Bottle Transfer Chain Conveyors

Get Price Quote

We are known for offering a range of bottle transfer chain conveyors that find their usage in transferring bottles of different diameters from one place to another. Provided with a railing for bottle support these are widely used in bottling and engineering industries. The high speed motor gets operational when strapping process initiates. We also made available this range in customized dimensions as per client requirements. there specifications include: •size: 1 meter to expand as per customers requirement •side plate: s.s. 304 2.5mm •height of conveyor: 850mm + 75mm •width of conveyor: 100mm •roller: stainless steel main drive and support •chain: stainless steel 82.50mm •spoket: split type 21 t. •gearbox: bonfiglioli make •motor: hindustan make •speed of conveyor: in 5 second 1 meter traveling for vfd •direction of control: direct drive

SS Slat Conveyors

Get Price Quote

1 Piece (MOQ)

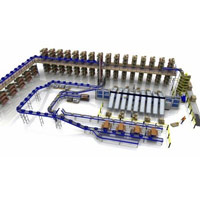

SS Slat Conveyors | Slat Conveyor Manufacturer and Exporter in India | Slate Chain Conveyor SS Slat conveyors play a role in modern industrial processes, providing efficient and reliable material handling solutions. As reputable slat conveyor manufacturers, we pride ourselves on delivering cutting-edge technology tailored to meet diverse industry needs. Slat Chain Conveyor | Slat Belt Conveyor | Slat Conveyor System | Steel Slat Conveyor Belt The slat chain conveyor/ slat type conveyor, featuring a chain-driven loop of slats, stands out for its ability to seamlessly move products from one end to another. Its motor-driven mechanism ensures a continuous, akin to the operation of traditional belt conveyors. The robust steel slat conveyor belt, a key element in our conveyor systems, guarantees durability and longevity, even in heavy-duty applications. SS Slat Chain Conveyor Manufacturers in India | Slat Conveyor Manufacturer | Steel Slat Conveyor Manufacturers in India Our stainless steel slat conveyor chain exemplifies precision engineering. Our heavy-duty slat conveyor offers a smooth and vibration-free transportation process. The slat-type conveyor is versatile, accommodating various materials and shapes with ease. Harikrushna Machines Pvt. Ltd. is a leading slat conveyor manufacturer in India. We prioritize quality and adhere to stringent specifications to ensure optimal performance and longevity. Investing in a slat chain conveyor is a wise decision for industries seeking reliable and efficient material handling solutions. The slat conveyor system, complemented by its customizable features, caters to the unique requirements of different sectors. The heavy-duty slat conveyor excels in handling bulk loads, enhancing overall operational efficiency. Are you looking for Trusted Slat Chain Manufacturers? Explore our range of slat conveyors, including the innovative SS slat chain conveyor, designed to meet the highest industry standards. Our commitment to excellence is the seamless integration of technology and functionality in our steel slat conveyor systems. We have successfully installed over 12,500 machines in 60 countries, solidifying our reputation as industry leaders. Contact us to discover how our slat conveyors can elevate your material handling processes, providing the reliability and efficiency your operations demand. Our team will help you with Slat Conveyor Specifications and reasonable Slat Chain Conveyor Price.

Best Deals from Chain Conveyors

Slat Chain Conveyor

135,000 - 250,000 Per piece

1 Piece (MOQ)

Slat conveyors use a slat and chain system to move components along an assembly line. They are often used where production operations are performed with the parts located on the conveyor. Steel panels are attached to the chain with special chain attachments, and the chain is driven by an electric motor and gearbox. Therefore they are one of the most commonly used types of conveyor for moving parts along and assembly line while the work is being performed. They are ideally suited to applications where components are being assembled onto a fixture located at an ergonomic working height. Slat conveyor system also allow production assembly operators to work on one or both sides of the line. Fixtures can be added to the slats to enable parts to rotate 90, 180 or 360 degrees to facilitate better ergonomic access. During model change-overs, the tooling or fixtures can be modified or replaced, and the conveyor is re-used for another new application. In automotive plants, a slat conveyor system may be used to convey parts like instrument panels, center consoles or door trims. They are used for engine and power-train assembly. They are also used for sub-assembly of frames and axles, and on a larger scale even for vehicles after they have been fitted with the chassis components and move to the final assembly line (sometimes known as a ‘flat top’ conveyor line). Customers sometimes call them slat conveyor belts as the slats look and operate like a belt conveyor.

Chain Conveyor

100,000 Per Piece

1 Piece (MOQ)

Owing to our expertise and experienced workforce, we are engaged in providing our clients high quality Chain Conveyor. This product is manufactured using superior quality raw materials available in the market under the guidance of skilled professionals. Latest tools are being used by our quality controllers to eliminate any kind of flaw, before delivering the products to the clients. We offer this range to our precious clients at very reasonable prices.Features : Low maintenance Optimum functionality Rust resistant

industrial chain conveyor

1,830,000 Per piece

1 piece (MOQ)

A slat chain conveyor is a type of conveyor system designed to transport products and materials over various distances. It uses slat chains—rigid, interlocking plates—to move items along a track. This type of conveyor is particularly useful for applications where the product needs to be conveyed over long distances, at high speeds, or in environments that may involve harsh conditions. Here’s an overview of its features, benefits, and typical applications: How It Works: Design: The conveyor system consists of a series of slats (flat, interlocking plates) mounted on a chain. These slats form a continuous surface on which items are placed for transport. The chain moves the slats around the conveyor’s track. Operation: As the chain moves, the slats carry the items along the conveyor path. The design of the slats ensures smooth and stable transport of materials, minimizing the risk of slipping or falling.

Drag Chain Conveyor

Get Price Quote

Techno Power engineering is leading manufacturer and exporter of drag chain conveyors in Ahmedabad. In this category we have covered a wide range of conveyors applicable in various industries and all utilizing chains as the driving elements which are Slat Conveyors, Overhead Chain Conveyors, Flight Conveyors (Scraper Conveyors), Drag Chain Conveyors, Wire mesh Conveyors, Redler Conveyors, Single and double Chain Conveyors for coal mines, Deep Bucket Conveyors & Apron Conveyors. A variety of special purpose chain conveyors are also manufactured to suit individual require Chains used on above conveyors vary in type. For instance, a slat conveyor uses pin & bush type with rollers, an overhead chain conveyor incorporates a special detachable chain assembly mints. Application: Suitable for conveying material over short to medium distances Can carrying abrasive, moderately abrasive and non-abrasive items. Designed to pull materials like briquettes, agro fuels, coal, woodchips, lime, etc. Can convey materials horizontally or on inclines up to 50 degrees Ideal conveying mechanism when a change in elevation is required on inclined conveying FEATURES: Robust and Sturdy Design Available in single or double chain Available in capacities up to 300 TPH Capable of moving material with speeds up to 25 feet per minute Capable to achieve inclinations up to 50 degree Occupies minimum space thereby optimizing space utilization Wear resistant liners can be provided for handling abrasive materials

Slat Conveyor System

Get Price Quote

Slat Conveyor

Get Price Quote

We are leading in the field of slat conveyor manufacturing for endowing cost effective and reliable solution associated with slat conveyor. Our conveyor system equipped with slats attached to double strand steel side bar bushed roller chains are robust, heat resistant and rust resistant boast potential to convey hot, oily or abrasive material, unlikely to rubber and canvas belt conveyors which are inappropriate to operate with such materials. Our slat conveyor is extremely versatile and available in disparate size, material and capacity as per customer requirement for handling a multitude of products, from raw materials, through manufacturing process to finished products. OUR SLAT CONVEYOR BOASTS EXCELLENT QUALITY WHICH WE DELINEATE IN TERMS OF: Long production life Extremely versatile Robust construction Heat and rust resistance Hassle free operation NOTE: Along with a specialization in strapping machine, we as manufacturer, supplier and exporter render an inclusive support and service associated with Slat conveyor at competitive rates in India as well as overseas.

Wooden Slat Conveyor

35,000 Per Meter

2 Meter (MOQ)

Air Conveyor for bottle

Get Price Quote

Construction of S.S. matt finished body This is basically conveyor to feed pet, LDPE, HDPE empty bottles The bottles are hold by Neck Vibration Free, Jerk Free, Noise less construction with the help

Chain Conveyor

10,000 Per Piece

Scrap Handling Conveyor

100,000 Per Piece

1 Piece (MOQ)

Drag Chain Conveyor

100,000 Per Piece

Slat Conveyor System

Get Price Quote

EEC Manufacturer & Exporter of Conveyor System & Slat Conveyor System, we hold years of experience in offering a qualitative range of Slat / Fix Conveyors. The offered range of slat/fix conveyors is manufactured by our experienced professionals using excellent quality raw material and components that are procured from the reliable vendors of the market. To meet the diverse requirements of our clients. Our product range also comprises of Vial Washing Machine, Ampoule Washing Machine and Bottle Washing Machine and many more. SALIENT FEATURES : CGMP Model All exposed parts of SS to avoid rusting Independent Motor and Gear Box Available at various sizes depends upon requirement TECHNICAL SPECIFICATIONS : Suitable for Vials, Bottles & Round Containers Electric Load 0. 5 to 1.5 HP Depend Upon Size. Single phase / 230 Volt / 50 Hz / A.C.

Drag Chain Conveyor

Get Price Quote

A Drag Chain Conveyor can be used for handling powdery, coarse, fine grained, abrasive and sticky bulk materials. Drag Chain Conveyor is capable of conveying the material to steep inclination of 50 degrees. In certain applications, Drag Chain Conveyor can also be used for reclaiming of bulk material from Silos Hoppers Drag Chain Conveyors consist of a series of metal or plastic flights attached at uniform intervals to one or two strands of endless chain. The chain moves the flights along in a trough thereby pushing or sliding the material along. Carry run is on the bottom side. Multiple inlets and discharge points can be provided with Drag Chain Conveyors, allowing for maximum efficiency. The intermediate discharge openings can be fitted with remote controlled shut-off gate valves to choose the receiving silo. In case of handling abrasive materials, drag conveyor has to be operated at very low speeds. Appropriate chain speed and chain width are vital for the service life of the drag chain conveyor. Features ; Robust and Sturdy Design Available in single or double chain Available in capacities up to 300 TPH Capable of moving material with speeds up to 25 feet per minute Capable to achieve inclinations up to 50 degree

Drag Chain Conveyor

Get Price Quote

A Drag Chain Conveyor can be used for handling powdery, coarse, fine grained, abrasive and sticky bulk materials. Drag Chain Conveyor is capable of conveying the material to steep inclination of 50 degrees. In certain applications, Drag Chain Conveyor can also be used for reclaiming of bulk material from Silos / Hoppers Drag Chain Conveyors consist of a series of metal or plastic flights attached at uniform intervals to one or two strands of endless chain. The chain moves the flights along in a trough thereby pushing or sliding the material along. Carry run is on the bottom side. Multiple inlets and discharge points can be provided with Drag Chain Conveyors, allowing for maximum efficiency. The intermediate discharge openings can be fitted with remote controlled shut-off gate valves to choose the receiving silo. In case of handling abrasive materials, drag conveyor has to be operated at very low speeds. Appropriate chain speed and chain width are vital for the service life of the drag chain conveyor. Drag Chain Conveyors manufactured by AEGIS come with generous design and rugged construction and can be used various applications across various industries. AEGIS designs, manufactures and supplies Drag Chain Conveyors to suit the property of bulk material handled number of operating hours and other surrounding conditions. Application Suitable for conveying material over short to medium distances Can carrying abrasive, moderately abrasive and non-abrasive items. Designed to pull materials like briquettes, agro fuels, coal, woodchips, lime, etc. Can convey materials horizontally or on inclines up to 50 degrees Ideal conveying mechanism when a change in elevation is required on inclined conveying Advantages Can convey to high inclinations up to 50 degree, depending on material handled Can effectively handled, “difficult to flow” materials Can be made dust and air tight Multiple inlet and outlet points allows to have intake and discharge flexibility Carry-over problems are minimized as the carry run is on the return side Features Robust and Sturdy Design Available in single or double chain Available in capacities up to 300 TPH Capable of moving material with speeds up to 25 feet per minute Capable to achieve inclinations up to 50 degree Occupies minimum space thereby optimizing space utilization Wear resistant liners can be provided for handling abrasive materials

Chain Conveyor

Get Price Quote

Supported by our hardworking professionals, we are also engaged in the manufacturing, trading, exporting and supplying of Slat Chain Conveyor. Used for general assembly production, offered conveyor is manufactured using superior quality components and cutting edge technology in adherence with industry standards. Our quality examiners test this conveyor on different parameters, before its delivery. In order to fulfill the needs of the customers, we offer this conveyor in different sizes and designs.Features : Accurate dimension High strength Precisely designed

bottle transfer conveyor

Get Price Quote

As, our organizations is a suppliers of bottle transfer conveyor; purchasers can place wholesale orders for it, and get them at the lowest prices. Our team members help us completely to deliver exceptional range of products that is in conformance with the standards.

Redler Chain Conveyor

Get Price Quote

Redler Conveyors are used to convey materials of powdered, granular, flaky or small lumpy formation, such as grain, coal, cement, etc. It causes the materials to flow like a liquid through enclosed dust-tight casings in any required direction by means of haulage chain with skeleton type flights, and in such a manner that there is no pressure on the materials, no movement between the particles and consequently no breakage whilst in transit. Redler Conveyors are completely enclosed. The closely spaced chain flights which constitute the conveying element travel through the enclosed casing wherever it may lead, and materials admitted into this casing travel quiescently with the chain up to the point of discharge. There is no dragging or scraping action as the material “simply flows” in a solid column ‘‘en-masse.”

Drag Chain Conveyor

75,000 Per NUMBER

1 NUMBER (MOQ)