Mini Ride-On Roller IVR 1200

Get Price Quote

Water cooling drum roller

10,000 Per Piece

1 Piece (MOQ)

Best Deals from Construction Machine

Drum Hoop Mixer

Get Price Quote

Our Drum Hoop mixer attachment is suitable for power and granule mixing. The Drum Hoop Mixer useful in research laboratory and also pharmaceutical, food, chemical and plastic fields having two parts, A. Main frame unit with Roller stand. B. Acrylic Mixing Drum with Rotating Arrangement. The Drum Hoop Mixer having drum capacity of 5 Kg. And operational capacity 2 to 3 kg. This Attachment is Suitable to Attached in our Both Main Drive.

Excavator Nut Bolt

Get Price Quote

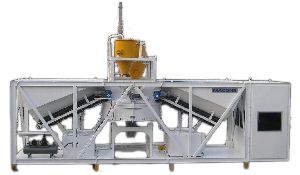

Semi Mobile Concrete Batching Mixing Plant (MASM)

Get Price Quote

Salient Features • Available in 20/25/30 m3/hr. capacity • Mixer PAN type, for continuous mixing. • Replaceable liner Tiles and Tips in to the mixer. • Inbuilt Water and Additive tank. • Fully Automatic plant with Electronic weighing of aggregate/sand/water/cement. • Loading of aggregates / sand Hoppers by wheel loader / conveyor manually. • Civil Foundation work is not required as fully containerized plant. • Easy transportation & shifting. • Compact and Economical design. • Easy installation and put into operation. • Remarkably cost efficient. • Plant operation is very silent, in a clean surrounding. • Least maintenance of plant, due to less wear & tear of parts. Optionals • Online Printing System. • Discharge Belt Conveyor. • Fly Ash Feeding System. • Cement Storage Silo. • Computer SCADA System with Software. • Touch Screen with provision of USB for data back up. Technical Specification

cnc channel letter bending machine

Get Price Quote

AUTOMATIC BENDING MACHINE Fully functional, which has combined both the plate and profile processing. This system integrated the most convenient switching function of material and cutter, the design of double slotting cutter and double bending tools can easily deal with stainless steel, galvanized sheet, aluminum plate and aluminum profile and other materials processing. Now the machine is the highest rate of return on investment in the market A13ESW Planer Full Function Bending Machine Double bending tools bending system, special designed bending tools and the tools edge, capable of bending with plate and profile. Better choice for small angle and radian bending. Double-cutter slotting, using plane cutter for Galvanized sheet and Stainless steel, using milling cutter for Aluminum plate and Aluminum profiles. Continual rolling press feeding, fast and precise, continual respond, shorten the time of feeding. The close-loop control from length encoder and system itself, makes possible to avoid the material slipping. AT1 Advance Full Function Bending Machine Double knife alternating bending system, according to the change of internal and external arc, automatically switch to bend the bending tool, reverse bending tool automatic income tools library, to avoid the phenomenon of intervention bending tools forming angle, for small arc of the small angle of the molding performance is very good. Under the same platform have the processing ability of profile, plate and profile processing without the need to replace the hardware Double cutter double drive slotting system, Planer cutter and milling cutter of combination configuration, The system is based on the processing of different materials to drive the slotting tool, no manual intervention tool switching procedure. Rolling continuous feeding system, Rapid and sensitive, continuous response. The pressure can be adjusted according to the change of material, which can avoid the occurrence of indentation and sliding material. The setting of the double feeding support avoids the change of feeding track, and ensures the smooth input of the material. processing without the need to replace the hardware.

Automatic Pin Wheel Weft Straightner

Get Price Quote

Key Features Comprehensive software with touchscreen control Intelligent drive Bypass function Adjustable unclipping device High lateral tension possible Pinning width adjustable during operation with software Suitable for woven fabrics only

Channel Letter Bending Machine

Get Price Quote

AUTOMATIC BENDING MACHINE Fully functional, which has combined both the plate and profile processing. This system integrated the most convenient switching function of material and cutter, the design of double slotting cutter and double bending tools can easily deal with stainless steel, galvanized sheet, aluminum plate and aluminum profile and other materials processing. Now the machine is the highest rate of return on investment in the market A13ESW Planer Full Function Bending Machine Double bending tools bending system, special designed bending tools and the tools edge, capable of bending with plate and profile. Better choice for small angle and radian bending. Double-cutter slotting, using plane cutter for Galvanized sheet and Stainless steel, using milling cutter for Aluminum plate and Aluminum profiles. Continual rolling press feeding, fast and precise, continual respond, shorten the time of feeding. The close-loop control from length encoder and system itself, makes possible to avoid the material slipping. AT1 Advance Full Function Bending Machine Double knife alternating bending system, according to the change of internal and external arc, automatically switch to bend the bending tool, reverse bending tool automatic income tools library, to avoid the phenomenon of intervention bending tools forming angle, for small arc of the small angle of the molding performance is very good. Under the same platform have the processing ability of profile, plate and profile processing without the need to replace the hardware Double cutter double drive slotting system, Planer cutter and milling cutter of combination configuration, The system is based on the processing of different materials to drive the slotting tool, no manual intervention tool switching procedure. Rolling continuous feeding system, Rapid and sensitive, continuous response. The pressure can be adjusted according to the change of material, which can avoid the occurrence of indentation and sliding material. The setting of the double feeding support avoids the change of feeding track, and ensures the smooth input of the material. processing without the need to replace the hardware.

Tile Abrasion Testing Machine

Get Price Quote

Tile Flexural Testing Machine Capacity 200 kg. for cement concrete flooring tiles. The specifications are similar to the above machine, but for the bearing rollers of 25 mm dia and spans of 150, 200 and 250 mm. The load is applied at the rate of 200 kgminmeter. Without lead shots.

Bar Bending Machine

135,000 - 145,000 Per piece

1 piece (MOQ)

AAC Autoclave Doors

350,000 - 650,000 Per Set

1 Set (MOQ)

bull block wire drawing machine

260,000 Per Piece

1 Piece (MOQ)

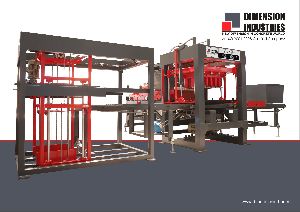

Compact Concrete Plant

2,450,000 Per Piece

1 Piece(s) (MOQ)

A compact concrete plant serves several purposes and therefore when you are investing 24.5 lac, surely you would be keeping in mind each factor like price point, performance, efficiency, and also after-sales services. And, when it comes to Vinayak Construction Equipment, we are a name that is not only well known throughout Ahmedabad but we have worked with clients all over India and abroad as well like Iraq, Sri Lanka, Nigeria and others. For compact concrete plant Indian Seaport, feel free to contact us and enjoy some early bird discounts that you would find nowhere else in the market. We have successfully completed so many projects and have made sure that no client has any complaint regarding us. Also, we have been highly appreciated by how dedicatedly our team works towards designing and monitoring everything from manufacturing, packaging, supplying and also after-sales service. We Deal With Both National And International Clients We have been appreciated for our services and the customer services alongside affordability that we offer. Located in Ahmedabad, we provide you with innovative design. We have representative offices all over the country so that you face no hassle regarding any aspect. We believe it is you who would help us grow and reach the top position in the market. We use CAD modelling system to offer realistic practical designs. As a compact concrete plant manufacturer, it is in the pursuit of excellence that we leave no stones unturned. The company has worked with many clients with years and have gotten repetitive orders. We have achieved or been called trendsetters. Working towards client satisfaction and timely delivery, you can trust us. We take every measure at every step and check it before they are finally dispatched. Email us or ping us up and we would be delighted to work with you. We understand that you are investing a lot and we only deliver you products we know will give you your money’s worth.

Hydraulic Plate Bending Machines

730,000 Per Piece

1 Piece (MOQ)

Asphalt Drum Mixing Plant

2,850,000 - 4,850,000 Per Set

1 Set (MOQ)

Asphalt Drum mix Plant

Concrete brick making machine

1,500,000 - 4,800,000 Per SET

1 Set (MOQ)

we are providing india's best hydro+vibro concrete compacting technology brick | paver | block making machine.

Transit Mixer

110,000 - 120,000 Per Month

1 Number (MOQ)

Rent top-quality transit mixers for seamless concrete mixing and transportation. Perfect for construction sites and projects of any scale. Contact us to book yours today

C Type Bending Machine

150,000 - 250,000 Per piece

1 piece (MOQ)

(A)Technical Details of ‘C’ Type Hydraulic Press : Ø Model : JSG-30 Ø Working Size : 630mm x 400mm Ø Stroke : 170mm Ø Electrical Motor : 3 H.P Ø Centre : 470mm Ø Number of Strokes per minute : 5-10 Ø Weight : 900 Kgs. (Approx.) Ø Hydraulic Oil Capacity : 60 Liter – 68 grade hydraulic oil (A) Standard Scope of Supply : · Main Drive Motor · Electrical Control Panel mounted on side frame. · Standard Panel Board- a. Manual b. Semi Automatic c. Fully Automatic · Foot Switch export quality · Valve Yuken Make and Pump Dowty Make · Stroke adjustment rod with limit switch. · Manual back gauge – 500mm · V block with Blade (blade-HARDNED + GRAIDING)size of 24”. vSpecial Application of this Model : · Bending (As require by you in any of degree) Die Work : Punching, Embossing , Deep drawing , Blowers, Corner Cutting Frame

Vibratory Table

25,000 - 125,000 Per piece

Our vibratory tables are fast, efficient, and economical. These tables are used in compacting before packing, a wide variety of powdery, granular, or flaky materials in boxes, drums, or cartons. The motorized electromechanical vibrating table consists of a solid base plate and a vibrating top. The top platform vibrates at 1500/3000 vibrations per minute through two/one unbalanced vibration motor housed inside. These motors will generate an amplitude of 1.5 mm to 3 mm, which will shake the material and push the material forward. Applications: · For testing of welded joints in the automobile industry· For testing of delicate joints in the electronic industry· For effective packing of fluffy and difficult-to-handle powder in chemical and pharma

working platform

100 - 150 Per Piece

Fully Automatic Fly Ash Brick Making Machine

Get Price Quote

Wire Straightening machine

230,000 - 325,000 Per piece

brick crushing machine

Get Price Quote

Plate Bending Machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering Mechanical Plate Bending Machine.

Two Rod Roller

Get Price Quote

Hydraulic Cutting Machine

Get Price Quote

A shearing machine is an industrial equipment with rotary disks and blades used to cut hard iron sheets and metal bars. The term shearing means to apply a high pressure tool on a metal bar once to remove a part of the metal. All metal shears use the same technique in cutting where there is a fixed upper blade, a lower blade and an adjustable clearance separating the two. When a force is applied on the upper blade it forces the lower blade to cut and separate the metal into two.

Heavy Duty Mini Concrete Mixer

47,000 - 48,000 Per Piece

1 Piece(s) (MOQ)

FPUR ROLL PLATE BENDING MACHINE

Get Price Quote

4 Roll Hydraulic Plate Bender INFORCE ENGINEERING is a known Hydraulic Plate Bending Machine manufacturer in India. We have manufacturing base in Ahmedabad and sales office in Pune, Jalgaon, in Maharashtra. Our 4 Roll Hydraulic Plate Rolling Machine is an ideal solution for conical bending. It is a double pre pinch hydraulic plate bending machine. 4 Rolls Hydraulic Plate Bender contains 4 nos of solid shafts. Top roll is fixed positions. The bottom roll is used for clamping of plate and avoid slippage of steel plate during the bending process. Two side rolls performs the bending operation. Other three rolls are independently adjustable by hydraulic cylinders. This mechanism allows machine to do pre bending to more closer area and it is helpful to reduce the flat end at minimum. This Hydraulic Sheet Bending Machine is ideal for making smaller diameters jobs. This type of Hydraulic Sheet Rolling Machine is most suitable for making conical shapes, ovals and square shaped object. The working cycle of the sheet bending machine is fast, smooth and easy because of the simple prebending and the possibility to roll the plate in one pass. Easy to integrate into a production line when equipped with automatic feeding table and automatic ejection. Hydraulic Plate Bending Machine Features 4 Roll Hydraulic Plate Bender Features Bottom rolls hydraulically driven independently. Sealed spherical roller bearings. Hydraulic powered bending roll adjustment. Push button Hydraulic powered pinch roll adjustment. Push button Hydraulic swing arm for finished part removal. Push button pendant control of forward/reverse. Spherical roller bearings on all roll shafts. Heavy duty reinforced welded steel frame. Hydraulic Plate Bending Machine Accessories Solid Rolls of EN 8/9 with material test certificates Epicyclic Planetary Gearbox for extra torque Variable Frequency drive, with control panel (VFD) Movable Operating desk with push button panel Electric motors with reputed ISO brand Complete hydraulic system with power pack & cylinders Hydraulic cylinder is double acting made from carbon steel seamless pipe. Spherical roller bearings on all roll shafts. M C B to protect machine against short-circuit and over-loading. Emergency Stop Switch is fitted on control panel to avoid any Accident. Optional Accessories of Sheet Bending Machine Linear guide ways to measure hydraulic cylinder movement Digital Readouts of 2 lower roll positions. Hardened and ground alloy steel rolls. Digital Readout Positioning of bending rolls. Material Feeding Table Side support for bending large diameter shells Hydraulic top support for large diameter shells. Auto Ejection system for removing bending parts Cone Bending Attachment Automatic Lubrication System NC Controller

automatic batch coding machine

285,000 Per Piece

1 Piece (MOQ)

Plate Compector

Get Price Quote

Manufacturer & Supplier of plate compector & Plate Compactor. Our product range also comprises of Concrete Mixer, Tower Hoist and Slab Trolley.We are an eminent name, which is engaged in delivering Vibrating Plate Compactor (445 X 270mm) at clients' premises. The offered range of vibrating plate compactor (445 x 270mm) is manufactured utilizing high grade raw material and innovative technology in complete adherence with the international quality norms. Along with this, the offered range of vibrating plate compactor (445 x 270mm) is suitably checked on different characteristics to maintain its authenticity throughout the designing process.