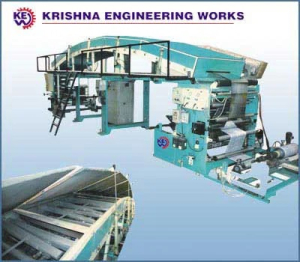

Paper Coating Machine

Get Price Quote

Krishna Engineering Works India, a leading manufacturer, exporter and supplier of Coating Machine from last 25 years. High-quality Coating Machine available with different types of range. Also manufacturer of Rotogravure Printing Machine and Slitter Rewinder Machine Manufacturer Heavy duty side M.S. steel walls to ensure vibration free running at high speed.Foundation free base frame. High velocity air blower for fast dying. Good quality electronic input drives, motors, Tension Control System etc. All free rollers are dynamically balanced.Pneumatic functions for impression rolls.Auto tension control. Auto web aligner.Careful quality control in manufacturing process to ensure years of maintenance free running.

sticker coating machine

Get Price Quote

Best Deals from Coating Machine

pvdc coating machine

1,851,000 Per Number

1 Number (MOQ)

pvdc coating machine

1,851,000 Per Number

1 Number (MOQ)

Hot Gum Cooking Pan

Get Price Quote

1 Piece (MOQ)

Details : Structure of M.S. Channel. Steady structure design. Drive single shaft bevel gear. Blade & shaft of stirrer SS. 304 SS. 304 heavy fabricated vessel. Pulley with V - Belt Drive

Rubber Coating Basket Centrifuge Machine

135,000 Per Piece

1 Piece (MOQ)

Bar Coaters

1,250 - 1,750 Per Piece

1 Piece (MOQ)

Tablet Coating Machine

Get Price Quote

We cater the best quality Tablet Coating Machine in the international market. Our Automatic Tablet Coating Machine is used for applying a layer of coating on tablets and capsules quite efficiently. They are highly durable and easy to operate. In addition, we are one of the principal High-Efficient Tablet Coating Machine Suppliers in India.

Coating Machine

Get Price Quote

Salient Features: Coating Pan is engineered to the perfection from SS 304 (SS 316 optional). Totally enclosed machine drive and hot air blowing system. 30”, 36”, 42” or 48” Coating Machine has variable speed drive. Hot air blowing system is separate. 60” or 72” Coating Machine has two speeds with step pulley without hota i r b lowing system. Hot air blowing system is with temperature control probe. Salient Features:- Coating Pan - Tablet Coating Machine with Hot Air Blowing System Coating Pan is engineered to the perfection from SS 304 (SS 316 optional). Totally enclosed machine drive and hot air blowing system. 30”, 36”, 42” or 48” Coating Machine has variable speed drive. Hot air blowing system is separate. 60” or 72” Coating Machine has two speeds with step pulley without hot air blowing system. Hot air blowing system is with temperature control probe.

Coating Pans

Get Price Quote

We maintain a high level of transparency when it comes to payment. Our methods are simple, as per your convenience, and practical. We ensure to agree upon a method during undertaking. The check on quality has been kept by our experts who ensure that the inputs we source are free from any sort of impurities. Thus, we ensure quality products at buyer's end.

zinc kettle

300,000 Per Piece

Tablet Auto Coater

Get Price Quote

Tablet Coating Machine with Completing Sparying Systems available from 12" to 72" Complete System & Seperate Coating Drums also.

60 Foot BOPP Tape Gum Coating Machine

215,000 Per Piece

1 Piece (MOQ)

vmch coating machine

Get Price Quote

From bulk to retail order fulfillment, we can do it all. Our company has a wide supply chain network to provide our buyers with the product all year round and make timely delivery. Our well-structured warehouse is the reason behind the safety of the products we offer. Moreover, we have installed advanced amenities essential for the safe storage of the lot. Salient Features of the Plant : Hot Air Temp - 50 – 1500oC Heat Source - Hot Air Generator (Optional) Exhaust - 3 HP Main Drive - Coater / Nip -3 HP, Rewind – 5 HP AC digital drive for tension controller Tendency roll drive AC. With timing pulley Maximum speed for solvent base adhesive 225 m.p.m. Fully pneumatically lifting tunnels and impressions rollers, Doctor blade, Lay and Rolls Chilling roll provided before rewinding Comfortable exhaust system for solvent fumes Uniform heating system

Lab Tablet Coating Machine

320,000 Per Piece

1 Piece (MOQ)

Coating Pan

50,000 - 150,000 Per piece

1 Piece (MOQ)

Coating Pan

Get Price Quote

Tablet Coating Machine, Rotary Tablet Machine, Mass Mixer Machine

wire coating machine

Get Price Quote

We manufacture and export plastic machineries along with surgical tubing plant, medical pipe plant, extrusion machineries, plastic processing machineries, PVC processing machineries, LLDPE pipe plant, soft PVC braided hose machinery, plastic recycling machine, PVC trunking machinery, PVC casing capping machinery, corrugated hose machinery, plastic profile machinery, jockey extruder, heater mixer unit, high speed mixer unit, automatic pipe, profile cutting unit, scrap grinder unit for plastics and pipe socketing machinery for various applications.

Autocoater Machine

Get Price Quote

We are among the prominent manufacturers and exporters of best quality Lab Auto Coating Systems. Owing to their fully automated operations, minimum maintenance, steady performance and robust design, these systems are highly demanded in the market. the auto coater manufactured by our company are mainly used in pharmaceutical and food industries. Featuring mechatronics and confirming to the requirement of CGMP, it is a high efficiency, energy saving, safe and clean equipment for film coating of tablets, pills and candies with organic film, sugar film etc. These Auto Coaters are highly appreciated and demanded by a large number of customers globally. Our clients can avail from us these products at most competitive rates NOTE : Technical details, specification & designs are subject to change without any prior notice.

automatic tablet coater

Get Price Quote

We have a well-maintained and spacious storage space and thus, we are flexible enough of meeting the urgent needs. Furthermore, we by no means go out of stock and thus we maintain year round accessibility of all the products. Assistance of diligent professionals and modern packaging facility give our clients and us a win-win situation at the time of tailored packaging requirements.