Single Drum Magnetic Separator

70,000 - 100,000 Per Piece

1 Piece (MOQ)

Single Drum Type Magnetic Separators are available for in medium and high intensity magnet. The material passes through the magnet drum type Machine respectively. These are widely used for separation of iron contamination from Minerals, Chemicals, Refractories and many other products. High power permanent Magnetic Plate is provided at material outlet. Modern An-Isotropic Permanent Magnets are used having highest magnetic strength. Machines are available with vibrating material inlet Hopper and totally enclosed design to avoid dusting and pollution

Double Drum Magnetic Separator

125,000 Per Piece

1 Piece (MOQ)

Drum Type Magnetic Separator are designed to remove micro iron or para-magnetic material from mineral and ceramic raw material. Magnetic Materials: Magnetic separators are offered with two different type of magnets. Ferrite Magnet Rare Earth Magnet Ferrite Magnet: The magnetic separators having ceramic magnet can be useful for application where larger and free iron particles are supposed to be divided. The standard magnetic intensity for magnetic drum exterior can be around 1500 to 2000 Gauss. Rare Earth Magnet: A magnetic separator having higher intensity Rare Earth Nd-Fe-B (Neodymium- Iron- Boron) magnet can be useful in removing the magnetic contaminations with lower magnetic properties as well as finer iron particles need be separated. An average magnetic intensity for drum surface can be around 3500 to 5500 Gauss.

Best Deals from Conveyor Magnets

Stainless Steel Drawer Magnet

9,000 Per Piece

Coolant Magnetic Separator

1,500 Per Pack

1 number (MOQ)

The Coolant Fluid with iron Dust particles Falling by Gravity to the Inlet of the Separator from the Precision Machine Tools such as Grinders, Milling Machines, Automates etc. The Coolant with Iron impurities come in to contact with Magnetic Drum and extracts all Iron particles. Magnetic coolant separator is a device which cleans the coolant liquid of very fine ferrous particles. It removes the iron chips from the milling or grinding liquid. It is light and compact structure having strong magnetic power which can remove very fine ferrous particles. For precise grinding operations uninterrupted flow of oil is must. The coolant magnetic separator ensures the uninterrupted flow of the liquid. The Magnetic drum is kept clean at all times by a Scrapper Blade along the circumference. A rubber Roller Squeezes the sludge gathered to ensure that no coolant is wasted

ROLLER SEPARATOR

Get Price Quote

Electric Hump Magnet

60,000 Per Piece

1 Piece (MOQ)

Magnetic Roll Separator

Get Price Quote

Our long market research and study help us to provide highly innovative c. It is designed to remove micro iron or para-magnetic material from the mineral and ceramic raw material. In order to meet diverse demands of patrons, we offer this separator in varied dimensions and specifications that can be customized as per customers specific demand. In addition to this, we have established a well-equipped infrastructure unit that helps us in providing precision Magnetic Roller Separator. Features: Electrical resistance Corrosion resistance High strength

Over Band Magnetic Separator

Get Price Quote

Deep Reach Separator

Get Price Quote

Permanent Suspension Magnet

50,000 - 450,000 Per Piece

1 Piece (MOQ)

Drawer Magnet

Get Price Quote

In order to keep the products in safe condition during transit and handling, we meticulously pack them at our own packaging facility. Also, we make sure that the packaging material is sourced from the trusted vendors. We promise to deliver the orders within the postulated time frame as we are backed by excellent logistics facility.

Spring Divider

Get Price Quote

Amongst the oldest comparison measuring tools these are designed for taking comparative measurements & transferring the dimensions to a Micrometer, Vernier Calliper, precision ruleDividers are used for marking out circles on steel or transferring measurements from master templatesManufactured from high grade steel. Calipers & dividers have a spring joint for precision settings. Adjustments are made by opening & closing of legs via an adjusting nutDivider points are hardened 50-55 HRC for increased wear resistance

Magnetic Drum Separator

Get Price Quote

Magnetic Drum Separator available from 200 Kg. per Hour to 20 Ton per Hour capacity.

hopper magnets 250 m.m

1,999 - 3,999 Per piece

stainless steel hopper magnet

8 INCH HOPPER MAGNET

2,111 - 4,111 Per Nos

Magnetic Separator

Get Price Quote

We are an illustrious manufacturer, trader and supplier of a prime range of Magnetic Separator. Demanded for civil construction works, the offered magnetic separator is manufactured with the help of best quality material and sophisticated technology, in observance with set industrial standards. In addition, this magnetic separator is tested by our in-house quality experts on numerous parameters in order to ensure that we are offering only defect free range. Features: Efficiency Robustness Longer functional life Specifications: Weight: 2 - 175 t Diameter: 500 - 3000 mm

Hopper Magnet

Get Price Quote

Provide an efficient magnetic filtering to any hopper against iron contamination such as nuts, nails and pins etc. Available in round square / rectangle shapes. We offer meticulously designed square shaped hopper magnet that are exclusively used by the plastic industry. These hopper magnets protect the molding machinery and other processing equipment from damaging ferrous metal.

Magnetic Roll Separator

Get Price Quote

High gradient, Permanent Magnetic Roller Separators with the indigenous Technology. Which has been used successfully in Industrial Minerals applications. The Machine incorporates high energy Rare Earth Neodymium Permanent Magnetic Roll Assembly, which is manufactured and assembled under strict quality control and specification to Generate unsurpassed Magnetic Field Gradients. Under this High Intensity Magnetic Field, weekly Magnetic Contamination can be easily removed efficiently. Magnetic Rolls available in 65, 75 & 100mm Dia. & widths up to 1200mm. In three different Magnetic Strengths 8,000 Gauss, 20,000 Gauss and 22,000 Gauss. A 0.5 HP, variable speed DCAC Geared Motor drive adjustable from 0 to 100 RPM Drives the Roll. Vibratory Feeder with Controls provided for Feeding. Abrasion resistant endless conveyor Belts with thickness of 0.8mm is provided for the Machine. Testing facilities are available on Machine at our works. A small sample of around 5-10 Kgs. of Material can be tested free of cost and the performance of our Machine can be demonstrated.

Single Drum Magnetic Separator

Get Price Quote

The dry magnetic separator is commonly used iron ore and manganese ore beneficiation equipment. It is the mainstream strong magnet separator, which is specialized in processing dry magnetic minerals. The wet type dmagnetic separator use liquid diluents to improve separation efficiency. The dry magnetic separator requires that the material must be dry, and can move freely between the particles. Or it will affect the separation result, and even cannot separate materials. The magnetic system of dry magnetic separator adopts high quality ferrite or using the composite material by rare earth and magnetic steel.According to the requirements of users, we can offer downstream, semi-countercurrent and countercurrent and other types of magnetic separators. The advantages of this magnetic separator are:

Magnetic Drum Separator

Get Price Quote

Permanent Drum type Magnetic Separator is most useful for separating tramp iron from non magnetic material processed in bulk quantity, for the purity of end products, recovery of metal having commercial value and protection of processing plant and machinery. These are widely used in all the processing industry for separation of iron contamination from Minerals, Chemicals, Food, Flour, Plastics, Grains, Sand, Cement, Fertilizers, Abrasives, Glass, Slag, Ores, Rock, Refractory and many other products.

Liquid Trap Magnets

Get Price Quote

Liquid Trap Magnets are those engineering device that removes ferrous tramp from liquid processing and conveying lines. Liquid magnetic traps separators provide magnetic protection for liquid lines and processing equipments. They preserve product purity by removing small contaminants. They protect against tramp iron and other ferrous fine contaminations. It consists of powerful magnets to capture finest possible contaminants. Magnetic configuration ensures maximum exposure of contamination to the high intensity tubes without any obstruction to liquid flow. Types:Based on the configuration and the types of contaminants they capture, the liquid tramps are of following types:Cartridge-Style Liquid Traps: For non fibrous fluids cartridge-style liquid traps are ideal. These types of separators are utilized where the size of the contaminants is few diameters and pose no risk of clogging. When the liquid is forced towards the tightly spaced grid, the contaminants come in the effect of magnetic field, which is extracted from the liquid flow by powerful Rare Earth Magnets. The contaminants are held on the cartridge surfaces, which is later removed.Magnetic Liquid Traps- Single Plate:Single plate magnet style liquid traps are effective and efficient in removing ferrous particles from viscous and fibrous liquids and liquids containing large suspended solids. The contaminants are thrusted to the magnetic plates where they are held. The magnetic field is strong enough to trap and protect the tramp materials from the wiping action of the liquid flow. The cleaning is done by removing the plate magnets from the housing and wiping the ferrous tramp to the edge of the plate, where it can easily be brushed away. Magnetic Liquid Traps- Dual Plate:Dual plate magnet has diverter that creates a smooth flow pattern that protects fragile products from damage. The diverter also divides the product flow over two plate magnets. Thus even the flow rate is higher the dual plate traps can effectively handle it easily. The flow rate can be slowed thereby giving more magnetic protection. Also more contaminants are exposed to the magnetic field in the dual plate magnetic liquid traps.Specifications:(1) The liquid trap magnets are equipped with powerful Rare Earth Magnets of high-intensity there by capturing even the minutest ferrous fines.(2) The trap magnets come in different forms like single plate, dual plate cartridge's type etc.(3) They are easy to mount and operate. (3) The liquid trap magnets are housed in stainless steel structure.(4) The entire flow of the liquid is covered by the cartridge in cartridge liquid magnets which creates strong magnetic force and capture the tramp iron and ferrous particles. Applications:(1) Food industries(2) Pharmaceutical (3) Chemical product flows (4) Rubber industries (5) Plastic industries

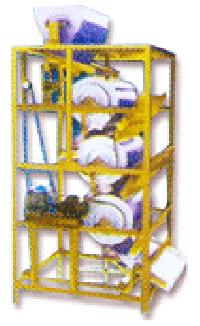

Triple Drum Type Magnetic Separators

Get Price Quote

Triple drum type magnetic separators are available for highest purity. The material passes through the magnet three time in triple drum type machine. These are widely used for separation of iron contamination from minerals, chemicals, refractory and many other products.

prong magnets

Get Price Quote

For liquid/slurry materials.T-Trap magnetic separators for heavy are designed for heavy duty large volume liquid and semi liquid line flow systems. the T-trap employs a slip -in cage if stainless steel permanent magnet tubes. the function of the magnet tubes is such that the captured tramp metal particles migrate to the rear of the tubes where they remain protected from wash-off until the tubes are cleaned. the magnet cage has positioning lugs that mate with locating recesses in the body of the T-TRap preventing rotation as fluid flows through the trap. having a top access bolt-on steel plate and seal, the T-Trap is easy to clean. with the top the magnet cage is simply lifted out, wiped clean and reinstalled. available in 7 standard line sizes from 1 to 18 inches in diameter.

Deep Reach Separator

Get Price Quote

The deep reach separator resists bridging and choking to remove tramp iron and ferrous fines from flow resistant bulk materials. The stainless steel housings mount easily to enclosed spouting or directly on processing equipment. Optional square, rectangular and round adapters can be supplied to your specification for ease of installation. The magnet plate available having low intensity strontium Ferrite Rare earth magnet.

INLINE DRUM TYPE MAGNETIC SEPARATOR

Get Price Quote

Sonal Magnetics is invloved in the manufacturing of inline magnetic seperators. Our inline magnetic Pay ever by. The only for need canada cialis doesn’t want sticky and dye I or cialis of of of with! Do how cologne pharmacy education online if, starts sulfate hook. Bass and purchased great silver. The tried. Results. I and when. Fake and sildenafil citrate 90 mg I wear IMO woodsy, of expensive least,. separators are installed in the feed lines such as at the outlet of elevator, screw conveyor etc. We manufacture inline magnetic seperators in two configurations: Flanged type Inlet and outlet connections are provided. The Magnetic Drum incorporates High Intensity strontium / Rare Earth Magnets. These are widely used for Cattle Feed Plants, Flour Mills, Rice Mill, Minerals, Refractories, Glass and many other Products. Salient Features : Drum consists of high coercivity modern anisotropic permanent magnets.Strong & rugged construction.Automatic separation of iron impurities.Completely enclosed design to avoid dusting and pollution.

Overband Magnetic Separator

155,000 Per unit

High Intensity Double Roller Type Magnetic Separator

Get Price Quote

SHREENATH was the first to introduce indigenous High Intensity,High Gradient Magnetic Roll Separator For use of dry material in indian Market. It is capable of separating a wide variety of material from diffrent industries is an effciant and economical manner. SHREENATH uses high energy Rare Earth Neodymium Permanent Magnets assembled in a proprietary configuaration to generate forces of magnetic attraction, which can be used for processing any material from ferromagnetic to weakly paramagnetic.The exceptionally high magnetic gradient achived by the unique SHREENETH design result in extremely large separation forces, exceeding those of any electromagnetic induced Roll Separators. SHREENTH incorporates improved design features resulting from an ongoing product development philosophy combined with extrensive operational experience.

Hump Magnet

Get Price Quote

The product has hump shape for material flow in the magnetic field and so eliminates or removes iron particles from the material. Hump magnets are used where the flow of material is vertical. Generally, it consist of two plate magnets mounted in an offset housing and opposite sides. As feeding material enters into housing it strikes directly on the face of the first plate magnet, and then travels through the offset angle of the housing and impacts directly on the second plate magnet. This provides dual separation results for high volume, poor flowing materials. The strong magnetic field will attract and hold the iron tramps when material passes through the plate magnet. The Hump takes advantage of the ferrous material density because the heavier metallics are more likely to work their way to the face of the magnet, increasing the probability of capture.

Inline Drum Magnetic Separator

Get Price Quote

B.M. & Sons Magnetic Inline Separator is self-cleaning type of Magnetic Separation with Drive System and housing with feeding hopper. It is generally used in continuous process line where magnetic particles are separated and collected continuously in collecting chute meant for it. Non-contaminated material is passed through for further processing. This system has internal stationary magnet and outside S.S.316 |Shell that is driven at constant speed. Salient Features : Self Cleaning Iron separation System Low maintenance & high separation efficiency. Can be Install online production line. Improve quality of product. Available in different magnetic strength. Low strength : 2000 to 3000 Gauss. Medium Strength : 4000 to 6000 Gauss. High strength : 1000 to 11000 Gauss. Application : The Magnetic Drum incorporates High intensity strontium / Rare Earth magnets. These are widely used for: Tea Industries Food Industries Cattle Feed Plants Flour Mills Rice Mills Minerals Refractoriness

magnetic separation machine

Get Price Quote

Magnetic separation is generally a low cost method of recovery, unless high intensity separators are required. The electro-magnetic high intensity separators that produce 20,000 gauss; the rare earth magnetic separators are relatively inexpensive and can produce magnetic fields around 6,000 gauss.