Conveyor Pulleys

Get Price Quote

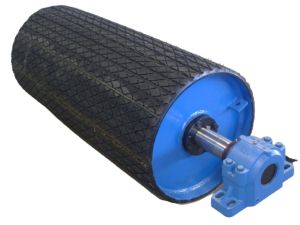

Jagruti can supply pulleys with hot vulcanized rubber lagging, plain or grooved, as required by client. Different patterns of grooving such as herringbone or diamond can be provided to increase tractive friction under dirty or wet conditions. Diamond grooves have the advantage of being installed in any orientation, regardless of belt direction.

Conveyor Head Pulley

2,500 - 120,000 Per Piece

1 Piece (MOQ)

Conveyor Head Pulley The belt conveyor head pulley is located at the discharge point of conveyor. It drives the conveyor belt. For better traction, the head pulley is usually lagged (with either rubber or ceramic lagging material). APPLICATION The head pulley is typically located at the discharge end of the conveyor system, opposite the tail pulley. The primary function of the head pulley is to transmit power from the motor to the conveyor belt, causing it to move and transport materials along the conveyor. It is widely used in: metallurgy, mining, quarrying, Cement and clinker, construction waste, chemical, fertilizer, aggregate, sand, gravel, materials, etc. FEATURES Heady Pulley Construction Head pulleys are usually constructed from steel. The outer surface of the pulley, where the conveyor belt makes contact, may be lagged with rubber or other materials to provide better traction and reduce wear. Various Diameter Selection The diameter of the head pulley is an important design consideration. Larger diameter head pulleys provide more surface area for the conveyor belt to grip, resulting in better traction and reduced tension requirements. Robust Shaft Design The design of the shaft on which the head pulley is mounted is important. It must be robust enough to handle the loads and forces exerted by the conveyor system. Environment Considerations The environmental conditions at the location of the head pulley, such as exposure to dust, moisture, or corrosive substances, may influence the choice of materials and coatings for the pulley. High Quality Bearings Bearings are mounted on the shaft of the head pulley to facilitate smooth rotation. The type of bearings used depends on factors such as load capacity, speed, and environmental conditions. We offer SKF, FAG, NSK, LYC, HRB, or ZWZ for selection. Belt Conveyor Head Pulley Belt Width 500-2800mm (19-110.2 inch) Pulley Length 500-3200mm (19-125.9 inch) Diameter 200-1800mm (7.8-70.8 inch) Standard ISO9001:2008, CEMA, DIN, TUV, etc. Working Life More than 30,000 hours. Surface Flat Rubber Lagged, Ceramic Lagged, Diamond Rubber Lagged, etc. Main Material Carbon Steel Shell Length of conveyor Head pulley depends on the width of conveyor Belt. You can get Head pulleys with hot vulcanized rubber lagging, plain or grooved, as required by client.

Best Deals from Conveyor Pulleys

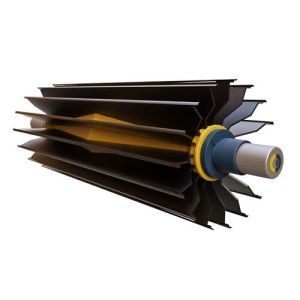

Wing Conveyor Pulley

5,000 Per Piece

Rubber Conveyor Pulley

1,500 Per Piece

Rubber Conveyor Pulley

3,200 Per Piece

5 Piece (MOQ)

Belt Conveyor Pulley

Get Price Quote

Belt Conveyor Pulley

Get Price Quote

We are offering belt conveyor pulley.

Conveyor Pulley

Get Price Quote

We Offer Conveyor Drum Pulley. Offering drum pulley:The head and tail drum pulleys manufactured by us are readily available throughout the market at industry leading prices. These are fabricated by experienced professionals, who adhere to all internal quality norms.

rubber coated pulleys

Get Price Quote

Rubber Pulley wheels are basically rubber coated metal wheels. Due to its outstanding flexibility, insulating, abrasion properties, Rubber is widely used as a coating material over wheels to be used in various industrial applications. Depending on the industry, it can be called by different name – Rubber Pulley, Rubber wheel, Friction rollers, Rubber pulley wheel etc. Rubber Concept produces wide range of Rubber pulleys. Depending on the application, selection of metal and rubber are the prime important factor. Rubber Concept uses MS, SS, Aluminium, CI, Fibre etc to make core of the wheel, over which finely compounded Rubber is bonded with special adhesives to ensure good bonding.

Rubber Lagging Conveyor Pulleys

Get Price Quote

Rubber Lagging Conveyor Pulleys, Industrial Shaft, steel shafts

Conveyor Head Pulley

3,000 Per Piece

Drum Pulley

Get Price Quote

Allied Manufacturing Company are engaged in manufacturing and supplying high quality Drum Pulley that are made available in varied specifications. We are instrumental in offering Magnetic Drum Pulley to our clients. These offered pulleys are engineered with utmost precision under the expert guidance of our skilled.

Conveyor Drive Pulley

6,500 Per Piece

2 Piece (MOQ)

permanent magnetic drum pulley

Get Price Quote

The version with permanent magnets are fitted with powerful and An-Isotropic hard ferrite magnets Rare earth magnets system is also available in two types: with longitudinal polar field distribution for use with low levels of iron contamination and thin mineral layers, and with lateral polar field distribution for greater material thickness and larger iron particles. The magnetic field range from 2500 to 8500 gauss is available. No maintenance.

Conveyor Pulleys

Get Price Quote

Being a client-centric organization, we are engaged in manufacturing Conveyor Pulley. Our dexterous engineers manufacture these pulleys using high quality raw material and advanced techniques in adherence to defined industry standards. Ahead of its final dispatch, the provided pulleys are duly tested by our quality examiners against different measures of quality. In addition to this, these pulleys are fitted in numerous types of conveyor and elevator.

Conveyor Pulley

Get Price Quote

With the help of our experienced engineers, we are able to manufacture, supply and export a vast array of Conveyor Pulley. The products offered by us are made using carbon steel that is machined with proper bore and key way.

Permanent Earth Magnetic Drum Pulley

Get Price Quote

The magnetic Drum pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the drum pulley are supplied made to measure and ready for installation. As the figure clearly show, the magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected. Head roller magnets for conveyor belt are supplied in permanent magnets. The version with permanent magnets are fitted with powerful and An-Isotropic Hard ferrite Magnets /high intensity Rare Earth Nd-Fe-B Magnets and operate without the need for power supplies. The magnet system is available in two types: with Longitudinal polar field distribution for use with low levels of iron contamination and thin material layers, and with lateral polar field distribution for greater material thickness and larger iron particles.

pulley legging

8,000 - 20,000 Per SqMTR

pulley legging, Conveyor Belt, bucket elevator cleats, PVC Conveyor Belt

Conveyor Rubber Legging Drum Pulley

Get Price Quote

Conveyor Rubber Legging Drum Pulley, Self Aligning Idlers, Table Conveyor

Conveyor Head And Tail Drum Pulley

Get Price Quote

Conveyor Head And Tail Drum Pulley, Self Aligning Conveyor Idler