air receiver vessel

Get Price Quote

Stainless Steel Pressure Vessels

25,000 - 1,000,000 Per Piece

1 Piece (MOQ)

Best Deals from Chemical Vessels

Pressure Vessels

Get Price Quote

The Pressure Vessel, we supply, is reckoned for its safe design and heavy duty performance. These vessels are constructed to carry materials at assorted pressures. The multi-layered walls of the container ensure the much safer storage of the materials. Features: Precision made High pressure handling Industrial application

Chemical Reactor Vessels

Get Price Quote

Our team members assist us in settling down the payment procedures and they help us in making transactions that are completely secured and are executed as per the client's convenience. The reason we are capable of delivering the best in class range of products is because of the stern checking on the raw material while sourcing. By this, we bring forth quality products. Application : Chemical & Processing Industries Pharmaceutical & Medicinal Product Manufacturing Industries Food Grade Products Manufacturing Industries Beverages, Alcoholic & Non-alcoholic Product manufacturing Industries Food Grade Oil Refinery Industries Fertilizer Industries Colours & Pigment Manufacturing Industries Details : Materials of Construction - Polypropylene, Polyethylene, FRP, PVDF, MS FRP Lined, MS PP Lined, MS HDPE Lined. Sizes and Performance - All sizes are available with capacities from less than 100 Litres to more than 35,000 Litres. Temperature Range Up to - 25o C to 150o C.

High Pressure Vessels

100,000 Per Piece

10 Piece(s) (MOQ)

holding vessels

Get Price Quote

We are bracketed with renowned Manufacturers, Exporters and Suppliers of Holding Vessels. Made in accordance with international quality management system, our vessels are safe, use-friendly, low maintenance and high performance. We make the Holding Vessels available in varied specifications and cater to customization requests. Buyers can obtain them from us at competitive prices and expect on time delivery of consignments. Highlights : Holding Vessels are mainly used as pressure vessels for physics and chemical reaction in reactor, oxidation reactor, decomposing reactor, polymreiator, crystallizer etc. Our company can manufacture the vessels with the volume to 80m3, the pressure to 10Mpa, and unit weight to 80t. The heating medium has electricity, steam, transecting oil, infrared, etc. The cooling way has jacket, half-piping and inside piping. The speed can be 0~1000r/min frequency conversion. The agitators blench can be adjusted by customers requirement. The material can be carbon steel, stainless steel, titanium, aluminum, alloy steel, double-phase steel etc. The sealing type of reaction vessel has stuff sealing, mechanical sealing and magnetic force sealing. The structure of reaction vessel has flat-cover type, open-flange type and closed type with their different usage and feature.

Magnetic stirring vessel

Get Price Quote

We make sure that the payment transaction of our customers, whether online or offline, is secured with us. We accept payment through all major payment modes. We are well equipped with the most recent machines and technology that help us in conducting stringent check on the raw materials that are used while manufacturing.

Pressure and Mixing Vessel

Get Price Quote

Our company is the trustworthy Manufacturer, Exporter and Supplier of Pressure and Mixing Vessel from Gujarat (India). Produced using top of the line quality basic material such as steel, aluminum, etc., our Pressure and Mixing Vessel is sturdy, durable and corrosion resistant. Also, our Vessel is known for its high performance. Talk of price, we are known all over the world for providing the best quality at the most discounted prices.

Vessel

Get Price Quote

The Vessels are Designed as per Std Codes as per Requirement of Processes and Working Pressure Suitable to Process.the Material Selection as per Process like Chemical,Pharma,General. We are Design Vessels for Isolation, Mixing, Reaction, And as per Requirement of Client in Various Capacity.

msrl vessel

150,000 - 4,250,000 Per piece

01 Nos (MOQ)

Storage Vessels

95,000 Per Piece

1 Piece(s) (MOQ)

We manufacture Hoppers and Silos of varying sizes as per the storage requirement of the customer. These are used in construction sites, cement and fly-ash storage, agro food industries etc. for Bulk Storage of material and have Vertical orientation for easy discharge of the stored contents. Various bin bottom designs are available, again depending on the flow properties of the material and the desired silo withdrawal method. Single or multiple steel hoppers, flat bottoms and custom mass flow designs can be provided.

Reaction Vessels

Get Price Quote

We are offering reaction vessels. Reaction vessel is made according to customer’s specific requirements in different sizes, shapes, with without jackets, various types of agitators, with limpet coils. They are designed and fabricated to match the optimum process conditions of temperature and pressure with efficient mixing application. Reaction vessels are widely used in liquid formulation, solid liquid mixing in chemical, food, pharma & paints industries.

Conical Vessels

Get Price Quote

Conical Vessels of top grade quality in all sizes are offered by us at affordable rates. The vessels are used in hydraulic systems and all hydraulic pressure applications in many factories and industries. We have earned a reputation as one of the most trusted suppliers and exporters of these vessels that we manufacture. Further details can be availed from our sales executives who will be glad to help you.

Pressure Vessel

Get Price Quote

Pressure Vessel

1 - 200,000 Per 1 unit

1 Litre (MOQ)

Ointment Manufacturing Vessel

225,000 Per Units

1 Piece (MOQ)

Vessels

Get Price Quote

We pride ourselves on being a premier fabricator of specialty vessels. Our design and manufacturing staff works closely with our customers to develop engineering specifications for process equipment customized to the specific industry applications. We manufacture Steel Chemical Reactor Vessels that are made using various grades of stainless steel SS304 and SS316. These vessels are mainly used in chemical and pharmaceutical industry. Our manufacturing range is from 0.5 kl to 20 kl capacity.

Reaction Vessels

250,000 Per Piece

01 Piece (MOQ)

Top Stirrer Prism Vessel

Get Price Quote

Autoclave Vessels

Get Price Quote

We are leading manufacturer of Rubber Autoclave for reclaim is fabricated from best Quality M. S plates of thickness depending upon the capacity and clients choice. External heating arrangement is provided which can be used both for steam and thermic fluid. It has a stirring arrangement totally different from those of conventional autoclaves. We are providing these autoclaves as per the client requirement Features: Durable Safe to use Quality tested

Stainless Steel Vessel

Get Price Quote

Our product range includes a wide range of Stainless Steel Vessel such as 1. Pressure Vessel 2. Chemical Vessel 3. Reaction Vessel 4. Pharmaceutical Vessel.

Preparation vessel, Reactor Storage Tank

Get Price Quote

Preparation vessel, Reactor & Storage Tank Application & Process : Prism has been designed & manufacturing preparation vessels, Reactor and storage tank and has consolidated a process as customer needs. Preparation Vessels, Reactor & Tank : Design compliance with cGMP Capacity up to 25,000 Liter. Product Contact AISI 316L . Vertical & Horizontal design Atmospheric, Vacuum or Pressure Operation. Plain, Jacket for heating & cooling. Option for Heating by steam, hot water or tharic fluid oil & Electric heater. Thermal Insulated. Mechanicals or Electro polishing of internal surface. Welded, flanged or hinged type cover Integrated Cleaning in Place-CIP. Sterilizing In Place-SIP as an Option. Option for mounting on legs or flange. Portable execution on request. Validation protocols & Instrumentation celebration. Variable Speed Agitation : Agitator can be top or bottom driven or magnetically driven. Propeller type, Anchor type provided with High speed disperser or rotor-stator homogenizer. Single or double mechanical seal. Turn Key Process Line : For production, filtration, transfer and storage solution. Pre reparation vessels. Inline homogenizer. Inter Connecting Pipe Solid or sugar Charging System Working Platform. Automation available, appropriate for the intended process function, including CIP and SIP : Controls of all function by PLC Controls with HMI Touch screen. Level controls by means of capacitance probe or electronic load cells. Digital indication and controls of all process parameters for Process time, agitator speed, temperature, pressure & level.

Premixing Vessel

Get Price Quote

We are offering premixing vessel ss 304316 mixing vessel is mainly used for homogenous mixture of size chemicals at ambient temperature. This stainless steel open vessel is provided with a high speed propeller stirrer which can be either clamped on to the rim of the kettle with swiveling arrangement or mounted vertically on the top of vessel. The position of propeller stirrer can be fixed high or low position to achieve best stirring results.

Stainless steel Storage Vessel

Get Price Quote

MOC: – S.S.304 / S.S.316 With Laboratory Tested.Smooth 180grit Mirror Polished.Available Sizes Are 100 / 200 / 300/ 500 / 1000 & 2000Liters.SS 304 PU castor wheels heavy duty, S.S Handles & Ball Valve for Out Let.

Jacketed Vessel

Get Price Quote

In chemical Machinery, a jacketed vessel is a container that is designed for controlling the temperature of its contents, by using a cooling or heating "jacket" around the vessel through which a cooling or heating fluid is circulated. A jacket is a cavity external to the vessel that permits the uniform exchange of heat between the fluid circulating in it and the walls of the vessel. There are several types of jackets, depending on the design.

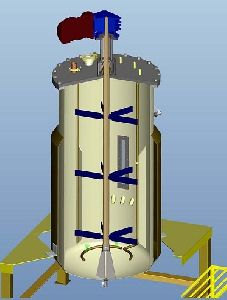

BOTTOM/TOP DRIVEN PROCESS VESSEL

Get Price Quote

Capacity available from 50 ltr to 35000 ltr.Contact parts S.S 316 quality and non contact parts S.S 304 quality.Compliance to ASME BPE guidelines, ensuring clean ability, drain ability and sterilizability.PLC control system with large scale touch Screen &SCADA. Internal finish ra

Pressure Vessel

90,000 - 100,000 Per Piece

HDPE Conical Bottom Reaction Vessel

Get Price Quote

spiral reaction vessel

Get Price Quote

Reaction vessels made using the spiral technology are sturdy, temperature resistant ( HDPE 90°C & PP 110°C ) non-corrosive and almost maintenance free. We also provide complete Reaction vessel assembly which includes M.S. Structure required to hold the vessel, agitator and gear box assembly.For special purposes we manufacture FRP reaction vessels. HDPE FRP & PP FRP Reaction Vessels are also manufactured for special applications and customer requirement. We Offer : HDPE reaction Vessel PP Reaction Vessel HDPE FRP Reaction Vessel PP FRP Reaction Vessel Advantages : 100% Corrosion free Light Weight Leak Proof Maintenance free

Pressure Vessels

Get Price Quote

Leveraging On The Vast Experience Of The Industry, We Are Involved In The Manufacture, Export And Supply Of Pressure Vessels. Offered Range Of Product Is Developed Under The Strict Supervision Of Our Experienced Professionals, Using Latest Technology And High Grade Material Obtained From The Trusted Vendors Of The Market. These Vessels Are Extensively Used In Various Industries Like Petrochemical, Food And Dairy, Pharmaceutical, Chemical, Fertilizers, Pulp & Paper And Many More. Owing To Features Like Sturdiness, Excellent Performance, Rust Resistance And Longer Service Life, These Products Are Highly Applauded And Demanded By The Clients Across The Region. Some Other Details Of The Offered Product Is Given Below: Material Of Construction: Carbon Steel LTCS NACE & HIC Resistant Material Low Alloy Steel For High Temperature Service SA 387 Gr 11 And Gr 22 Cladded Steel (CS With SS, Cupronickel, Aluminium Nickel Bronze, Aluminium Brass, Titanium, Inconel And Many More) SS (300 & 400 Series) Duplex & Super Duplex Stainless Steel Cupronickel Monel Inconel Nickel & Nickel Alloys Hastelloy Titanium Aluminum And Aluminium Alloys.