Color Mixer

Get Price Quote

Our company is based in Ahmedabad, Gujarat where manufacturing and exporting of Color Mixer is initiated. Many tests are performed simultaneously by our experts in view of making it free from flaws. Several parameters are checked before supplying the product in order to maintain a defect free stock. The performance of the product is trouble free and is highly durable. Moreover, we are capable of handling bulk orders. Features : Sturdiness Hassle-free performance Durability

Single Arm Continuous Mixer

750,000 Per Units

Best Deals from Continuous Mixers

high speed dispenser

250,000 Per Piece

Automatic Twin Shaft Disperser

385,000 Per Unit

Single Shaft Paddle Mixer

Get Price Quote

We are instrumental in providing our clients a comprehensive range of Single Shaft Paddle Mixer

chemical mixers

Get Price Quote

YRVD vacuum disperser is used to mix, disperse and dissolve different viscous materials. The highly rotating disc exerts a strong shear, impact and crush force to rapidly mix and grind materials. It is widely used in paint, printing ink, dyestuff, color paste, fine chemicals etc. industry.

Single Arm Continuous Mixer

750,000 Per Units

Dual Shaft Mixer

65,000 Per Piece

Compact High Shear Mixer

Get Price Quote

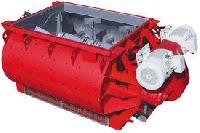

TWIN-SHAFT PUGMILL MIXER

Get Price Quote

1.Direct gear-motor drive with transmission through synchronous, helical spur gear. 2.Robust and rugged design to suit hardest site condition. 3.Inner mixer wall is bolted with extremely high wear resistance austenitic Ni-Hard liners. 4.Mixer arms and paddles, which are made from high-chrome alloy-steel and special caststeel ,are bolted to allow for easy replacement of these wear parts. 5.Mixer discharge gate with wear resistance liners is a rotary type and pneumaticallyoperated by two cylinders. 6.Capable to produce homogenous mix within a short mixing time, minimizing oxidation of bitumen. 7.Non-contact infrared temperature measurement at mixer outlet.

Contra Rotating Mixer

Get Price Quote

"CHITRA" TOOTHPASTE MANUFACTURING MIXER consists of a Main Manufacturing Vessel also known as Contra Mixer. Contra Mixer as the name suggest works on the principle of Contra rotation of Blades for simultaneous beating and scraping operation. The mixer is highly versatile and mostly used for manufacturing Tooth Paste, Creams, Cosmetics and other viscous products.The Mixing Assembly consists of series of paddle type blades of appropriate shape to move the material back towards the centre of the container. The paddle type blades are provided on the central shaft which runs through a hollow shaft on which other sets of blades are welded. Both the sets of blades intermeshes with each other and rotates in clockwise and anti-clockwise direction respectively and one sets also scraps the container wall for thorough and uniform mixing of the material. The mixer is so designed to withstand high vacuum applied during the process for optimum mixing. Contra Mixer is provided with a jacket for cooling or heating as per the application. The vessel shall have a shell of suitable thickness with a hemispherical bottom and flanged top dish made out of S.S. 316 plate. The vessel shall be jacketed with MS jacket ( SS304 jacket provided on extra cost on demand, if required ) of suitable with stiffeners suitable for steam pressure of 4 to 5 Kg/cm2. The jacket shall be insulated with 50 mm thick glass wool insulation and shall be cladded with 16 SWG M.S. or SS304 material. The vessel shall be suitable for 600 to 700 mm of Hg vacuum and internal pressure of 3 Kgs / cm2. The top lid of the Mixer m/c shall be provided with hydraulic lifting and lowering arrangement, if required. Hydraulic arrangement will consist of : ( Optional at extra cost )Hard Crome plated HYDRAULIC CYLINDERS ( 2 Nos. ) Limit switches at upper and lower limits Power pack with direction control valve by actuated SPECIAL FEATURESAll contact parts are made out of SS 304 / SS 316 quality material. Compact design requires comparatively smaller floor space. Product container mounted on mounting lugs or legs as required by customer. Hydraulic power pack with cylinders are provided for lowering and lifting movement of top cover with stirrers drive assembly. Lowering and lifting movement of drive assembly will be achieved through hydraulic lifting system for easy of cleaning and changeover of products. (OPTIONAL - Provided On Demand) Fixed product container for safe operation during mixing. Product container having hemispherical shape bottom. As stirrer is a top driven and sealing doesnt comes in contact with product, there isnt any black particle contamination problem. Steam circulation jacket for mixing bowl, to heat the product during operation & water circulation facility to cool the product during or after mixing. ( made out of mild steel or SS304, as per customer requirement ) All Non contact parts (general structure) made out of mild steel (SS304 provided on demand, on extra cost) and claded with SS304 or crome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and noncontact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model. General structure & all non contact parts are made out of Mild Steel & same will painted in Standard Model. Digital temperature indicator provided to indicate the temperature of the product. (Temperature controller for steam heating is not in our scope of supply.) SPECIAL FEATURESMachine design as per the vacuum application for de-airation of mixing container, to remove air bubbles from the product during mixing for GEL products. ( Vacuum System) vacuum pump is not in our scope of supply. Insulation will be provided on jacket of container. The insulation will be covered with M.S. material in standard model and SS304 material in GMP model. Material discharge from bottom. Flush bottom valve provided for material discharge. M/C provided with Light glass, Sight glass, material inlet, water inlet, steam & washing water inlet, air suction valve for vacuum, vacuum gauge etc... Mixing assembly have two speed facility. Variable speed drive facility for mixing assembly will be provided on extra cost, as a OPTIONAL facility. Digital Timer for Batch time setting. Ampere Meter for main motor. OPTIONAL"PLC" based operating panel for automation. Variable speed drive for main motor for variable rpm of mixing assembly. Online sampling port to take sample of product during mixing. Inline homoginizer or Colloid Mill.

Contra Mixer

Get Price Quote

the contra rotary mixer is designed to achieve better mixing and consistent granules at lower operating cost along with higher productivity. It works with full vacuum or pressure and at higher speeds. It is comprehensively jacketed for steam or hot water circulation. It comprises of paddled form blades for movement of material back towards the center of the container. The contra mixer comprises of mainly two blades including that rotate clockwise and anticlockwise simultaneously. There are two different shafts that include, solid and hollow shafts. The vessels are fabricated in a form that it can handle complete vacuum or pressure. characteristic features the contra mixer is equipped with pitched paddle blades throughout the height of vessel intimate mixing, shearing and blending possible with the central shaft in the rotary mixer effective teflon scrapper blades for scrapping product material from the vessel wall uniform and homogeneous mixing of viscous products due to the contra rotary motion efficient sanitary design to prevent product contamination all the contact parts made up of ss 314 and ss 306 material compact in size with smaller floor size all the non contact parts configured with mild steel or ss 304 material mounting possible with the mounting of product containers on the mounted legs steam circulation function available for mixing bowl equipped with digital temperature indicator for keeping a check on temperature parameters thick glass wool insulation available no air contamination due to vacuum operation ideal mixer for high density and viscosity materials provides durability, sturdy design and smooth functionality flame proof control panel available for safe functioning appropriate for thorough mixing, blending of toothpaste, grease and all other viscous compounds also solid shaft with multiple paddle blades for rapid operation inbuilt homogenizer with mechanical seal, that is helpful for emulsification

Variable High Speed Dispenser

300,000 Per Units

1 Units (MOQ)

Twin shaft Disperser

Get Price Quote

We are one of the leading manufacturers, exporters and suppliers of Twin Shaft Dispersers. These are manufactured using quality materials and precision engineering techniques. Our range also complies with the international standards and is offered at competitive prices. The Twin shaft Variable Speed Dispersers Hydraulic Lifting that we manufacture are at par with the international quality standards. These are manufactured using quality materials and offered to our clients at industry leading prices. Twin Shaft Variable Speed Dispersers Hydraulic Lifting We manufacture Twin Shaft Variable Speed Dispersers Hydraulic Lifting with Tank. This is a highly versatile machine for the production of paints, inks, pharmaceuticals and other construction chemicals. These machines ensure proper breaking of agglomerates and can also mix various types of liquid in order to receive premium quality output. Advantage No pre-mixing Easy cleaning Low noise level Low maintenance cost Safe and easy performance High viscous materials can be dispersed Economical, consume less power per liter of materials Application Paints Coatings Cosmetics Printing inkss Pharmaceuticals Other chemicals processing industries

Rotary Color Mixer

Get Price Quote

toothpaste mixer

Get Price Quote

The Mixing Assembly consists of series of paddle type blades of appropriate shape to move the material back towards the center of the container. The paddle type blades are provided on the central shaft which runs through a hollow shaft on which other sets of blades are welded. Both the sets of blades intermeshed with each other and rotates in clockwise and anti-clockwise direction respectively and one sets also scraps the container wall for thorough and uniform mixing of the material.

Twin Shaft Mixer

Get Price Quote

Twin Shaft Mixer, Concrete Batching Plant, concrete laying canal paver

Single Shaft Mixers

Get Price Quote

Single Shaft Mixers

Single Shaft Mixer

Get Price Quote

Single Shaft Mixer, Dry Mix Concrete Batch Plant

dry color mixer

Get Price Quote

dry color mixer, Foam Generator, Color Mixer, Foaming Agent, Fly Ash Bricks