cement mixture machine

Get Price Quote

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Cement Silo

Get Price Quote

01 Set(s) (MOQ)

We are a manufacturer of cement silo as per customer requirement all of size and capacity are also as per requirement..

Best Deals from Cement Plant Parts

Cement Storage Silo

750,000 Per Piece

Dry Mix Mortar Plant

975,000 Per Unit

1 Unit (MOQ)

cement bag filling machine

400,000 - 410,000 Per piece

2 piece (MOQ)

Adhesive Coating Lamination Plant

3,251,000 Per Piece

1 Piece (MOQ)

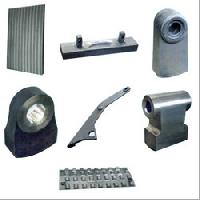

Cement Plant Spare Parts

Get Price Quote

we are engaged in offering a quality range of cement plant spare parts to the clients. Cement plant spare parts, offered by us, are easy to install and have longer service life. Our cement plant spare parts have sturdy construction and, are resistant to corrosion. We offer these cement plant spare parts in corrugated box packaging.

Cement Feeding System

Get Price Quote

It is the most versatile and speedy method of transferring bulk material from one point to another within a defined area.The Umiya Screw Pumps are heavy-duty, screw-type pneumatic pumps. These pump systems are most commonly used to convey dry, free-flowing, pulverized materials from grinding mills, transfer materials from silo to silo, transfer dust from collectors, and load and unload railcars, ships and barges. The materials are conveyed literally anywhere a pipeline can be run and to any number of delivery points.

cement plant machinery power plant spares

Get Price Quote

cement plant machinery power plant spares, Vessels, REACTOR, Boiler

Manual Cement Brick Making Machine

Get Price Quote

With the significant support of our seasoned professionals, we have evolved as a reputed manufacturer and supplier of Manual Cement Brick Making Machine. Specifications: Motor 2 H.P 1440 RPM (universal type) all mold will be fitted No of Operations Per Hour: 50 to 60 Motor Single / Three Phase: 2HP Weight Approx: 300 Kg No of block production using wooden pallets per stroke: 400 X 200 X 200 2 No’s 400 X 150 X 200 2 No’s 400 X 100 X 200 2 No’s 230X110X75 MM 6 No’s

CEMENT FEEDING

Get Price Quote

Pneucon is considered as one of the very well trusted and leading Cement feeding system manufacturer that supplies huge range of Cement Feeding Systems. We provide finest quality products made out of superior components and raw materials acquired from the best suppliers in the market. To avoid complaints regarding the defects in the product the manufacturer severely keep check of the various parameters before the delivery of the product. These cement feeding system are known for their durability, strong construction with minimum maintenance cost and high performance. The cement feeding system is the quickest as well as flexible method which is used to transfer the bulk material from a particular to point to another in a specific area. Pneucon is engaged in supplying huge range of such systems to the various construction sites across many destinations. We manufacture hassle free performance giving systems and are one of the top Cement Feeding System Manufacturer Gujarat. The products manufactured by Pneucon are heavy duty as they are used mostly to transfer dry, crushed material from mills, free flowing, load the railcars and unload those and covey the dust from collectors. The materials can be transferred to anywhere. See how our Products are Useful & Reliable: The sophisticated machines provided by the company are very useful and reliable. The products are manufactured under high supervision of the professionals to ensure the safety and maintain the consistent quality of the products. The design of the cement feeding systems by Pneucon is compact and is rigid built and serves many clients in the market. This cement system manufacturer India will soon occupy the best position in market. The material to be transferred goes into the hopper because of the gravity. The system is so developed that the material gets compacted. The density of the materials increases due to the space present in the front of the non-return valve and terminal of the screw flight in order to create a seal so that blowback is prevented. Later, the components go inside the discharge body and compressed air fluidizes it and is transferred in the transport line. Pneucon holds an expertise in supplying strong and tough products with no corrosion assurance. The professionals in the company can deal with the queries of the customers and their requirements. Cement Feeding Systems are generally made of structured and mild steel which are placed on a base. FS pumps helps to operate smoothly as they possess pedestal blocks that are important to provide support to pump screw. The screw is very well balanced and made with an appropriate hard surfacing, wear resistant material and tough coating whenever required. The screw is connected directly with the motor. The equipment used on FS pumps is standard and the assembly that handles the system is durable enough to extend the life of the materials used in manufacturing the product and avoids the problem. Every system of pump comes with a pump, a motor and a source of air that is compressed. Following Accessories Included - Suction Silencer - Discharge Silencer - Spring Loaded safety Valve - Pressure gauge - Suction Filter - Driven Pulley - Non Return Valve - V-Belt Set - V- Belt Guard - Drive Pulley Salient Features - Closed System - Ensures contamination free transfer for material - No Spillage or wastage involved - Minimum Maintenance - Speedy & User friendly designs

Vertical Shaft Kiln

Get Price Quote

Vertical Shaft Kiln is the right option for the refractory. Numerous fuels such as coke, coal, gas, oil, as well as other alternative fuels are combusted using different types of burner or charging systems. Our Production capacities for Vertical Shaft Kiln vary from 70 to 500 TPD are achieved.Equipped with external burners and inside special refractory structures, that allows a homogeneous heat distribution in all the kiln cross section. These kilns allow the use of a wide range of fuels, alternate andor contemporaneously. Thanks to their particular technology, in these kilns it’s also possible to use solid pulverized fuels as pet-coke, coal, saw dust or other waste fuels.

Cement Block Making Machine

Get Price Quote

Cement Block Making Machine, Fly Ash Brick Making Machine

Cement Silo

Get Price Quote

Cement Silo, Concrete batching Plants, Plc Control Panel

Cement Plant Machinery

Get Price Quote

Cement Plant Machinery, chemical machine, Heavy Fabrications

Rotary Kilns

Get Price Quote

viki refractory works manufacturing rotary kiln and supplies. the moist material moves through the rotary kiln, it is dried and preheated by the kiln gas, flowing in a counter-current pattern. in the reaction zone, reduction of the metal oxides occurs around 1200ã‚â°c as the zinc is vaporized as metal vapor into the gas cleaning system. zinc is then re-oxidized in the kiln atmosphere that is operated with excess air (process air is injected from the kiln end).

Cement Plant Gear

Get Price Quote

Cement Plant Gear, Ductile Iron Casting, Carbon Steel Casting

Cement Plant Gears

Get Price Quote

Cement Plant Gears, Straight Bevel Gears, Hob Cut Gear, hypoid bevel gears

Plaster Of Paris Powder

Get Price Quote

Plaster Of Paris Powder, Gypsum Plaster