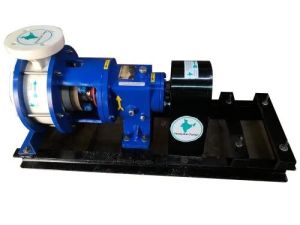

Milk Centrifugal Pump

Get Price Quote

5 Piece(s) (MOQ)

We sternly keep a check on the designing and manufacturing of products and ensure that the material is strictly procured from the leading names only. The raw material is examined on the grounds of quality to deliver finest range of products. We are flexible enough in meeting the ever-evolving requirements of the customers as we have well-structured and capacious storage space. We efficiently keep stock of products in diverse grades and stipulation.

Centrifugal Domestic Monoblock Pump

Get Price Quote

Features High operating efficiency resulting in lower power consumption. Dynamically balanced rotor for longer trouble-free life of the pump. Dynamically balanced impeller for vibration-free operation and long life of the bearings. Rotating parts are dynamically balanced to ensure minimum noise and vibration. “A” Class insulation and low temperature for trouble-free operation in wide voltage bends. Grease-lubricated anti-friction ball bearings of “SKF” brand are fitted at both ends to withstand radial and axial loads. Single shaft for motor and pump ensures good mechanical strength and higher efficiency. Application Lawns and gardens Car washing Hotel and hospitals Community water supply Domestic water

Best Deals from Centrifugal Pumps

CENTRUFUGAL PUMP

Get Price Quote

We are offering CENTRUFUGAL PUMP. CENTRIFUGAL PUMP M.O.C SS.316 C I

Centrifugal Monoblock Pump

Get Price Quote

Lubi brand is a prominent centrifugal monoblock pump manufacturer based in india. They provide centrifugal monoblock pump 50z & centrifugal monoblock pump 60z at very reasonable prices.

Centrifugal Monoblock Pumps

Get Price Quote

LUBI & Kirloskar brand Monoblock pumpsets are manufactured in reference to IS : 9079 and motor with reference IS : 996 & IEC 34-I, Special care and quality control measures are adopted to give efficiency and reliable operation for years. These pumps can withstand voltage fluctuations from 300-440 volts. These have dynamically balanced rotating parts to ensure minimum vibrations. Cast iron impeller, delivery casing, these pumps are suitable for gardening and small farm irrigation, agriculture for clear water handling, water supply for agriculture, used in apartments, buildings and hotels.

Stainless Steel Centrifugal Pump

Get Price Quote

100 Piece (MOQ)

Matallic Centrifugal Pump

25,000 Per Piece

We offer matallic centrifugal pump. With the valuable assistance of our skilled team of professionals, we have been able to come up with a wide range of ss centrifugal pumps. We make use of the optimum quality raw material with the latest technology to manufacture these pumps. Due to the remarkable quality of the offered range, we have successfully attained the position of the market leader in this domain. reliable engineers are expertise in manufacturing of centrifugal pumps, design of pump is sturdy and parts are with long life, manufacturers & exporters stainless steel centrifugal pumps, special features: pumps are fabricated type from rolled sheet horizontal centrifugal pumps with close semi- open open type impeller design less maintenance due less rotating parts. safe and quite operation levels. suitable for standard motor or flange type or foot cam flange type motor also available in bare and mono block pump flame proof mono block are also available according to requirement different connection are available like dairy connection, tri clover connection, flange end connection, nipple connection economic, efficient & easy in maintenance moc : ss-304ss316ss316l application: ideal for handling of water, dmdi water, mineral water, hot water, pharmaceuticals liquid drugs & syrups, milk, butter milk, soft drink, beverages, solvents, acids, alkalis, light petroleum products etc. acid and light chemicals, color dyes and pigments booster application water treatment plants, r o plants manufacturer & exporters centrifugal bare pumps

centrifugal mud pump

Get Price Quote

Backed by the team of professionals we are able to offer you a quality centrifugal mud pump. These centrifugal mud pump are manufactured by considering IS: 8034 standards and BIS standards. Centrifugal mud pump are also known as sand pumps or mud pumps. Having the great design these pumps are convenient for purpose of engine driving pump. Our centrifugal mud pump are mainly known for its sturdy construction. More over for its error free and noise less working they are highly demanded in the market both domestic and international. Features: Long life service Noiseless operation Less maintenance needed No foot valve required No priming of suction pipeline Suitable for motor Non-clogging impeller Applications: Dewatering mud Industrial pumping of petroleum products Industries Municipalities Public health department

Centrifugal Solar Pumps

Get Price Quote

Centrifugal Solar Pumps, Centrifugal Pumps, Openwell & Borewell Pumps

Close Coupled Centrifugal Pump

15,750 - 86,250 Per Piece

Centrifugal Process Pump

20,000 Per Piece

5 Piece(s) (MOQ)

JBCP Series With the support of our adroit professionals, we provide our clients a high-quality Solvent pump that is widely used in food industry, salt industry, textile industry and paper industry. Technical data Liquid temperature -200 to d1000 Ambient temperature: Max. +400 Altitudc: Max. 1000m Max operating pressure: 10bar Applications Water supply Industrial pressurization Transportation of industrial liquid Water treatment Irrigation Features and benefits Beautiful appearance Light and handy structure High efficiency Energy saving Durable Low noise

Sewage Pumps

Get Price Quote

We are offering sewage pumps,. Applications where self priming action is required. Industrial: pumping polluted liquid, petroleum product,sewage muddy & storm water, tiles & marbles,effluent plant, chemical/diesel/kerosene/ash water. Marine: pumping water from vessel, docks & ports. Civil construction: dewatering foundations, swimming pools, trenches & pits mobile machinery: cooling tower for marine engine & shovels, dewatering from godowns, basements, multistoreys, shopping malls, etc.

Centrifugal End Suction Pumps

Get Price Quote

The company is a prominent Centrifugal End Suction Pumps Manufacturer and Supplier in India. The "VIRAJ" make "VCCP" Series is radial split Backpull out design process and clear water pump consisting of 35 models with six group of bearing housing for minimum inventory of spares. The standard design of Centrifugal End Suction Pumps is foot mounted. In this design for the facility of maintenance to easily removed without disturbing the motor form the base frame & the pump casing fixed to the pipe line. Design Features : Available in 960, 1450 & 2900 RPMBack pullout design for ease of maintenanceHorizontal jacketed, centre line supported process pumps offered for handling high temperature liquids / oilsShaft sealing with gland packing single or double mechanical sealStandard and special materialsClosed or semi open impellerCustom engineering to meet customer requirements Maximum interchangeability of components is possible for a particular series, resulting in lower inventory of spares Application Area : AcidCooling TowerSteel plantChemical IndustryWater supplyBrineAlcoholFire SystemPaper /Plup millPower PlantProcess Industries Accessories : CouplingBase FrameFlangeMotorVirbating PadTrolly Material of Construction : C.I. as per is 210 ( with requre as per application grade)Cast Steel –ASTM 216 Grade WCB Bronze – IS 318 GR. LTB- IIStainless Stell – ASTM -743 , CF8MAlloy 20 – ASTM – 743 ,CN7MonelCD4MCU

centrifugal chemical pumps

20,000 Per Piece

We design high performing Centrifugal Chemical Pumps that are reckoned for speed and efficiency. Centrifugal process pumps, offered by us, are manufactured from optimum quality raw materials using advanced technology that ensures their maximum output with minimum maintenance. Available in Back pull-out construction Horizontal foot mounted single stage End suction Top centerline discharge Material of Construction Cast Iron, Cast Steel, SS304, SS316, SS304L, SS316L, Alloy20, CD4MCu, Hast Alloy b & C etc Conforms to DIN 24256 / ISO 2858 standards and in general is conforms to API 610 as well. Applications Fertilizer Plants Chemical Process Industries Bulk Drugs and Pharmaceutical Sugar Plant Heating and Air Conditioning Plants Water Supply Cement Pulp and Paper Agriculture Textile Organic & Inorganic Liquids Refineries Jet Dyeing Dyes & Intermediates Cooling Towers Effluent Treatment Plants Fire Fighting Steel Power Oil Extraction and Waste Oil Refineries Thermic Fluid Operating Range Capacity M3/hr Up to : 700 m3/hr Head Up to : 150 mtr. Product Features Casing Bonus casing thickness: Class 150 pumps feature Class 300 wall thickness as standard; increased reliability and maximized casing life. Top centerline discharge for air handling, self-venting. Back pull-out design for ease of maintenance. Integral casing feet prevent pipe load misalignment�maximized seal and bearing life. Serrated flanges standard for positive sealing against leakage. Meets ANSI B16.5 requirements.Class 150 FF flanges standard, optional Class 150 RF, 300 FF/RF. Fully Open Impeller Acknowledged best design for CPI services�solids handling, stringy material, corrosives, abrasives. Two times the wear area of closed type impellers for longer life. Back pump-out vanes reduce radial thrust loads and seal chamber pressure.

Centrifugal Pump

Get Price Quote

A centrifugal pump is also known as a Hydrodynamic pump or dynamic pressure pump. It works on the principle of centrifugal force, which are usually quick to install and easy to repair. Ambica Machine Tools is among the largest Centrifugal Pumps manufacturers and suppliers in India.We manufacture,supply and trade excellent Centrifugal Pump. We are using latest technology in order to meet variegated demands of our patron. Our pumps are used in chemical industries, laminates industries, rubber industries, textile industries, power stations, handing of hydrocarbons, in industries such as fertilizers, water desalination plants. SPECIAL FEATURES › MODULAR CONSTRUCTION, HIGH INTERCHANGEABILITY, FAST DELIVERY. › VERSATILE SHAFT SEALING ARRANGEMENT, GLAND PACKING AS A STANDARD ARRANGEMENT AND OPTION TO USE MECHANICAL SEAL. › PROCESS TYPE DESIGN RESULTS IN MINIMUM DOWNTIME. › BACK PULL-OUT DESIGN ENABLING EASIER REMOVAL FOR INSPECTION AND MAINTENANCE. › CLOSED IMPELLER ENSURES HIGH EFFCIENCY FOR A LONG PERIOD OPERATION. › PUMP COMES IN 3 BEARING DESIGN RESULTING GOOD CONTINUOUS PROCESS WITH HIGH PRODUCTIVITY. › BIGGER SHAFT AND BEARING SIZE ENABLING STURDY DESIGN. APPLICATION OF CENTRIFUGAL PUMPS FOR HANDING AGGRESSIVE ORGANIC & INORGANIC FIUIDS IN THE CHEMICAL & PETROCHEMICAL INDUSTRIES, CENTRIFUGAL PUMPS ARE AISO USED AT REFINERY OFF - SITES, PAPER & PULP INDUSTRIES, FOOD INDUSTEIES, SUGAR INDUSTRIES, DEA WATER DESALINATION PLANTS, ABSORPTION PLANTS IN ENVIRONMENTAL ENGINEERING, POWER STATIONS, LAMINATES INDUSTRIES, TEXTILES INDUSTRIES, RUBBER INDUSTRIES, HANDING OF HYDROCARBONS, D.M.WATER, SALT POWER STATIONS AND IN INDUSTRIES SUCH AS FERTILIZER AND OTHER PROCESS INDUSTRIES ETC. » BACKPULL - OUT DESIGN THE SPACE NECESSARY TO WITHDRAW THE PUMP ROTATING ELEMENT IS OBTAINED BY REMOVING THE COUPLING SPACER, AFTER DISMANTILING OF THE CASING COVER, SUPPORT FOOT, COOLING WATER CONNECTIONS, HEATING CONNECTIONS AND SEALING LIQUID (IF ANY) THE COMPLATE PUMP ROTATING ELEMENTS IS WITHDRAW FROM THE PUMP CASING, THE PUMP CASING IS LEFT IN THE PIPE WORK. THE MOTOR REMAINS FIXED TO THE BASE PLATE, THE PUMP ROTATING ELEMENT CAN EASILY BE DISMANTIED INTO ITS COMPONENTS, AFTER RE-ASSEMBLY NO TIME CONSUMING RE ALIGNMENT IS NECESSARY.

Centrifugal Pump

Get Price Quote

Non Metallic Centrifugal Pump

15,000 Per

02 Piece(s) (MOQ)

PVDF Centrifugal Pump

28,000 Per Piece

01 Piece(s) (MOQ)

Centrifugal Monoset Pump

2,000 - 5,000 Per piece

1 piece (MOQ)

Single-phase Water Pump In-built Thermal Over Load Protector Power Rating: 0.37 kW Power Supply: 220 Motor Power: 0.5 hp

Teflon Lined Centrifugal Process Pumps

1,000 Per Piece