Rubber Coating Basket Centrifuge Machine

135,000 Per Piece

1 Piece (MOQ)

Coating Pan

50,000 - 150,000 Per piece

1 Piece (MOQ)

Best Deals from Coating Machine

Coating Pans

Get Price Quote

We maintain a high level of transparency when it comes to payment. Our methods are simple, as per your convenience, and practical. We ensure to agree upon a method during undertaking. The check on quality has been kept by our experts who ensure that the inputs we source are free from any sort of impurities. Thus, we ensure quality products at buyer's end.

Tablet Coating Machine

150,000 Per Piece

automatic tablet coater

Get Price Quote

We have a well-maintained and spacious storage space and thus, we are flexible enough of meeting the urgent needs. Furthermore, we by no means go out of stock and thus we maintain year round accessibility of all the products. Assistance of diligent professionals and modern packaging facility give our clients and us a win-win situation at the time of tailored packaging requirements.

Uv Coating Machine

Get Price Quote

Uv Coating Machine, Uv Machine, Thermal Lamination Machine

sugar coating machine

Get Price Quote

Traditional sugar coating is performed in what is generally described as a conventional coating pan. However, the desire to reduce the time needed for the sugar coating process has led to the trend towards side-vented pans, which can be modified to introduce the sugar syrup via a dosing bar, rather than spraying the tablets as with film coating. Sugar coating liquids used in preparing sugar coated tablets contain binders such as gelatin or gum arabic so as to increase strength of the sugar coating layer or to increase bonding strength between an uncoated tablet and the sugar-coating layer.

Sugar Coating Machine

Get Price Quote

Tablet Coating Machine, Mass Mixer Machine

Lamination Coating Machine

Get Price Quote

We are offering lamination coating machine max. Width: - 1200mm working speed: - 100 to 120 mmin. drying speed: - multi zone heating source: - electrical hot air coating section: - gravure reverse roll laminating coating section: - heating roller with nip roll chilling roll price: - variable speed dcac unwind rewind: - simplex duplex 3 drive -5 drive manually

vmch coating machine

Get Price Quote

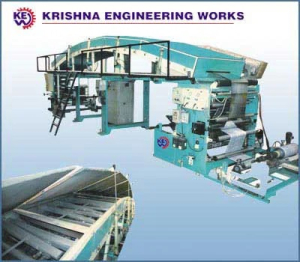

Krishna Engineering Works India, a leading manufacturer, exporter and supplier of Coating Machine from last 25 years. High-quality Coating Machine available with different types of range. Also manufacturer of Rotogravure Printing Machine and Slitter Rewinder Machine Manufacturer Heavy duty side M.S. steel walls to ensure vibration free running at high speed. Foundation free base frame. High velocity air blower for fast dying. Good quality electronic input drives, motors, Tension Control System etc. All free rollers are dynamically balanced. Pneumatic functions for impression rolls. Auto tension control. Auto web aligner. Careful quality control in manufacturing process to ensure years of maintenance free running.

Tablet Coating Machine

100,000 - 400,000 Per Piece

1 Piece(s) (MOQ)

Salient Features: Pan is made by SS 304 (SS 316 optional). Totally enclosed with MS cladding with a standard gearbox, motor, and hot air blowing arrangement. Designed with M.S. fabricated structure and all arrangement except electric control, and SS Pan is inside the enclosure, which makes simple cleanable outside covering. 30”, 36”, 42” or 48” Coating Machine has variable speed drive. Hot air blowing system is separate. 60” or 72” Coating Machine has two speeds with step pulley without hot air blowing system.

sticker coating machine

Get Price Quote

Tablet Coating Pan

Get Price Quote

Conventional Coating Machine

Get Price Quote

APPLICATION & PROCESS : Conventional coating machine are used to sugar coat tablets, pills, etc in for a variety of industries such as Pharmaceutical, Confectionery, Food and others. They are also used for rolling and heating beans and edible nuts or seeds. The product is to be filled inside the pan. During the rotation motion, coating material is sprayed by spraying system according to the technological process and rational technological process. So process materials (product) are coated due to rotating pan. The coating round pot is rotated by variable speed. At the same time hot air is supplied through inbuilt Hot air blower system which dries rapidly (heating or cooling) and evenly thus forming a solid and smooth surface. SALIENT FEATURES : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316/304 & non contact parts AISI 304. Conventional coating system for manual film coating and sugar coating. Machine is designed with fabricated structure fitted with SS enclosure which makes simple, cleanable outside covering and mounted on anti vibration pad. Closed powerful pan drive with reduction gearbox and motor by variable speed pulley. Movable hot air blowing system with electric heater. Easy to replace polishing pan and other size coating pan. OPTIONAL FEATURES : A.C. frequency Drive for pan. Fixed or detachable type baffles. Interchange different size Pan & Polishing Pan. Atomized Spraying system with Spray Gun, Peristaltic Pump and Solution tank and Electro Pneumatic controls. Pressurized vessel with spray gun. Flame Proof Electrical. Pellegrini type Coating machine. SAFETY FEATURES : Overload pressure release mechanism.

pharmaceutical coating machine

Get Price Quote

As one of the pioneering manufacturers of the Tablet Coating Machine, we, at Shree Bhagwati Machtech (India) Pvt. Ltd follow the top quality standards for designing our machines. The tablet coating machines manufactured by us have SS 304-complinat screen and parts. Moreover, the coating pan is highly durable and resistant to heat.Tablet Coating Pan is especially designed for film coating of oral solid dosage forms at controlled atmosphere in pharmaceutical industries ensuring user friendly operation. Benefits of our tablet coating equipment include effective mixing of final product bed, lowering emission of organic solvents, long term performance, automatic emptying and many more.

Coating Pan Machine With Hot Air Blower

Get Price Quote

Salient Features: Pan is made by SS 316 & All Non Contact Parts SS304. Totally enclosed with MS cladding with standard gearbox, motor, and hot air blowing arrangement. Designed with fabricated structure and all arrangement except electric control, and SS Pan are inside the enclosure, which makes simple cleanable outside covering. 30”, 36”, 42” or 48” Coating Machine has variable speed drive. Hot air blowing system is separate.

spray coating machine

Get Price Quote

MINI COTA (Semi automatic Spray coating Machine) is mainly designed to replace the conventional method of manual coating of tablets and granules. Mini cota is comprised of pressure vessel whish can be provided with S.S. jacket (for Sugar Coating) with controlled heaters, safety valve, pneumatic stirrer (Oscillating type) , spraying nozzles and compact control panel with Pneumatic cylinder for intermittent spray with timer. Vessel is filled with coating solution and pressurized by oil moisture free compressed air at pressure of 3 to 4 Kegscm 2 to get uniform atomized conical spray. The coating is done by spray guns which are mounted on a heavy S.S stand can be adjusted. A Digital Timer and Pneumatic cylinder through a solenoid valve control duration of air and liquid spray.

Tablet Coating Pan

Get Price Quote

Introduction: The machine fitted with gear box 1/2 H.P. electric Motorto work by Oil immersed gear box. Air blower is operated independently. An energy regulator is provided to control temperature from 5 deg.C above room temperature to 70 deg. C approx. Punch having switch for motor blower heat with neon indicator to work on 220 Volts. Size HP Pan HP Blower12" dia. 0.5 0.25

seed coating machine

150,000 Per Piece

Applicator Pad Kit

Get Price Quote

Auto Coater

Get Price Quote

Pearlcoat Ci auto coating systems are intelligently innovated for consistency, simplicity and flexibility in coating. It is a system that operates for any kind of coating automatically by process integrated control system. Ci – Auto coating system stands testimony to the fact that a precisely controlled process is best achieved with matched system components in keeping with the desired coating objectives. A highly efficient pan design, solution spray system and process control provides accurate batch consistency with high production efficiency.

Lab coating pan

Get Price Quote

In compliance with cGMP guidelines. Also available with Standard Painted Model & for small scale laboratory purpose. Conventional Coating Pan with very sturdy M.S structure made of angles & channels which are covered from all the sides by covers & doors. The Coating Pan drive is through standard make heavy duty worm reduction gear box & electrical motor by means of belt and pulley drive fitted on a rigid structure. Coating Pan Speed can be changed through variable speed pulley mounted on the shaft of electric motor (AC Variable Frequency Drive – Optional with extra cost). Coating Pan made of SS 304 SS 316 or SS 316L material and mirror polished from inside & outside. Baffels either welded or detachable (welded are the standard supply if not specified) provided inside the pan considering production requirements. Easy mounting arrangement considering changeover of coating polishing pan.

pvdc coating machine

Get Price Quote

rotary screen coating machine

Get Price Quote

Introduction The MAHESH coating machine is specially developed for precise uniform and smooth Silent coating on rotary screen. Advantages An efficient and simple and trouble free operation by a single operator Ensuring a subsequent trouble-free coating. It is very easy to operate and smooth in running. The coating process is Safe for its operators and surrounding environment. Labor costs are drastically reduced. Employees can perform other tasks instead of spending hours at the tedious traditional method of screen hand Coating. Size Available With a circumference of 640 mm, 820 mm, 914 mm.1018 mm. and up to 3500 mm. length of screen.If you require further technical assistance or other information please feel free write to us.

Tablet Coating Machine

Get Price Quote

We manufacturer wide range of Tablet Coating Machine, Tablet Coating Equipment, Pharmaceutical Coating Machine , tablet coating pan for granules, tablet coating machine, tablet coating equipment, pharmaceutical Pellets/Tablets coating machine, tablet coating pan manufacturer, Candy tablet coating machine , tablet coating equipment, pharmaceutical coating machine manufacturer, Vitamins tablet coating pans, Food tablet coating machines Many different model we manufacturer Tablet Coating Pan for sugar and film coating of tablets, pallets and granules - Tablet Coating Machine, Tablet Coating Equipment, Pharmaceutical Coating Machine , tablet coating pan for granules, tablet coating machine, tablet coating equipment, pharmaceutical Pellets/Tablets coating machine, tablet coating pan manufacturer, Candy tablet coating machine , tablet coating equipment, pharmaceutical coating machine manufacturer, Vitamins tablet coating pans, Food tablet coating machines. Our range of tablet coating pans is extensively used for sugar and film coating of tablets, pallets and granules. The unit comprises of ellipsoidal shaped pan fabricated using stainless steel sheet and mounted on the gearbox shaft, which is driven by an electric motor. These tablet coating pan are available in standard and GMP model with SS 304 or 316 contact parts. FEATURES OF TABLET COATING PAN: The complete drive unit is enclosed in a sturdy cabinet Hot air blower with flexible SS Pipe heaters are provided with thermostat control for fast drying Heaters are interlocked with the blower motor therefore unless the blower is on, heater does not start

Coating Pan

Get Price Quote

Description of Batch Type Flavor Mixing Machine (coating Pan)Our range of flavor mixing machine is extensively used for apply seasoning to fried product in uniform manner. The unit comprises of ellipsoidal shaped pan fabricated using stainless steel sheet and mounted on the heavy duty reduction gear box shaft, which is driven by an electric motor. These flavor mixing machine are available in stainless steel 304 or 316 contacting parts. Exterior drum surfaces are available with satin finish or polished to near mirror finish to provide ease in cleaning of the unit.This batch type flavor mixing machine is useful for potato chips, banana chips, fried or roasted nuts, bangle grams or pulses, pellet / kurkure (cheese puffs, cheese curls, cheese balls, cheesy puffs, corn curls, corn cheese) nik naks( extruded corn snack). Construction of coating pan Stainless steel 304 semi ellipsoidal size pan with a circular mouth for charging and discharging of fried food products pan mounted at an inclination of 45 degrees to the horizontal. Suitable TEFC motor with suitable worm reduction gear box and pulley arrangement for rotating coating pan. The motor and gear box is mounted inside sturdy mild steel frame and the pan mounted on the gearing housing fitted in the stand. All joints argon arc welded and all stainless steel parts polished to suitable finished required of food processing equipment mild steel parts automotive painted to smooth finish.

Aqua Coater Machine

Get Price Quote

UV Coating / Aqua Varnish / Blister Coating Machine : This machine is used for multipurpose chemicals. SIGMA Machine is designed considering the latest current needs of clients. Our adroit professionals manufacture this machine using unmatched quality components and sophisticated techniques in tandem with international quality standards. Besides this, we offer this Machine to the client at the most competitive prices. SIGMA offer manual feed Coater for Duplex Boards and thick paper above 130 GSM to 600 GSM. Main Features : It coats UV Varnish or any other lacquer very smoothly. It is very useful for any surface i.e. Paper, Board, Plastic, different paper boards etc. AC / DC frequency drive for variable speed. Digital Sheet Counter (Optional). Motorised Pump for uniform Chemical / Varnish Flow. Trouble free automatic varnish up-lifting with pump. Compatible rubber rollers for UV Coating. Machine is suitable for chemicals like Aqueous, UV, Blister coatings etc. Easy to operate and maintain. Noiseless operation. Lower Power Consumption The machine is available in sizes 25", 30", 36", 40" and as per customer requirement.

pvdc coating machine

1,851,000 Per Number

1 Number (MOQ)

rotary screen coating machine

Get Price Quote

Introduction The MAHESH coating machine is specially developed for precise uniform and smooth Silent coating on rotary screen. Advantages An efficient and simple and trouble free operation by a single operator Ensuring a subsequent trouble-free coating. It is very easy to operate and smooth in running. The coating process is Safe for its operators and surrounding environment. Labor costs are drastically reduced. Employees can perform other tasks instead of spending hours at the tedious traditional method of screen hand Coating.

pvdc coating machine

1,851,000 Per Number

1 Number (MOQ)