Gravity Roller Conveyor System

Get Price Quote

1 Piece (MOQ)

Inspection Conveyor System

500 - 5,000 Per Piece

1 Piece (MOQ)

Best Deals from Conveyor Systems

Curve Type Conveyor System

Get Price Quote

1 Piece (MOQ)

Tobacco Bales Loading Conveyor System

Get Price Quote

We offer Tobacco Bales Loading Conveyor System that finds its application in Tobacco industry for loading and unloading the product thereby saving time and energy. It is designed and developed according to international standards to ensure quality. This Tobacco Bales Loading Conveyor System is applauded for smooth and trouble-free functioning.Details : Tobacco Bales loading Conveyor has the ability to having the 4 Tobacco Bales of 100 kg. And 150 kg. In 1 min. This is having the ability to low worker for loading and unloading. Tobacco Bales Loading Conveyor is Movable and Adjustable Height. You can use it factory, godown or compound. Tobacco Bales Conveyor Size : Length 30 Feet. Length 35 Feet. Hydraulic Tobacco Bales Loader Conveyor will arrange in the truck 12 feet .Benefits : Minimum Labor required for Tobacco Bales. It is having the required only 3 worker to use any way or any space. It is covered very low space. Maximum work in Minimum time.

Stainless Steel Swing Conveyor

100,000 Per Piece

1 Piece (MOQ)

Loading Unloading Conveyor System

50,000 - 200,000 Per piece

1 piece (MOQ)

Belt Conveyor System

120,000 - 350,000 Per piece

1 piece (MOQ)

A belt conveyor system can be implemented with a very economical cost per foot of the conveyor for many warehouse and industrial applications. Because it includes just one motor and a simple belt system they are quite simple. Hence they’re often one of the first productivity improvement purchases that a growing company will make. Although there are many belt conveyor types, the simplest style is known as a slider bed style. When linked together with sensors and other automation equipment a conveyor belt system can greatly enhance productivity. The weakness for them though is that generally they are only used for transport applications. This means that the belt conveyor equipment just moves the product from point A to point B. This may be sufficient, but a belt conveyor cannot typically buffer or accumulate the parts. Nor are they typically used as a working surface for production team members. As one of the leading online belt conveyor manufacturers, Ultimation can guide you through the pros and cons of the different types of belt conveyors. We’ll also help you compare if another different type of conveyor would be a better choice. WHAT ARE THE TYPES OF CONVEYOR BELT SYSTEMS? Slider Bed Belt Conveyor Roller Bed Incline Belt – Slider Incline Belt – Roller Troughed Belt Conveyor Trough Drum conveyor belt Looking for a conveyor belt for sale? These models shown below are a small sample of the variations available from our catalog. You can download the full catalog from this page or call our team for help. BELT CONVEYOR ADVANTAGES – USE THEM TO: Move simple products from one location to another Move products up or down inclines. Check with our engineers on the highest angle for your product. We generally limit the incline of a belt style system to 25 degrees Move in either continuous or indexing modes. The belt can stop and starts each time to move a product. If you place a sensor at the end of the belt, the conveyor can stop. In other cases, packages are loaded and unloaded from a continuously running belt Use when changing the speed is necessary. We can add a VFD (variable frequency drive) for speed control. This works by changing the frequency of the electrical current. A powered conveyor with a belt is a simple conveyor to adjust the speed on Moving a product around curves. Curve style systems are available to maintain the proper product orientation while a product moves around the curve DISADVANTAGES – DON’T USE THEM IF YOU NEED: Accumulating products (i.e. for a buffer). Belt style conveyors can’t allow the products to nest up against each other (“accumulate”). If you let products pile up against each other, they will get damaged. You could also have problems with them pushing product off the belt. If you need accumulation, use a roller conveyor or overhead conveyor. Accumulation means buffering. Products that won’t slide or roll off the belt. A powered belt system requires the part to ride on the belt without sliding. If you need the parts to be held while on the conveyor, there are other alternatives. Consider a slat conveyor which can be fitted with tooling to hold the product in place. As the conveyor moves along the product rides in the tooling on the slats. To use the conveyor as a working surface. Belt style conveyors are made for transport, not for production operations on them. Use a slat conveyor or roller conveyor for these type of situations. DIFFERENT TYPES OF BELT MATERIAL CHOICES General purpose belting material Rough top belt – for extra grip on inclines, declines and products that might slide Higher chemical resistance – for best protection from chemicals Cut resistant conveyor belt material – for rough or sharp items like sheet metal or bricks. The extreme heavy duty belts are very strong High temperature conveyor belt. For parts coming out of hot presses, we have belt materials available. In some cases, belt conveyors can run through lower temperature ovens. STYLES AVAILABLE IN CUSTOM CONFIGURATIONS: De

Conveyor Belt Tracking System

Get Price Quote

Pneumatic Conveyor Edge Trackers are coming in pair for left & right mounting on width adjusting frame. It is important to know the speed of the Conveyor Tracker and also thickness of the conveyor. Edge sensed by sensor is used to work the other side edge pneumatic tracking unit. Conveyor Tracking Systems can be obtained at reasonable prices. Apart from acquiring distinguished position as the trusted Conveyor Belt Trackers Manufacturer, we are also named as one of the leading Belt Conveyor Tracking Systems

Screw Conveyor System

100,000 Per Units

1 Piece(s) (MOQ)

Roller Conveyor System

60,000 - 80,000 Per Piece

1 Piece (MOQ)

Inspection Conveyor Machine

100,000 Per Piece

1 Piece (MOQ)

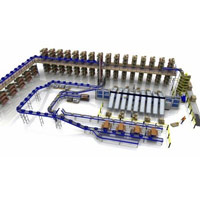

Conveyor System

Get Price Quote

The organization has created repute for itself as Conveyor System Manufacturer and Supplier in Ahmedabad, Gujarat. We offer Conveyor System that is required for different types of conveying applications in several industries. Assembled from quality parts and components, the Conveyor System is compact and sturdy. As well, Conveyor System, offered by us, ensures high performance. Clients can avail from us belt Conveyor Systems in different type of material like MS, SS, etc. We also manufacture and supply Screw Conveyor. Why Our Conveyor System? Huge variety Precisely designed Economically priced Efficient functioning

Material Handling Conveyor Systems

Get Price Quote

1 Piece (MOQ)

Ptfe Teflon Conveyor Belt

Get Price Quote

We are manufacture of all type of PTFE TEFLON BELTS for various industrial applications like sealing, side-sealing, wrapping, fusing, conveying, food processing, casting, releasing, laminating, curing, cooling, baking, frying, soldering and drying process.....etc, and we are also make special purpose Ptfe Teflon belts for as per client special requirements. Our PTFE TEFLON CONVEYOR BELT specialty is best material quality, heat resistance up to -60’c to +270’c temperature, smooth release, outstanding non-stick properties , high tensile & tear strength, dimensionally stable, resistance to most chemicals and solvents, non Flammable, non toxic We have various belt sizes, thicknesses, textures, strength, stability, and splice/edge/tracking (button, revert or guider) options all factor into the level of customization and overall performance specifications to best meet your needs. Application : • Conveyor belts for biscuits, cocoa powder and food stuff through vacuum dryers• A necessary for dairies and others producing chocolates, jams, tomato ketchups, frozen cereals• Conveyor belts for baking & food processing• Confectionery conveying – chocolates, biscuits etc.• Chute Lining in sugar and flour industries• Microwave cooking• Belts for extruded rubber profile curing• Rubber extrusion – rubber foam processing • Belts for curing of paint chips, P.U., P.E. & PVC products• Process belts for curing and impression of PVC backed carpets • Continuous casting of polyurethane release• Belts for curing of hot melt adhesives and adhesive tapes

Ptfe Glass Mesh Belts

Get Price Quote

Harshdeep offers a wide range of ptfe coated fiber glass open mesh fabric conveyor belts up to a maximum width of 4200mm, both edges reinforced and different types of joints to suit customers application. Our belts are used for rotory printing and relaxo dryers for non-woven textile, textile printing, silk printing and dyeing ; shrink packers and high frequency uv dryers ; paper glazing and waxing; food baking, quick frozen machines. benefits of ptfe/glass belts v/s. Stainless and other plastic belts. 1.energy savings: ptfe/glass belts prove better heat transfer and absorb less energy. 2.maintenance costs: ptfe/glass belts have non-stick surface and are easy to clean. 3.cost: a ptfe/glass belt costs less to purchase. its low relative mass allows it to function in a simpler, less expensive pulley and drive systems most ideal splices for dryer belts are – •bullnose joint: made of specially woven open weave mesh from kevlar thread. this extremely strong seam is then stitched to the belts ends, resulting in an open weave mesh seam that does not block airflow. •alligator joint: exceptionally strong splice is constructed with metal alligator lacing through which a pin is placed to complete the splice. edge reinforcement: harshdeep offers a wide range of edge reinforcements for belts in order to protect the belt edges from wear, abrasion and snagging. the reinforcements strengthen the sides and support guide strips, dots and other guiding & tracking devices.

teflon belt

Get Price Quote

50 Number (MOQ)

Belt Conveyor System

Get Price Quote

Features: Used for conveying materials horizontally and also on inclined paths. Used to move materials over long distances. Can be used to handle wide range of bulk materials. Well suited to convey corrosive materials effectively. Can be used to convey various size of materials from fine to lumps.

Small Conveyor Belt System

Get Price Quote

Stainless Steel Conveyor System

200,000 Per Piece

1 Piece (MOQ)

Feed Track

Get Price Quote

The Feed Track : Robust feed chain & conveyor system with German gearbox gives straight movement & effective pressure on small / big panels