Woltmann Water Meters

50mm -500mm (2 ”- 20” ) A removable mechanism type Woltmann water meter with magnetic drive and vacuum sealed register. STANDARDS:- Conforms to ISO 4064 , Class-B APPLICATION:- Water Distribution Network industrial / Commercial water supply FEATURES:- Leak proof and sealed totaliser. Magnetic drive. Repairable without interrupting water supply. Removable mechanism ensures easy maintenance. Totaliser protected by metallic cover. Reliable sensitive metrology and low pressure loss. OPTIONS:- Hot water meters (

...more

Water Meter

Application : Water

Application : Metering

Brand Name : TEP

...more

Vertical Multistage Inline Pump

features:- highly efficient hydraulics design fabricated components less friction in system (pressed components) no expensive foundation required easy installations small floor space applications:-vertical multistage centrifugal pumps type mc are designed for a wide range of applications. water supply systems. water circulation /water treatment plant hydro pneumatic systems / condensate transfer. agriculture /industrial washing coolant circulation. boiler feeding / fire fighting / booster applications. ship building / ro-dm plants. sprinkle irrigation. range:- range : up to 4” outlet size maximum head ………280 meter maximum capacity … 90 m3/hr suction x delivery sizes :- 32 x 32 mm can handle liquids up to 120ºc .

...more

VERTICALMULTISTAGE PUMP

features:- highly efficient hydraulics design fabricated components less friction in system (pressed components) no expensive foundation required easy installations small floor space applications:-vertical multistage centrifugal pumps type mc are designed for a wide range of applications. water supply systems. water circulation /water treatment plant hydro pneumatic systems / condensate transfer. agriculture /industrial washing coolant circulation. boiler feeding / fire fighting / booster applications. ship building / ro-dm plants. sprinkle irrigation. range:- range : up to 4” outlet size maximum head ………280 meter maximum capacity … 90 m3/hr suction x delivery sizes :- 32 x 32 mm can handle liquids up to 120ºc .

...more

Vertical Turbine Pump

a wide range of vertical pumps are available for handling clear water or contaminated water application. These pumps are designed to operate at 50hz and 60hz , in single or more than one stages according to head required. These pumps consisting of bowl assembly, column pipe-assembly, bearing housing assembly along with n.r.r (non reverse ratchet) assembly & motor stool/driving unit assembly. range capacities up to 20,000 m3/hr, head up to 300 mtrs. bowl sizes from 100mm to 1600 mm constructions • self-water lubrication, oil lubrication external water lubrication • motor water lubrication] • combination motor-gear drive above ground / under ground discharge • standard / special material of construction. applications • general water pumping /conveying used for various industries. • spray and injection water in sugar industry. • cooling tower circulation. • irrigation and drainage for agriculture. • process and cooling water pumps for power plants. • fire fighting. • tube well irrigation / open well irrigation and river / canal irrigation • sprinkle irrigation • urban water supply / rural water supply • domestic water supply in high rise building and water fountain. • raw & threaded water services / mine dewatering. • fire fighting services. • on line boosting • oil / petroleum handling services. special features • vertical pumps take little space in plan since the liquid in led away to the axis of shat. • the impeller is submerged, so pump does not require to be primed and is always ready to use. • the suction condition also prevents the caviation in the pump and pitting in impeller & diffuser. • due to positive head at suction the pump gives its rated performance as well as high ovarall efficiency, whereas in horizontal pumps due to losses in suction line,foot valve etc. The rated performance of the pumps is not achieve. techanical specification bowl assembly:- bowl assembly consists of suction bell , impeller , bowl, pump shaft. suction bell:- suction bell designed for smooth & steady entrance of liquid with minimum losses. bowl :- the bowl is a casing with diffuser vane cast integrally to reduce the velocity of the liquid coming from impeller & increasing the pressure. impeller:- impellers are of open (propeller),semi-open (mixed flow) & closed (vertical turbine) type depending upon the specific speed of pumps and are accurately machined ,dynamically & hydraulically balanced. shaft:- the shaft is of high tensile strength steel. column pipe assembly:- it consists of column pipe, line shaft & line shaft bearing. column pipe:- casted or fabricated, it houses line shaft bearing retainer. line shaft bearing:- line shaft bearing provided in leaded bronze shell with cut less rubber (natural/synthetic) bearing lubrication self or pressurized external water. trust bearing assembly:- anti friction bearings are provided to take care of axial thrust & weight of rotor assembly as well as radial load. Lubrication with oil/grease non reverse ratchet are provided with thrust bearing housing assembly to avoid the rotation of impeller (pump) in opposite direction causing opening of the threaded coupling. discharge head / discharge elbow:- either cast of fabricated designed to direct flow from column pipe to discharge pipe. It may be on ground level or below ground level. motor stool:- m.s fabricated heavy duty to ensure vibration free operation. couplings:- for line shaft threaded barrel or muff type coupling as per requirement. For pump to motor pin bush flexible coupling are provided. direction of rotation:- counter clock wise when viewed from driving end.

...more

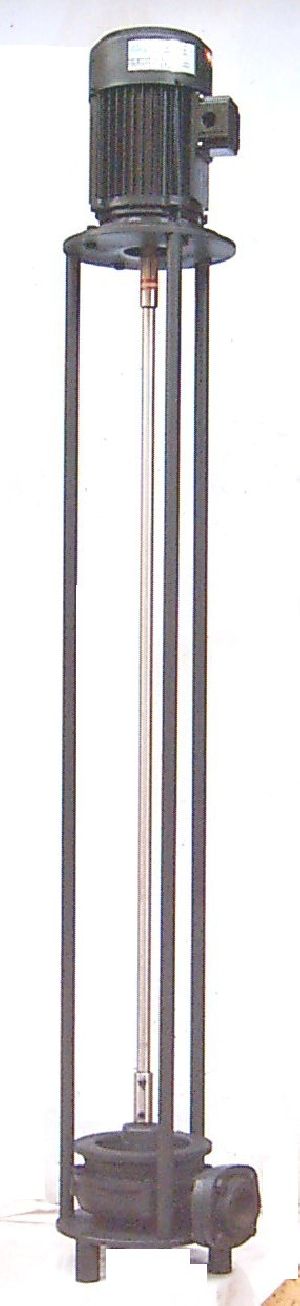

VSP SERIES VERTICAL SUMP PUMP

vertical centrifugal process pump can be used in any installation or specially where the saving of space is important factor and most important where liquid is difficult to lift because of nature like temp , corrosiveness etc these pump are designed for use where the liquid handled to be is of highly corrosive nature or where non – adherence of product or zero metallic contamination is must these pumps are equally ideal for continuous or intermittent service for handling corrosive as well as ultra pure chemicals without fear of corrosion or contamination. high temperature services : maximum working temperature is 110 c / 200 c. length : pumps lengths available from 1’ to 12’ with flow rate up to 50m3/h or 120 meter head. Higher capacities and head available on request and even multistage pump can be also made . models : available in conventional or tailor-made configuration. Several models such as suction extension with float switch, duplex pumping station with float switch (auto on/off device) also available. special features • bearing free design for handling abrasives in solutions. • motors are flange mounted single or three phase tefc from 1 hp to 100 hp . • epoxy / polyurethane paints are used on metallic bearing housing. • radial vanes on backside of impeller increase flow or fluids through the sleeve bearing preventing overflow at top of column. • lubrication of bearings by product itself or by fresh water. • all models operate at 1450 rpm / 2900 rpm (variable speed motor available ) • specially designed vapor seal provided to protect bearing from corrosive fumes • dynamically balanced impeller. application fields these pumps are in extensive use in the fields of • pollution control. • filtration . • transferring corrosive chemicals . • slurries . • bio gas plants. • sewage. • waste water treatment plant. • phosphoric acid plant. h,po,h2sifs,h2so4,hf and . their mixtures. • gas washing plant . • scrubbed liquids containing , f,cl,so2,ammonia • water treatment plant . • any types of acidic water lifting . • m.s vertical pump are used for transfer of sulphuric acid 98 %. Olum,cloto,neptha advantages of vertical submerged pump • no mechanical seal or stuffing box required • construction withstand corrosion & erosion • no foot valve required to lift from negative suction • no leakages problem just like gland or mechanical seal • normal maintenance • easy alignment

...more

Vertical Sump Pump

Vertical Centrifugal process pump can be used in any installation or specially where the saving of space is important factor and most important where liquid is difficult to lift because of nature like temp , corrosiveness etc These pump are designed for use where the liquid handled to be is of highly corrosive Nature or where non – adherence of product or zero metallic contamination is must These pumps are equally ideal for continuous or intermittent service for handling Corrosive as well as ultra pure chemicals without fear of corrosion or contamination

...more

Vertical Submersible Pump

APPLICATION : Agricultural, Industries, High rise Buildings, Fire Fighting, Sea water application. Etc.. The material of construction for the complete range of Submersible Pumps is as

...more

VERTICAL SINGLE STAGE CENTRIFUGAL PUMP ILS SERIES

Single Stage Pump ISL Series are primarily designed to handle water and are suitable for handling water in water supply systems for domestic and industrial use. Single stage pumping units of compact design with back pullout feature with suction & discharge flange arranged in-line opposite one another for direct installation in the pipeline. Motor and pump are close coupled by rigid coupling. The completer rotating portion can be removed without disconnecting the pump casing from the connecting pipe line APPLICATIONS “MALHAR” Volute casing IN-LINE centrifugal pumps Type MIL are space saving pump units designed for easy installation and are used generally for circulating clean non-aggressive fluids. • Water Supply Systems • Water circulation / Transfer • Hot water Circulation • Agriculture • Industry • Ship Building • Cooling Towers • And many other Applications DESIGN DETAILS Direction of Rotation : Clock wise looking from the motor end at the pump. Shaft Sealing : The Shaft is sealed by means of a Mechanical seal. Wearing Ring : Every Volute Casing is fitted with a Replaceable wearing ring. Casing Gasket : The Volute casing is sealed be means of a flat gasket

...more

Vertical single stage Centrifugal Pump

applications:-“malhar” volute casing in-line centrifugal pumps type mil are space saving pump units designed for easy installation and are used generally for circulating clean non-aggressive fluids. water supply systems water circulation / transfer hot water circulation agriculture industry ship building cooling towers and many other applications motor option:- standard pumps are fitted with motor adaptor suitable for mounting vertical flange mounting v-1 frame motor, to suite particular specification where protection class & enclosure are required . Special suitable adaptor can be provided.the pumps is coupled with a electric motor , which is totally enclosed , fan cooled squirrel cage motor. Single-phase motors have a built in thermal overload protection.three phase motors should be protected by a suitable motor starter as per local regulations. nominal speed :- 2900/1450 rpm, range:- capacity : up to 280 m3/hr head : up to 95 mtr higher capacity and head available on request

...more

Vertical Polypropylene Pump

Vertical Centrifugal process pump can be used in any installation or specially where the saving of space is important factor and most important where liquid is difficult to lift because of nature like temp , corrosiveness etc These pump are designed for use where the liquid handled to be is of highly corrosive Nature or where non – adherence of product or zero metallic contamination is must These pumps are equally ideal for continuous or intermittent service for handling Corrosive as well as ultra pure chemicals without fear of corrosion or contamination.

...more

Vertical Openwell Submersible Pump

the pumps are centrifugal, multistage, vertical type suitable for transfer of cold, clear, fresh water with max, temperature 40ºc, built with radial flow impeller rotates on motor shaft, surrounded by diffuser mounted on the motor bracket forming moonset / coupled configuration. the motors are wet type , water lubricated squirrel cage type 2 pole , three phase induction motors with rewind able option , they are equipped with specially designed axial thrust bearing to take thrust loads with minimum wear & tear ,the motors run on water lubricated high graded bronze metal bushes which ensures long life cycle time with minimal maintenance. the rated power supply for the pump is 230 v.ac, 50 hz for single phase and 375/415 v.ac, 50 hz for three phase pumps. however, superior quality winding materials enable them to withstand wide voltage fluctuations and variable head conditions through out the operating period. application • domestic water supply, gardeners, • farm irrigation, • high rise buildings, • agriculture , • industrial & rural water supply • hospitals , hotels, fountains , • pressure systems, fire fighting, • drip & sprinkler irrigation. • to lift and transfer water from openwell , pond , river , tank and dam with installing beneath the water surface. features • high efficiency , • lower power consumption, • noiseless operation, • easy installation, • rewind able option, • lower maintenance & operation cost assures the buyers for long term restless operation and to recover spending within a minimal time span.

...more

VILM SERIES VERTICAL MULTISTAGE IN-LINE CENTRIFUGAL PUMPS

The pumps are non – self priming vertical multistage centrifugal pumps designed to occupy minimum floor space. Unlike other pumps with sheet metal and plastic fabricated components, our pumps have components all cast in various metals like cast iron , bronze, stainless steel 304 & 316. Excessive axial trust is balanced by assembling the pump stages with equal number of opposed impellers. Balancing of axial thrust allows the use of standard flange mounted motor without special bearings. Pressure on mechanical seal reduces to half the working pressure due to opposed impellers. the shaft is well supported in bush bearings making operation noise less. The maintenance is easy & in expensive. PUMPS LIQUID The pumps are primarily designed to handle water and are suitable for handling hot & cold water supply systems for domestic and industrial use RANGE • RANGE : UP TO 4” OUTLET SIZE • MAXIMUM HEAD ………280 METER • MAXIMUM CAPACITY … 90 M3/HR • SUCTION X DELIVERY SIZES :- from 32 mm to 100 mm • CAN HANDLE LIQUIDS UP TO 120ºC DESIGN DETAILS Direction of Rotation : – Clock wise looking from the motor at the pump. Shaft Sealing :- The Shaft is sealed by means of a Carbon- Ceramic, SC/SC, TC/TC Mechanical Seal. Carbide Bushes :-The Bottom casing is fitted with Tungsten carbide Motor support. Casing Gasket :- The Outer Shell is sealed by means of flat Gaskets. Foundation Base :- Cast Iron FEATURES • Highly Efficient Hydraulics Design • Fabricated Components • Less Friction in system (Pressed Components) • No Expensive Foundation Required • Easy Installations • Small Floor Space. APPLICATIONS Vertical multistage centrifugal pumps type MC are designed for a wide range of applications. • Water supply systems. • Water Circulation /Water Treatment Plant • Hydro Pneumatic Systems / Condensate transfer. • Agriculture /Industrial Washing • Coolant Circulation. • Boiler Feeding / Fire Fighting / Booster Applications. • Ship Building / RO-DM Plants. • Sprinkle Irrigation.

...more

VERTICAL MULTI STAGE IN LINE PUMP

FEATURES:- Highly Efficient Hydraulics Design Fabricated Components Less Friction in system (Pressed Components) No Expensive Foundation Required Easy Installations Small Floor Space APPLICATIONS Vertical multistage centrifugal pumps type MC are designed for a wide range of applications. Water supply systems. Water Circulation /Water Treatment Plant Hydro Pneumatic Systems / Condensate transfer. Agriculture /Industrial Washing Coolant Circulation. Boiler Feeding / Fire Fighting / Booster Applications. Ship Building / RO-DM Plants. Sprinkle Irrigation. RANGE:- RANGE : UP TO 4” OUTLET SIZE MAXIMUM HEAD ………280 METER MAXIMUM CAPACITY … 90 M3/HR SUCTION X DELIVERY SIZES :- 32 X 32 MM CAN HANDLE LIQUIDS UP TO 120ºC

...more

MVGP SERIES VERTICAL GLANDLESS PUMP

“mvgp” pumps are vertical molded polypropylene corrosion resistant pumps.pumps for leakproof and maintenance free pumping of corrosive and abrasive liquids. principal of vertical glandless pump the “malhar” pump is similar hydraulic design to any conventional centrifugal pump. It differs in so far as it is always mounted in the vertical position. A restriction is provided above the impeller and need for any from of liquid seal is obylated by allowing a small leakage to escape by way of an overflow connection in the upper pump body return to suction vessel. the most suitable method of installation will depend on the pumping application. The simplest and most widely adopted method is mount the pump close to the feed tank at such a level that the impeller is flooded and the pump therefore pumped when the liquid reaches a certain height in the tank.the pump will deliver liquid until the suction pipe becomes uncovered , when it will run dry until the liquid level is restored to the point where re-printing can take place,this cycle of operation may be repeated indefinitely. Contact vertical glandless pump supplier, vertical glandless pump manufacturer today. The vertical glandless pump is vertical molded polypropylene corrosion resistant pumps.pumps for leakproof and maintenance free pumping of corrosive and abrasive liquids. operation advantages of glandless pump • the recognizable leading improvement is the deletion of problems get to your feet from the use of powered seal, insulation box and inside bearing. • the aptitude of pump to run dry eliminates single reason of interruption which is regularly attributable to the human component this feature is very convenient in process needing continuous transference of a corrosive fluid with a high gradation of reliability e.g. Disposal of acid effluent. • the glandless pumps lend itself to process incorporating automatic control of a pump discharge valve. The “controlled leakage” acts as an integral by-pass. The pump suffers no ill effects if the discharge valve is partially or fully closed. • the maximum main improvements to be derivative from the use of glandless pump are in the province of maintenance and following reduction in down time invention victims. Normal maintenance on the glandless pump is confined to lubrication of the driving. sailent features of vertical glandless pump • no mechanical seal, stuffing box and internal bearings provided. • no maintenance since the pump can even run dry indefinitely as there is no packing, bushes or internal bearings. • reduction of downtime production losses in view of above features. • all the wet-end parts are in solid molded construction to with stand corrosion and erosion. • the impeller is semi-open type used in our all-vertical pumps to suit both clear and polluted fluids. • pump mounted outside the suction tank and is not submerged type. • polypropylene are manufactured by solid injection molding process with high pressure hence. temperature resistance • pp 50º to 80 º c • pph 90 º to 100 ºc • pvdf 100º to 115ºc range of performance • because glandless pumps do not have any packing bush or internal bearing, full advantage can be taken of available drive speeds. The pump may be run at 1450 and 2900 rpm respectively and a range of impeller diameter for each pump size gives a wide spread of performance. • in general the range cover flow up to 100m3/hr. And discharge head up to 50 meters.

...more

Vertical Glandless Pump

The most suitable method of Installation will depend on the pumping application. The simplest and most widely adopted method is mount the pump close to the feed tank at such a level that the impeller is flooded and the pump therefore pumped when the liquid reaches a certain height in the tank.The pump will Deliver liquid until the suction pipe becomes uncovered , when it will run dry until the liquid level is restored to the point where re-printing can take place,this cycle of operation may be repeated indefinitely. Contact vertical glandless pump supplier, vertical glandless pump manufacturer today. The Vertical glandless pump is vertical molded Polypropylene corrosion resistant pumps.Pumps for Leakproof and Maintenance free pumping of corrosive and Abrasive Liquids.

...more

VERTICAL GLANDLESS PP PUMP

operation advantages of glandless pump:- the recognizable leading improvement is the deletion of problems get to your feet from the use of powered seal, insulation box and inside bearing. the aptitude of pump to run dry eliminates single reason of interruption which is regularly attributable to the human component this feature is very convenient in process needing continuous transference of a corrosive fluid with a high gradation of reliability e.g. Disposal of acid effluent. the glandless pumps lend itself to process incorporating automatic control of a pump discharge valve. The "controlled leakage" acts as an integral by-pass. The pump suffers no ill effects if the discharge valve is partially or fully closed. the maximum main improvements to be derivative from the use of glandless pump are in the province of maintenance and following reduction in down time invention victims. Normal maintenance on the glandless pump is confined to lubrication of the driving. sailent features of vertical glandless pump no mechanical seal, stuffing box and internal bearings provided. no maintenance since the pump can even run dry indefinitely as there is no packing, bushes or internal bearings. reduction of downtime production losses in view of above features. all the wet-end parts are in solid molded construction to with stand corrosion and erosion. the impeller is semi-open type used in our all-vertical pumps to suit both clear and polluted fluids. pump mounted outside the suction tank and is not submerged type. polypropylene are manufactured by solid injection molding process with high pressure hence. temperature resistance pp 50º to 80 º c pph 90 º to 100 ºc pvdf 100º to 115ºc

...more

VERTICAL BOREWELL SUBMERSIBLE PUMP

malhar submersible pumps are vertical , multi stage, centrifugal pumps with motor at the bottom & pump at the top. The water enters at the bottom of the pump and flows upwards through many stages. the stainless steel bronze impellers rotate inside the diffusers with inherent guide vanes. The diffusers direct water leaving each impeller towards suction opening of the next impeller, such a flow through each stage of impeller and diffuser combination adds pressure at each stage and finally water under high pressure is discharged through outlet at the top. construction details motors are wet-type, water lubricated,water cooled rewindable squirrel cage induction asynchronous type capable of with standing wide voltage fluctuations. Specially designed tilting pad thrust bearings can with stand axial thrust loads with negligible wear. The stator is wound with water proof synthetic film insulated winding wires. Spring loaded seal rings , grommets & sand guard prevent ingress of water in to the motor. An elastic diaphragam compensates for variations in pressure of cooling water as it gets heated during functioning. the supply cables are protected by special stainless steel guards along the full length of the pump. malhar submersible pumps are manufactured as per is 8034 : 1989 with strict quality control for years of efficiency and reliable peration. Special design of the winding ensures efficient operation even high head and low voltages. Malhar pumps are available in both radial & mixed flow. The pump is multistage of superior hydraulic design for maximum performance and operating efficiency. The bowls are made of close grained cast iron for greater abrasion resistance. The impellers are of high quality graded bronze , dynamically balanced for best results. The stainless steel shaft is ground to close tolerances and guided by water lubricated gun metal bearings, provided in each bowl of impeller casing. Hydrostatic tests are conducted on each pump to ensure maximum discharge at selected heads variable voltage conditions. A stainless steel coupling is provided to couple the motor and pump. application agricultural, industries, high rise buildings, fire fighting, sea water application. Etc. the material of construction for the complete range of submersible pumps is as follows:-

...more

Vertical Axial Flow Pump

three- or four-vane axial flow propeller is hydraulically balanced via pressure equalizing balance holes and a top propeller hub wear ring to reduced axial down thrust. outer flanged columns are bolted together with through bolts for ease in assembly. Alignment is maintained via centering fits on all parts flared suction bell provides a smooth waterway entrance to the impeller and has integral splitters to reduce inlet swirl and entrance losses stator case with integral diffuser vanes may be either a single-piece casting or a fabrication. discharge elbow may be located above or below ground and at any outlet orientation. seal chamber accepts packing or mechanical seal to suit service requirements. opening parameters • flows to 181700 m3/h (800 000 gpm) • heads to 11 m (35 ft) • speeds to 1770 rpm • sizes 200 mm (8 in) to 3.1 m (123 in) • settings to 8 m (25 ft) the vaf is a vertical high efficiency, axial flow impeller pump together. We have a complete range of this type of pumps which are suited for applications that require large quantities of flow with low head. characteristics • multi-stage vertical centrifugal pump, diffuser type bowl. • axial flow impeller, high efficiency. • can handle solids up to 14” diameter (365 mm). • counter clockwise rotation viewed from shaft coupling. design features • api 610 latest edition construction available (vs3 type on special request only) • above or below base discharge. • discharge elbows designed to reduce friction losses, diffusers designed to minimize turbulence and increase efficiency. • product, oil or fresh water lubrication. • rotor ‘pull-out’ design available. standard construction materials • bowls: cast iron with bronze impeller. • column: carbon steel with aisi-1045 shaft. • discharge head: fabricated steel. optional accessories • basket type strainer. • extended suction bell (umbrella) to minimize vortices. applications • flood control, • water treatment, • shipping, • ground water development and irrigation, • cooling water (power), • dewatering and water supply (mining), • agriculture industries • mining, • water resources, • power generation, • general industries

...more

TWO STAGE OPENWELL SUBMERSIBLE PUMP

5,200 - 10,000 Per Unit

1 Piece (MOQ)

applications • rural and urban drinking water installations. • agricultural-lift, sprinkle and drip irrigation. • decorative water foundations. • water supplies for high raise buildings and tanks. • water circulating systems, lawn & garden watering. • industrial service water supply schemes. • clear water transfer industries. • agriculture fields. standard features • most modern and latest in design. • superior design materials & manufacturing processes assure a longer life. • all the units are thoroughly tested for field conditions. • easy installation. • high efficiencies-better than international values, leading to energy saving. • silent vibration-free runnig. • the components are made of selective materials under strict quality control. • effective after-sales service. • suitable for 160/240 v in 1ph. And 380 volts to 440 volts • manufactured by iso 9001

Country of Origin : India

Type : Open Well Submersible Pump

Certification : ISO 9001:2008

Application : Submersible

Fuel : Electric

Brand Name : malhar

...more

turbine flow meters

Applications:- Turbine flow meter transducer adapts to measure the liquid rate and total flow rate of low viscosity and for clear liquid. It can be widely used in the fields of petrol, chemical Industry , Metallurgy , Scientific research for measuring or control. Several output display methods can be selected. Technical specification:- High-accuracy: 0.2%, 0.5% , 1% Wearable Tungsten carbonized shaft and bearing Erode-resistant applicable for sea water, ammonia , etc. Bi-Direction measuring bi-direction flow (optional) Multi-output pulse , 4-20mA DC, total and rate display in the field. Power-supply 5-24 V DC, Explosion-proof Ex d II BT4/Ex ib I Pipeline range 6,10,15,25,40,50,80,100,150,200,250,300 mm.

...more

Turbine Flow Meter

Applications:- Turbine flow meter transducer adapts to measure the liquid rate and total flow rate of low viscosity and for clear liquid. It can be widely used in the fields of petrol, chemical Industry , Metallurgy , Scientific research for measuring or control. Several output display methods can be selected. Technical specification:- High-accuracy: 0.2%, 0.5% , 1% Wearable Tungsten carbonized shaft and bearing Erode-resistant applicable for sea water, ammonia , etc. Bi-Direction measuring bi-direction flow (optional) Multi-output pulse , 4-20mA DC, total and rate display in the field. Power-supply 5-24 V DC, Explosion-proof Ex d II BT4/Ex ib I Pipeline range 6,10,15,25,40,50,80,100,150,200,250,300 mm.

...more

THERMIK FLUID PUMP

features :- low maintenance easy to operate longer service life. specifications (as per iso 2858/din 24256) :- capacity up to 250 m3/hr temperature up to 350ºc tdh up to 95 mlc working pressure up to 20 bars delivery size up to 100 mm. speed – n- :- 960/1450/2900 rpm industries covered:- pharmaceuticals & chemical :- oil extraction plants pulp & paper industries :-waste oil refining plants starch industries :- air-conditioning heating plants effluent treatments plants :-cooling tower water circulation dyes & intermediates :- solvent transfer ro & dm water plants: - thermic fluid circulation. material of construction:- pumps are manufactured in variety of materials such as carbon steel / wcb as per astm / din standards stainless steel as per astm a 351/743 gr. Cf8/cf8m carbon steel (wcb) / alloy steel cf-8 , cf-8m cf-3 ,cf-3m (ss-316l) , alloy 20 , cd4mcu

...more

Thermic Fluid Pump

70,000 - 100,000 Per Unit

1 Piece (MOQ)

These pumps are manufactured from best quality stainless steel and cutting-edge technology. Offered pumps are appreciated for their noise and vibration free performance, easy installation and high degree interchangeability. Our pumps are suitable for both organic and inorganic fluids and used in oil refineries, paper, food, chemical, textile industries and sea water desalination plants. These pumps are equipped with water self cooling feature that makes them suitable for the applications in heat transfer plants and handling of organic heat transferring of oils.

Country of Origin : India

Type : Thermic Fluid Pumps

Certification : ISO 9001:2008

Application : Industrial Use

Condition : New

Automatic Grade : Manual

Power : 10hp

Pressure : High Pressure

Warranty : 1year

Driven : Electric

...more

Air Operated Diaphragm Pump

Chambers A & B are alternatively filled and emptied by drawing liquid in through a common inlet © and out through a common outlet (D). The Diaphragms in each chamber are connected by a common shaft so that they move., backwards together. Compressed dry air is directed by the air valve (E) alternatively behind each diaphragm to power discharge strokes. Pump speed and therefore fluid flow-rate can be infinitely controlled by increasing or decreasing or decreasing air pressure and or volume.

...moreBe first to Rate

Rate ThisOpening Hours