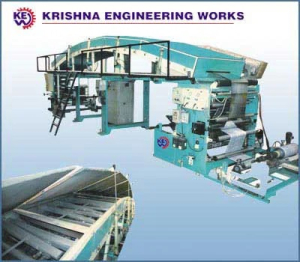

Extrusion Coating Lamination Machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering extrusion coating lamination machine. plastic extrusion coazting lamination plant for tarpauline/bag pp with bopp paper lamination

automatic coating machine

Get Price Quote

1 Piece (MOQ)

Details : C-KANARO history is significant to understand today's realities, values and targets. It is applied in one cycle of operation from top to bottom (immersion effect). CKB-69 guarantees uniform layer of emulsion on the screen because of its sturdy vibration-proof frame structure. The built in two motors help reduce downtime of coating subsequent screens to a minimum. Cones and emulsion reservoir are made of light weight aluminum alloy ensuring minimum wear to the working parts. Coating squeegee are made of water resistant top Quality rubber ensuring smooth and even emulsion layer on the screen Automatically height adjustment systems for reused screen. Spares for repeat changing components are available from C-KANARO 640 mm to 1018 mm Repeat. Complete Electrical Panel with PLC logic invertor. Single button operated system for all operation. Alarm system on finished coating. Top & Bottom head sliding on linear rail motion system (Made in Taiwan) for long life. Top & Bottom head traveling by Wire rope for smooth & maintenance free life. Variable Coating speed & Universal Reserve wire system for equal coating & coating thickness. Double squeegee system for fast & better coating for Inkjet & Laser Engraving. Very easy manual cone locking system with cone locking sensor. 220 V (Single Phase) Connection (Not r equired Three phase 440V, & Pneumatic line).

Best Deals from Coating Machine

Bar Coaters

1,250 - 1,750 Per Piece

1 Piece (MOQ)

Paper Coating Machine

Get Price Quote

Krishna Engineering Works India, a leading manufacturer, exporter and supplier of Coating Machine from last 25 years. High-quality Coating Machine available with different types of range. Also manufacturer of Rotogravure Printing Machine and Slitter Rewinder Machine Manufacturer Heavy duty side M.S. steel walls to ensure vibration free running at high speed.Foundation free base frame. High velocity air blower for fast dying. Good quality electronic input drives, motors, Tension Control System etc. All free rollers are dynamically balanced.Pneumatic functions for impression rolls.Auto tension control. Auto web aligner.Careful quality control in manufacturing process to ensure years of maintenance free running.

BOPP Cello Tape Gum Coating Machine

125,000 Per Piece

1 Piece (MOQ)

BOPP Cello Tape Gum Coating Machine

Get Price Quote

Tablet Coating Machine, Rotary Tablet Machine

COATING MACHINE FOR TABLETS

Get Price Quote

Tablet Coating Machine

Get Price Quote

We cater the best quality Tablet Coating Machine in the international market. Our Automatic Tablet Coating Machine is used for applying a layer of coating on tablets and capsules quite efficiently. They are highly durable and easy to operate. In addition, we are one of the principal High-Efficient Tablet Coating Machine Suppliers in India.

wire coating machine

Get Price Quote

We manufacture and export plastic machineries along with surgical tubing plant, medical pipe plant, extrusion machineries, plastic processing machineries, PVC processing machineries, LLDPE pipe plant, soft PVC braided hose machinery, plastic recycling machine, PVC trunking machinery, PVC casing capping machinery, corrugated hose machinery, plastic profile machinery, jockey extruder, heater mixer unit, high speed mixer unit, automatic pipe, profile cutting unit, scrap grinder unit for plastics and pipe socketing machinery for various applications.

Lab Tablet Coating Machine

320,000 Per Piece

1 Piece (MOQ)

vmch coating machine

Get Price Quote

From bulk to retail order fulfillment, we can do it all. Our company has a wide supply chain network to provide our buyers with the product all year round and make timely delivery. Our well-structured warehouse is the reason behind the safety of the products we offer. Moreover, we have installed advanced amenities essential for the safe storage of the lot. Salient Features of the Plant : Hot Air Temp - 50 – 1500oC Heat Source - Hot Air Generator (Optional) Exhaust - 3 HP Main Drive - Coater / Nip -3 HP, Rewind – 5 HP AC digital drive for tension controller Tendency roll drive AC. With timing pulley Maximum speed for solvent base adhesive 225 m.p.m. Fully pneumatically lifting tunnels and impressions rollers, Doctor blade, Lay and Rolls Chilling roll provided before rewinding Comfortable exhaust system for solvent fumes Uniform heating system

zinc kettle

300,000 Per Piece

sticker coating machine

Get Price Quote

Tablet Auto Coater

Get Price Quote

Tablet Coating Machine with Completing Sparying Systems available from 12" to 72" Complete System & Seperate Coating Drums also.

Coating Pan

Get Price Quote

We are main supplier of this product.

Tablet Coating Pan

Get Price Quote

The prism compact NewLABOcoata- Lab Automatic tablet coating is high efficiency and intelligent automated film & sugar coating advance technology is mainly used in pharmaceutical and food industries. Featuring mechatronis and confirming to the requirement of cGMP. It is a high efficiency, energy saving, safe and clean equipment for film & sugar coating of tablets, Pills and candies with film - organic solvent and aqueous coating.

pvdc coating machine

1,851,000 Per Number

1 Number (MOQ)

Adhesive Coating Machine

Get Price Quote

The above 2 rollers shall be made out of steel pipes having sufficient wall thickness.A sliding arrangement with a coating tray & width adjusting stopper , with 3 Nos. Aluminium rollers . All the above assemblies shall be mounted on the proper frame structure along with the base.

automatic tablet coater

Get Price Quote

Application & Process: The Prism’s advanced high efficiency automated tablet coating machine is mainly used in pharmaceutical and food industries. Featuring mechatronis and confirming to the requirement of cGMP. It is a high efficiency, energy saving, safe and clean equipment for film and sugar coating of tablets, Pills and candies with organic film, aqueous coating and sugar film etc. Automatic Tablet Coater is designed for the application of Film Coating with organic solvent, Enteric Coating and aqueous coating Sugar Coating SALIENT FEATURES Design is cGMP – Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Fully automatic film & sugar coating process by PLC Controls with HMI Touch screen. Flexible batch operations Complete separation of production and technical area Extremely user friendly software and operation through PLC The machine structure made from S.S.304 quality fitted with Closed Drive, Perforated Pan, Washing sink, Inlet air plenum, Exhaust air plenum with Air tight door. Perforated pan with 50% opening for better quality finish. Excellent mixing and tumbling by special design of removable on each sloping face of the pan and anti sliding baffles provided on perforated diagonal face. Perforated Pan having variable speed through AC frequency Drive. Pan mouth closed with Stainless steel door with a glass for process visualization. A stainless steel 316 sinks at bottom of pan for collection of powder with necessary stainless steel piping with tri-clover joints for ease of cleaning during the changeover. FLP Fluorescent Light is provided for illumination inside the pan All doors, safety guards and covers are provided with a silicon food grade seals Automatic Spraying systems provided with Atomized spray Gun, Adjustable spray gun arms, High precise flow peristaltic pump, solution holding tank with pneumatic stirrer. Front Entry stainless steel arm, with facility to adjust the angle of spray guns is provided. Inlet air and Exhaust air plenum provided with silicon seal with easy removable for cleaning. Inlet air and outlet air will be controlled by pneumatic operated damper which is provided on top of the machine and at inlet and outlet duck. Inlet air and Exhaust air flow controls through AC Frequency drive of both blower. Inlet Air handling unit made from double screen insulated with puff with inside stainless steel 304 quality and outside powder coated. The Inlet air handling units fitted with Pre filter- 10 micron, Inlet air blower with motor, Dehumiditifier- child water circulation coil, Stainless steel 304 quality Steam/ Electric heat exchanger with fins, Final filter with 5 micron, HEPA filter -0.3 micron. Exhaust Air handling unit provided with dust collection system with 5 micron filter or wet scrubber and exhaust blower. The Exhaust air dust collector unit is made from .S.S.304 Quality. Treatment of exhaust air for pollution free operation. The Entire Inlet Air handler and Exhaust air unit to be install in technical service area. Tablet discharging facility will be through the special diverter assembly Advanced CIP /WIP System is provided for pan internal by spraying ball and outer washing by spraying nozzle both side. The complete system will operate and controls through machine PLC for washing cycle for Plain water, Detergent, Hot water, Distilled water and Drying by air. All motor are flam proof/ Explosion proof provided. Advance PLC Controls system with HMI- color Touch screen provided of Allen Bradley/ Siemens make for complete automatic coating process and batch data receipt management . Also option for SCADA connectivity with FDA 21 CFR part 11 The machine instruction manual and Validation document provided for DQ, FAT, IQ, SAT and OQ with test and calibration certificate. Optional Features: Interchangeable Pan Solid Pan for confectionery products. Wet Scrubber Dry Dust Collector Dehumidifier Steam or Electric Heat Exchanger Tablets charging by bin loader SCADA Connectivity

vmch coating machine

Get Price Quote