioxide Alumina Vermiculite Iron ore pellets

Dry Mix Mortar Plant

1,200,000 Per Set

1 Set (MOQ)

Automatic flyash cement brick making machine

780,000 Per Unit

1 Set (MOQ)

JEs700 Fly ash /Cement Bricks & Blocks Making Machine. This machine can make 700 bricks per hour. In this model you will get 5 feet roller pan mixer and 15 feet long conveyor belt and top mounted hopper. Raw Material feeder system for feeding the raw materail in the machine. 3500 PSI Pressuer for perfect finishing the bricks or blocks, 7 feet long conveying railing to easy moving the bricks pallets, and after changing the die machine can make Paver blocks and solid blocks.

Bopp Self Adhesive Tape Plant

4,515,000 Per Piece

Cement Treated Feeding System

Get Price Quote

Owing to the expertise in the market we are one of the manufacturing and supplying a wide range of Cement Treated feeding System. The materials to be conveyed enter the hopper is manufactured by utilizing optimum quality components and advanced technology in line with the set industry standards. Having high efficiency screw conveyor deliveries the specified quantity of the line to the pug mill unit. Our highly skilled professional teams test the entire range of the feeding system on different quality parameter before dispatching it. Our Filler silo has 40 MT capacities with a bucket elevator arrangement for receiving cement line from bags. We offer cement treated feeding system at a very nominal rate to our clients. Features Smooth operation, high efficiency and long service life Provide a high degree of Sanitary environment Trouble free functionality Less maintenance due to the rugged construction Easy to operate Convey line is connected with the high capacity blower to generate the sufficient force to convey the materials in to the storage silo.

Cement Feeding System

Get Price Quote

Cement Feeding System, Two Stage Liquid Ring Vacuum Pumps

cement feeding pump

Get Price Quote

Cement Fly Ash dual feeding system (Screw Pump + Twin lobe root blower) (For bag cement & loose cement), Model : PCP – 2.It consist of a single axle tyre mounted chassis with the arrangement of unloading cement fly ash from bulker as well as for bag cement (manual) with a small debagging hopper of 800 Kg. (600 lit.) in which cement bags are emptied.

Cement Silo

700,000 Per Piece

1 Piece (MOQ)

Cement Machinery

Get Price Quote

Cement Machinery, Roller type edge sensor

Cement Feeding System

Get Price Quote

Cement Feeding System, Twin Lobe Roots Blower, bulker unloading system

cement plant machinery part

Get Price Quote

cement plant machinery part, acme screw, Sugar Machinery Parts, Roller Shaft

reliable cement plant parts

Get Price Quote

reliable cement plant parts, transit cement mixer, Concrete Transit Mixer

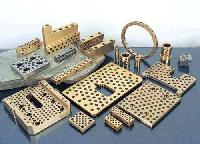

Cement Plant Spare Parts

Get Price Quote

Cement Plant Spare Parts, construction machinery spares parts

thrust roller rotary kilns

Get Price Quote

thrust roller rotary kilns, locking rotary kilns, cement rotary kilns

Cement Feeding System

Get Price Quote

Cement Feeding System, aggregate feeding system, Screw Conveyor

Cement Machinery

Get Price Quote

Cement Machinery, heavy duty stretcher systems, paper mill machinery