Channel Magnet

10,000 Per Piece

1 Piece (MOQ)

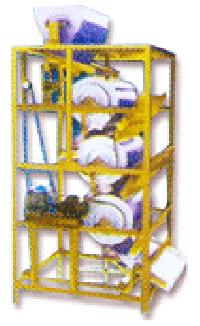

Roller Type Magnetic Separator

Get Price Quote

Shree Vishwakarma Magnets is a leading manufacturer of High Intensity Roller Type Magnetic Separator with 15 years of experience. We are developed cost-effective, high-intensity, high-gradient, permanent magnetic roller separators with the indigenous technology which has been used successfully in industrial minerals applications. High-intensity roller type magnetic separator incorporates high energy rare earth neodymium Permanent Magnetic Roller assembly, which is manufactured and assembled under strict quality control and specification to generate unsurpassed magnetic field gradients. Under this high-intensity magnetic field, weakly magnetic contamination can be easily removed easily and efficiently. Working Principle: In High Intensity Roller Magnetic Separator, a short conveyor belt envelopes the magnetic roll and a tensioning ideal roll. A suitable feeder discharges materials on the belt. The ferromagnetic and paramagnetic particles adhere to the belt while the nonmagnetic particles flow freely off at the end of the conveyor. Features: Magnetic Rollers is available in 75(3 inches) & 100mm(4 inches), 150mm(6 inches) , 200mm (8 inches). More Size as Per Client Required. We Are Using a Motor 0.5 HP to 2 HP as per Machine dimension and Also We are using Standard Company Gearbox with Variant ratio as per material flowrate. Vibratory feeder provided with high quality unbalanced vibratory motors. Abrasion resistant endless conveyor Belts with a thickness of 0.35mm to 5 mm is provided for the Machine. Salient Features: Vibratory Feeder with controls provided for Feeding. The high efficiency of the iron separation system. Abrasion resistant endless conveyor belt with a thickness of 0.35mm to 5 mm is provided for the Machine. Multi-stage system up to 6 stages is available. Different Magnetic Strengths are available: 8,000 Gauss 10,000 to 12,000 Gauss High Intensity Roller Type Magnetic Separator is used for Cleaning and Processing for various types of Grains: Rice Cleaning Garnet Sand Silica Sand Mineral Product Wheat Cleaning Corn Cleaning Pulses Cleaning Spices Cleaning Seed Cleaning Semolina Cleaning Chili Flakes Sesame Cleaning Cumin Cleaning Fennel Seed Cleaning Applications: Shree Vishwakarma Magnets machines are mostly used in various industries like minerals applications such as abrasive, refractory and ceramic raw material beneficiation, alumina, silica, carbide, magnetite, quartzite, etc. Glass raw materials cleaning silica and quartz, feldspar, dolomite, etc. Ultra high purity quartz cleaning, graphite upgrading, manganese ore beneficiation, bauxite upgrading, diamond ore beneficiation, selective separation of garnet/limonite/rutile, zircon, beneficiation of iron ore, recovery of metals from slag, removal of ferrous silicates from limestone, magnesite etc. Also, our magnetic separators are used as magnetic destoner for food processing industries which can remove mud balls from wheat, rice, sesame, semolina, cumin, Fennel, chili flakes and many other food products. Testing Facilities: Live working of a machine will be demonstrated at our workplace. A small sample of around 5-10 Kgs. of material can be tested free of cost and performance of our machine can be demonstrate.

Best Deals from Conveyor Magnets

Hopper Magnet

3,000 Per Piece

Spring Divider

Get Price Quote

Amongst the oldest comparison measuring tools these are designed for taking comparative measurements & transferring the dimensions to a Micrometer, Vernier Calliper, precision ruleDividers are used for marking out circles on steel or transferring measurements from master templatesManufactured from high grade steel. Calipers & dividers have a spring joint for precision settings. Adjustments are made by opening & closing of legs via an adjusting nutDivider points are hardened 50-55 HRC for increased wear resistance

Drawer Magnet

Get Price Quote

In order to keep the products in safe condition during transit and handling, we meticulously pack them at our own packaging facility. Also, we make sure that the packaging material is sourced from the trusted vendors. We promise to deliver the orders within the postulated time frame as we are backed by excellent logistics facility.

Hopper Magnets

Get Price Quote

With the help of our technically proficient employees, we have been able to manufacture and supply best quality Industrial Hopper Magnet. It is made using high coercive permanent magnets that are sealed in non-magnetic tubes at our state-of-the-art manufacturing premises. In the production process of these industrial tools, we use best quality magnets and other raw material such as stainless steel that is procured only from reputed vendors of this industry. Our rich domain expertise and team of dedicated professionals assist us in meeting bulk as well as urgent requirements of Industrial Hopper Magnet. Feature: Corrosion resistance High coercive force Chemical resistance

Magnetic Drum Separator

Get Price Quote

Magnetic Drum Separator is provided by us with a modernized infrastructure to assure fewer complications in processing and producing. We are manufacturers and exporters from Ahmedabad, Gujarat offering this particular product for removing iron particles from various materials. Basic materials are utilized with ultra-modern technique by the proficient trained professionals. Magnetic drum separator is highly reliable with easy operation and low maintenance cost. Features : User-friendly operation Low maintenance Long working life Sample Availability : Yes Brand : Mix Well Supplier Product Code : HE / 015

Magnetic Drum Separator

Get Price Quote

Magnetic Drum Separator available from 200 Kg. per Hour to 20 Ton per Hour capacity.

Hopper Magnet

2,000 - 3,000 Per Piece

1 Set (MOQ)

Magnetic Separator

Get Price Quote

Magnetic Coolant Separator

Get Price Quote

The Coolant Fluid with iron Dust particles Falling by Gravity to the Inlet of the Separator from the Precision Machine Tools such as Grinders, Milling Machines, Automates etc. The Coolant with Iron impurities come in to contact with Magnetic Drum and extracts all Iron particles. The Magnetic drum is kept clean at all times by a Scrapper Blade along the circumference. A rubber Roller Squeezes the sludge gathered to ensure that no coolant is wasted. Features : A sturdy welded M.S. Frame. The Magnets enclosed in Stainless Steel Drum having Powerful An - Isotropic Ferrite Magnets with Uniform Magnetics field all along the Circumference. A Neoprene Rubber Roller with Covered bearings. A Stainless Steel blade with adjustments for efficient scrapping of the sludge. An Elec.Motor working 440 V with Reduction Gear revolving the Drum at about 4 RPM. We are manufacturing Coolant Separators in Standard capacity of 50, 100, 150, & 200 Liters/Min. However custom made Coolant.

Hopper Magnet

Get Price Quote

Hopper Magnet provide an efficient magnetic filtering to any hopper fed injection moulding, blow moulding, extruders, cattle feed plants, flourmills rice mills etc. Made up of high coercivity, permanent magnets sealed in non magnetic tubes they provide better magnetic filtering due to their high magnetic flux density. This is a unique device to protect Plastic Extrudes/Maudling Machines against iron contamination such as Nuts, Nails, Iron Bits etc. and ensure the trouble free and smooth operation of the machine. Four standard sizes both in Round and square are available and can be selected on the basis of the size and shape of Hoppers. High power Magnetic Rods are provided which prevents any iron material to enter in to the Machine. Special size Hopper Magnets are also supplied. Most useful for Plastic, rice Mill, Flour Mills, Cattle feed & Guar Gum industries. Available in S.S. 304/316 construction also for Dyes & Chemical Industries. Features : Durability Sturdy construction Easy installation Trouble free performance Effective separation property

high intensity roller type magnetic separator

Get Price Quote

KUMAR have Developed High Intensity, High Gradient, Permanent Magnetic Roller Seperators with the indigenous Technology. This technology can be successfully used in Industrial Minerals applications. The Technology involves high energy Rare Earth Neodym Permanent Magnetic Roll Assembly, Which is developed and assembled under strict quality control and specification to generate unsurpassed Magnetic Field Gradients. Under this high Intensity Magnetic Field, weekly Magnetic Contamination can be easily removed effectively. Operating Method :A Short conveyor belt envelopes the Magnetic Roll and tensioning the Ideal Roll. An efficient Feeder discharges material on the Belt. The Ferro Magnetic and Para-magnetic particles adheare to the Belt while the non-magnetic particles flow freely off the end of the Conveyor. Features : Magnetic Rolls are available in 65, 75 & 100 mm dia and widths upto1200mm . There are three different Magnetic Strengths i. e. 8000 Gauss, 20,000 Gauss and 22,000 Gauss. The Roll is driven by a 0.5 HP, variable speed DC/AC geared Motor drive adjustable from 0 to 100 RPM. For the purpose of Feeding, Vibratory Feeder with Control is Provided. The Machine is Provided with Abrasion resistant endless conveyor Belts of 0.8mm thickness.Applications :Kumar Machines are most suitable for various types of Industrial Minerals applications i. e. Abrasive, Refractory and Ceramic Raw Material beneficiation, Alumina, Silica, Carbide, Magnestic, Quartzite, etc. Glass Raw Materials, Clean Silica Sand, quartz, Feldspar, Dolomite etc., Ultra High Purity Quartz Cleaning, Graphite Upgrading, Mangenese Orebenification, Bauxite Upgrading, Diamond ore benification, Selective Separation of Garnet / Ilmenite/Rutile, Zircon, Benification of Iron ore, Recovery of Metals from Slag, Removal of Ferro Silicatge from Limestone, Megnesite etc.Testing Facilities : Please feel free to ask for Free Demonstration by testing 5/10 Kgs of any material, at our Works.

Self Cleaning Over Band Magnet

Get Price Quote

Safely and automatically remove tramp iron from heavy product flows. O.b.m.s. Are used for resource recovery, reclaiming steel for resale and separating ferrous contaminants from other recyclabel material such as aluminium, glass, plastic, tires, crushed concrete and wood. Many facilities use o.b.m.s. To protect machinery, such as crushers at quarries, cement plants, and mines. At power plants, they keep tramp metal out of coal pulverizers, pulp & paper mills use them on wood chips. In foundries, they remove chills, spruces and gaggers from sand.

Drawer Magnets

Get Price Quote

The drawers have magnet tubes on alternate centres to force a zigzag material movement between the tubes. maximum tramp metal capture is achieved as material flows through the housing. the pull out drawers provide for fast efficient cleaning of the captured tramp metal the body of the housing is constructd of stainless steel and is designed to fit the mating chute, spout, tube or line in which the housing is to be used.

Triple Drum Type Magnetic Separators

Get Price Quote

Triple drum type magnetic separators are available for highest purity. The material passes through the magnet three time in triple drum type machine. These are widely used for separation of iron contamination from minerals, chemicals, refractory and many other products.

Double Drum Type Magnetic Separator

Get Price Quote

Double Drum Type Magnetic Separators are available for highest purity. The material passes through the magnet twice in Double Drum type Machine. These are widely used for separation of iron contamination from Minerals, Chemicals, Refractory and many other products.

Magnetic Drum Separator

Get Price Quote

1 Set(s) (MOQ)

We are offering magnetic drum separator .salient features : permanent drum type magnetic separator efficient working sturdy design maintenance free.

Hopper Magnets

Get Price Quote

We manufacture and supply fine quality hopper magnets which are widely used in various industries like plastic industry, glass industry etc. Hopper magnets are designed for separating tramp iron material from free flowing materials. These magnets protect molding machinery and other processing equipment from damaging ferrous metal. The transparent drawer face monitor the process of separation conveniently. Slide gate is a standard feature that shuts off product flow. An easy clean design is available.

Drawer Magnet

Get Price Quote

INLINE DRUM TYPE MAGNETIC SEPARATOR

Get Price Quote

Inline Magnetic Separators are available for installation in the Feed lines such as at the outlet of elevator, screw conveyor etc. Flanged type Inlet and outlet connections are provided. The Magnetic Drum incorporates High Intensity stroncium / Rare Earth Magnets. These are widely used for Cattle Feed Plants, Flour Mills, Rice Mill, Minerals, Refractories, Glass and many other Products.

magnetic separation machine

Get Price Quote

Magnetic separation is generally a low cost method of recovery, unless high intensity separators are required. The electro-magnetic high intensity separators that produce 20,000 gauss; the rare earth magnetic separators are relatively inexpensive and can produce magnetic fields around 6,000 gauss.

Magnetic Filter

Get Price Quote

Hopper Magnet

Get Price Quote

We are offering hopper magnet. Fabricated in stainless steel, the hopper magnet protects plastic extruders and molding machine against iron contamination such as nails, nuts, iron bits, so on and so forth. The hopper magnets are available in various shapes, circular, square or rectangular to match the size and shape of the hopper precession.

hand magnets

Get Price Quote

Drawer Magnet

3,500 Per Piece

Double Drum Magnetic Separator

125,000 Per Piece

1 Piece (MOQ)

Drum Type Magnetic Separator are designed to remove micro iron or para-magnetic material from mineral and ceramic raw material. Magnetic Materials: Magnetic separators are offered with two different type of magnets. Ferrite Magnet Rare Earth Magnet Ferrite Magnet: The magnetic separators having ceramic magnet can be useful for application where larger and free iron particles are supposed to be divided. The standard magnetic intensity for magnetic drum exterior can be around 1500 to 2000 Gauss. Rare Earth Magnet: A magnetic separator having higher intensity Rare Earth Nd-Fe-B (Neodymium- Iron- Boron) magnet can be useful in removing the magnetic contaminations with lower magnetic properties as well as finer iron particles need be separated. An average magnetic intensity for drum surface can be around 3500 to 5500 Gauss.

Hopper Magnet

Get Price Quote

Provide an efficient magnetic filtering to any hopper against iron contamination such as nuts, nails and pins etc. Available in round square / rectangle shapes. We offer meticulously designed square shaped hopper magnet that are exclusively used by the plastic industry. These hopper magnets protect the molding machinery and other processing equipment from damaging ferrous metal.

Magnetic Grills

5,000 Per unit

Hopper Magnet

1,111 - 3,111 Per Piece

1000 Piece (MOQ)